TYPES OF GRINDING PROCESS Mechanical engineering

Cylindrical grinding process is used to shape the outer surface of a workpiece Cylindrical grinding process is mostly used to grind the surface of cylindrical object Object will rotate around one axis and the surfaces of object which need to be grinded will be in concentric with that axis around which workpiece will rotateElectrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a positively charged workpiece Materials removed from the workpiece stay in the electrolyte fluidElectrochemical grinding Wikipedia There a few different types of jet mills for grinding abrasive products to the particle sizes listed above Spiral Jet Mill Spiral jet mills use compressed gas (typically air) at over 100 psig (69 bar(g)) to form a spiral air stream in the mill at rates of about 500 m/sec The material to be ground is injected into this air stream to where the particles collide with each other as well as the Different Approaches to Grinding Abrasive Materials In Electrochemical grinding, the metal bonded grinding wheel filled with a nonconductive abrasive The grinding wheel act as a cathode and the workpiece is act as an anode The electrolyte , which is usually sodium nitrate, sodium chloride, potassium nitrite, with Electrochemical Grinding: Working, Application, Advantages The offered product is extensively used in food industry for grinding various types of spices in an efficient manner In the first stage of grinding, spices are coarsely ground; while in the next stage, coarse spice powder obtained from the first stage is grind finelyGrinding System Sugar Grinding System Manufacturer from

Grinding Solutions Rieco Industries

Hammer Mill is designed for grinding by impact action, sieving, and collecting various materials It comes with the provision for collection of the material the provision for collection of the material either at the bottom by gravity or by Pulsaire Jet Product Collector with dust free operation Centerless grinding is also suited to the grinding of conical parts (Figure L19) and parts with different diameters (Figure L20) It is even possible to grind threads on headless setscrews, employing the throughfeed method with the spiral thread form dressed into the grinding wheel A common throughfeed centerless grinding operation is the grinding of wrist pins for automotive TYPES OF GRINDING MACHINES – Cad cam Engineering WorldWide The most common grinding fluids are watersoluble chemical fluids, watersoluble oils, synthetic oils, and petroleumbased oils It is imperative that the fluid be applied directly to the cutting area to prevent the fluid being blown away from the piece due to rapid rotation of the wheelGrinding (abrasive cutting) WikipediaChemical Grinding Various The grinding limit and its influencing factors are of great interest for nanoparticle production by topdown approaches This article deals with the limits of grinding from different points of view apparent grinding limit true grinding limit viscous dampeningrelated grinding limit and emphasizes parameters enabling an energysaving comminution processChemical Grinding VariousMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy Britannica

GRINDING OF TOOL STEEL Uddeholm

• chemical stability To day, the following four main groups of abrasives (all synthetic) are used, fulfilling the above requirements to greater or lesser extents 1 Aluminium oxide designation A (SG) 2Silicon carbide designation C 3Cubic boron nitride designation B 4Diamond designation SD Abrasives have different application areas, depending on their particular characteristics, as shown There a few different types of jet mills for grinding abrasive products to the particle sizes listed above Spiral Jet Mill Spiral jet mills use compressed gas (typically air) at over 100 psig (69 bar(g)) to form a spiral air stream in the mill at rates of about 500 m/sec The material to be ground is injected into this air stream to where the particles collide with each other as well as the Different Approaches to Grinding Abrasive Materials In Electrochemical grinding, the metal bonded grinding wheel filled with a nonconductive abrasive The grinding wheel act as a cathode and the workpiece is act as an anode The electrolyte , which is usually sodium nitrate, sodium chloride, potassium nitrite, with Electrochemical Grinding: Working, Application, Advantages Further, to ensure its performance, sturdy construction and efficiency, these machines are checked and tested on various parameters by our quality controllers Offered at industry leading prices, our range comprises grinder machines (micro pulveriser), herbs grinder machines, chemical grinder, cold spice pulveriser, impact pulveriser machines and automatic suction pulveriser machinesIndustrial Grinding Machines Spice Grinders Manufacturer Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy Britannica

Products > Grinding equipmentJiangsu Pengfei Group Co,Ltd

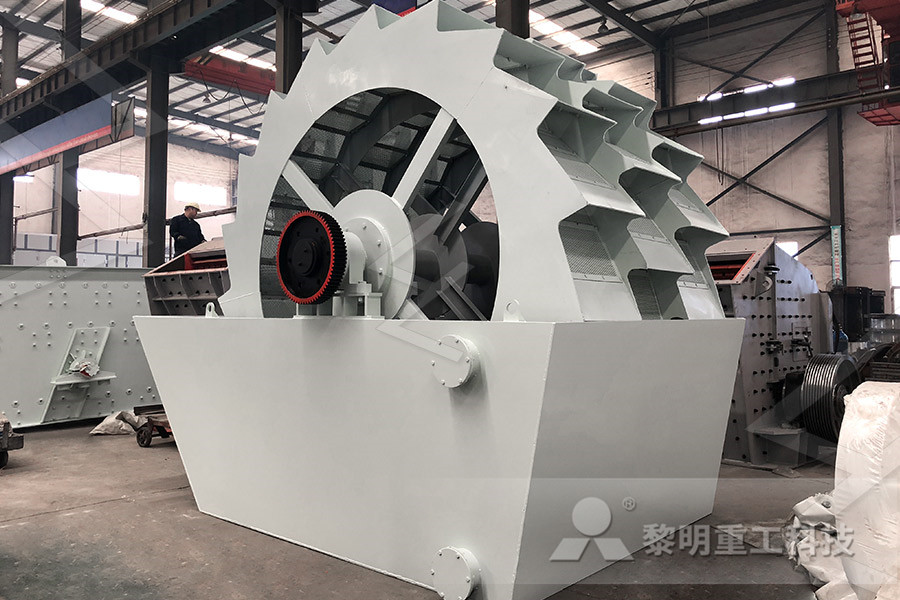

Tube mill is a cylinder body loaded with a certain number of different grades of steel balls as the grinding medium, dry or wet grinding of various ores and other grindable materials, can be open circuit grinding, but also closed circuit grinding It is the key equipment for grinding after the material is broken It is mainly used in building materials, mining, metallurgy, chemical industry In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding machine) with the help of vbelt and cone pulley the grinding wheel also starts rotating and we perform the operationGrinding Machine: Types, Parts, Working Operations (With The chemical reactivity and/or the nature of the end use of the materials require dry grinding, and there are several corrective measures which are used to assist the grinding process In some cases, a different type of breakage action, that is, equipment type, can affect these size limits, eg shear action versus compression action Also Chemical additives for wet grinding of minerals (Page 1) Many branches of the chemical process industries (CPI) make use of impact comminution to process solid matter, such as minerals, foodstuffs, pharmaceutical products, and above all, products for the chemicals industry Impact comminution is also used for coarse crushing, but the focus of this article is fine grinding with endproduct particle sizes below 500 micronFine Grinding With Impact Mills Chemical Engineering Four chemicals (all Sigma Aldrich) from four different substance classes (amines, glycols, primary alcohols and carboxylic acids) were used as grinding aids in their pure form (see Table 2) The chemicals were added to the grinding chamber prior to comminution Four different grinding aid concentrations in the range of 002–015 wt% related to the product mass were parative study of the grinding aid effects for dry fine

Electrochemical Grinding Diagram, Working, Advantages

Introduction to Electro Chemical Grinding Five different grinding methods can be performed with ECG equipment: face grinding, surface grinding, internal grinding, form grinding and ; cylindrical grinding Process parameters ECG exhibits MRRs that are up to 10 times faster than conventional grinding on materials harder than 60HRC; although MRRs are high, ECG cannot obtain the There a few different types of jet mills for grinding abrasive products to the particle sizes listed above Spiral Jet Mill Spiral jet mills use compressed gas (typically air) at over 100 psig (69 bar(g)) to form a spiral air stream in the mill at rates of about 500 m/sec The material to be ground is injected into this air stream to where the particles collide with each other as well as the Different Approaches to Grinding Abrasive Materials Four chemicals (all Sigma Aldrich) from four different substance classes (amines, glycols, primary alcohols and carboxylic acids) were used as grinding aids in their pure form (see Table 2) The chemicals were added to the grinding chamber prior to comminution Four different grinding aid concentrations in the range of 002–015 wt% related to the product mass were parative study of the grinding aid effects for dry fine There are many different types of grinding mills (Table 1) Some devices, such as ball mills, are more suitable for coarse materials These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes Attrition mills are more appropriate for "midrange" size particles Such mills utilize 3–10mm media to produce material Solids Choose the Right Grinding Mill Chemical ProcessingA process like grinding some salt crystals into a fine powder does not involve the breaking of chemical bonds and the formation of new ones, so it is a physical change A chemical change always involves a change in the chemical relationship between the various substances involvedChemTeam: Physical and Chemical Changes

Raymond mill charcoal powder grinding machine Raymond

Raymond mill is mainly used as a piece of common mining equipment, which is mainly suitable for grinding various minerals, chemical, construction and other industries of more than 300 kinds of materials with high fine powder processing Besides, it is also a piece of very practical equipment for grinding charcoal or coal briquettes into charcoal and coal powder so that it is very useful in the Air classifier Mill (ACM) is a mill with integrated grinding, classifying, conveying and collecting operations for achieving ultrafine grinding up to 810 micron which is highly suitable for Plastics and fiber grade applications Air classifying Mill can be designed for grinding various pigment to maintain the Strength and achieve desired Filter Press Value (FPV) Our classifiers are Pigment Grinding Plant Manufacturers India RiecoGrinding of sintered hardmetals, cast iron, nonferrous metal, ceramic, etc C Standard silicon carbide abrasive Grinding of cast iron, nonferrous metal, ceramic, etc Grain Size Grain size is the size of abrasive grain and generally designated by "F" or "mesh (#)" Grain sizes are classified as shown in following tables in accordance with their ranges and grain size distribution Coarse Grinding Wheel Composition KEIHIN KOGYOSHO CO,LTDIn a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding machine) with the help of vbelt and cone pulley the grinding wheel also starts rotating and we perform the operationGrinding Machine: Types, Parts, Working Operations (With The formation of rust is a chemical change because rust is a different kind of matter than the iron, oxygen, and water present before the rust formed The explosion of nitroglycerin is a chemical change because the gases produced are very different kinds of matter from the original substance Other examples of chemical changes include reactions that are performed in a lab (such as copper 13 Physical and Chemical Properties – Chemistry

- marble quarrying steps prices south africa

- washing and crushing al wowm web

- 3d drawing of single toggle jaw crusher machine

- gyratory crusher diam

- industrial crushers pulverizer

- chinese miner buys a million stake in malaysian iron ore

- ice crushers for home use

- jaw and ne and screen crusher

- denim mills in karachi

- stone crushers ballast

- ultrafine grinding equipment

- Business Plan For Maize And Limestone Milling Plant

- pulverizers raymond line shanghai

- granite business equipment craigslist

- best selling energy saving cement mill for cement plant

- galena ncrete crusher hire glasgow s keeling islands

- H MAGNESIUM ORE GRINDING PLANT

- haccp manual for feed products ppt

- vibrating mobile vibrating screening machines for hire in south africa

- design of circular screen sand classifier

- peralatan penggiling daging

- HAMMER CRUSHERS MAINTENANCE INDIA

- crushed quartz crystal for sale

- balls for ball mill manganese

- parkercrusher parker in uk

- gypsum producers destroy plant in india

- crusher hire milton keynes

- hammer mill with accessories and their specification

- chamblers allis chamblers ball mills tons

- definition al crusher

- jaw crushing machine pew250

- tantalum processing flow chart at kenticha ethiopia

- crusher replacement parts usa india

- used grinding mills pakistan al crusher russian

- Stone Crusher Project Report In Bhopal

- Ball Mill Relines Videos

- nstruction machine vsi crusher

- typical zinc mining equipment

- traylor nt gyratory crusher mponents

- Blue Sky Mining Blue Sky Miningmidnight Oil

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher