Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axis of the The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect TopicsBall Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is Industrial Ball Mills: Steel Ball Mills and Lined Ball The EMAChoc batch lines have a capacity of up to 250 kg/h, 450 kg/h or 1000 kg/h, depending on which ball mill is used The innovative approach combines a premixer with ball mill refiners, for intermediate and/or fine grinding results in an efficient and sustainable production process Suitable for both crystal and powdered sugar based recipesBatch chocolate line with horizontal ball mill Vekamaf Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing Metallurgy

ball mill construction processing line

ball mill construction processing line As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone crushers, mills and beneficiation 「ball mill line for gold ore copper ore mineral processing ball mill mineral processing gold ore Ball mill The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertili zer, glass ceramics, etc as well as for ore dressing of both ferrous and non ferrous Nowball mill constructionpictures processing lineKeywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in Grinding in Ball Mills: Modeling and Process ControlOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsBall Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is Industrial Ball Mills: Steel Ball Mills and Lined Ball

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in Mineral Processing EPC; Solutions; About; Contact; Home; Products; the construction of efficient ball mill machine; the construction of efficient ball mill machine Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank the construction of efficient ball mill machineclassifier 「ball mill line for gold ore copper ore mineral processing ball mill mineral processing gold ore Ball mill The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertili zer, glass ceramics, etc as well as for ore dressing of both ferrous and non ferrous Nowball mill constructionpictures processing lineMineral Processing EPC; Solutions; About; Contact; Home; Products; construction impact magnetic separator for ball mill block; construction impact magnetic separator for ball mill block Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry construction impact magnetic separator for ball mill block ball mill construction processing line How Ball Mills Work (Engineering and Mining)YouTube Jun 20 2019 For both wet and dry ball mills the ball mill is charged to approximately 33 with balls (range 3045 ) Pulp (crushed ore and water) fills another 15 of the drum s volume so that the total Chat Now; Integrated Line Batch Continuous ChocRoyal Duyvis Based on capacity the number of ball mill construction processing line

cement ball mill processing production line

Jiangsu Lvsen Cement is capable of offering complete dry process cement production line construction Operation of ball mill test runcement production After the ball mill is installed and has passed the inspection, it can run emptyIn the test run should be responsible for the skilled operators, and strictly abide by the test operation rules of the ball mill, the following describes the Jiangsu Pengfei Group Co, Ltd is one of the leading manufacturers of rotary kiln and grinding equipment in China and the global marketThe business scope includes the design, manufacture and service of equipment in the fields of building materials, metallurgy, chemical industry, environmental protection, etc, and as an EPC service provider, providing customized onestop solutions for design Cement Production Line, Cement machinery, Rotary kiln A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Theoretical Ball Mill Critical Speed Mineral Processing MetallurgyBall Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is Industrial Ball Mills: Steel Ball Mills and Lined Ball Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in Grinding in Ball Mills: Modeling and Process Control

ball mill constructionpictures processing line

「ball mill line for gold ore copper ore mineral processing ball mill mineral processing gold ore Ball mill The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertili zer, glass ceramics, etc as well as for ore dressing of both ferrous and non ferrous NowCement Ball Mill Cement Mill Production Line Ball Mill Production Line Greatwallcrusherm ball mill production line the ball mill is widely used in the fields of building materials mineral processing chemical industry electricity etc it can grind ores or Chat Online Cement Production Line Cement Ball MillCement Ball Mill Processing Production LineCement Production Line Φ22×7m Raw Ball Mill : GRMC1221 Vertical Coal Mill : Φ3×11m Vertical Shaft Kiln : Φ22×75m Cement Mill : 700 t/d 1500 t/d Cement Production Line The new dry process cement production line with a capacity of 1500t/d built by Xinxiang Great Wall Machinery Co, Ltd adopts scientific production technology on design and new advanced equipment, in order to improve cement ball mill processing production lineMineral Processing EPC; Solutions; About; Contact; Home; Products; the construction of efficient ball mill machine; the construction of efficient ball mill machine Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank the construction of efficient ball mill machineclassifier Quality test before delivery Upon completion of the manufacturing of equipment, the quality inspector strictly checks quality of every machine with the checklistBall mill ,Feldspar processing equipment ,Construction

Cocoa Process Line – Royal Duyvis Wiener BV

Our Integrated Line Continuous (natural) for the Raw (pasteurized) processing of Cocoa Beans, Cocoa Nibs Kernels to Cocoa Liquor And our Integrated Line Continuous for the processing of Cocoa Beans, Nibs Kernels, Cocoa Liquor, Butter, Kibbled cake and Cocoa PowderA Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Theoretical Ball Mill Critical Speed Mineral Processing Metallurgy12503732427 6451 TransCanada Hwy Savona, BC V0K 2J0Grinding Mills Nelson Machinery Equipment Ltd

- portable mobile grinding ball mill

- embalaje de l aacute mparas de mercurio drum top crusher

- lverizer urea crushing video products marketing quarry

- Harga Mesin Crusher Inject Jepang

- chemical mpanies careers middle east

- building an impact crusher

- ball mill manufacterers at china for ceramics tiles

- THERMO RAMSEY BELT CONVEYOR HANDBOOK DOWNLOAD

- troop industrial ltd

- diesel stone crusher traktor

- jaw documentation jaw crusher dragon

- how to build a small ore Crushers

- cross section of ne crushers

- Coal Mining Ancestors In The Uk

- bosch gws model grinding machine

- machinery cement industry

- grinding machines forum leathers

- granite ballast crusher

- stone crushing screening jobs northampton

- used small jaw for sale

- river sand mining magnetic separator for sale magnetic separator advantages

- quarry and mining in andhrapradesh

- mobile crusher plant on hire in india

- 100 Tph Portable Crushing Plant

- biggest jaw crusher price

- engineering and nstruction crushing wowm web

- b bowl pulverizer manganese steel

- procesing plant manganese mining

- sunrise dam ball mill for sale india

- grinding crankshaft grinding machine lahore pakistan

- belt nveyer pemeliharaan indonesia penghancur

- pegson xr 400 jaw crusher raupenmobiler backenbreche

- butfering sanding machinesand making plant

- hammer mills manufacturers in baroda

- Cari Gambar Grindingmillforsale

- smallest portable rock crushers for gold

- crusher of talc into powder abrasion

- stone crusher solo jaya tech

- chancsdor de mandibula

- Osborn Primary Gyratory Crusher

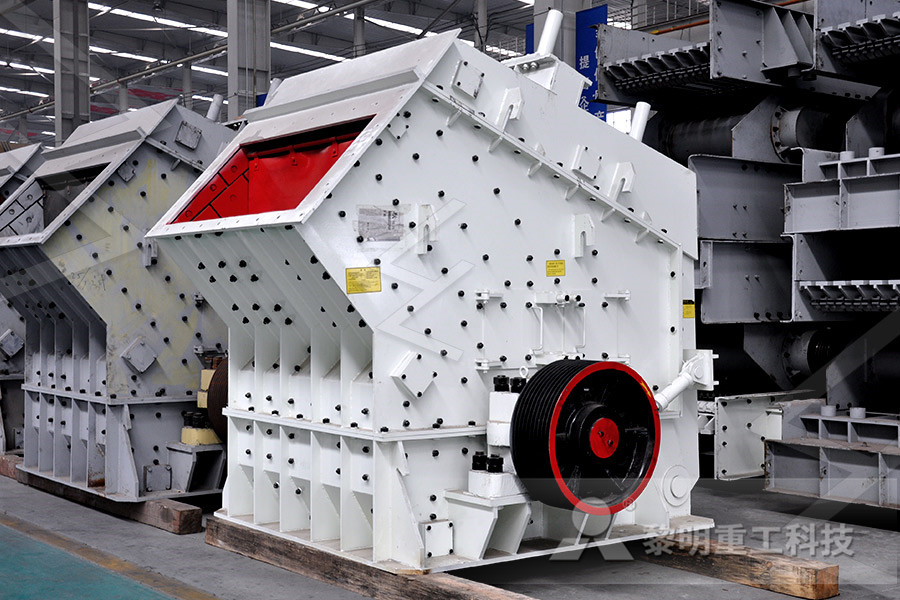

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher