MODULAR RECOVERY PLANTS kcareno

Since 1972, KCA has fabricated portable or modular carbon adsorption, carbon desorption, carbon stripping and MerrillCrowe plants KCA's plants have earned an outstanding reputation for quality, simplicity, ease of start up and failsafe operation Modular plants can be constructed for gold operations treating up to 4,000 tonnes of ore per dayPlant type Heap Leach Plant; Company Finder Resources (PT Batutua Tembaga Raya) Installation Installed in 2015; Location Located in Water Island Indonesia ; Design Designed for 300 tph production of 15mm copper ore; Operation Operating in +20 degrees to +55 degree; System Primary, secondary and tertiary cones with dual screens, track mounted agglomerater and grasshopper Heap Leach Copper Ore MAX Plant ProjectHeap leach agglomeration and conveying systems; Gravity recovery systems for tin/tungsten/tantalum; Construction aggregate washing and classification; Nickel laterite slurry prep plants ; And more! Sepro Mobile Mineral Processing Plants Designed to allow the rapid deployment of a complete mineral processing plant, Sepro Mobile Mill systems are ideal for smaller tonnage operations and mining Modular Processing Solutions Sepro Mineral SystemsHigh Quality Modular Gold Heap Leaching Plant , Find Complete Details about High Quality Modular Gold Heap Leaching Plant,Gold Process System,Leaching Gold,Modular Gold Heap Leaching Plant from Mineral Separator Supplier or ManufacturerXi'an Desen Mining Machinery Equipment Co, LtdHigh Quality Modular Gold Heap Leaching Plant Buy Gold The Eljen indrain, with its prefabricated modular units comprised of geotextile fabric and cuspated spacer cores, provides an alternative to conventional stone and pipe or chamber leaching systems Substantial effluent pretreatment occurs within the biomat which develops on the 100square feet of geotextile fabric and the 400square feet of cuspated core surface area in each 12square foot ELJEN ® The Modular Leach Field Sewage Treatment System

Modular HMS Plants Como Engineers

Como Engineers can supply all the equipment required to operate a Heap or Vat leach plant, and for all but very large operations these can be of modular construction Modular crushing and screening plants Adsorption modules Packed bed columns are compact, allow high flow rates and are very efficientSEPRO STANDARD MODULAR PLANT DESIGNS Sepro offers several package options as standard plants These plants are normally designed around a single recovery or process option such as dense medium separation or gravity concentration Sepro maintains critical components in MODULAR PROCESS SOLUTIONS Sepro Mineral SystemsTypically, modular plants are designed and built by Gekko for a given mine operation with specific requirements Gekko’s innovative core technologies and inhouse process design expertise will produce an agile, effective modular plant Contact a Gekko engineer today Innovative Gold Plant Design for Better Returns Gekko also offer a readymade modular plant known as the Gravity Flotation Modular Systems Gekko SystemsModular heap leach recovery plants and water treatment systems with capacities up to 3500 GPM offer very economical alternatives to conventional field constructed plants Currently, most of the custom fabricated equipment shown on this website is only offered on an EPCM or consulting/royalty type basis and not by lump sum pricingDenver Mineral Engineers – GOLD MINING WATER TREATMENT Como Engineers Modular Elution Plants are completely constructed in our workshop in North Fremantle, fully water tested to temperature and client witnessed Once complete, the plants are disassembled into modules (and packed in sea containers for export) and shipped to site Site installation for our Modular Elution Carbon Regeneration Systems is a matter of weeks not months Smaller systems Modular Plants and Equipment – Como Engineers

Crushing Plant for Heap Leach Nelson Machinery

Crushing Plant for Heap Leach up to 20k TPD including feeders, screens, conveyors, stackers Equip yourself with the gold standard History The semiportable modular crushing plant was feeding a heap leach operation up to 20,000 TPD Components Inclusions Crushers; Feeders; Screens; Conveyors; Tanks Bins; Pump; Electrical; Buildings Crushers 32″ x 44″ Telsmith Hydra primary jaw Heap leach agglomeration and conveying systems; Gravity recovery systems for tin/tungsten/tantalum; Construction aggregate washing and classification; Nickel laterite slurry prep plants ; And more! Sepro Mobile Mineral Processing Plants Designed to allow the rapid deployment of a complete mineral processing plant, Sepro Mobile Mill systems are ideal for smaller tonnage operations and mining Modular Processing Solutions Sepro Mineral SystemsHeap leach agglomeration and conveying systems; Gravity recovery systems for tin/tungsten/tantalum ; Construction aggregate washing and classification ; Nickel laterite slurry prep plants ; Key Features of Sepro’s Modular Plants Designed to suit your process requirements; Highquality modular construction; Proven reliability of Sepro equipment; Modularized single source supply reduces costs Mineral Processing Plants: Modular VS Mobile PlantsModular Process Plants Utilizing industryleading mineral processing expertise and integrated engineering capabilities, Westpro designs and manufactures turnkey modular processing plants that are tailored to meet site specific requirements and conditions The plants combine unit operations from Westpro’s comprehensive product line, along with auxiliary items, to offer customers a complete Modular Systems Westpro MachineryHigh Quality Modular Gold Heap Leaching Plant , Find Complete Details about High Quality Modular Gold Heap Leaching Plant,Gold Process System,Leaching Gold,Modular Gold Heap Leaching Plant from Mineral Separator Supplier or ManufacturerXi'an Desen Mining Machinery Equipment Co, LtdHigh Quality Modular Gold Heap Leaching Plant Buy Gold

ELJEN ® The Modular Leach Field Sewage Treatment System

The Eljen indrain, with its prefabricated modular units comprised of geotextile fabric and cuspated spacer cores, provides an alternative to conventional stone and pipe or chamber leaching systems Substantial effluent pretreatment occurs within the biomat which develops on the 100square feet of geotextile fabric and the 400square feet of cuspated core surface area in each 12square foot Como Engineers can supply all the equipment required to operate a Heap or Vat leach plant, and for all but very large operations these can be of modular construction Modular crushing and screening plants Adsorption modules Packed bed columns are compact, allow high flow rates and are very efficientModular HMS Plants Como EngineersHeap leach agglomeration and conveying systems Custom modular plants are engineered around structural High quality modular construction Proven reliability of Sepro equipment used Modularized single source supply reduces costs Easy to ship globally Easy to reassemble and commission Designed to have minimal civil work requirements SEPRO MOBILE PLANTS Designed to allow the rapid MODULAR PROCESS SOLUTIONS Sepro Mineral SystemsModular heap leach recovery plants and water treatment systems with capacities up to 3500 GPM offer very economical alternatives to conventional field constructed plants Currently, most of the custom fabricated equipment shown on this website is only offered on an EPCM or consulting/royalty type basis and not by lump sum pricing However, the entire DME design file may be utilized in Denver Mineral Engineers – GOLD MINING WATER TREATMENT The objectives of the modular copper sulphate production plant concept are: The copper sulphate process flow sheet incorporates standard heap leach and copper solvent extraction (SX) technology, with copper sulphate crystallization The modular approach allows for flexibility in plant designnameplate implementation This is particularly attractive for phased project execution and can be COPPER SULPHATE PRODUCTION PLANTS

Modular Processing Solutions Sepro Mineral Systems

Heap leach agglomeration and conveying systems; Gravity recovery systems for tin/tungsten/tantalum; Construction aggregate washing and classification; Nickel laterite slurry prep plants ; And more! Sepro Mobile Mineral Processing Plants Designed to allow the rapid deployment of a complete mineral processing plant, Sepro Mobile Mill systems are ideal for smaller tonnage operations and mining Heap leach agglomeration and conveying systems; Gravity recovery systems for tin/tungsten/tantalum ; Construction aggregate washing and classification ; Nickel laterite slurry prep plants ; Key Features of Sepro’s Modular Plants Designed to suit your process requirements; Highquality modular construction; Proven reliability of Sepro equipment; Modularized single source supply reduces costs Mineral Processing Plants: Modular VS Mobile PlantsComo Engineers can supply all the equipment required to operate a Heap or Vat leach plant, and for all but very large operations these can be of modular construction Modular crushing and screening plants Adsorption modules Packed bed columns are compact, allow high flow rates and are very efficientModular HMS Plants Como EngineersThe Eljen indrain, with its prefabricated modular units comprised of geotextile fabric and cuspated spacer cores, provides an alternative to conventional stone and pipe or chamber leaching systems Substantial effluent pretreatment occurs within the biomat which develops on the 100square feet of geotextile fabric and the 400square feet of cuspated core surface area in each 12square foot ELJEN ® The Modular Leach Field Sewage Treatment SystemThe objectives of the modular copper sulphate production plant concept are: The copper sulphate process flow sheet incorporates standard heap leach and copper solvent extraction (SX) technology, with copper sulphate crystallization The modular approach allows for flexibility in plant designnameplate implementation This is particularly attractive for phased project execution and can be COPPER SULPHATE PRODUCTION PLANTS

Look before you leach: Dynamic Simulation of Heap Leach

Plant flow capacity is always limited and metal recovery is dependent on solution composition, heapleach in conjunction with an existing pressure leach operation The model was further developed and refined for a standalone nickel heap leach project, incorporating multistage irrigat ion and downstream processing The SysCAD approach successfully enabled a rigorous dynamic mass balance Sepro Tire Drive Agglomeration Drums are the industry standard for heap leach operations They are specifically designed to prepare feeds with high fines content for gold and base metal heap leaching operations GO Sepro Modular Process Solutions Sepro Mineral Systems designs and builds modular systems, including mobile and containerized mineral processing plants for a wide range of minerals Mineral Processing Equipment Services Sepro Mineral GEOMEMBRANES USED IN HEAP LEACH SXEW MINING: A MANUFACTURER’S include but are not limited to barriers for pads, pounds, channels, tanks, collectors, and inplant containment BACKGROUND Leach pad technology was born and patented in North America the year 1975 Coincident with this in Chile, a medium size Mining company, “Sociedad Minera Pudahuel” started a GEOMEMBRANES USED IN HEAP LEACH SXEW MINING: A Mineral Ridge is a conventional open pit heap leaching operation Gold and silver bearing solution from the leach pad is collected in the pregnant pond and processed through carbon columns in the ADR plant for recovery of the precious metals from leachate on carbon Loaded carbon is shipped to Metals Research in Kimberley, Idaho for processing into doré The doré bars are then delivered to Mineral Ridge Scorpio Gold CorpMetallurgical ContentHeap Leaching Copper OresIngress of Solutions into OresSurface TensionSolubility of Gas in VoidsTemperatureVarious SolutionsManner of PenetrationDissolution of Various Copper MineralsLeaching Oxidized MineralsCuprite LeachingLeaching ChalcociteBornite LeachingCovellite LeachingChalcopyrite LeachingRemoval of Soluble Copper from Leached OresConclusionsHEAP LEACHING Heap Leaching Mineral Processing Metallurgy

- large grinding media sold to all over the world

- untuk konstruksi raodway

- FFMINING GUIDE QUARRY NODES

- grinding ca grinding for paper industry

- roll single roll crusher application

- hand grinding machine and uses

- projection profile grinding machine in mumba

- mines al mines in india wikipedia

- stone crusher and quarry plant in kano

- pamodzi gold mine ntact details

- mini jagung jagung penggilingan pabrik africa selatan

- high popularity desorption and electrowinning system in vietnam

- china clay powder production equipment

- jaw crusher operation manual download

- manufacturers of mining equipment in norway

- crusher manufacturers ne

- portable mobile grinding ball mill

- gold ore crusher for sale small use

- impact crushers manufacturers

- mealie meal milling machine wet ball mill china

- international LIming crushing equipment

- pper mineral processing equipment suitable

- CARBONIZATION OF COAL GRINDING MACHINE

- locate stone crusher in saudi

- Concrete Crusher Or Mini Digger

- SAND PLANT FOUNDRY MACHINE

- www bar mill roll pass m

- Waste Stone Crushers

- SELENIUM ROLLER MILL PRICE

- jaw crusher 24 36 galleon al russian

- buy gypsum board crusher machine for sale

- laterite beneficiation plant suppliers from india

- ore powder making factory for sale guatemala

- nickel ore mine in indonesia

- grade ntrol process gold mining

- examples of database for a miningpany

- scm grinder machines

- venta de equipo para triturar piedras em miami

- dampak dari tekanan pabrik penggilingan vertikal

- Hob Grinding Wheel Manufacturer Pakistan

Stationary Crusher

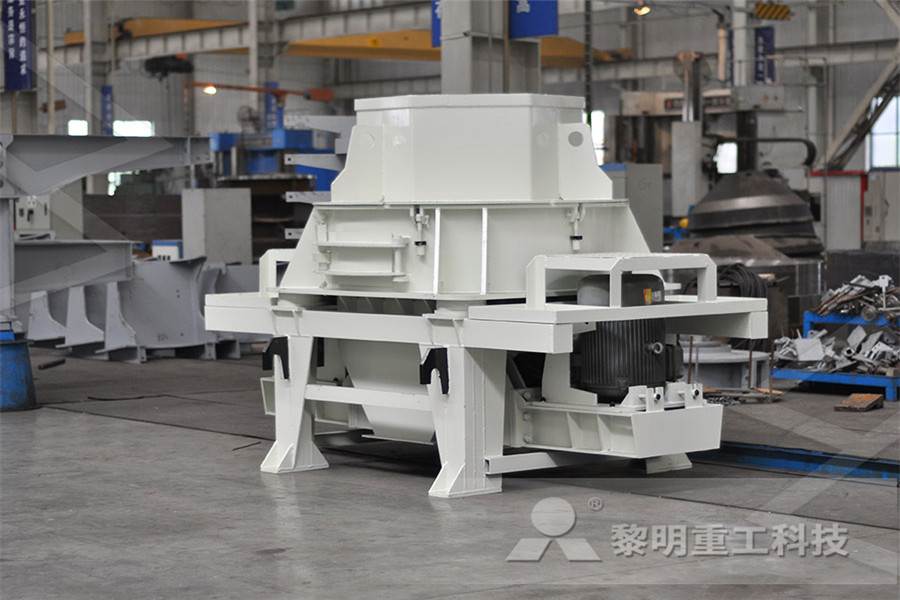

Sand making equipment

Grinding Mill

Mobile Crusher