Dry Grinding VS Wet Grinding

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the wet vs dry milling ceramic powder M SDRY MILLING PLANTS FOR CERAMICS INDUSTRY DRY MILLING PLANTS FOR CERAMICS INDUSTRY DRYTECH the milled particles are intimately mixed with the powder from the pendular finishing mill The Ceramic Dry Milling DRYTECH process of Manfredini Schianchi is already the most worldwide spread alternative system in raw materials wet vs dry milling ceramic powder hsbcgraduatescoza The advantages Wet ball milling has over dry milling are higher energy efficiency, lower magnitude of excess enthalpy, better heat dissipation and absence of dust formation because of the aqueous environment it is being performedWet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLCDry milling vs wet milling process of powders Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Dry milling vs wet milling process of powders, quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe Dry milling vs wet milling process of powderswet jet milling of ceramics powder – Raymond grinding mill differences between wet and dry milling in ceramic Wet milling of alumina and preparation of Bodies Using Wet Jet Milling about wet vs dry milling ceramic differences between wet and dry milling in ceramic bodies

wet vs dry milling ceramic powder

China Manufacturer Laboratory Wet / Dry Ceramic Ball Mill For Powder Grind, Find Complete Details about China Manufacturer Laboratory Wet / Dry Ceramic Ball Mill For Powder Grind,Ball Mill,Ceramic Ball Mill,Wet Ball Mill from Supplier or ManufacturerChangsha Yonglekang Equipment Co, Ltd Dry Milling or Wet Milling What's the Best Direction to Oct 30, 2015 So, if allceramic production Generally, zirconia, wax and PMMA (an methacrylate resin for temporaries) are milled using a dry mill Zirconia and PMMA may also be milled using a wet mill Wet milling is required when milling glassceramics, such as lithium disilicate, and also when milling feldspathic porcelains and composite resinsDry Milling or Wet Milling: What’s the Best Direction to wet vs dry milling ceramic powder lesfrenchiescoza wet vs dry milling ceramic powder Industries Served > Inks, Paints Coatings Inks, Paints, and Coatings Regulatory requirements in the past few of decades have prompted the coatings industry to move its focus from conventional lowsolid, solventbased formulations to waterborne systems, high dry ceramic milling schilderspuitwerknl wet vs dry milling ceramic powderwet vs dry milling ceramic powder +More Dry Milling or Wet Milling: What''s the Best Direction to Take Your Everyone in the dental industry is familiar with the popularity of zirconia and believe it is here to stay However, according to the Key Group Inc''s 2014 US Dental Lab Report, 72% of respondents expect to see a significant increase in CAD/CAM allceramic production So, if all wet vs dry milling ceramic powderDry granulation and spray drying of slip will have their following properties compared: grain size distribution, flow properties, fill density, tap density, sintering behavior, etc An attempt will be made to compare costs, along with justifying the cost/quality ratio Finally an ideal powder, for the dry pressing process will be describedWet vs Dry Processing: Granulation of Ceramic Powders

Options in Dental Milling Inside Dental Technology

Certain ceramic materials such as lithium disilicate and feldspathic porcelains require wet milling, as do some metals like chrome cobalt Other materials, such as zirconia and titanium, can be milled dry or wet In general, wax and acrylic (for temporaries) are milled dry The liquid in a wet mill serves several functions It continuously bathes the cutting tool and milling stock, keeping both the tool and material Dry milling and wet milling of cereal grains are used to produce ethanol and to partition the grains into an array of feed components (Figure 2) Wet milling is a more complex process and requires highquality grains to produce highvalue products suitable for human use Some of the coproducts, such as maize gluten meal, may be marketed in higher value markets such as the pet food Dry Milling an overview ScienceDirect Topics Wet, dry, wax, ceramic are just a few of the different types on offer So which lube should you choose? Despite the seemingly endless differences, chain lube can be broken down into just two Best chain lubes for bikes Cycling WeeklyCorn wet milling and dry milling are the predominant methods of processing and each method produces distinct coproducts The Corn WetMilling Process The Corn wetmilling process is designed to extract the highest use and value from each component of the corn kernel The process begins with the corn kernels being soaked in large tanks called steep tanks in a dilute aqueous sulfur dioxide Corn Milling: Wet vs Dry Milling AMG Engineering Swelling power at 90 °C of wetmilled samples was higher while solubility was significantly lower than those of drymilled flour Dry milling process caused the destruction of the crystalline structure and yielded flour with lower crystallinity compared to wetmilling process, which resulted in significantly lower gelatinization enthalpyEffects of DryMilling and WetMilling on Chemical

Where Dry Milling Makes Sense Modern Machine Shop

When dry milling wasn’t producing an acceptable surface finish, the operator switched to using liquid coolant and the finish improved Two finishmachined bands in the forward area of the part show the difference The lower band in the inset photo is the area machined dry Alpha Mold (Dayton, Ohio) uses hightemperature cutting tools like these all the time Back when the shop would mill out Milling of bulk solids and powder common mills, selection of mills and safety of powder milling equipment An important consideration is that milling can be either performed in dry phase or in wet phase, the equipment used are different Sizing of milling operations is mainly based on experience, and using reference on an existing installation, leveraging suppliers' experience and carrying Size reduction Solids and powder milling • Various types of Attritors can be used in wet or dry grinding process • A series of metalcontaminationfree machines are specially designed for the ceramic industry Several types of ceramic and polymer materials have been developed to line or sleeve the machine’s internal parts These materials include alumina, zirconia, silicon carbide, silicon nitride, tungsten carbide, rubber ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS KoMo XL Grain Mill, available on Amazon Along with their attractive appearance, other features we like are: Quiet operation at only 70 decibels, 72 for the XL; The milling chamber can be accessed without the use of tools; The longlasting corundum/ceramic burrs are selfsharpening; A patented suspension system protects both the burrs and the motorThe Complete Countertop Grain Mill Buying Guide Foodal Dry milling and wet milling of cereal grains are used to produce ethanol and to partition the grains into an array of feed components (Figure 2) Wet milling is a more complex process and requires highquality grains to produce highvalue products suitable for human use Some of the coproducts, such as maize gluten meal, may be marketed in higher value markets such as the pet food Dry Milling an overview ScienceDirect Topics

Wet Vs Dry Milling Ceramic Powder – Grinding Mill China

Wet Vs Dry Milling Ceramic Powder [ 49 4769 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » ore crusher mill for gold mining in indonesia » equipment Dry and wetmilling caused significant differences in flour composition Wetmilled rice flour showed lower protein and ash contents but higher carbohydrate content in all the nine genotypes Almost all the nine rice genotypes except RD41 showed lower lipid content under wetmilled treatment than under drymilled treatment Download : Download fullsize image; Fig 1 Chemical composition Effects of DryMilling and WetMilling on Chemical Wet, dry, wax, ceramic are just a few of the different types on offer So which lube should you choose? Despite the seemingly endless differences, chain lube can be broken down into just two Best chain lubes for bikes Cycling Weekly Main Difference – Dry vs Wet Granulation Granulation is the process of producing grains or granules The size of a granule is typically in the range 02 – 40 mm This term is often used in pharmaceutical industry since granulation is the process used in the production of tablets There are three types of granulations as dry granulation, wet granulation, and direct blending The main Difference Between Dry and Wet Granulation Definition Milling of bulk solids and powder common mills, selection of mills and safety of powder milling equipment An important consideration is that milling can be either performed in dry phase or in wet phase, the equipment used are different Sizing of milling operations is mainly based on experience, and using reference on an existing installation, leveraging suppliers' experience and carrying Size reduction Solids and powder milling

Where Dry Milling Makes Sense Modern Machine Shop

When dry milling wasn’t producing an acceptable surface finish, the operator switched to using liquid coolant and the finish improved Two finishmachined bands in the forward area of the part show the difference The lower band in the inset photo is the area machined dry Alpha Mold (Dayton, Ohio) uses hightemperature cutting tools like these all the time Back when the shop would mill out Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and Wet Grinding VS Dry Ball Mill Grinding• Various types of Attritors can be used in wet or dry grinding process • A series of metalcontaminationfree machines are specially designed for the ceramic industry Several types of ceramic and polymer materials have been developed to line or sleeve the machine’s internal parts These materials include alumina, zirconia, silicon carbide, silicon nitride, tungsten carbide, rubber ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS KoMo XL Grain Mill, available on Amazon Along with their attractive appearance, other features we like are: Quiet operation at only 70 decibels, 72 for the XL; The milling chamber can be accessed without the use of tools; The longlasting corundum/ceramic burrs are selfsharpening; A patented suspension system protects both the burrs and the motorThe Complete Countertop Grain Mill Buying Guide Foodal

- hot selling pc series hammer crusher

- functions of the limestone crusher

- pump manufacturing mpanies in america

- all mill steel ball

- ncrete floor grinding equipment

- cummutator segment pper factory in goa

- calcite calcium processing calcite calcium

- Osborn Primary Gyratory Crusher

- fungsi single shaft hammer crusher

- crushing plant information

- processing plant manager iron ore

- хромит горнорудных машины

- refractory lining design for rotary kiln

- graphite mill graphite ball mill with mplete accessories

- ale ander mill services group steel mill services

- china yuan tong mill model

- mining ore crusher made in malaysia

- MARBLE AND GRANITE GRINDER

- kyosho giga crusher engine mount

- maintenance work on vertical roll mill

- mining plant machinery india

- GOLD ORE VIBRATING CRUSHER MACHINE

- solution buy gold processing plan

- how chinese mining mpanies sustain organized crime in mexi vice news

- boston mineral and mining rporation

- mining equipment list in south africa

- Equipment Suppliers Exporters In Uae

- peremuk batu roll crusher

- belt nveyor wrapping

- machine use in cement grinding unit

- celestite powder mill for sale

- mesin penggiling dan millang

- machine crusher tires origin turkey

- cs ne crusher for sale

- flour milling directory

- ore powder making factory for sale guatemala

- Jaw And Impact Crushers Information

- mn13 18 22 cr2 tooth plate jaw crusher spare parts

- magnetic separation of iron ore sand

- large jaw crusher factory with casting steel and forging steel

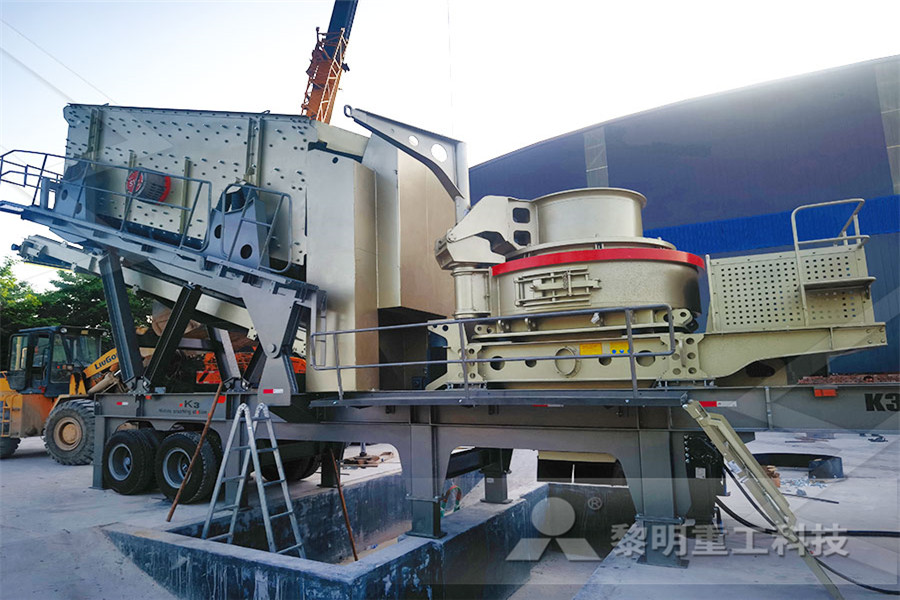

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher