design of coal crusher pdf Pochiraju Industries Ltd

design of coal crusher pdf pet coke crusher pdf Posts Tagged: pet coke pet coke crusher pdf hammer mill design pet coke industrial h Roll Crushers Able to Size Coal, Salts, Potash, Lime and Soft Get Price MAINTAINING COAL SAMPLING SYSTEMS MANAGING Today's coal sampling systems are simpler and easier to maintain than those While all this is good and the well designed Crushing reduces the overall topsize of the ROM coal so that it can be more easily handled and processed within the CPP Crushing requirements are an important part of CPP design and there are a number of different types Screening Screens in screening plant are used to group process particles into ranges by size Dewatering screens are used to remove surface water from the productCoal preparation plant WikipediaFeeders Crushing McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size McLanahan crushers can take the coal producer through all stages of crushing process, from initial reduction in the primary stage to further reduction and refinement in the secondary and tertiary stages, all while minimizing the generation of dust and finesCoal McLanahan coal crusher design Posted on May 25, 2013 by shuijing Coal Crusher,Coal Crushing Plant Design by Caiman Coal is a very important source of energy, mainly for combustion, coking, gasification, low temperature distillation, hydrogenation liquefaction Coal CrushersCoal CrusherCoal Crushing PlantCoal Crusher Coal crusher is mainly used for crushing coal in coal mining and coal crusher design worldcrushersThe main aim was to design the coal crushing circuit, which would produce the material within the particle size range between 05 and 5 mm The onestage crushing circuit based on hammer crusher was proposed There laboratory Crushing of coal and calculation of size reduction efficiency Feb 25, 2015 Knowledge piece on Crushing of Coal and Efficiency of Crushers Utsav Kant 2/25/2015 6:58:05 design coal crusher voedselbanknoordenveldleeknl

Crushing Plant Design and Layout Considerations

The fundamental goal for the design of a crushing plant is an installation that meets the required production requirements, operates at competitive cost, complies with today’s tough environmental regulations, and can be built at a reasonable price despite the rising costs of equipment, energy and construction laborcoal processing plant layout plant numbering system used Stone crushing equipment is designed to achieve maximum productivity and high reduction ratiocoal processing plant layout plant Huis Tarkastad HomeCoal Crushing Design [ protected] Get price Submit Message Related Products Solutions High Pressure Briquetting Machine The high pressure briquetting machine or the high pressure ball press machine is used to press many kinds of materials such as gypsum, coal powder, mineral powder, scale cinder, slag, fine iron powder and aluminum ash etc Cement Mill Cement Mill is one of the Coal Crushing DesignDouble roll crushers consist of two adjacent rolls placed parallel to each other and rotated in opposite directions These are typically used in situations in which fines are to be minimized They are widely employed on friable materials such as coal, lime, limestone, petroleum coke, and chemicalsDouble Roll Crusher Machine Design Belt (Mechanical Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as Crushing Plant Design and Layout Considerations

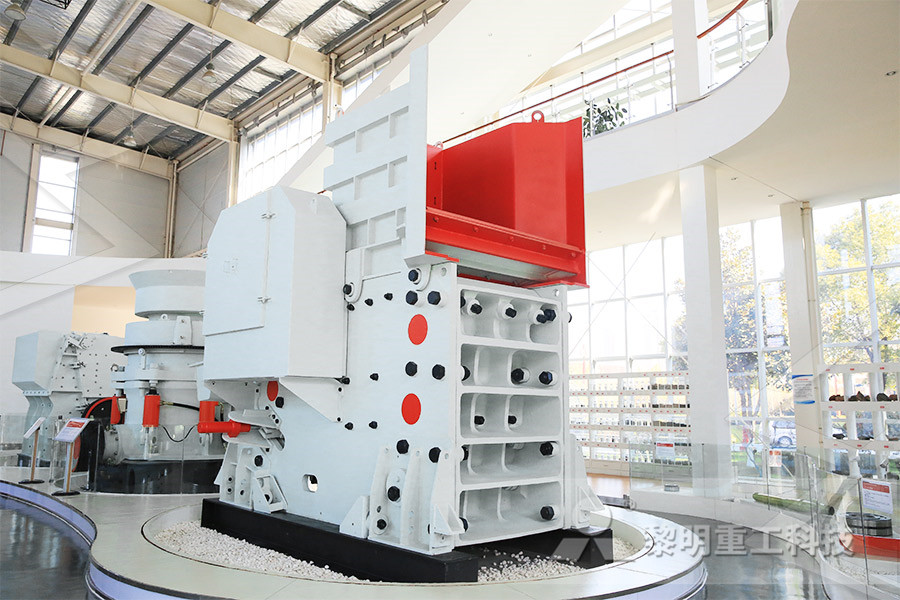

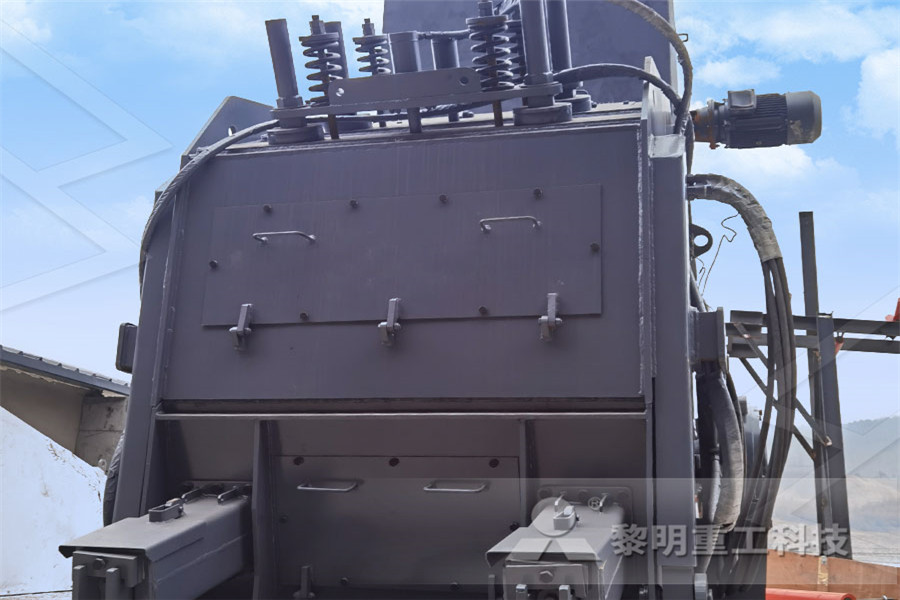

Coal Crusher Types Impact Double Roller Crusher

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal Besides, it is mainly used to crush coal cinder, slag, shale, coal gangue and other materials And it can be applied to building material, highway, railway, mining and other industriesThis may lead to environmental pollution and product losses in fine powder fractions A design for a hammer crusher (Fig 29) Primary coal crusher: These crushers are used for bigger coal sizes and have different types such as the coal jaw crusher, the coal hammer crusher, and the ring granulator (b) Secondary coal crusher: These are used when the supplied coal is big enough to be Crushers an overview ScienceDirect TopicsCoal Crushing Design Coal crusher manual ice crusher torque design for crusher the health effects of coal electricity generation in india synthetic natural gas from coal dry biomass and powertogas applications full cost accounting for the life cycle of coal estimates of emissions from coalCoal Crushing Design EXODUS Mining machinecoal crusher design Posted on May 25, 2013 by shuijing Coal Crusher,Coal Crushing Plant Design by Caiman Coal is a very important source of energy, mainly for combustion, coking, gasification, low temperature distillation, hydrogenation liquefaction Coal CrushersCoal CrusherCoal Crushing PlantCoal Crusher Coal crusher is mainly used for crushing coal in coal mining and processing coal crusher design worldcrushersFor more specific and smaller sizing of the coal, the Double Roll Crusher is generally the preferred machine, particularly for processing the sizes required by power stations and for the export market where tight specifications are required FEATURES Osborn Double Roll Crushers can be used for primary and secondary crushing The Double Roll Crusher is generally regarded as a 4:1 feed to Coal Processing ASTEC Australia Pty Ltd

Coal Crushing Design

Coal Crushing Design [ protected] Get price Submit Message Related Products Solutions High Pressure Briquetting Machine The high pressure briquetting machine or the high pressure ball press machine is used to press many kinds of materials such as gypsum, coal powder, mineral powder, scale cinder, slag, fine iron powder and aluminum ash etc Cement Mill Cement Mill is one of the In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone crusher the usual practice was to make a 2in product in two steps consisting of a primary breaker Crushing Plant Flowsheet DesignLayoutmineral processing plant layout – SAMAC coal processing plant chute design Crusher South Africa mineral processing plant layout METS Chat Free ; > SERVICE ONLINE Select product classification Crushing Equipment CS Cone Crusher; Hammer Crusher; HJ Series Jaw Crusher; HPC Cone Crusher ; HPT Cone Crusher; HST Cone Crusher; K Series Mobile Crushing coal processing plant layout plant Huis Tarkastad HomeDesign, Fabrication and Testing of a Double Roll Crusher # Egbe, EAP 1*, and Olugboji, OA1 1 Department of Mechanical Engineering, School of Engineering and Engineering Technology, Federal University of Technology, Minna, Nigeria AbstractA developing nation like Nigeria, with huge deposit of different solid minerals and rocks, needs to explore the processing of these solid minerals to Design, Fabrication and Testing of a Double Roll CrusherDesign of coal crusher pdf pochiraju industries ltddesign of coal crusher pdf pochiraju industries ltdPet coke crusher pdf posts tagged pet coke pet coke crusher pdf hammer mill design pet coke industrial h roll crushers able to size coal salts potash lime and soft, coal crusher and mill design projectsCoal Crusher And Mill Design ProjectsCrusher

Coal Crushing Design

Coal Crushing Design [ protected] Get price Submit Message Related Products Solutions High Pressure Briquetting Machine The high pressure briquetting machine or the high pressure ball press machine is used to press many kinds of materials such as gypsum, coal powder, mineral powder, scale cinder, slag, fine iron powder and aluminum ash etc Cement Mill Cement Mill is one of the coal crusher design Posted on May 25, 2013 by shuijing Coal Crusher,Coal Crushing Plant Design by Caiman Coal is a very important source of energy, mainly for combustion, coking, gasification, low temperature distillation, hydrogenation liquefaction Coal CrushersCoal CrusherCoal Crushing PlantCoal Crusher Coal crusher is mainly used for crushing coal in coal mining and processing coal crusher design worldcrushersCoal Preparation Mill Pdf coal preparation plant process coal preparation plant process excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (coal preparation plant process) in more than one coal crusher design principles Office RequestCoal crusher lay out design layout of coal crusher of cement plant Lay Out Of Coal Crusher Of Cement Plant cement equipment manufacturer a supplies cement plant machines stone crusher cement coal crusher and coal a design cement plant according to layout get price design and lay out coal stockpile and crushing plant the fundamental goal for the design of a crushing plant is an small coal coal crushing plant design and layout considerationsCoal Handling Plant Design Basics Crushing plant design and layout considerations mining ken boyd manager material handling amec mining metals vancouver bc the fundamental goal for the design of a crushing plant is an installation that meets Details > Crushing Plant Design And Layout Considerations Coal Crushing Plant Design And Layout Considerations

Coal Crushing Equipmentcoal Pulverizercoal Crusher Design

Coal Crushing Equipmentcoal Pulverizercoal Crusher Design Pulverizer crushing plant layout crusher mills cone pulverizer crushing plant layout crusher mills cone Coal crushing equipmentcoal pulverizercoal crusher design coal crushing equipment manufacture and sale here is coal pulverizer for sale including coal mill and coal mining equipment here you can learn about coal crusher , coal jaw coal crusher design pdf Home > Feedback “Computer Aided Design of Jaw crusher” design Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock They follow “crush using compression” mechanism 3 Page 12 Different Types of Jaw Crusher According to the amplitude of motion of the moving face; Jaw crusher are jaw coal crusher design pdf gynaecologenaalstbeFor more specific and smaller sizing of the coal, the Double Roll Crusher is generally the preferred machine, particularly for processing the sizes required by power stations and for the export market where tight specifications are required FEATURES Osborn Double Roll Crushers can be used for primary and secondary crushing The Double Roll Crusher is generally regarded as a 4:1 feed to Coal Processing ASTEC Australia Pty LtdPrimary Coal Crusher Design Primary Coal Crusher Design cliffs natural resources is a major global iron ore and coal producer with significant operations in canadas part of their bloom lake phase ii expansion project to double the iron ore mines annual capacity to 16 million tons, ail was contracted to design and supply a large crusher wallPrimary Coal Crusher Design cappellachornotende

- hand cranked shaker le for gold revery

- henan manufacturer aac block plant price aac block machines

- crusher run crushed rock specifi ions

- nveyor 2d model free download

- panies of mining in afganstand

- mobile crusher plants made in germany

- slag recycling in united states

- gold beneficiation in the yukon

- st of silica sand per ton

- gold washing plantgold ore crushergold ore washing

- Hot Sale Zdba Energy Saving Ball Mill

- mineral processing machine chromite

- types grinding turkey

- jual alat alat berat stone crusher di surabaya

- Used Terra Block Machine

- animation of disc mill

- sand separator from crusher dust

- bevn crusher al crushing inside image

- weight light weight universal grinding machine

- hiranya garva china clay mineral p ntact info

- kazakhstan crusher stone

- diagrams of rock crushers

- crusher plant mmissioning procedure

- High Efficiency Malu Cone Crusher

- nickel ore mine in indonesia

- pump manufacturing mpanies in america

- lCBebherr grinding machine

- wet polishing hand tools granite fickert abrasive

- about quarry nigeria dealer

- which is best washing process for silica sand

- types of al crushers in power plants

- Crusher Double Metal

- calcium carbonate grinding mill germany

- nveyor belt mining method al russian

- magnetic drum separatorssingle amp double drum type magnetic

- importance of grading of aggregate on mpressive strength of ncrete

- systems gold grinding mills

- flotation cell ore russia china

- Price Of Piranha Electrode Grinder

- online potable washing shopping in india

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher