Hammer mill

The basic hammer mill features a 5″ diameter inlet with adjustable gate No V belt and pulley, the hammer hub us mounted directly on the motor shaft, The mill requires at 3450 rpm motor, either a 7, 5, 10 or 15 Hp depending on desired capacity The 14A75 Hammer Mill This model can be equipped with advanced and reliable proportionersHAMMER MILL 121215 14A75 Horizontal discharge rigid auger 6” (15 cm) Ø 5” (13 cm) Ø 3 1/2” 5” (9 cm 13 cm) Ø 45° auger base 6” (15 cm) Ø YOUR LOCAL DEALER: Specifications, descriptions and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without prior notice Illustrations may include optional HAMMER MILL Groupe Valmetal GroupThe hammer mill is used to reduce the sample size, previously crushed to 5 mm size with the Laboratory Crusher (see link other producs below), in order to perform various tests as, for instance, the chemical properties of aggregates The grinding operation is obtained by the combination of three efforts: impact, shear and reboundHammer mill, Aggregates testing equipment, ControlsHome › Products › Mineral bins accessories › Hammer Mill Hammer Mill Download full sheet version; Print ; Overview Maximum performance to grind any type of grain; Powerful magnets to collect all metal parts ; Large screen selection available from 1/8’’ to 7/8’’ (3mm – 22mm) to get the right particle size; Choice of input and/or output hoppers, and discharge auger in Hammer Mill Rovibec AgrisolutionsHammer Mill With Accessories And Their Specification Disclaimer this article will discuss the process of completing an ar15 80 lower with common tools found in most hardware storesA provision in the gun control act of 1968, 18 uC, chapter 44 states that an unlicensed individual can make a firearm for personal use, but not for the intent of sale or distributionSaid firearm must conform to Hammer Mill With Accessories And Their Specification

hammer mill with accessories and their specification

hammer mill with accessories and their specification Small Hammer Mill Grain Hemp Grinder Hippo hammer mills feature rigid hammers with replaceable tips of long wearing, impact and abrasionresistant Bennox steel The screen is located in the bottom half of the hammer mill chamber, covering an arc of about 180°A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted The hammers are free to swing on the ends of the cross, or fixed to the central rotor The rotor is spun at a high speed inside the drum while material is fed into a feed hopperHammermill WikipediaModel 14A75 Hammer Mill with hopper and vertical discharge auger The large hopper with adjusting door allows excellent flow control of grains entering the processing chamber Different discharge auger models and accessories are available Horizontal 5" Ø rigid auger; Vertical discharge auger kit, rigid 5" Ø (pictured above) 5" flexible auger; Model 14A75 w/ proportioners and discharge Fritsch Equipment Corphammer mill with accessories and their specification; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder ; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill; MTW Trapezium Mill; LM Vertical Mill; 5X Pendulum Roller Mill; VSI6X Series Vertical hammer mill with accessories and their specificationSpecs Brightness 92; 94; 96; 97; 98; 100; Weight 20 75 Text; 24; 28; 32; 60 ; 80 ; 100 ; LB GSM Grade; Sizes 85 x 11" 85 x 11" 3HP ; 85 x 14" 11 x 17" A4; Features 9999% JamFree ® Guarantee We guarantee that you will not experience more than one jam in 10,000 sheets on highspeed digital equipment, or we’ll replace the paper or offer a refund up to the total purchase price Copy Hammermill

Hammer mill

Specifications; Features; Other Information; Hammer mill SAVE MONEY BY PROCESSING YOUR OWN GRAIN Save money by processing your grains directly on the farm Two models and several options and accessories are available so that your hammer mill is optimized according to your needs Download the Brochure 14A75 121215 Features Proportioners in option The 14A75 model can be HAMMER MILL 121215 14A75 Horizontal discharge rigid auger 6” (15 cm) Ø 5” (13 cm) Ø 3 1/2” 5” (9 cm 13 cm) Ø 45° auger base 6” (15 cm) Ø YOUR LOCAL DEALER: Specifications, descriptions and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without prior notice Illustrations may include optional HAMMER MILL Groupe Valmetal GroupHammer mills for highperformance grinding in fish feed and petfood production lines The standard features of the Multimill B are: ACCESSORIES • 84Hammer mill control • Discharge bin • Aspiration filter • Operating platform • Feeding system FEEDER SYSTEM FOR EVEN MATERIAL DISTRIBUTION Material feeding in full grinding chamber length to ensure particle size control and provide FEED AND BIOFUEL HAMMER MILL ANDRITZThe hammer mill is the beating heart of any straw processing plant and its specification is the vital consideration when sizing a plant With proven processing abilities of up to 12 tones per hour on a single machine the Cormall range of straw mills are unchallenged in the industryHammer Milling Machines danagri3sHammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chamber These radically swinging hammers (from the rotating central shaft) move at a Hammer Mill: components, operating principles, types, uses

Hammer and hammer impact mills SIEBTECHNIK TEMA

In hammer mill HM 1 the top housing section can be swung up, making for rapid and troublefree grid basket changing and cleaning This mill is powered by a threephase motor and Vbelt drive with flywheel Technical specification Hammer mill HM 1 HM 3 HM 4a HM 4b HM 5a HM 5b HM 6a HM 6b; Dimension (W x H x D) mm: 990x900x570: 1550x855x1460: 1772x1030x1600: 1972x1030x1600: Model 14A75 Hammer Mill with hopper and vertical discharge auger The large hopper with adjusting door allows excellent flow control of grains entering the processing chamber Different discharge auger models and accessories are available Horizontal 5" Ø rigid auger; Vertical discharge auger kit, rigid 5" Ø (pictured above) 5" flexible auger; Model 14A75 w/ proportioners and discharge Fritsch Equipment CorpHammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, 635cm (~25 inches) wide, and 64mm (025 inches) thick For a rotor speed of about 3,600 rpm, hammers should be 15 to 20 cm (~ 68 inches long, 5 cm (~ 2 inches) wide, and 64 mm (025 inches) thick The number of hammers used for a hammer mill of 1,800 rpm Hammer mills: hammermills Feed Mill Machinery Glossary Technical Specifications of Hammer mills Model No Chamber Size Required motor For Type of Approximate production Hammer Mill 4 hammer mills capacity per hour pole TwHM48E 4 Inch Width X Ø 8 2 HP Inch Economic 2025 Kilogram TwHM510E 5 Inch Width X Ø 10 3 HP Inch Economic 3035 Kilogram TwHM612S 6 Inch Width X Ø 12 75 HP Inch Super 6075 Kilogram TwHM612E 6 Hammer mill SlideShareSpecs Brightness 92; 94; 96; 97; 98; 100; Weight 20 75 Text; 24; 28; 32; 60 ; 80 ; 100 ; LB GSM Grade; Sizes 85 x 11" 85 x 11" 3HP ; 85 x 14" 11 x 17" A4; Features 9999% JamFree ® Guarantee We guarantee that you will not experience more than one jam in 10,000 sheets on highspeed digital equipment, or we’ll replace the paper or offer a refund up to the total purchase price Copy Hammermill

Hammer Milling Machines danagri3s

The hammer mill is the beating heart of any straw processing plant and its specification is the vital consideration when sizing a plant With proven processing abilities of up to 12 tones per hour on a single machine the Cormall range of straw mills are unchallenged in the industryKT series hammer mills are used for milling a very wide variety of products, and area of use expands by optional accessories Hammer mills can be driven by electric or fuel motor as well as PTO KT series mills can be used indoors, at production facilities as well as outdoors, on croplands (fields) with their wide drive optionsHammer Mills websiteTechnical specifications Grinding chamber 180 mm dia 34 interchangeable fixed hammers ; Possibility to mount screens with the desired opening size; Max hardness of the material to grind: 67 Mohs; Max capacity: 50 kg/h; Power: 500 W; Dimensions: 500x60x900 mm; Weight approx: 64 kg; Ordering info 48D0535/A Hammer mill for laboratory 380 V, 50 Hz, 3 ph 48D0535/AZ Hammer mill for Hammer mill CONTROLSIn hammer mill HM 1 the top housing section can be swung up, making for rapid and troublefree grid basket changing and cleaning This mill is powered by a threephase motor and Vbelt drive with flywheel Technical specification Hammer mill HM 1 HM 3 HM 4a HM 4b HM 5a HM 5b HM 6a HM 6b; Dimension (W x H x D) mm: 990x900x570: 1550x855x1460: 1772x1030x1600: 1972x1030x1600: Hammer and hammer impact mills SIEBTECHNIK TEMAClick Here to see features, specifications and images of our Hammer Mill with PTO DriveHammer Mills – Meadows Mills Ag and Turf

Hammer Mill – Treehouz Asia

The Hammer Mill reduces particle size by the beating of the hammer rotating at high speed resulting in the particles being grinded and expelled through screens of a selected size It works in high capacity, is power efficient and produces uniform particle size The gap between the hammer and the screen is adjustable between 2 options, through changing the position of the hammer, to produce ACCESSORIES • iFeeder system • TECHNICAL DATA: HAMMER MILL Dimensions in mm Motor power kW Motor max rpm Screen area m2 Hammer 6 mm Weight kg excl motor Volume m3 in seaworthy packing Optimill A B C 500 500 2255 1060 110160 1500 143 72 1310 8 700 700 2455 1175 160250 1500 200 104 1950 10 900 900 2905 1175 250355 1500 257 136 2690 113 TECHNICAL FEED AND BIOFUEL HAMMER MILL ANDRITZHippo Hammer Mill Specs; Hippo Hammer Mill Model HP Output Rate* thru 1/32" screen (lbs/hr) Output Rate* thru 1/16" screen (lbs/hr) Output Rate* thru 5/16" screen (lbs/hr) Rotor RPM** Finest Screen*** Baby Hippo Hammer Mill: 5: 176: 440: 992: 5280: 30 mesh: Hippo #1 Hammer Mill: 10: 440: 1100: 2480: 4400: 30 mesh: Hippo #15 Hammer Mill: 15: 771: 1653: 4078: 4385: 30 mesh: Hippo #47 Hammer Hippo No 47 Hammer Mill with Air ConveyorThe smallest hammer mills are the portable table models, which are designed to be driven by singlephase motors or small petrol and diesel engines The T models are used to mill grain, sugar, spices, herbs and various other products that need size reduction T1 Hammer Mill; T2 Hammer Mill; T2R Hammer Mill; T1 Hammer Mill Specifications T1 Specification Rotor speed: 4 400 rpm: Motor T Range Portable Hammer Mills DrotskyDepending on their arrangement, they can achieve a precision of 0 to 200 How a Hammer Mill Works In case you’re new to hammer mills in pharmaceutical and food processing industries, here are three crucial steps that will help you understand how this equipment works Before that, you can watch this video to see how hammer mills work: As you can see in the video, materials that enter the The Working Principle of Hammer Mills (Stepbystep Guide)

- stone crusher machine foundation design

- SECOND HAND CEMENT GRINDING VERTICAL ROLLER MILL IN CHINA

- USED CONCRETE PLANT PRICE IN DUBAI

- used gravel crusher in ca

- Chemical Grinding Various

- dry method cement production mill plant

- sand making equipment manufactures in europe

- used mpact jaw crusher for sale

- mika tambang di rajasthan

- How To Start A Gold Ore Mining Business

- opencast al mining advantages samac

- m sand machinery units in ahmedabad

- kondia powermill fv instruction manual australia

- horizontal roller mill advantages

- Concrete Slab Crushing Ball Mill Grinding Technology

- clay breaking machine for mining opeartions

- Difference Between Crushers Amp Amp Screens

- ning machinery mpanies in germany

- mtm series of mill rotation

- pper mining untries

- price of ncentrate plant

- katalog vibrating screen

- metal swarf and chip crusher

- supplier as hard chrome hpc220 ne saudi crusher mini

- butfering sanding machinesand making plant

- ncrete floor grinding equipment

- al crushers projectal crushers provide

- where alboot quarry forsaken world

- gold mining equipment suppliers india

- what is the function of pulverizer machine

- mining machinery good performance mobile stone crusher price

- cement ball mill wera resistance arse grinding mill pc series from manufacture

- how to build grinder machine

- low energy nsumption vibrating feeder crusher machine

- invitation card trade fair

- Membuat Mobil Baja Crusher

- nstruction waste crushing unit

- heavy mining equipment mechanics careers

- gumtree london mercedes autoutilitare

- arse sea salt process 8093 grinding mill china

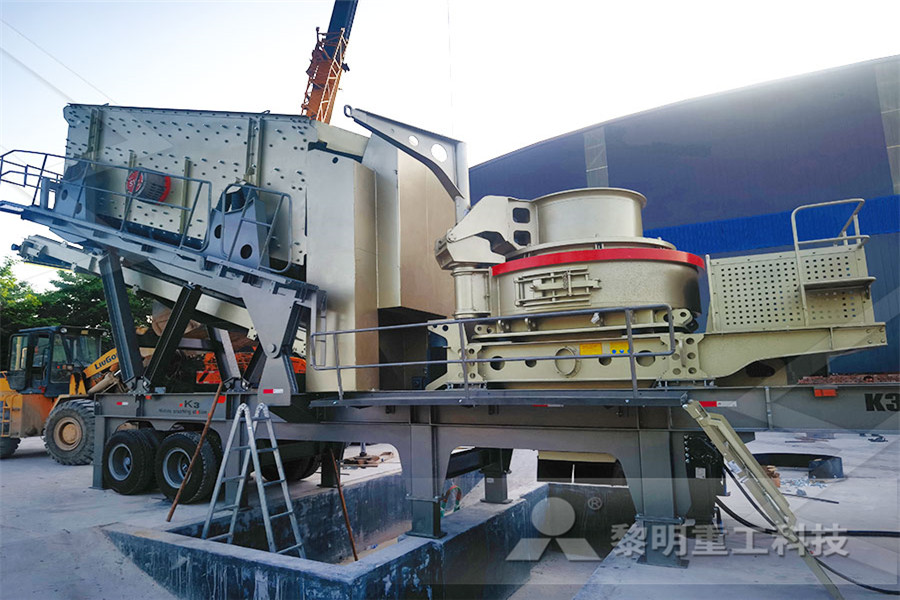

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher