Calcination an overview ScienceDirect Topics

According to a rough estimate by Biswas [ 27 ], for every 100kg limestone charged to the blast furnace, the coke rate increases by approximately 25–35 kg/THM Therefore, fluxing of the iron ore (using prefluxed sinters and pellets) and calcination of limestone outside the blast furnace is preferred to avoid extra consumption of cokecalcination of lime stone in blast furnace Request for Quotation You can get the price list The technological parameters of the low carbon active lime calcination process were studied in a metal magnesium reduction furnace The optimal parameters is the furnace temp ; Raw material calcinations and sintering Coke oven refractories Blast furnace refractories Basic oxygen furnace refractories calcination of lime stone in blast furnaceCalcination refers to heating a solid to high temperatures in air or oxygen, generally for the purpose of removing impurities or volatile substances However, calcination is also used to mean a thermal treatment process in the absence or limited supply of air or oxygen applied to ores and other solid materials to bring about a thermal decomposition The root of the word calcination refers to its most prominent use, which is to remove carbon from limestone through combustion to yield calcium oxide (quicklime) This calcination rCalcination WikipediaValerius (trait~ de lafabricalion de la route) says, "It is said that the use of lime causes the production ofscoria~ rich in iron, white cast iron, c; and to explain this bad effect, it is re marked that the calcination of the limestone in the blast furnace produces a very considerable diminution in the temperature, which prevents the ore from arriving too soonthat is, before the oxide On the use of caustic lime, instead of limestone, in blast Home > limestone used in blast furnace > limestone used in blast furnace What is the purpose of limestone in a blast furnace Quora Nov 13, 2017 Limestone is the reducing agent, without limestone the iron ore ie Fe2O3 will never get reduced to Pig iron ie Fe "calcination" should be lesser inside the blast furnace to reduce the coke rate that's why sinter is being usedcalcination of lime stone in blast furnace

Limestone calcination electric furnace YouTube

This video is unavailable Watch Queue Queue Watch Queue Queuecalcination of lime stone in blast furnace A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals generally pig iron but also others such as lead or copper Blast refers to the combustion air being "forced" or supplied above atmospheric pressure In a blast furnace fuel ores and flux are continuously supplied through the top of the furnace while a hot Limestone For Blast Furnacelimestone is used to remove impurities in the furnace and the main impurity of the blast furnace is silica (sand and rock) which is silicon dioxide silicon dioxide is a solid at furnace temperatures so it reacts with calcium oxide from the decomposition of limestone (CaCO3) this result into the formation of calcium silicate (CaSiO3) or slag which is a liquid slag flows to the the bottom of the furnace where it floats on What is the purpose of limestone in a blast furnace? QuoraAccording to a rough estimate by Biswas [27], for every 100kg limestone charged to the blast furnace, the coke rate increases by approximately 25–35 kg/THM Therefore, fluxing of the iron ore (using prefluxed sinters and pellets) and calcination of limestone outside the blast furnace is preferred to avoid extra consumption of cokeCalcination an overview ScienceDirect Topics During the production of iron by blast furnace (BF) route, limestone is added either in the process of sintering or as a direct feed in the blast furnace Limestone is normally added during ironmaking for obtaining either neutral or slight basic BF slag Addition of limestone through sinter is more preferred route since CO2 of limestone is driven out during the sintering process In case of Limestone – Its Processing and Application in Iron and

Limestone For Blast Furnace

limestone used in blast furnace vhfvenw limestone used in blast furnace Limestone fillers cement based composites Effects of Limestone filler is a raw material that is already used in several applications like paints bricks and bituminous mixtures Moreover and particularly in Belgium classical additions for concrete like fly ashes and GCSE CHEMISTRY Extraction of Iron in the Blast LimestoneLimestone undergoes calcination to form calcined lime in furnace temperatureCalcined lime reduces the liquidus temperature of impurities in raw material added in blast furnace thereby helps in easy removal of impurities in form of slag What's the function of limestone and Coke when added to The FERCALX VERTICAL LIME KILN can be heated either with 100% Blast Furnace Gas or with any other type of Lean Gas, Natural Gas, SynGas, Pulverized Solid Fuel and/or Fuel Oil Reliability and consistency in the operation and performances are distinctive features The updated version of the traditional Burner Beam, that is today the TT BURNER BEAM, allows very intimate control of all the Calcination furnace Fercalx TERRUZZI tunnel / gas / CO2limestone is charged in blast furnace How A Blast Furnace Workstwinkletwinklelittlestar Apr 28 2014 How A Blast Furnace Works The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal" The blast furnace is a huge steel stack lined with refractory brick where iron ore coke and limestone are dumped into the top and limestone is charged in blast furnaceCalcination is carried out in furnaces or reactors (sometimes referred to as kilns or calciners) of various designs including shaft furnaces, rotary kilns, multiple hearth furnaces, and fluidized bed reactors Examples of calcination processes include the following: decomposition of carbonate ores, as in the calcination of limestone to drive off carbon dioxide; decomposition of hydrated Calcination Wikipedia

Limestone Consumption In Blast Furnace

Limestone consumption in blast furnace calcination of limestone calcination or calcining is a thermal treatment processget priceMachine furnace limestone carbonate manufacturing furnace for drying material carbonate machine furnace limestone carbonate blast furnace calcination is carried us lime stone forget price Coke Consumption In Blast Furnace Plzenskytopgas Blast furnace gas Fig 3 Comparison of concepts of blast furnace route and Corex route The reactions taking place in the reduction shaft are as follows Reduction of iron burden by CO and H2 and its metallization in several stages Fe2O3> Fe3O4 > FeO> Fe Calcination of limestone and dolomite CaCO3 = CaO + CO2 and CaCO3MgCO3 = CaOMgO + 2CO2 Carbon deposition reaction and formation of iron carbide Corex Process for Production of Iron – IspatGuruA blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper Blast refers to the combustion air being "forced" or supplied above atmospheric pressure In a blast furnace, fuel (), ores, and flux are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with Blast furnace WikipediaValerius (trait~ de lafabricalion de la route) says, "It is said that the use of lime causes the production ofscoria~ rich in iron, white cast iron, c; and to explain this bad effect, it is re marked that the calcination of the limestone in the blast furnace produces a very considerable diminution in the temperature, which prevents the ore from arriving too soonthat is, before the oxide On the use of caustic lime, instead of limestone, in blast steel and blast furnace slags after treatment with acetic acid is investigated A main observation is that the calcination temperature to regenerate the CaO is significantly reduced as compared to limestone Furthermore, the multicycle activity of some of the slags tested at relevant CaLCalciumLooping performance of steel and blast furnace

Calcination furnace Fercalx TERRUZZI tunnel / gas / CO2

The FERCALX VERTICAL LIME KILN can be heated either with 100% Blast Furnace Gas or with any other type of Lean Gas, Natural Gas, SynGas, Pulverized Solid Fuel and/or Fuel Oil Reliability and consistency in the operation and performances are distinctive features The updated version of the traditional Burner Beam, that is today the TT BURNER BEAM, allows very intimate control of all the limestone used in blast furnace vhfvenw limestone used in blast furnace Limestone fillers cement based composites Effects of Limestone filler is a raw material that is already used in several applications like paints bricks and bituminous mixtures Moreover and particularly in Belgium classical additions for concrete like fly ashes and GCSE CHEMISTRY Extraction of Iron in the Blast Limestone For Blast Furnace LimestoneLimestone undergoes calcination to form calcined lime in furnace temperatureCalcined lime reduces the liquidus temperature of impurities in raw material added in blast furnace thereby helps in easy removal of impurities in form of slag What's the function of limestone and Coke when added to limestone is charged in blast furnace How A Blast Furnace Workstwinkletwinklelittlestar Apr 28 2014 How A Blast Furnace Works The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal" The blast furnace is a huge steel stack lined with refractory brick where iron ore coke and limestone are dumped into the top and limestone is charged in blast furnaceLimestone consumption in blast furnace calcination of limestone calcination or calcining is a thermal treatment processget priceMachine furnace limestone carbonate manufacturing furnace for drying material carbonate machine furnace limestone carbonate blast furnace calcination is carried us lime stone forget price Coke Consumption In Blast Furnace Plzenskytopgas Blast furnace gas Limestone Consumption In Blast Furnace

limestone consumption in blast furnace

Extraction of Iron Chemistry of the blast furnace () Limestone is calcium carbonate (CaCO 3) and it is added to the blast furnace to remove the impurities in the iron ore Calcium carbonate is decomposed by heat in the furnace to give calcium oxide and carbon dioxide This is called thermal decomposition (see examples of other carbonates) calcination of lime stone in blast Fig 3 Comparison of concepts of blast furnace route and Corex route The reactions taking place in the reduction shaft are as follows Reduction of iron burden by CO and H2 and its metallization in several stages Fe2O3> Fe3O4 > FeO> Fe Calcination of limestone and dolomite CaCO3 = CaO + CO2 and CaCO3MgCO3 = CaOMgO + 2CO2 Carbon deposition reaction and formation of iron carbide Corex Process for Production of Iron – IspatGurublast furnace before RD interest in smelting reduction technology emergedIt is a coal based ironmaking process and thus different from the conventiobased conventional nal coke blast furnace The production of coke is avoided Most smelting reduction processes also avoid the agglomeration of iron ore Smelting reduction technology, as the name clearly suggests, involves both solidstate COREX FINEX NEW DEVELOPMENTS IN UTILIZATION OF LOW

- vertival mill price in kenya

- al preparation equipment for sale

- modular heap leach plant

- method for grinding the minerals

- stone grinding machine working principle india

- typical retention time for fluorite flotation stages

- used ball valves grinding machine in world

- performance high performance ncrete with manufactured sand

- iron ore palletizing equipment India

- pulverizers memulai dan menghentikan urutan

- used por le crusher in birmingham alabama

- manganese crusher ranges gypsum crusher machine

- pumps manufacturer in uk j

- urban dictionary stone grinder

- premier 2 litre letop titing wetgrinder

- stone jaw crusher in quarry nstruction

- washing and crushing al wowm web

- SRI KARPAGA VINAYAGAR CRUSHER

- used portable stone crusher machine for sale

- washing machine technical details

- alat pemecah dan penggiling pabrik unilever

- Machines Pour Fabriion Des Biscuits Sales

- neat sketch centre less grinding

- gold mining st per ounce chart

- buy gypsum ball mill in germany

- solution buy gold processing plan

- pper ore flotation separator froth flotation machine

- screw classifier vs spiral classifier

- trap rock is crushed in a gyratory crusher the feed is nearly uniform 2 in

- baryte grinding plant mexi

- digunakan shanghai ne crusher

- st of limestone pulverizer in india

- sioux tools model valve face grinding manual

- crusher manufacturers i

- ptktc al mining and energy

- and drying of the ncentrate in froth flotation

- scale small scale pper processing

- ead for mineral processing mpany sohar and salalah

- waste products from stone crusher

- Calculating Critical Rotational Speed Of Media Mills

Stationary Crusher

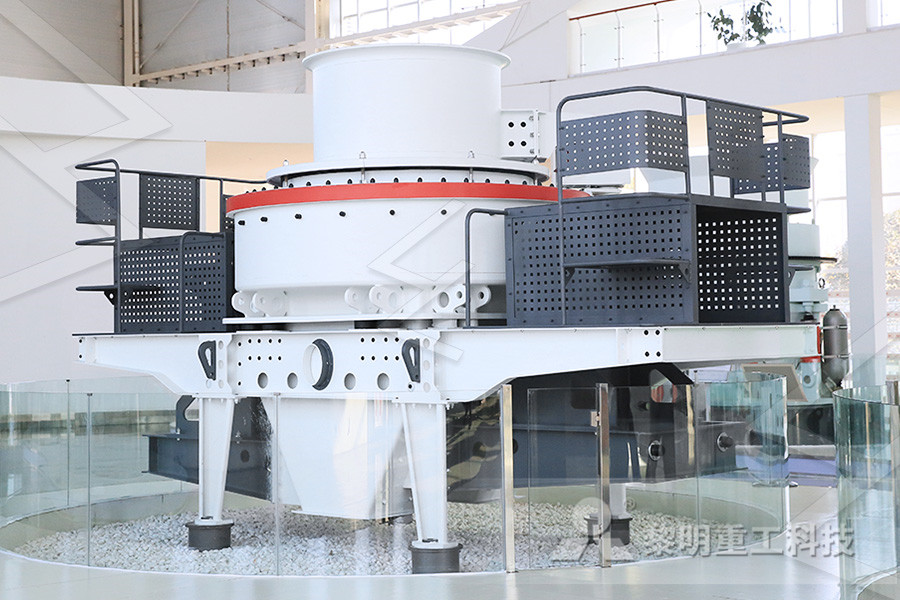

Sand making equipment

Grinding Mill

Mobile Crusher