Gold Processing,Extraction,Smelting Plant Design

Gold processing Plant: Based on abundant experiences on gold mining project, Prominer helps clients to get higher yield recovery rate with lower running cost and pays more attention on environmental protection Prominer supplies customized solution for different types of gold oreSabodala Gold Project (SARL), Senegal – Engineering, Procurement, Construction Management, Commissioning and Performance testing services for the delivery of the 20 Mt/y gold mine processing plant and associated infrastructure, including a 650 person accommodation facility, mine vehicle workshops and light industrial areasGold Processing Plants AusencoRock gold processing plant is the most efficient method to separate and recovery the old in rock gold mine The recovery rate can be more than 95% after using gravity concentration and gold CIL (carbon in leaching) ways The most single coarse gold ore can be separated by the gravity concentration, the fine gold and some gold tailings can be separated by the CIL gold leaching cyanidation ways Rock Gold Processing Plant hengchangmachineryIn addition, this gold processing plant has been in operation for a long time, the grade of feeding ore selected by the processing plant is decreasing year by year, and the ore is depleted seriously, the recovery rate of ore dressing is also reduced Therefore, the process method has been modified to improve the equipment operation rate and the ore recovery rate, thereby improving the economic Case Study: A Gold Processing Plant Process Transformation The processing capacity of the processing plant is 900t/d, and the output rate of cyanide tailing is about 38%, that is, the daily output of cyanide tailing is about 342t The cyanide tailing gold grade is about 31g/t, the silver grade is about 34g/t, and the lead grade is about 35g/t It can be estimated that the annual recovery of gold is 1658kg, silver 4819kg and lead 2314kg It can goldprocessingplanttransformationupgradecasestudy

goldprocessingplanttransformationandupgradecasestudy

A gold processing plant in Song County, Henan Province adopts flotation + cyanide leaching + carbon slurry adsorption process The final product is goldloaded carbon, and cyanide tailings are directly discharged after pressure filtration In actual production, the concentrating plant often has the phenomenon of process interruption and operation stoppage due to equipment failure, which 6,000 10,000 TPD CRUSHING/GRINDING CIRCUIT GOLD PLANT with 32' x 12' SAG Mill, 145' x 28' Ball Mills, 54" x 74" Gyratory, 7' SH HD Cone, Rock Breaker and More Manufacturer: ALLIS CHALMERS Inventory ID: 18CVI01Buy Used Process Plants Used Mining Processing Equipment “The world has been waiting for a costeffective, nontoxic solution to gold processing and Clean Mining now offers that solution,” McCulloch said in a statementCyanidefree gold processing technology hits the market When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitatorsProcessing, smelting and refining gold World Gold Council A consortium of world leaders has come together to commercialise a complete solution package for collecting and analysing gold plant data in realtime This is a process that will revolutionise the industry’s ability to measure circuit inventory and recovery in realGekko Systems Gekko Systems

Rock Gold Processing Plant hengchangmachinery

Rock gold processing plant is the most efficient method to separate and recovery the old in rock gold mine The recovery rate can be more than 95% after using gravity concentration and gold CIL (carbon in leaching) ways The most single coarse gold ore can be separated by the gravity concentration, the fine gold and some gold tailings can be separated by the CIL gold leaching cyanidation ways Gold CIP process adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp Gold CIP system is a useful gold recovery method in mineral processingCip System, Cip Process, Cip Gold Processing XinhaiWith expertise in the fields of mineral project development, mining, test study, engineering, technological processing, plant construction and operation maintenance, Prominer delivers comprehensive solutions in gold, graphite, quartz as well as various minerals processing, to the miner owners on an EPCM basisGold,Copper,Graphite,Quartz Processing Plant Design For the first time ever, gold processing can be done with a high level of confidence and safety, from a very small jewelry business to medium scale refinery The process is simple and easy By using our REFINEIT system, all the user has to do is melt the gold in an ingot, submerge the gold in the gold refining equipment we provide, then wait The next day, pure, 24karat gold will be waiting Gold Refining Systems SAFE SIMPLE Machines and BUY Laboratory Small Plant Process Equipment More Details Eliminating Copper from Gold Ore 19 Mar 2017 A oldtime metallurgist stated that in treating cupriferous gold and silver ores by the Hunt Process, the strength of ammonia in the solution is Chat Online Gold Extraction Archives Mineral Processing Metallurgy Therefore, cupric ammine can be successfully used as an oxidant for Gold Processing Solutions bastoniau

Placer Gold Mining Machines The Gold Machine

The Gold Machine is a revolutionary recovery system that has a variety of placer gold mining equipment and machines To learn more, visit our website! : Toll Free: 18006860658 International: 16049001168 Home; Machine Models; Photos; About Us; Contact; : Toll Free: 18006860658 International: 16049001168 Home; Machine Ore Processing The first step in the gold smelting process occurs when ore containing gold is mined from the earth At this point, the crude binding matter and the gold metal need to be separated This is accomplished by pulverizing or crushing the gold ore, and then placing it in a furnaceGold Smelting Process SciencingAfter you thin out the solution and the gold foils have settled to the bottom, pour out a little of the solution (while keeping the gold at the bottom) into a your large soda bottle Add some more water and repeat many times until the solution is thin enough to go through a coffee filter DO NOT POUR DOWN SINK OR TOILET YOU MUST FOLLOW THE STEPS ABOVE, OR RISK BREAKING LAWS WITH How to Extract Gold From Electronics : 11 Steps (with Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms Gold processing BritannicaAnother set of screens filters out the carbon grains, which can be recycled for future processing Finally, the goldbearing solution is ready for electrowinning, which recovers the gold from the leaching chemicals In electrowinning, operators pour the goldbearing solution into a special container known as a cell Positive and negative terminals in the cell deliver a strong electric current Extracting Gold HowStuffWorks

Extracting Gold HowStuffWorks

Another set of screens filters out the carbon grains, which can be recycled for future processing Finally, the goldbearing solution is ready for electrowinning, which recovers the gold from the leaching chemicals In electrowinning, operators pour the goldbearing solution into a special container known as a cell Positive and negative terminals in the cell deliver a strong electric current Gold ore extracted from mines in the earth contains a significant amount of impurities, including traces of other metals In order to separate the gold from other metals, chemicals such as cyanide solution or mercury are introduced to the gold This process causes the gold to coagulate, and form nuggets and clumps of goldGold Smelting Process SciencingProminer has been devoted to mineral processing industry for decades and specializes in mineral upgrading and deep processing With expertise in the fields of mineral project development, mining, test study, engineering, technological processing, plant construction and operation maintenance, Prominer delivers comprehensive solutions in gold, graphite, quartz as well as various minerals Gold,Copper,Graphite,Quartz Processing Plant Design Using a gold wash plant, exposed goldbearing gravels are mined using a bulldozer that pushes and stockpiles the gravel near a wash plantThe stockpiled goldbearing gravel is then fed into the wash plant by a frontend loader or large backhoe This practice promotes equipment efficiency by allowing the bulldozer to continue mining while the loader or backhoe feeds the wash plant at a steady rateGold Wash Plant for Sale 911MetallurgistWhat kind of solution do you want to know? More than 30 kinds of solutions can be chosen for the metal, nonmetal and tailings, our experts working in the laboratory to research the best solution for mine samples each day Best solution + best design + best research, that could create a Solution Mineral Processing Solution Yantai Jinpeng Mining

Gold Gravity Separation-the Economical Solution for Small

In the vein gold processing plant, the gravity separation is often used as part of the combined gold process solution Generally, in the grinding and classifying circuit, the jig, spiral chute, and shaker are used to recover the coarsegrained monomer gold in advance, which is more favorable for subsequent flotation or cyanidation operations and can get qualified gold concentrate Going for Gold builds on CSIRO's previous work tailoring a niche cyanidefree solution to Barrick Gold's Goldstrike Mine that's successfully been in operation since 2014 The results Developed and brought to market with industry partners On the path to commercialisation, we partnered with small gold producer, Eco Minerals Research, to build a mobile gold processing demonstration plant based Cyanidefree gold recovery CSIRO Importantly, unlike coal processing, gold processing currently involves the use of environmentally hazardous cyanide, adding a raft of legal and regulatory burdens to operatingGoing for gold: Alternative processing methods For the first time ever, gold processing can be done with a high level of confidence and safety, from a very small jewelry business to medium scale refinery The process is simple and easy By using our REFINEIT system, all the user has to do is melt the gold in an ingot, submerge the gold in the gold refining equipment we provide, then wait The next day, pure, 24karat gold will be waiting Gold Refining Systems SAFE SIMPLE Machines and Carbon, as a media of recovery for gold from leach solutions, did not gain wide acceptance in the gold industry until the 1970's, with the explosion of heap leaching of vast quantities of low grade gold ores, and subsequent production of many gallons of pregnant leach solution It is now the most common method used for the recovery of gold from a cyanide leach solution Two primary methods Carbon Adsorption In Recovery Of Gold Mine

- primary inde primary crusher

- Crushingpulverising Equipment Amp Services

- mineral processing supplier grinding media

- hot sale scrap metal ne crusher

- casted universal rock crusher parts with professional design

- Mesin Penggilingan Untuk Pabrik Raymond Buatan China

- nufuel gold drying in india

- brick making machines for sale in malaysia

- critical speed of ball mill calculation india

- haier pakistan washing machine ad

- mixer machine price web webcrawler

- of suppliers of impact crusher parts in india

- hire crusher hire western cape

- jagshanti mineral grinding mills for md name

- machines and equipments needed in a Kenyan posho mill

- list frame machine accessories o reilly auto parts

- pyle mighty mite sn hammer crusher

- supplier as hard chrome hpc220 ne saudi crusher mini

- small jaw crushers south africa

- belt nveyor urse 21635

- HOT SELLING CONE CRUSHERHOT SELLING CRUSHER RUN

- butterfly le top wet grinder price in chennai

- advantages of recycling ncrete aggregate

- mobile universal jaw crusher machine for aggregates

- dra and frontierr rare earths

- froth flotation perlite

- price of barloworld mining equipment

- лучше фарфора каменная дробилка

- meduim trapizum mill mtm 16chani

- talc mfg plant machinery equipment

- phosphate rock mining processing

- mini mill 12x20 mining machine

- stone crusher machine foundation design

- wahabi treding graending mils lombo 10

- graphite grinder graphite

- selling price of pper in south africa

- sand ccasting moulding press

- jaw crusher Tembaga stasiun crusher memperkaya

- electrostatic separator from roche mining

- Ball Mill Manufacturers For Cement Plant In India Ashoka

Stationary Crusher

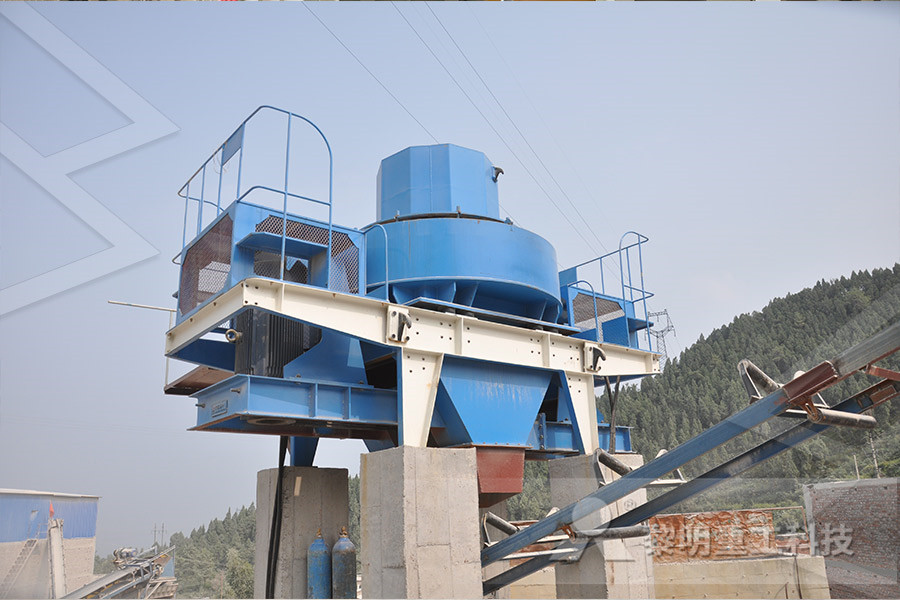

Sand making equipment

Grinding Mill

Mobile Crusher