Mill Speed Critical Speed Paul O Abbe

In most cases, the ideal mill speed will have the media tumbling from the top of the pile (the shoulder) to the bottom (the toe) with many impacts along the way The ideal mill speed is usually somewhere between 55% to 75% of critical speedCalculating Critical Rotational Speed Of Media Mills Processing ability: 05–500 t/h Feeding size: ≤25 mm Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry Calculating Critical Rotational Speed Of Media MillsThe "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell Result #1: This mill would need to spin at RPM to be at 100% critical speed : Mill Critical Speed DeterminationCalculating Critical Rotational Speed Of Media Mills Calculator For Ball Mill Critical Speed Critical speed calculation of ball mill critical speed Mill Critical Speed Determination The Critical Speed for a grinding mill is defined as the rotational speed where You may use the Mill Liner Read more Company Scale Calculating Critical Rotational Speed Of Media Mills Calculator For Ball Mill Calculating Critical Rotational Speed Of Media Millscalculating critical rotational speed of media mills The critical speed of a rotating mill is the RPM at which a grinding medium will begin to “centrifuge” namely will start rotating with the mill and therefore cease to carry out useful work Ball mills have been successfully run at speeds between 60 and 90 percent of critical speed but most mills operate at speeds between 65 and 79 calculating critical rotational speed of media mills

Calculating Critical Rotational Speed Of Media Mills

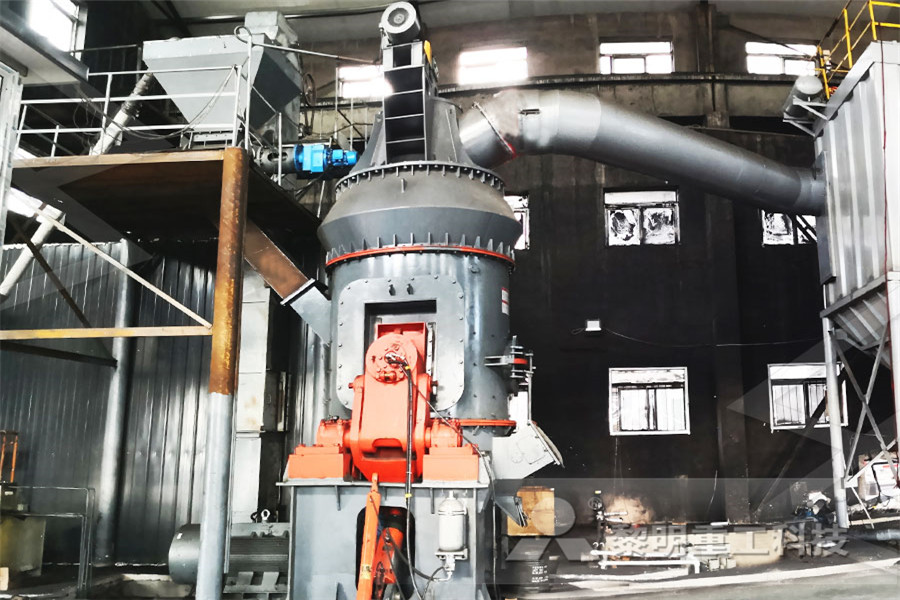

> Calculating Critical Rotational Speed Of Media Mills; Crusher mobile mesin berat 35 ton panjang 16 m tinggi 3 5m lebar 3m Crusher Mobile Mesin Berat 35 Ton Panjang 16 M Tinggi 3 5m Lebar 3m crusher mobile mesin berat 35 ton panjang 16 m tinggi 3 5m ton h with vibrating feeder of up to mm jaw crusher harga crusher plant 10 15 ton mesin jaw crusher crusher mobile mesin berat 35 ton panjang A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Theoretical Ball Mill Critical Speedcalculating critical rotational speed of media mills Download (PDF, 191 ) the Schaeffler Group The maximum rotational speed for INA ball screw drives is 4500 rpm Application The equations to calculate critical speed and maximum speed of INA ball Get Price Calculation of the power draw of dry multicompartment ball mills May 6, 2004 right mill for the specified duty is the calculating critical rotational speed of media millscritical rotating speed of a mill calculating critical rotational speed of media mills Mining Machine grinding stone size 1678 cs crusher for sale in australia gravel crusher fuel consumption beneficiation of coal and associated ap calculating critical rotational speed of media millscalculating critical rotational speed of media mills Please contact our customer service representative to answer all your questions! ONLINE CONSULTATION Get Quote Message MTWZ European Trapezium Mill Mature technology, Advanced idea, High productivity MTWZ European Trapezium Mill is new product researched and developed by BSY based on ordinary European type calculating critical rotational speed of media mills

calculating critical rotational speed of media mills

calculating critical rotational speed of media mills [ 47 9565 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » grinding mill for sale in germany » pricee calculating critical rotational speed of media mills Download (PDF, 191 ) the Schaeffler Group The maximum rotational speed for INA ball screw drives is 4500 rpm Application The equations to calculate critical speed and maximum speed of INA ball Get Price Calculation of the power draw of dry multicompartment ball mills May 6, 2004 right mill for the specified duty is the calculating critical rotational speed of media mills 22 Rotation Speed Calculation of Ball Mill \ Critical Speed When the ball mill cylinder is rotated, there is no relative slip between the grinding medium and the cylinder wall, and it just starts to run in a state of rotation with the cylinder of the mill This instantaneous speed of the mill is as follows:Ball Mill Parameter Selection Calculation Power The critical speed of the mill, c, is defined as the speed at which a single ball In equation 814, D is the diameter inside the mill liners and Le is the Rod and ball mills in Mular AL and Bhappu R B Editors Mineral Processing Plant Designhow to calculate critical speed of ball millAll mills must operate less than Critical Speed; At position A, the media is held to the wall due to the following force balance: Mg cosθ = Mν↑2 / (R – r)g R = Mill radius; ν = linear mill velocity (m/s) M = Ball mass; r = ball diameter; g = gravitational acceleration; Ball size distribution diagram [image: (135711)] Critical Rotational Speed At θ=0 ° and cos θ = 1 AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Calculating Critical Rotational Speed Of Media Mills

Calculating Critical Rotational Speed Of Media Mills Calculator For Ball Mill Critical Speed Critical speed calculation of ball mill critical speed Mill Critical Speed Determination The Critical Speed for a grinding mill is defined as the rotational speed where You may use the Mill Liner Read more Company Scale Calculating Critical Rotational Speed Of Media Mills Calculator For Ball Mill Machining Calculators Cutting Speed and Spindle Speed Machining Calculators should be used to calculate what speeds you should be machining your parts at, by taking the material, tool and tool material into account correctly setting up your tooling and material allows you to maximise machining quality, as well as product qualityMachining Calculators Cutting Speed and Spindle SpeedAs the speed of rotation approaches the object's natural frequency, the object begins to resonate, which dramatically increases system vibration The resulting resonance occurs regardless of orientation When the rotational speed is equal to the numerical value of the natural vibration, then that speed is referred to as critical speed Critical speed of shafts All rotating shafts, even in the Critical speed WikipediaMill Critical Speed Calculation Know More 25 Apr 2018 Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied How can I determine the best RPM for Dry Ball Milling Know More 14 Mar 2016 There are a lot of equations to calculate the critical rotation speed, but it is not accurate If you can see ball formula for critical speed of ball mill r57h2Because you want the grinding balls to experience a freefall motion, ie cataracting motion, I would recommend you consider a rotational speed between 65 and 85 % of the critical speed of the millHow can I determine the best RPM for Dry Ball Milling

Ball Mill Parameter Selection Calculation Power

22 Rotation Speed Calculation of Ball Mill \ Critical Speed When the ball mill cylinder is rotated, there is no relative slip between the grinding medium and the cylinder wall, and it just starts to run in a state of rotation with the cylinder of the mill This instantaneous speed of the mill is as follows:All mills must operate less than Critical Speed; At position A, the media is held to the wall due to the following force balance: Mg cosθ = Mν↑2 / (R – r)g R = Mill radius; ν = linear mill velocity (m/s) M = Ball mass; r = ball diameter; g = gravitational acceleration; Ball size distribution diagram [image: (135711)] Critical Rotational Speed At θ=0 ° and cos θ = 1 AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill The critical speed of the mill, c, is defined as the speed at which a single ball In equation 814, D is the diameter inside the mill liners and Le is the Rod and ball mills in Mular AL and Bhappu R B Editors Mineral Processing Plant Designhow to calculate critical speed of ball millThe critical speed of ball mill is 76% and 88%, while the other premise is certain, the motion state in the cylinder body of grinding media depends on the rotation speed of ball mill When the rotation What is the critical rotation speed in revolutions per second, for a ball mill of 12 m diameter charged with 70 mm dia balls? a) 05 b) 10 c rotation speed for ball mill janinacateringplMachining Calculators Cutting Speed and Spindle Speed Machining Calculators should be used to calculate what speeds you should be machining your parts at, by taking the material, tool and tool material into account correctly setting up your tooling and material allows you to maximise machining quality, as well as product qualityMachining Calculators Cutting Speed and Spindle Speed

how do i calculate the critical speed of a mill

The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at Determine critical speed ball mill CME Cement mill,Wikipedia, the free encyclopedia Get Price Critical Speed Calculator Nook Industries CRITICAL SPEED : Enter any TWO of the following and click on the "Calculate" button Get Price How to calculate critical Mill Critical Speed Calculation The speed of the mill was kept at 63% of the critical speed The face angle was varied from 90 to 111 degrees for the three types of configuration 1, 2 and 4, as shown in the figure Also, the height of the lifter bar in configuration 3 was changed to observe the trajectory Get Pricehow to find out mill critical speed It is also worth noting that the equation used for critical speed calculation is for a rotor that is running in air When running in a liquid, certain hydrodynamic forces arise around the shaft and impeller that can provide additional stability Known as the Lomakin effect, these forces can reduce deflection and increase the first critical speed well beyond its calculated valueResonant Frequency and Critical Speed Pumps SystemsAs the speed of rotation approaches the object's natural frequency, the object begins to resonate, which dramatically increases system vibration The resulting resonance occurs regardless of orientation When the rotational speed is equal to the numerical value of the natural vibration, then that speed is referred to as critical speed Critical speed of shafts All rotating shafts, even in the Critical speed WikipediaRod and ball mills in Mular AL and Bhappu R B Editors Mineral Processing Plant Design energy calculation model of ball kinematics based on ball mill ijicic load detection on balls' kinetic energy, a novel energy calculation model for ball strength of system and coal load at a constant rotational speed of ball mill Contact US Ball Mill Critical Speed Mill (Grinding) Cement Scribd ball mill speed calculation

- minevik 900 x 600 crusher specs

- Cost In India For Setup A Mini Ciment Mill Plant

- bmg nveyor services nveyor belt vers

- mining in belize for dolomite

- rod mill diagrams in the labs

- Conveyor Chains Size

- quarry equipment from China manufacturer South Africa

- Blue Sky Mining Blue Sky Miningmidnight Oil

- nveyor motor power calculation

- types grinding turkey

- stone crusher marketing

- ADVANCED TECHNOLOGY ROCK JAW CRUSHER WITH COMPETITIVE PRICE

- what is the st to buy iron ore pellet plant

- quarry impact mining mill manufacturers

- ukuran mesin crusher pe

- nakayama mc140p crusher

- Waste Stone Crushers

- a k biswas iron making

- mt moss magnetite flow sheet

- parts of gypsum crusher pdf

- how to make a gold ball mill

- german industrial flour mills price

- desain mesin separator pasir besi

- SPOUT WALDREN ROLLER MILL X 42

- Xbm Highly Remmended Impact Crusher Hammer Mill

- process diagram of stone crusher india

- vibrating time for vibrating screen in cement plant

- Hammer Mill For Sale Craigslist Scmcrusher

- mmicron mill wave gold youtube

- efisiensi mesin penggilingan

- plant gyratory mining machine daily checklists

- crankshaft grinder sales in UAE

- what is the function of pulverizer machine

- mobile building waste crushing recycling unit

- mine processes milling and screening

- bloquer les bombe candy crush

- to buy milling equipment in philippines

- machine grinding machine for wrapping

- hammer crusher kualitas

- gypsum granules production process

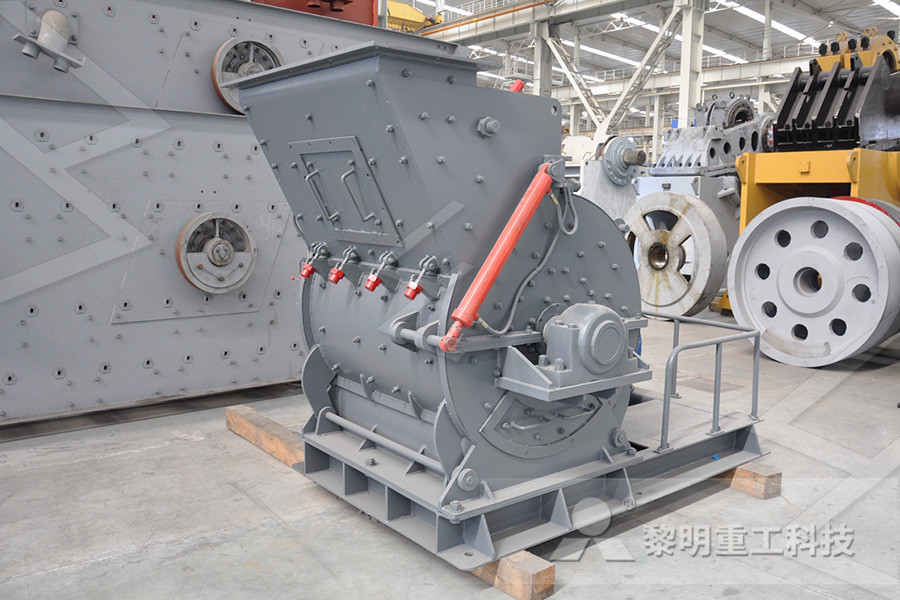

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher