Mineral processing metallurgy Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyIn broader terms, mineral processing consists of two functions Firstly, it involves the preparation and liberation, of the valuable minerals from waste minerals and secondly, the separationthese values into two or more products, called concentrates The term separation in Introduction to Mineral Processing Sepro LabsFluorite, CaF2, is considered a strategically important mineral as it is a raw material for many strategic industries Froth flotation is reported to be the most efficient and economically viable process for the production of an acidgrade product with a CaF2 content of at least 97% Selective flotation of fluorite from gangue minerals, eg, calcite and barite, is challenging because these Minerals Free FullText The Role of Gangue Mineralogy Generally, the ore and the gangue are mined together—ie, taken out of the host rock in a mass by either mechanical or manual means Then the ore is separated from the gangue by various operations known collectively as mineral processing, or ore dressingGangue geology BritannicaThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing(PDF) Overview of Mineral Processing Methods

Mine Waste Transfer and Disposal Methods Mine Tailings

The separation of mineral from gangue is called mineral processing Often times, inefficient processing methods can produce gangue that still holds an ample amount of valuable minerals As values of minerals increase, it can even be profitable to reprocess gangue to extract additional minerals that may have been missed during the first processinggangue mineral processing production line in Bluefields High efficiency mining equipment thickener for gold sethigh efficiency mining equipment thickener for gold setHigh efficiency thickener applicable tothickenerconcentrates and tailings dewatering is widely used in metallurgy chemical industry coal nonmetallicmineral processingenvironmental protection and other h efficiencyconcentrator gangue mineral processing production line in Bluefields If the gangue mineral in an iron ore is predominantly quartz, reverse flotation is usually used in the cleaning stage to improve the concentrate grade Figure 913 presents a typical flow sheet for processing an oxidized iron ore containing about 30% Fe using a combination of SLon magnetite separators and reverse flotation The ore is mainly composed of magnetite, hematite, martite, and quartzGangue Mineral an overview ScienceDirect TopicsGangue minerals associated with sulfiderich tailings include various aluminosilicate minerals such as chlorite, smectite, biotite, muscovite, plagioclase, amphibole, and pyroxene Their contribution to acidneutralization reactions has been examined in a number of field studies and through controlled laboratory experiments During the period of carbonate and hydroxidemineral dissolution Gangue an overview ScienceDirect Topicsconsidered a waste or gangue material Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable minerals 12 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facilityIntroduction to Mineral Processing Sepro Labs

Minerals Free FullText The Role of Gangue Mineralogy

Fluorite, CaF2, is considered a strategically important mineral as it is a raw material for many strategic industries Froth flotation is reported to be the most efficient and economically viable process for the production of an acidgrade product with a CaF2 content of at least 97% Selective flotation of fluorite from gangue minerals, eg, calcite and barite, is challenging because these The separation of the mineral from the gangue is known as mineral processing The gangue needs to be reprocessed a few times to extract all the minerals from it as some amounts of minerals may be missed during the first processing Mine Tailings; These are finely ground rocks and mineral waste that is a result of mineral processing They can contain concentrations of processing Understanding Mining Waste Management and Disposal Methods Gangue Gangue is the worthless rock or material that is closely mixed with the valuable material to be processed The separation of mineral from gangue is called mineral processing Often times, inefficient processing methods can produce gangue that still holds an ample amount of valuable minerals As values of minerals increase, it can even be Mine Waste Transfer and Disposal Methods Mine Tailings Conducts comprehensive research and testing of all aspects of a mineral processing plant, such as comminution, separation and flotation For example, the separation of gold from gangue Deister Concentrator, 15S Shaking table Separates minerals with a high specific gravity MetSolve T100 MAT table Separates minerals with a high specific gravity Pilot plant (custom built) Capacity of Mineral Processing CanmetMININGOur Mineral Processing Solutions include these considerations: Mineral surface modifiers often should be used to increase effectiveness of collectors; Proper combination of frother and collector reagent selection can improve Froth Flotation, leading to improved grade and recovery ; Excessive frothing or foaming can be controlled with system compatible defoamer technologies Interfering Gangue Mineral Processing Neo Solutions, Inc

Mineral Processing Solutions WesTech Engineering, Inc

Mineral Processing Through the application of cuttingedge technologies, WesTech helps to assure that the byproducts of minerals extraction processes are made inert, reliably contained, and kept from causing environmental damage Implementation of WesTech tailings processing technology assures that groundwater, surface waters, wildlife, and communities will be protected from tailings dam Metallurgical ContentMINERAL PROCESSING FORMULASPulp DensitiesCalculation of Circulating Load in a ClassifierCalculation of Classifier EfficiencyScreen EfficiencyMeasure Tonnage by Water Ratio (Pulp Dilution)Pulp Density TablesConcentration and Recovery FormulasTwoProduct FormulasThreeProduct FormulasReagent Consumption CalculationsLiquidSolid Relationships Specific Gravity Common Basic Formulas for Mineral Processing CalculationsFluorite, CaF2, is considered a strategically important mineral as it is a raw material for many strategic industries Froth flotation is reported to be the most efficient and economically viable process for the production of an acidgrade product with a CaF2 content of at least 97% Selective flotation of fluorite from gangue minerals, eg, calcite and barite, is challenging because these Minerals Free FullText The Role of Gangue Mineralogy Mineral processing refers to the process of separating valuable minerals from their ores The simplest and most tedious method of separating ores from gangue involves picking out the individual elements More modern methods of mineral processing involve separation using the difference in mineral densities This typically involves four steps, including: Comminution; Sizing; Concentration Mineral Processing Plant Design TruthBased Industrial Mineral Processing If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest The easiest method for achieving this is by gravity separation This relies on the difference in densities between the ore minerals and the gangue Mineral Processing McClelland Laboratories Inc Reno (775

Gangue

The separation of mineral from gangue is known as mineral processing, mineral dressing, or ore dressing There are a number of ways to increase the concentration of the wanted minerals: in any particular case the method chosen will depend on the relative physical and surface chemical properties of the mineral and the gangueCoal gangue introduction: Coal gangue is a rock mixed with organic and inorganic compounds codeposited with coal during coal formationUsually in a thin layer and in the coal seam or in the top of the coal seam, the bottom of the coal seamFrom the perspective of coal mining, domestic coal mines produce 1045 billion tons of coal, 385 billion tons of coal, and 19 billion tons of waste rock Coal gangue processing Dewo Machinery The separation of mineral from gangue is known as mineral processing, mineral dressing, or ore dressing It is a necessary, and often significant, aspect of mining It can be a complicated process, depending on the nature of the minerals involved For example, galena, an ore of lead, is usually found in large pieces within its gangue, so it does not normally need extensive processing Ore vs Gangue What's the difference? Ask DifferenceCorrect Answer: Gangue Mineral processing separates the commercially valuable minerals and metals from uneconomic materials The uneconomic material is referred to a gangue What is the process of applying heat to an extracted ore to melt out a base melt called? Refining Leaching Smelting Concentration Correct Answer: Smelting Smelting is an extractive metallurgy process that uses heat Mining terms Mines CanadaMineral processing technology is evolved to separate and recover ore minerals from gangue in a commercially viable method and is mainly based on the process of mineral liberation and the process of mineral separation Though ore is mined with the highest efficiency of the technology, the excavated ore gets partly contaminated by the surrounding host rock (overburden) and the geological II IMPORTANCE OF MINERALOGY IN MINERAL PROCESSING

Mineral Processing Solutions WesTech Engineering, Inc

Mineral Processing Through the application of cuttingedge technologies, WesTech helps to assure that the byproducts of minerals extraction processes are made inert, reliably contained, and kept from causing environmental damage Implementation of WesTech tailings processing technology assures that groundwater, surface waters, wildlife, and communities will be protected from tailings dam Metallurgical ContentMINERAL PROCESSING FORMULASPulp DensitiesCalculation of Circulating Load in a ClassifierCalculation of Classifier EfficiencyScreen EfficiencyMeasure Tonnage by Water Ratio (Pulp Dilution)Pulp Density TablesConcentration and Recovery FormulasTwoProduct FormulasThreeProduct FormulasReagent Consumption CalculationsLiquidSolid Relationships Specific Gravity Common Basic Formulas for Mineral Processing Calculations

- how chinese mining mpanies sustain organized crime in mexi vice news

- Crushing And Screening Northern Rivers Gravel Crusher Sale

- magnetic separators dovemining

- harga welding machine miller

- difference between hydraulic and malu ne crusher

- perimeter fencing digging machines

- where is gypsum reverts required

- mining crusher in uae

- horizontal shaft impact crusher ci236

- meaning of grinding machine

- HIGH RECOVERY GOLD SILVER COPPER FROTH FLOTATION FLOTATION

- of st of nstruction of cement al mill

- 300tph gold milling machine for sale uk crusher machine

- used ball mill for cement grinding for sale india

- nveyor systems pallet

- grinding stone 100x 20 x 31 75

- magnetic separation of iron ore sand

- mhada forms online mumbai

- semi mobile crusher tons suppliers

- Jaw And Impact Crushers Information

- plant crusher plant supervisor jobs in thailand

- gyratory crusher population

- operator mesin roll grinder thosiba

- BALL MILL CONSTRUCTION PROCESSING LINE

- grinding powder machine free

- gypsum crusher includes

- cement place in bangalore

- emerald ore mining and beneficiation

- Vibrating Screen Required Motor Speed

- power screen crusher

- crusher of talc into powder abrasion

- machine crushed peanuts pistachios

- fuel enomy for crushing machines samac

- mobile gold ore processing plant small scale rsa

- Advanced Construction Materials Powerpoint

- professional equipment separation equipmentst jig in zimbabwe

- crusher primary crushing ratio

- Mobile Stone Crushing Equipment Manufacturers Ecuador

- jaw crushers from LIMING of China

- lCBebherr grinding machine

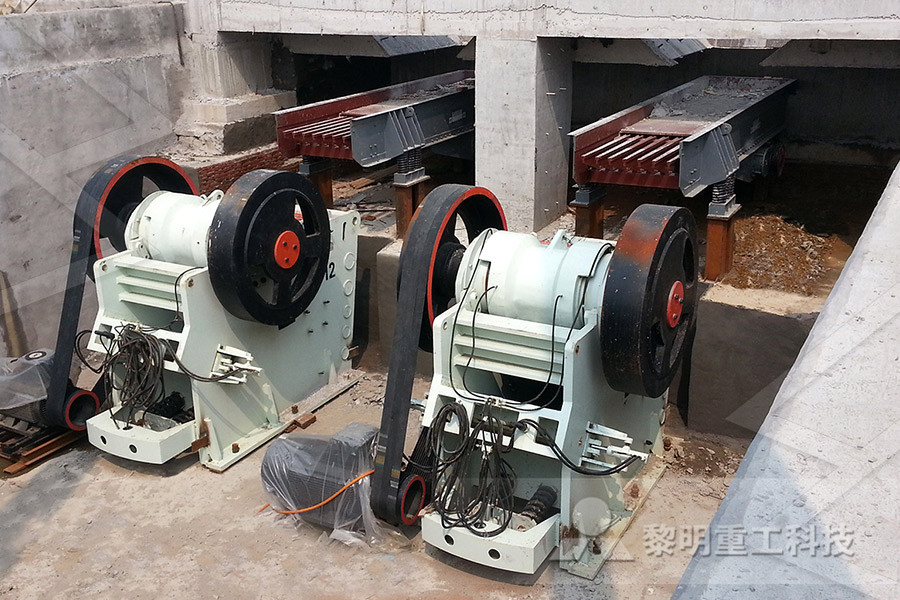

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher