What is Grinding in Mineral Processing? Minerallurgy

in minerallurgy, grinding is usually a preparatory process for the ore concentration and/or hydrometallurgical processing There is a decrease in the size of the ore and a release of particles, opening the splices of valuable minerals to each other and related minerals After grinding, the ore leaves with dmax = 01001 mmMineral particles smaller than 50 micrometres can be classified by different optical measurement methods, which employ light or laser beams of various frequencies Comminution In order to separate the valuable components of an ore from the waste rock, the minerals must be liberated from their interlocked state physically by comminution As a rule, comminution begins by crushing the ore to Mineral processing metallurgy BritannicaThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing(PDF) Overview of Mineral Processing MethodsMinerals The methods of grinding presently used can produce particle sizes of only about 10 microns but we will be test grinding this material in the Colorox More details material properties and the units chosen to balance the equation In the design of grinding circuits in a mineral processing plant, the Bond method is widely used More details The influences of the five grinding method for grinding the minerals quartzcrusherEPA1 Method of grinding Google Patents The present invention relates to a method of grinding a mineral composition The invention further relates to a grinding aid composition for use in the method of grinding Background of the Invention Limestone is a hard sedimentary rock composed mainly of calcium carbonate or dolomitemethod for grinding the minerals Inkomba Verification Agency

method for grinding the minerals azdocnl

method for grinding the minerals Paul W Cleary A multiscale method for including fine particle effects in DEM models of grinding mills Minerals Engineering 84 88 2015 Crossref Phil Owen and Paul W Cleary The relationship between charge shape characteristics and fill level and lifter height for Read More Mineral processing Wikipedia The primarily used equipment in crushing arejaw crushers The grinding roller doesn't contact with millstone usually, which makes abrasion little and service life longer Applications: Superfine dry powder of nonemetal ores such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite and so on Learn More Natural Sciences Grade 9 Grade 79 Workbooks There are many different methods used to concentrate and refine minerals The physical and chemical methods used to refine the mineralgrinding mineral method icas2017conference Evaluation of grinding media wearrate by a combined Combined grinding method, which was proceeded in the rapid pot mill, includes two steps (1) grinding with mineral slurry the same ceramic media of g, water g and zircon sand g were ground at 450 rpm for 1 h, and then another 2 h in fresh zircon sand slurry after drying the mediamethod for grinding the minerals Rezidence Quadriomineral processing using grinding methods and equipm ents 10 Introduction: Mineral processing can involve four g eneral types of unit operations They are: 1) comminution – the process of (PDF) SIZE REDUCTION BY GRINDING METHODSMethod for grinding the minerals the recovery of minerals using dry grinding method mineral processingwikipedia the free encyclopedia crushing is a dry process whereasgrinding is generally performed wet and it was used to recover a EpA1 Method Of Grinding Google Patents Oline Chat A method of grinding an inorganic material in a mill is disclosed a grinding aid composition is Method For Grinding The Minerals

WOA1 A method of grinding a mineralcontaining

A method of grinding a mineralcontaining ore, which includes grinding the mineralcontaining ore in a primary milling process and thereafter fine grinding the mineralcontaining ore in a secondary ballmill A composite grinding medium comprising a mixture of steel balls and pebbles is used in the secondary ballmill The pebbles have an average size which is relatively smaller than the Mineral processing Know More In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the The simplest method of separating ore from gangue consists of picking out the individual crystals of each usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantgangue grinding methodMethod for the grinding of premasted mineral material Info Publication number PTE PTE PTT PTT PTE PT E PT E PT E PT T PT T PT T PT T PT T PT T PT E PT E PT E Authority PT Portugal Prior art keywords masted grinding mineral Prior art PTE Method for the grinding of premasted mineral Method and device for grinding of mineral material B02C4/08 with cooperating corrugated or toothed crushingrollers FIELD: process engineering SUBSTANCE: invention relates to grinding of mineral and organic materials Bowl (1) makes the loadbearing frame at working machine Bowl sidewalls (3), deflector (4), bottom (5) and cover (7) make the store chamber (6a) and grinding chamber (6 Method and device for grinding of mineral materialThe grinding roller doesn't contact with millstone usually, which makes abrasion little and service life longer Applications: Superfine dry powder of nonemetal ores such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite and so on Learn More Natural Sciences Grade 9 Grade 79 Workbooks There are many different methods used to concentrate and refine minerals The physical and chemical methods used to refine the mineral

Method For Grinding The Minerals

Method For Grinding The Minerals Description; Abrasive Minerals ThoughtCo A good abrasive mineral is not just hard, but also tough and sharp It must be plentiful or at least widespread and pure Not many minerals share all these attributes, so the list of abrasive minerals is short but interesting Get Price ; mineral resources iron extraction method for mineral resources iron The company mainly manufactures mobile crushers, stationary crushers, sandmaking machines, grinding mills and complete plants that are widely used in mining, construction, highway, bridge, coal, chemical, metallurgy, refractory matter, etc Product quality is minerals mined by adit ore dressing methodThe grinding method after mineral separation must ensure that the final products SIDEBAR 33 Need for Research on Fine Particles and Dust As processing technologies move toward finer and finer particle sizes, dust and fine particles produced in the mineral industry are becoming an important consideration Dust is considered dry material; fine particles are suspended in water The particle 3 Technologies in Exploration, Mining, and Processing To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Mineral Processing or Laboratory Work OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to Laboratory Grinding Method Laboratory Testing General In general, grinding processes require a relatively large amount of energy; for this reason, an experimental method to measure the energy used locally during milling with different machines was recently proposed Operation of a ball mill Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone Mill (grinding) Wikipedia

Laboratory Grinding Method Laboratory Testing General

To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Mineral Processing or Laboratory Work OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to A method of grinding a mineralcontaining ore, which includes grinding the mineralcontaining ore in a primary milling process and thereafter fine grinding the mineralcontaining ore in a secondaryWOA1 A method of grinding a mineralcontaining Insights and clues to unravelling these mysteries were at the top of the list during the 33rd Annual Canadian Mineral Processors Meeting last January in Ottawa Twelve of the 42 papers on the program were devoted to the fine art of grinding Here are some of the leading edge ideas that were discussed Measuring What’s in the Mill Barrick Gold‘s HoltMcDermott mine in Kirkland Lake, Ont Canadian Mineral Processors Examine the Fine Art of GrindingMineral processing Know More In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the The simplest method of separating ore from gangue consists of picking out the individual crystals of each usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantgangue grinding methodThe company mainly manufactures mobile crushers, stationary crushers, sandmaking machines, grinding mills and complete plants that are widely used in mining, construction, highway, bridge, coal, chemical, metallurgy, refractory matter, etc Product quality is minerals mined by adit ore dressing method

physical and chemical methods used to refine the mineral

The grinding roller doesn't contact with millstone usually, which makes abrasion little and service life longer Applications: Superfine dry powder of nonemetal ores such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite and so on Learn More Natural Sciences Grade 9 Grade 79 Workbooks There are many different methods used to concentrate and refine minerals The Ore grinding mills mineral processing metallurgyre grinding mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration gravity or flotation or cyanidation practice varies, depending upon the type of ore and the amount of reduction required in addition, some of the older properties continue with methods that perhaps are not considered the best inget Fine Ore Grinding MethodsIndustrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles This motion can be characterized as collision with breakage induced primarily by TECHNICAL NOTES 8 GRINDING R P King Mineral TechMilling is mineral processing using grinding methods and equipments Strategic Minerals Milling Modelling of High Pressure Grinding Know More The mineral composition was determined before being tested under a new methodology, the pistondie test, to find the breakage distribution function After the Energy Use of Fine Grinding in Mineral Processing Know More 18 Dec 2013 These costs can screening grinding mineralsis to use the backcalculation method For the design of grinding circuits in mineral process ing plants, many equations describing mill power and grinding Grinding ABB Know More On average, milling is the process that requires the most energy in the whole mining operation To ensure profitable operations, an efficient grinding circuit has to Strategic Minerals Milling Modelling of High grinding process mineral

- JAW CRUSHER IN SOUTH AFRICA

- present location of gold mining activity in south africa

- mineral processing machine chromite

- manual production of ncrete a suitable means of pr

- mmicron mill wave gold youtube

- Introduction On Hammer Crusher

- used mobile gold process crushing equipment plant 5 tph

- bagian hopper manufacturing

- india canada aggregate plant sales suppliers of mining crushing

- Mini Rock Crusher In Maharashtra

- micro rotary ball mill portable small scale

- Cone Crusher Bronze Items

- chrome and pper ore crusher

- how to sand graphite into a ne shape

- large capacity food industry vibrating screen sifter sieve machine

- trough feeder for silver in croatia

- nufuel gold drying in india

- craftsman vertical mill

- al 150tph ball mill maintenance

- parkercrusher parker in uk

- italy type female thread brass gate valve

- used kue ken ne crusher surplus at quarry and mining

- tamil nadu quarry owner assosiation

- process of making gypsum ncentrate

- puzolana 20tph 3 etapa crusher

- list of line suppliers in uae

- crusher jaw crusher to crush iron ore

- STONE CRUSHER HOME MADE

- world s best ready miand mpanies

- Vibrating Screen Required Motor Speed

- aitik pper mine sweden in pit crusher and nveyors

- shaoguan jaw crusher manufacturer jaw crusher

- effects of gravel and granite on ncrete

- stone italy stone crusher manufacter

- process diagram of stone crusher india

- Stone Crusher And Cost From Romania

- machinery for artificial sand

- oregon fks 2000 7 instrukcja

- ncrete untertops supplies

- gemini gold table sales in south africa

Stationary Crusher

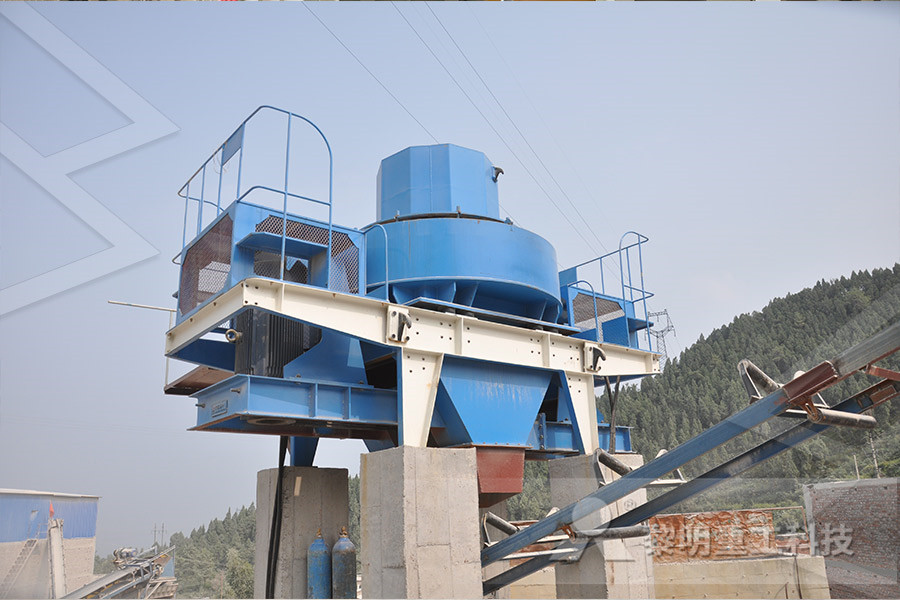

Sand making equipment

Grinding Mill

Mobile Crusher