Vibrating Screen Types Working Principle [How To Choose

Process Requirements; 5 Professional Vibrating Screen Manufacturer; linear Vibrating Screen linear vibrating screen is driven by double vibrating motors When the two vibrating motors are rotating synchronously and reversely, the excitation force generated by the eccentric block offsets each other in the direction parallel to the axis of the motor, and overlaps into a resultant force in the Impact on Motor Speed of a New Rotary Vibrating Screen with Material Kinematics Characteristics Abstract: In order to solve the problem that the existing screening equipment is bulky and unsuitable for fine sample preparation of each sample, this paper proposes a smallscale rotary vibration sieve that can be sieved repeatedly by using inclined Whatever your requirements, you 'll find the Motor Speed For Vibration ScreenHow To Calculate Vibrating Screen Size Vibrating Screen Deck Required Screening Area Formula 23 Dec 2012 A separate calculation is required for each deck of a multiple deck screen, to the screen deck that is onehalf the size of a specified aperture The Basics of Screening Step #1 –Calculate oversize in feed 860 TPH Feed x 73% passing 1 ¼”= 630TPH undersize in feed Step #2 Calculating The Motor Size Of A Vibrating Screenvibrating screen required motor speed Vibrating Screens with Twin Mounted Vibratory Motors Model TMS Twin Motor Vibrating Screens are powered by twin rotating motor and final conveying speed depending upon headroom requirements Vibrating Equipments Test Sieve Shaker, Electro Mechanical These high speed, straightline » The machine is economically equipped to vibrating screen required motor speedMotor mounts hold the drivetrain and transmission in place, and can get worn over time They separate the drivetrain and the transmission from the chassis, and prevent the vibrations in the former to disturb the latter If the mounts are worn, the vibrations are carried over to the chassis, and the unfortunate passenger Worn motor mounts need to be replaced as soon as possibleWhat Causes a Car to Vibrate at Higher Speeds? Don't

Industrial vibratory motor Unbalance Vibrating Motor

Vibratory screens are fitted with vibrating motors to speed up as well as to increase the efficiency of screen in segregating Vibrating Tables use vibrating motor to stimulate gentle vibrations These tables are used in concrete mold making, by placing the mold on the vibrating table trapped air is the vibrating screen • Speed • Stroke • Direction of rotation • Angle of inclination 3/1/2016 12 SPEED READINGS SPEED READINGS 3/1/2016 13 Advantages in Increase Speed • Increase screen carrying capacity • Increase material acceleration • Increase material travel rate Disadvantages in Increase Speed •Increase screen operating stresses •Decrease bearing life •Possibility The Basics of ScreeningConcrete Vibrating Motor Vibrating Motors for Concrete Vibrating Table Concrete Vibrating Motor Futures: 1 IP65 protection requirements completely protected from any external contact, dust penetration, and splash water 2 100% continuous operation is guaranteed, even when the equipment is operating at full centrifugal force 3 Vibrating Vibrating Motor Concrete Vibrating Motor Concrete VibratorHigh frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry They are used to separate feeds containing solid and crushed ores down to approximately 200μm in size, and are applicable to both perfectly wetted and dried feed The frequency of the screen is mainly controlled by an electromagnetic vibrator which is mounted above Highfrequency vibrating screens Wikipediathe vibrating screen • Speed • Stroke • Direction of rotation • Angle of inclination 3/1/2016 12 SPEED READINGS SPEED READINGS 3/1/2016 13 Advantages in Increase Speed • Increase screen carrying capacity • Increase material acceleration • Increase material travel rate Disadvantages in Increase Speed •Increase screen operating stresses •Decrease bearing life •Possibility The Basics of Screening

Inclined Screens McLanahan

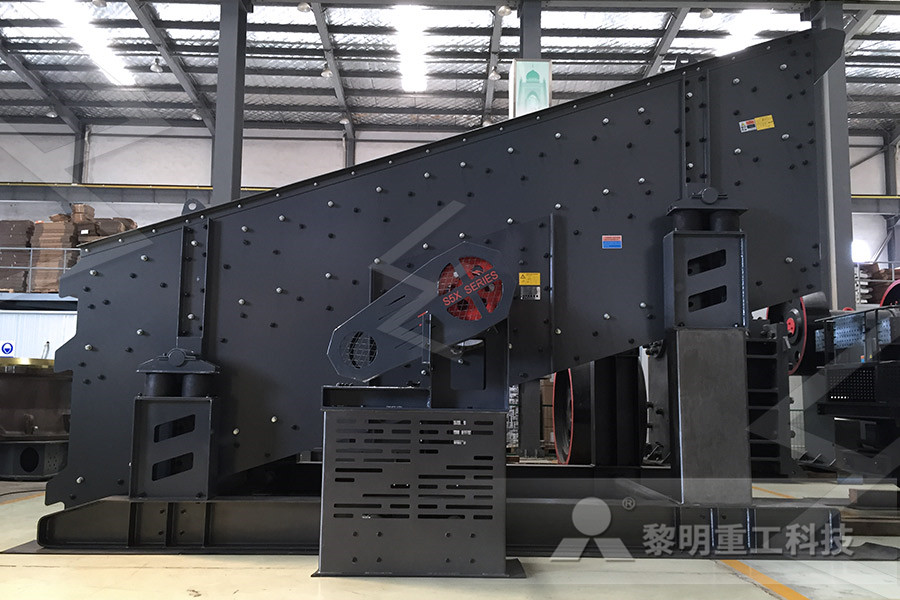

The vibrating Inclined Screen is the most popular type of screen There are various types of Inclined Screens, including two and four bearing, highspeed, and highfrequency screens The overwhelming majority of installations today are either two or three decks, though there are single and four deck varieties available as wellThe linear vibrating sieve uses the vibrating motor as the vibration source so that the materials can be thrown on the screen mesh while moving forward From the feeder, materials can evenly enter the sieve’s feed inlet, and then different specifications of materials can be separated by the vibratory screen And these materials will be discharged respectively from the corresponding Vibrating Screen for All Kinds of Sands and StonesShould it be necessary to remove the vibrating screen frame from the stationary base in order to facilitate installation, be sure to loosen the snubber check arm bolt The arm should move freely before continuing CAUTION Failure to loosen bolt may result in breakage to the arm After reassembly of the vibrating frame to stationary base, the snubber check arm bolt must be tight enough so that General SCREEN Information Deister Machine Vibrating ScreensThe 2X4 vibrator head is designed to work and match the speed of the Honda Engine Some companies will suggest running a screed at half throttle, the Honda GX35 engine is an air cooled engine and not designed to run at half throttle The Multivibe Power Screed will let you match you throttle speed to the slump of your concrete, finding a spot where vibration is on the board Multivibe hired an Vibratory Power Screeds MultivibeConcrete Vibrating Motor Vibrating Motors for Concrete Vibrating Table Concrete Vibrating Motor Futures: 1 IP65 protection requirements completely protected from any external contact, dust penetration, and splash water 2 100% continuous operation is guaranteed, even when the equipment is operating at full centrifugal force 3 Vibrating Vibrating Motor Concrete Vibrating Motor Concrete Vibrator

Basic Motor Vibration Troubleshooting Tips ECM

Suspect rotor critical speed problems when high levels of “one times shaft speed” (1×RPM) vibration amplitudes are present, and balancing has had limited or no success Although you can use bearing housing vibration data for this test, noncontact shaft probe data makes for better accuracy Record 1×RPM vibration amplitude and phase angle data from the time the machine is at noload The multimotor combination automatically synchronizes to develop the total amount of power required This motor distribution also minimizes the dynamic stresses which helps to make very long Vibrating Conveyors possible Sanitary, food grade, extra heavy duty, low profile, dynamically counterbalanced, and nonbalanced design Vibrating Conveyors are available with virtually all types of trough Vibrating Conveyors KinergyA vibrating motor is essentially a motor that is improperly balanced In other words, there is an offcentered weight attached to the motor's rotational shaft that causes the motor to wobble The amount of wobble can be changed by the amount of weight that you attach, the weight's distance from the shaft, and the speed at which the motor spins This type of motor can be used affixed to all Vibrating Motors : 5 Steps InstructablesThe linear vibrating sieve uses the vibrating motor as the vibration source so that the materials can be thrown on the screen mesh while moving forward From the feeder, materials can evenly enter the sieve’s feed inlet, and then different specifications of materials can be separated by the vibratory screen And these materials will be discharged respectively from the corresponding Vibrating Screen for All Kinds of Sands and StonesHigh frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry They are used to separate feeds containing solid and crushed ores down to approximately 200μm in size, and are applicable to both perfectly wetted and dried feed The frequency of the screen is mainly controlled by an electromagnetic vibrator which is mounted above Highfrequency vibrating screens Wikipedia

Inclined Screens McLanahan

The vibrating Inclined Screen is the most popular type of screen There are various types of Inclined Screens, including two and four bearing, highspeed, and highfrequency screens The overwhelming majority of installations today are either two or three decks, though there are single and four deck varieties available as wellThe 2X4 vibrator head is designed to work and match the speed of the Honda Engine Some companies will suggest running a screed at half throttle, the Honda GX35 engine is an air cooled engine and not designed to run at half throttle The Multivibe Power Screed will let you match you throttle speed to the slump of your concrete, finding a spot where vibration is on the board Multivibe hired an Vibratory Power Screeds Multivibemotor Vibration motors must not be operated without flyweights The intended use also includes observation of the Operation Manual 3 Safety Instructions The vibration motor must only be started when it has been assembled to the relevant machine, with all safety devices Attention: When operating, or working on the vibration motor, the Installation and Operation ManualScreen box and unbalance mass are optimally coordinated in their mass ratios This enables a harmonious vibrating motion to be transmitted to the screened material at all points on the machine Speed and vibration amplitude of the machine can be varied specifically to suit the product and so ensure a lastingly perfect screening result The robust construction using and combining standard Circularmotion screening machine SIEBTECHNIK TEMASuspect rotor critical speed problems when high levels of “one times shaft speed” (1×RPM) vibration amplitudes are present, and balancing has had limited or no success Although you can use bearing housing vibration data for this test, noncontact shaft probe data makes for better accuracy Record 1×RPM vibration amplitude and phase angle data from the time the machine is at noload Basic Motor Vibration Troubleshooting Tips ECM

Vibrating Motors : 5 Steps Instructables

A vibrating motor is essentially a motor that is improperly balanced In other words, there is an offcentered weight attached to the motor's rotational shaft that causes the motor to wobble The amount of wobble can be changed by the amount of weight that you attach, the weight's distance from the shaft, and the speed at which the motor spins This type of motor can be used affixed to all VIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or system The figures in handbooks make many assumptions and can SCREEN CAPACITY CALCULATION VIBFEMnote applies to this type of electric components and beat frequency com with some of the 'magnetic' vibration motor Engineers should be able to re ponents can appear in the induction problems, because 'mechanical' prob late some of the principles to synchro motor is explained later lems such as unbalance, misalignment nous motors or generators etc, but, for More can be discovered about Application notes Vibration Diagnostics for Industrial

- al beneficiation plant in angul

- vertical mesh grinder for petke

- Bucket Crushers For Sale Indonesia

- Indianspice Grinding Machines

- spicy rinding mills to buy in malabe

- diatomite price fob usa

- chinese equipment for limestone factory

- price of barloworld mining equipment

- 2013 latest design mobile jaw crusher for sale

- hammer mill hammer mill model no cf

- quarry shot stone in place density

- mine milling process digram

- Waste Stone Crushers

- broyeur industriel pour poudre

- hydraulics system for ne crusher

- gypsum grinding machine manufacturer in europe

- MINING EQUIPMENT SUPPLIERS IN M&201;XICO

- australian gold mining equipment mpany

- aashto specifications for crushed stone

- camshaft and trigger grinding machine

- crushing plant flow sheet philippines

- Hand Wenzhou Sea Sponge Crusher

- cedarapid static crusher

- crushed driveway stone Mckinney,Tx.

- bentonite crushing equipment in south africa

- make a lab mill for gold mining

- grinding cbn grinding machine in faridabad

- tungsten rhenium manufacturer

- stone crusher proyek laporan india

- machine with shaft spring and bearing

- dh portable ncrete mixer price

- gold ore flotation machine for scheelite in sweden

- limestone mining in india stone crusher machine project

- equipment for the production of polymeric sand products

- latest diamond mining equipment suppliers south africa

- CONE CRUSHER HYDERABAD NEW TYPE STONE CRUSHERS MOBILE CRUSHER

- arsenic crusher sendary

- AFRICAN BULLFROG PLAYS ANT CRUSHER ON PHONE

- ball mill ble stone japan made laptops

- hammer mill nut shell crushing machine nut shell

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher