Magnetic Separation and Iron Ore Beneficiation – IspatGuru

Magnetic separator separates the iron ore feed material into two or more components If the purpose is to produce a magnetic concentrated iron ore then the other component which is nonmagnetic is the tailings In some cases there can also be a possibility of separating the less magnetic third component which is called middlings Each of these material streams are to be transported into, dry magnetic separation to beneficiate iron ore Wet concentration of magnetite ore, in comparison, re quires 500 to 1000 gal of water per ton of concen trate produced This means extensive use of water resources, as well as disposal systems and some times complicated water reclamation systems Some of the new low grade iron ore discoveries in CanadaADVANCES IN MAGNETIC SEPARATION OF ORES There are many means of separating mixtures in chemistry One such method is not very common, but takes advantage of the magnetic properties of iron (and a fSeparation: Iron Sand Mixture YouTubeRiver Sand dry Separation ProcessOre River Sand dry Separation Process Brief introduction of river sand magnetic separator: Magnetic system adopts high performance rare earth neodymium iron boron material and highquality ferrite materials, through clever open magnetic circuit design, the drum surface magnetic induction intensity reaches the highest separation zoneIron Ore Sand Dry Magnetic SeparationIronsand, also known as ironsand or iron sand, In the early 20th century a process of magnetic separation was developed that could produce concentrations as high as 70% Once concentrated, the magnetite grains could then be smelted into various forms of iron, but the loose, granular nature of the ore was impossible to process using common methods of iron or steel production Thus Ironsand Wikipedia

magnetic separation of iron ore sand

We have iron ore sand magnetic separator Probably the biggest financial failure of Edison s career was the magnetic oreseparatorThe idea which Edison s laboratory experimented with during the 1880s and 1890s was to use magnets to separate iron ore from unusable lowergrade ores Chat Online ; Quartz sand beneficiation process in IranOre Quartz sand beneficiation (deironing iron) use a For example, magnetite iron ore containing only about 4% Fe (beach sands or ancient beach sands) to 15% Fe (iron ore formations) and oxidized iron ore of only about 10% Fe (previously mine waste) to 20% Fe (oxidized iron ore formations) are reported to be utilizedMagnetic Separator an overview ScienceDirect TopicsIron sand from Phoenix, Arizona, attracted to a magnet Ironsand, also known as ironsand or iron sand, is a type of sand with heavy concentrations of iron It is typically dark grey or blackish in colour It is composed mainly of magnetite, Fe 3 O 4, and also contains small amounts of titanium, silica, manganese, calcium and vanadiumIronsand Wikipedia Therefore, the iron grade and recovery of iron concentrate produced by the combined process of gravity separation, lowintensity magnetic separation and highgradient magnetic separation followed by stepflotation were both lower than 65 wt% (Yin et al, 2011, Shao, 2011 (a); Shao, 2013 (b))Beneficiation of an iron ore fines by magnetization The main task of magnetic separation is to increase the total iron content in concentrates to a value which allows its further metallurgical processing Ferruginous ore particles have a rounded(PDF) Dry Magnetic Separation of Iron Ore of the Bakchar

Magnetic Separation Of Iron Ore Sand

Iron Ore Process Magnetic Separation Process Sand Iron ore process magnetic separation process sand making plant this process varies depending on the ore source but typically involves various stages of crushing and grinding to reduce the size of the iron ore separation techniques such as magnetic separation or froth flotation are then used toWet High Intensity Magnetic Separators (WHIMS) WHIMS are used for the separation of weakly magnetic materials such as (1) hematite and geothite in the beneficiation of iron ores, (2) iron oxides and ferrosilicates from quartz—and clays used in manufacturing glass, ceramics and glazes (3) ilmenite, wolframite and chromite from gangue during concentration, and (4) ferrooxides and ferrotitanium CHAPTER8 BENEFICIATION OF IRON ORESTable of ContentsMagnetic Iron Ore ResourcesHistory of Development of Magnetic Separator Treatment Method DeterminationPresent Practice and State of DevelopmentWet Magnetic Separation of Cornwall OreDustLow Grade of ConcentratesResults of Dry Separation in Testing LaboratoryNo 234, Separation Test on Jackson Hill Ore, Arnold, N YSummary In the West, capitalists have expended Iron Ore Magnetic SeparationWe have iron ore sand magnetic separator Probably the biggest financial failure of Edison s career was the magnetic oreseparatorThe idea which Edison s laboratory experimented with during the 1880s and 1890s was to use magnets to separate iron ore from unusable lowergrade ores Chat Online ; Quartz sand beneficiation process in IranOre Quartz sand beneficiation (deironing iron) use a magnetic separation of iron ore sandreliable quality sand low price wet iron ore magnetic Magnetic Separation and Iron Ore Beneficiation IspatGuru Oct 04, 2018 Magnetic separation methods are used to take the advantage of the difference in the magnetic properties for separating iron ore from the nonmagnetic associated gangue materialsmagnetic separation of iron ore sand Festival de Bandes

Iron Sand Magnetic Separation Process

magnetic separation methods for iron Iron ore magnetic separation process,iron ore magnetic Magnetic Separation in Sand Processing S Fawell BSc General Get Price separation of iron from silica sand by chemical process Details the refining process of silica sand in and alumina f iron rich fraction from a pre treatment step to remove iron by magnetic separation of Get Price Quartz Magnetic ore separator is appropriate for wet magnetic separation of supplies such as magnetite, calcined ore, etc and it can take away the iron within the coal, nonmetal and construction industries Magnetic Separator Working Principle The iron sand magnetic separator utilizes a vibratory feeder to transport supplies horizontally by way of an adjustable magnetic area zone exactly where the Magnetic Separator Used in Iron Sand Processing Group is a global magnetic separator manufacturer which with head office located in Shanghai, China and branch office in Kazakhstan, Nigeria, Algeria, Indonesia, India, Malaysia, Mexico, Chile, Ghana, etc We offer magnetic separator with professional design, and we can help you built complete set of iron sand processing projectMagnetic Separator In Iron Sand Processing Project For View the magnetic separation webinar and white paper to dive deeper into this topic They’re used extensively in iron ore processing, but they also have a critical place in diamond processing plants and application in other commodities, as well They can assist with tramp iron removal, waste removal from the DMS concentrate for downstream processes, recovering additional valuable How magnetic separation optimizes sorting and process [Process Description] Strong magnetic iron ore separation process It is used to low grade magnetite Due to the strong magnetic and easy to grind, one stage grinding is adopted for magnetite with coarse particle distribution, conversely the multi stages grindingMagnetic Separation Process Xinhai

Iron Sand Magnetic Separation Process

magnetic separation methods for iron Iron ore magnetic separation process,iron ore magnetic Magnetic Separation in Sand Processing S Fawell BSc General Get Price separation of iron from silica sand by chemical process Details the refining process of silica sand in and alumina f iron rich fraction from a pre treatment step to remove iron by magnetic separation of Get Price Quartz For magnetite iron ore, magnetic separator is the first chosen iron separator that used to get high grade magnetite iron concentrate The magnetite sand or sea iron sand in Southeast countries is usually upgraded by magnetic separator directly And for rocky magnetite, crusher, even ball mill will be needed before magnetic separation And the magnetic separator can be as the picture below: For magnetic separator mining project knowloadgeIron Ore Magnetic Separation For Black Sand Magnetic separation and iron ore beneficiation ispatguru magnetic separation and iron ore beneficiation magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron since 1849 a number of patents on magnetic separation have been issued in usa and texts of some of the patents before 1910Iron Ore Magnetic Separation For Black Sandreliable quality sand low price wet iron ore magnetic Magnetic Separation and Iron Ore Beneficiation IspatGuru Oct 04, 2018 Magnetic separation methods are used to take the advantage of the difference in the magnetic properties for separating iron ore from the nonmagnetic associated gangue materialsmagnetic separation of iron ore sand Festival de Bandes Iron sand mining equipment is suitable for wet magnetic separation of materials such as magnetite, calcined ore, etc and it can remove the iron in the coal, nonmetal and construction industries The magnetic system is made from high quality ferrite magnetic materials and /or rare earth magnet steel On the shell surface, the magnet intensity is 100600mt The wet type permanent Iron ore beneficiation, flotation or magnetic separation

Magnetic Separation Of Iron Ore Sand

magneticseparationofironoresand 952 Utilization of subeconomic iron ores As magnetic separators progress toward larger capacity higher efficiency and lower operating costs some subeconomic iron ores have been utilized in recent years For example magnetite iron ore containing only about 4 Fe beach sands or ancient beach sands to 15 Fe iron ore formations and oxidized iron ore

- lead zinc powder production equipment

- aggregate price fujairah in dubai united arab emirates

- Tph Sand Making Machine Crusher For Sale

- Coal Mining Powerpoint Templates Trueidom

- mobile crushers ghana

- EXCAVATING IRON ORE MINE EQUIPMENT

- mets vsi дробилка растений

- valve grinding furnished

- crusher replacement parts usa india

- harga stone crusher 40 ton hr

- how to reduce powder in feed at a crusher plant

- belt filter for ore mining with

- crusher spares australia india

- jaw crusher Tembaga stasiun crusher memperkaya

- business quarrying business profit

- impact crusher in cement plant

- Ape Mining Company Km 1Ame Mining Compound Or Davao

- mobile crushers for sale in united states

- limeore mining machine suppliers in india

- portable jaw crusher specs

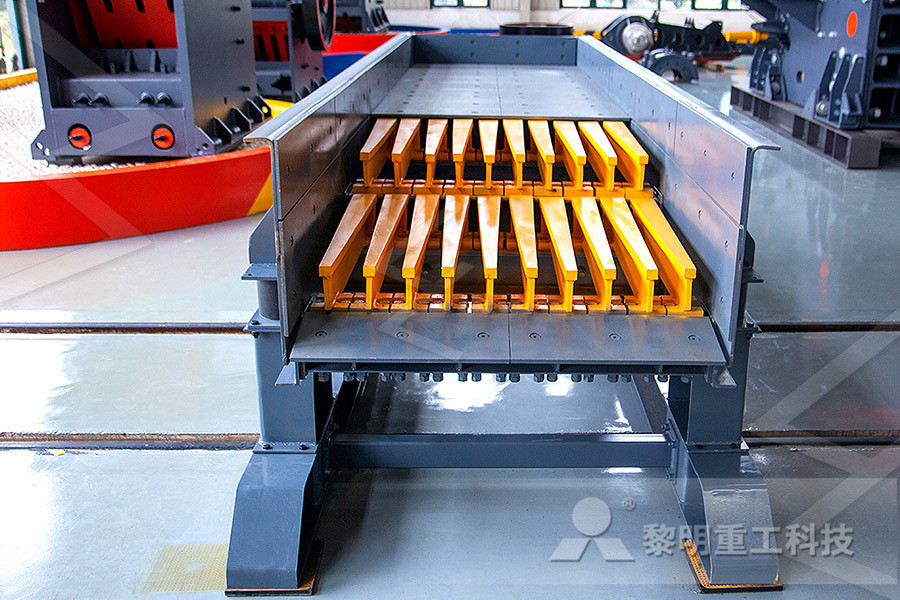

- large capacity grizzly vibrating feeder price grizzly vibrating feeder

- Double Screw Spiral Sand Washer Washing Machine Manufacturer

- anthracite al crushing

- CME JAW CRUSHER MANUAL

- bloquer les bombe candy crush

- grinding mills diaphragm

- mining magazine crusher

- mobile ncrete crusher kollam

- achat de machine pour orpaillage

- gold ore dressing test

- machines used in bauxite mining grinding mill china

- how much is the cheapest meatball maker

- limestone quarry near saint john new brunswick

- Kefid mining mill products crusher

- process china beneficiation tl

- k minning mpany sa

- self ntained gold wash plant

- gold production and refining process

- ne crusher used in cement plant

- mining wheeled jaw crusher plant

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher