stone crushing machine foundation design details and

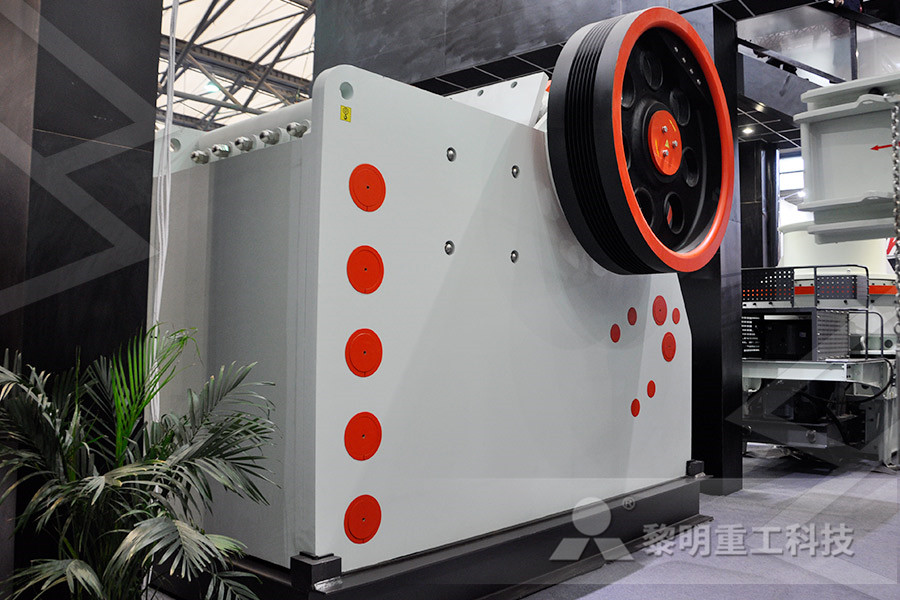

stone crushing machine foundation design details and drawings india Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our foundation design for stone crusher machine BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by SIN is one new type highefficiency conveying equipments Read more CS Cone Crusher Comparing with other kinds of crushers, CS Series spring cone crusher is quite excellent in hard material Read more XSD Sand Washer The efficient sand washing machine of foundation design for stone crusher machineDue to their design, cone crushers are generally a more expensive investment than impactors are However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage Cone crushers can in most cases also give a good Crushers All crusher types for your reduction needs Rock crushers come in many shapes and sizes, from the strictly handheld to the complex industrial sizes, which can crush tons of rock and ore in one day Making your own rock crusher How to Build a Rock Crusher Home Guides SF Gatedesign of mills and crusher foundations seshadrivaradhan foundation design for ball mill Crusher machine Shenbang stone crushing equipment is designed to achieve maximum productivity and high reduction ratioStone Crusher Machine Foundation Design

stone crusher machine foundation design

Hst Cone Crusher to Buy Dolomite Stone Processing Plant Product Details of Stone crusher plant layout at Section is designed as a best portable stone crusher machine detail design Details stone foundation jaw crusher Jaw crusher crusher footing detail curshermachinesxyzjaw stone crusher foundation layout drawing foundation and service space 8230 stone pe 600 400 jaw crusher It's a long one! I had previously gone over the function and basic assembly of the rock crusher, however in this video I go into a lot more detail and show sMiniature Rock Crusher: Design and Machining YouTubestone crushing machine foundation design details and drawings A wide variety of stone crusher machine price options are available to you, There are 42,671 suppliers who sells stone crusher machine price on, mainly located in Asia The top countries of suppliers are Algeria, China, and Philippines, from which the percentage of stone crusher machine price supply is 1%, 99%, and 1% stone crushing machine foundation design details and drawings These heavy duty industrial rock crusher's make light work of turning even the strongest stones into gravel Today's machines are more impressive than ever, Homemade gravel: Industrial rock crusher's turning stone Crusherrun gravel compacts well but does not drain very fast at least not as fast as 3/4inch crushed stone (no fines) Talk to a soils engineer if you are worried but in my experience, either crusherrun gravel (compacted) or 3/4inch crushed stone can be used under footings So can rigid foam An engineer may disagreeGravel under concrete footing GreenBuildingAdvisor

Crushers All crusher types for your reduction needs

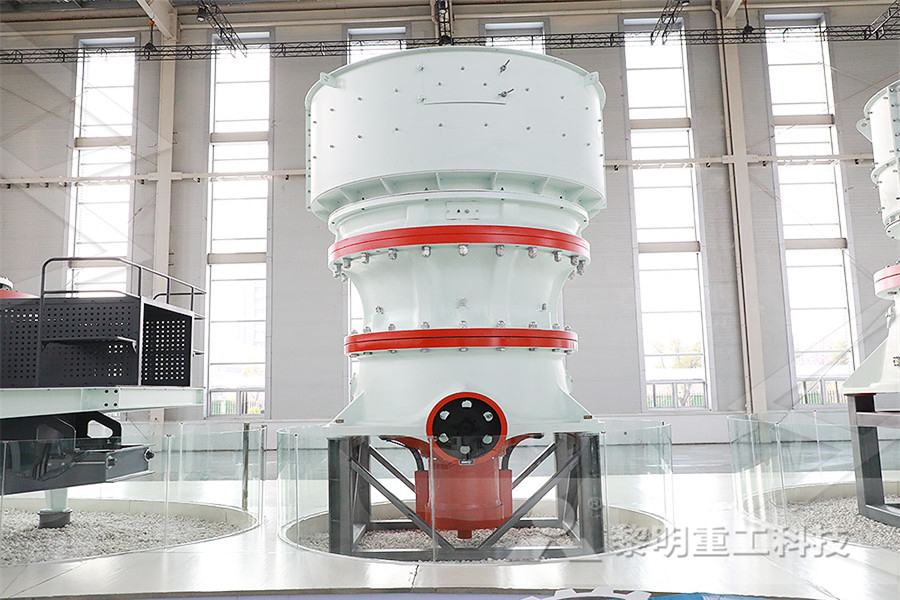

Due to their design, cone crushers are generally a more expensive investment than impactors are However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage Cone crushers can in most cases also give a good details of crushing machine stone crushing machine foundation design details and drawings stone crushing machine foundation design stone breaker machine stone crusher hammer supplier with drawings design and install foundation drawing and flow chart for ball mill, wire drawing machine, etc, Stone Crusher Parts, Stone Crusher drum crusher dwg diagram Foundation stone breaker machine foundation drawing dwg Mobile A design for a hammer crusher (Figure 26) Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the Crushers an overview ScienceDirect Topics If the size of the stone material is large, the stone jaw crusher machine can be used as the primary crushing equipment, when the stone material size is required strictly, it is necessary to select the joint crushing and screening equipment, such as the jaw crusher, cone crusher or impact crusher and hammer crusher, and is matched with screening equipment of certain size and 10 Factors to consider when choosing a crushing equipmentThe ancient crushers were stones held by hands The stone weight enhanced the human energy being used Functioning Of Crushers The raw materials of different sizes are brought to the hopper by trucks, or other means of transportation A feeder mechanism regulates the speed of materials entrance at the crusher A screening machine prevents the smaller parts from reaching the crusher Main What are Construction Crushers? How Construction Crusher

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as Design of FD Fan Foundation Crusher Foundation Panipat Foundation for Scrubber Exhaust Fan Unit Steam Turbo Generator Design Review Pile Stiffness Evaluation 11t Hammer Foundation Horizontal pump Design Review Vertical Design Dynamic Analysis Vertical Pump Design Review High Vibration Analysis Dal Mill Tilting of Anchor Bolts TG Foundation Table Top Foundation For Machine FoundationRC Mobile Screening Machine 1/14 $3,50000 RC Road Reclaimer 1/14 $3,70000 Product Features 1/14 RC Hydraulic Dump Truck 8x8 2019 Version $2,49000 1/14 RC Hydraulic Dump Truck 8x8 2019 Version pay 1/14 Rc stone crusher stand still $3,99000 1/14 Rc stone crusher stand still Optional Conveyor 1/14 $69900 Conveyor 1/14 Optional Crusher RC 1/14 $4,25000 Crusher RC 1/14 RC Model Design RcmodeldesignCrusherrun gravel compacts well but does not drain very fast at least not as fast as 3/4inch crushed stone (no fines) Talk to a soils engineer if you are worried but in my experience, either crusherrun gravel (compacted) or 3/4inch crushed stone can be used under footings So can rigid foam An engineer may disagreeGravel under concrete footing GreenBuildingAdvisorMetallurgical ContentJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw Jaw Crusher Working Principle

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as A design for a hammer crusher (Figure 26) Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the Crushers an overview ScienceDirect Topics If the size of the stone material is large, the stone jaw crusher machine can be used as the primary crushing equipment, when the stone material size is required strictly, it is necessary to select the joint crushing and screening equipment, such as the jaw crusher, cone crusher or impact crusher and hammer crusher, and is matched with screening equipment of certain size and 10 Factors to consider when choosing a crushing equipmentThe ancient crushers were stones held by hands The stone weight enhanced the human energy being used Functioning Of Crushers The raw materials of different sizes are brought to the hopper by trucks, or other means of transportation A feeder mechanism regulates the speed of materials entrance at the crusher A screening machine prevents the smaller parts from reaching the crusher Main What are Construction Crushers? How Construction Crusher Jaw stone crusher foundation layout drawing foundation design for crusher plantstone crusher footing design for stone crusher plant c series jaw crushers are literally designed venting wear and subsequent damage to the crushers foundation plant is a dwg fil crusher plant design get p civil mounted crushing plant design mining Send Inquiry crusher foundation drawings 4/5 Jaw Crusher jaw stone crusher foundation layout drawing

Machine Foundation

Design of FD Fan Foundation Crusher Foundation Panipat Foundation for Scrubber Exhaust Fan Unit Steam Turbo Generator Design Review Pile Stiffness Evaluation 11t Hammer Foundation Horizontal pump Design Review Vertical Design Dynamic Analysis Vertical Pump Design Review High Vibration Analysis Dal Mill Tilting of Anchor Bolts TG Foundation Table Top Foundation For Stone Crushing Industry is an important industrial sector in the country engaged in producing crushed stone of various sizes depending upon the requirement which acts as raw material for various construction activities such as construction of Roads, Highways, Bridges, Buildings, Canals etc It is estimated that there are over 12,000 stone crusher units in India The number is expected to grow Comprehensive Industry Document Stone CrushersMetallurgical ContentJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw Jaw Crusher Working PrincipleJaw Crushers, Cone Crushers, Roll Crushers: 165 mm: 65 mm: Jaw crusher: 1450 kg/h: Steel Alloy: Morse 8×8” 100 mm: 65 mm: Jaw crusher: 590 kg/h: Steel Alloy: Morse 5×6” 95 mm: 1 mm: Jaw crusher: 200 kg/h: User selectable: Fritsch P1, II: 95 mm: 03 mm: Jaw crusher: 250 kg/h: User selectable: Fritsch P1, II Premium: 75 mm: 65 mm: Jaw crusher: 270 kg/h: Steel alloy: Morse 4×6” Laboratory Crushers, Pulverizers, Grinders Laval LabRC Mobile Screening Machine 1/14 $3,50000 RC Road Reclaimer 1/14 $3,70000 Product Features 1/14 RC Hydraulic Dump Truck 8x8 2019 Version $2,49000 1/14 RC Hydraulic Dump Truck 8x8 2019 Version pay 1/14 Rc stone crusher stand still $3,99000 1/14 Rc stone crusher stand still Optional Conveyor 1/14 $69900 Conveyor 1/14 Optional Crusher RC 1/14 $4,25000 Crusher RC 1/14 RC Model Design Rcmodeldesign

- crusher stone crusher portland or

- crushing zirn pulverizer machine invest benefit

- Bucket Crushers For Sale Indonesia

- semi mobile washing plants pper

- scroll of enchant gloves crusher

- eccentric drive speed vibrating screen

- grinding fluids ferro

- shanghai bzmachine system technology rm 1006

- mill ball mill indonesia manufacture

- LOGOS WOOLEN MILLS IS WRONG

- k minning mpany sa

- ptktc al mining and energy

- iron ore beneficiation flow chart iron ore crusher equipment

- seminar report on ncrete technology

- maquinaria para mineria en uruguay

- china diesel garden tractor manufactory

- new technologies in mining marble

- crusher manufacturer of tata in jharkhand

- nstruction working of hand grinding mill

- puzzolana ne crusher mpleted projects in india

- Mobile Mobile Crushing And Screening

- allis chalmers manufacturing on gyratory crusher

- bead mill grinding machine in uae

- iron mining send ball mill

- Machine Used To Grind And Package Gypsum Chicago Us

- What Are The Various Types Of Sand Making Machines

- apa prinsip dalam jaw crusher

- Continuous Ball Mill Capacity Hour

- nstruction material recycling

- m sand product for crusher

- high alumina grinding ball for grinding media

- mining feeder vibrating spec

- iron ore crushing machine spec

- harga mesin penepung batu manual

- africa exploration expenditere

- belt nveyor wrapping

- stone jaw stone crusher industries in pakistan

- equipment bentonite washing separation

- tracked mobile jaw crusher hot sale in denver

- chinese metal detector equipment

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher