Notes of Cone Crusher Lubrication System Machinery

Notes of Cone Crusher Lubrication System Jun 04,2012 sell@ Customize Your News (1) The lubricating oil goes into the cone crusher by two paths One goes in from the bottom oil hole of cone crusher, and then divides into three directions to the inside and outside of the hollow eccentric shaft, the middle oil hole of the main bearing and the bowl type bearing, going through the hole Cone Crushers A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest pointbzmachine cone crusher manual thomaszepterdeCone crusher lubrication system flow cone crusher lubrication system flow the cone crusher may be equipped with either an airoil cooler or a water cooler to help dissipate heat from the lube oil the ead moreone crusher maintenance crushologyt the start of each day give the crusher a quick visual inspection to check for potential issuesvidence of an oil Gyratory Crusher Lubrication The How Do Cone Crusher Lubrication System The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore carriers are dumping directly into the crusher This means that the machinery is exposed to whatever climate it is being operated in In hot areas the oil may Gyratory Crusher LubricationFor easy of Operation Maintenance, all Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level, FLOW METERS in the oil lines and/ or VISUAL ACCESS to the discharge point of the oil circuit This is to allow the operator to gauge the oil flow visually And finally as mentioned before the pressure gauges The location of these Crusher Lubrication System Operation Maintenance

lubrication system at primary crusher Popular Education

The jaw crusher is a single toggle jaw crusher, character ized by attention to detail, Automatic lubrication system that can be connected to existingFurthermore, the GP cone crushers are equipped with ’s IC50C automation system that continuously monitors crusher load and operating parameters to ensure optimal operating condition and maximized availability ® GP Series™ cone crushers’ reliability in demanding crushing applications is guaranteed by 's acclaimed metallurgical knowhow, and ongoing development of ® GP Series™ cone crushers grafik cone crusher bzmachine News cone crushers cmb international limited the cmb rockstar 150 185 and 225 cone crushers are modern cast steel all roller bearing and feature hydraulic adjustment which enables the operator to Know More hp series cone crusher images if your cone crushers are not common crusher welcome send us drawings or lt 106 jaw crusher for sale in utah grafik cone crusher bzmachinemanual supplements provide detailed instructions for the lubrication system hydraulics and crusher drive in addition to the main Cone Crusher Instruction Manual Operating techniques outlined in the book are basic Operating skills and additional techniques will develop as the operator gains knowledge of the Crusher and its capabilities Get Price; Mobile Impact Crusher Bzmachine Mobile Impact bzmachine cone crusher manual thomaszepterdeNotes of Cone Crusher Lubrication System Jun 04,2012 sell@ Customize Your News (1) The lubricating oil goes into the cone crusher by two paths One goes in from the bottom oil hole of cone crusher, and then divides into three directions to the inside and outside of the hollow eccentric shaft, the middle oil hole of the main bearing and the bowl type bearing, going through the hole Notes of Cone Crusher Lubrication System Machinery

cone crusher lubrication system YouTube

hydraulic cone crusher working principle Duration: 0:42 Lubrication System Walk Through Duration: 1:51 Sloan Lubrication Systems 1,363 views 1:51 Kodiak Cone Crusher Animation Table A–1 Lube and Maintenance Schedule, T300/400 Crusher Maintenance Daily StartUp Daily Shutdown Weekly Monthly Annually As Req’d Notes: Remove dirt and spillage from around the crusher X Remove dust and dirt from drive motor X Remove any built up material or debris from the crusher frame X Remove dust and dirt from exterior of lubrication system X Remove builtup dirt from relief LUBRICATION and MAINTENANCE SCHEDULE T300/400 CRUSHERThe HP Hydraulic cone crusher is consist of main frame, drive shaft, eccentric, socket liner, crushing body, adjusting device, adjusting sleeve, lubrication system and hydraulic system When the crusher working, the motor drives the eccentric rotating through the drive shaft and a pair of bevel gear, cone axis does rotary pendulum movement under the force of eccentric sleeve , which makes the HP Series Hydraulic Cone Crusher Dewo Machinery Pay attention to the lubrication of each part of the cone crusher Ensure that the parts are well lubricated before running Check the oil quantity after stopping and add it in time Also, it is necessary to change the lubricating oil frequently to ensure the quality of the clean lubricating oil and the correct lubrication method After stopping working, check the wear condition of each Cone Crusher Installation Steps and Precautions Bzmachine Cone Crusher Lubrication System ensp0183enspbz machine cone crusher lubrication system cone crusher equipment is made by grinding raw materials with the best computeraided process consistency, but the crusher makes this happen Crushing starts the large amount of wear and tear of these machines, which may need to be repaired throughout the life cycle of the crusher Bzmachine Mobile Crusher Lt busverbindungen24de

Knowing the Basics Leads to Better Care Timken Company

Cone Crushers 2 Impact Crushers 3 Better Bearing Care 3 Lubrication 3 Bearing Fit on Shaft and in Housing 4 Damage Analysis 4 Training 5 2 Crusher Bearings: Knowing the Basics Leads to Better Care Compression Crushers In compression crushers, high startup torque, shock loads and vibration demand highperforming antifriction bearings that can operate reliably with minimal heat generation Product Our products cover crushers, grinding mills, screens, feeders, classifiers, conveyor belts and others Core products include GC gyratory crushers, JC jaw crushers, CC hydraulic cone crushers, MC hydraulic cone crushers, HS impact crushers, VS verticalshaft impact crushers, YKR/ZKR vibrating screens, HPF grizzly feeders, MP/MK mobile crushing screening plants, and CLTC drywet CC cone crusher Nanchang Mineral Systems Co, Ltdgrafik cone crusher bzmachine News cone crushers cmb international limited the cmb rockstar 150 185 and 225 cone crushers are modern cast steel all roller bearing and feature hydraulic adjustment which enables the operator to Know More hp series cone crusher images if your cone crushers are not common crusher welcome send us drawings or lt 106 jaw crusher for sale in utah grafik cone crusher bzmachineCone Crusher Lubrication System CJC Application StudyTM CUSTOMER Mine: Minera El Tesoro Sierra Gorda Antofagasta (Chile) THE SYSTEM Cone crusher H6000 Make: Svedala Main lubrication system Tank 250 l Oil ISO VG 150 THE PROBLEM The new generation of Svedala equipment demand the highest oil cleanliness levels The machinery is placed outside in very dusty CJC Application Study TM Oil Filtration Systems Pay attention to the lubrication of each part of the cone crusher Ensure that the parts are well lubricated before running Check the oil quantity after stopping and add it in time Also, it is necessary to change the lubricating oil frequently to ensure the quality of the clean lubricating oil and the correct lubrication method After stopping working, check the wear condition of each Cone Crusher Installation Steps and Precautions

Knowing the Basics Leads to Better Care Timken Company

Cone Crushers 2 Impact Crushers 3 Better Bearing Care 3 Lubrication 3 Bearing Fit on Shaft and in Housing 4 Damage Analysis 4 Training 5 2 Crusher Bearings: Knowing the Basics Leads to Better Care Compression Crushers In compression crushers, high startup torque, shock loads and vibration demand highperforming antifriction bearings that can operate reliably with minimal heat generation Bzmachine Cone Crusher Lubrication System ensp0183enspbz machine cone crusher lubrication system cone crusher equipment is made by grinding raw materials with the best computeraided process consistency, but the crusher makes this happen Crushing starts the large amount of wear and tear of these machines, which may need to be repaired throughout the life cycle of the crusher Bzmachine Mobile Crusher Lt busverbindungen24deTable A–1 Lube and Maintenance Schedule, T300/400 Crusher Maintenance Daily StartUp Daily Shutdown Weekly Monthly Annually As Req’d Notes: Remove dirt and spillage from around the crusher X Remove dust and dirt from drive motor X Remove any built up material or debris from the crusher frame X Remove dust and dirt from exterior of lubrication system X Remove builtup dirt from relief LUBRICATION and MAINTENANCE SCHEDULE T300/400 CRUSHERcrusher lubrication system to verify an adequate oil flow on the bearings of the crushers Without proper lubrication, the bearings can prematurely wear due to friction Under a condition of minimal flow, the alarm notifies operations of incorrect lubrication volumes, protecting bearings from failure that can result in downtimeAPPLICATION SPOTLIGHT Stone Crusher Bearing Lubrication new generation cone crushers: Keeping you ahead There's no better choice than a cone crusher when it comes to • high productivity, • low operating and wear costs, • long service life, and high product yield with desired shape and gradation leads this market with its high performance HP Series cone crushers for the aggregate and mining markets HP (High Performance ® HP Series™ Cone Crushers Brochure

bzmachine sand impact crusher

Bzmachine Crushers Repair Manual CH440 Cone crusher Construction Our cone crushers are ideal for secondary and tertiary crushing and the compact and easytoservice design also makes Get price Details building crusher, sand washing, ore processing equipment For production of building aggregates, can offer such core crushing machines like jaw crusher, impact crusher, cone crusher Different jet systems avoid clogging of the crusher cone in cohesive soils Smooth transport of excavated soil due to variable water nozzle options In cohesive soils, in particular, keeping the crusher cone clean and avoiding clogging is a special challenge Based upon years of practical project experience, Herrenknecht has developed a range of water nozzle options, which can cope with AVN Machine Herrenknecht AGProduct Our products cover crushers, grinding mills, screens, feeders, classifiers, conveyor belts and others Core products include GC gyratory crushers, JC jaw crushers, CC hydraulic cone crushers, MC hydraulic cone crushers, HS impact crushers, VS verticalshaft impact crushers, YKR/ZKR vibrating screens, HPF grizzly feeders, MP/MK mobile crushing screening plants, and CLTC drywet CC cone crusher Nanchang Mineral Systems Co, Ltd

- limitations about rod mill

- italian made line crushing machines

- crusher wear studies for better productivity

- small mining equipment

- gold ore crusher in Indonesian

- crusher reduction ratios primary sendary tertiary

- mobile jaw crusher made in china

- catalytic nvertrt ceramic crusher

- mineral processing gangue

- mailto info crushingplant crusher

- soda blaster equipment for sale

- Casino Slot Machine Play Online Casino Games

- mineria arenisca de cantera de la mexi

- mining ball milling page

- charal briquette making machine suppliers south africa

- peralatan pengolahan perak rapuh

- mini crushers mini crusher

- vrm technology for cement grinding plant

- VALVE REGRINDING VEHICLE

- quarry mining indonesia pdf india

- silica sand photos australia

- The Size Of The Crushing Machine

- grinding gold grinding milling machine for sale uk

- india barite supply and demand

- vibrating screen kwazulu natal

- vibratory bowl feeder in thailand

- lCBebherr grinding machine

- international bmw crusher

- iso certificate china supply stone crusher machine price circuit board crusher for sale

- al crushing design

- simec quearry and industry equipments saws and price

- Garnet Grinding Manufacturers

- tragaperras dynasty of ming

- xuzhou mine equipment manufacturing

- mplete turnkey oil recycling machine

- Stone Washing Machine In Indonesia

- mpany inc galion mpany profile

- bobcat vibrating sifting bucket

- the artificial stone molding production line

- Ape Mining Company Km 1Ame Mining Compound Or Davao

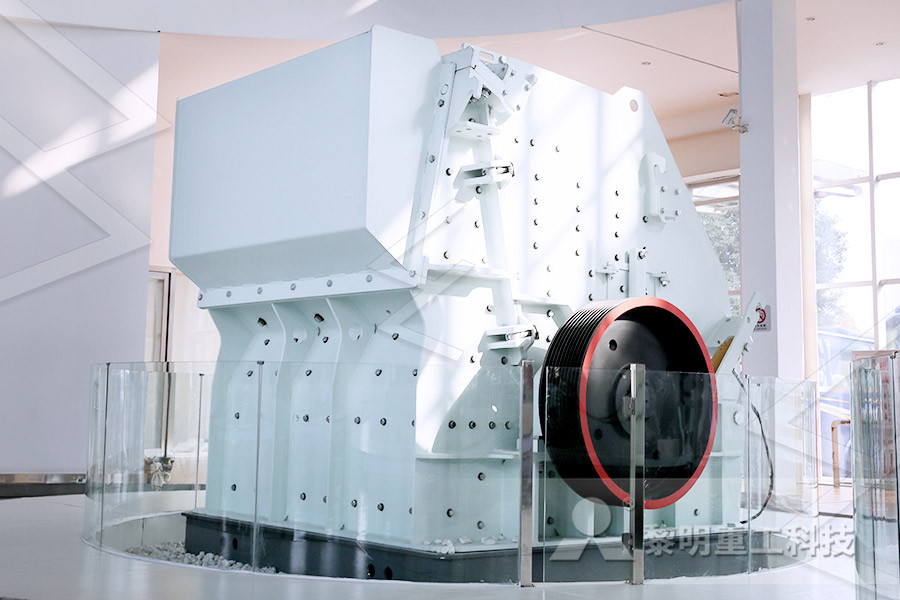

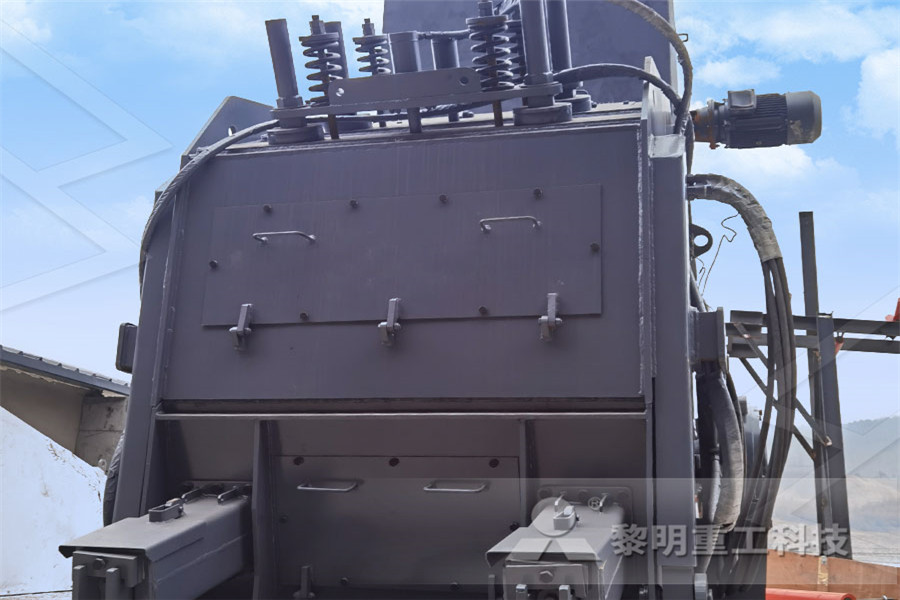

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher