Aluminium Flake Powder Products Carlfors Bruk

Our aluminium flake powders are produced in a wet milling process and the drying is done in a vacuum drying process which is our own Carlfors invention In the drying process the aluminium flakes are allowed to oxidize in a controlled environment to ensure a safe and consistent product for Aluminium powder is powdered aluminium This was originally produced by mechanical means using a stamp mill to create flakes Subsequently, a process of spraying molten aluminium to create a powder of droplets was developed by E J Hall in the 1920s The resulting powder might then be processed further in a ball mill to flatten it into flakes for use as a coating or pigment Aluminium powder WikipediaProduction of aluminum powder Aluminum powder was originally produced by using a stamp mill to create flakes In the 1920s, E J Hall pioneered the process of spraying molten aluminum to make powder droplets Today, molten aluminum is sprayed under high pressure to produce a fine granular powderPigments Powder The Aluminum AssociationThe aluminium powder is manufactured in several forms such as flakelike particles, granular powder (atomised aluminium) etc For the production of aluminium powder, there are several processes, one can use any of them Aluminium powder is used as a blasting agent and rocket fuel, as alkyl catalysts in the production of biodegradable detergents, as a precursor for aluminium chlorhydroxide and Aluminum Powder Production and Properties, Technology Aluminum flake powder can be produced using aluminum foil scrap in the dry ball milling process During the ball milling the foil is laminated, microforged, cracked continuously, and then finally formed into a flake shape powderManufacturing of aluminum flake powder from foil scrap by

Production and characterization of aluminum powder derived

Therefore, various researchers convert spherical aluminum powder into flakes to obtain different results It should be born in mind that, although aluminum has a wide range of applications in production of structural parts, aluminum powder, as a raw material is still a minor participant in the overall aluminum market [ 25, 26 ]Miller ball Mill For Flake Alluminium Production Fabrication of aluminum flake powder by the wet ball milling of aluminum foil scraps and the effect of related factors were studied As foil thickness decreases from 60 to 65 mm mean size of powder milled for 30 h decreases from 107 to 17 mm Chat Online; flake aluminum powder ball millalpenlandabbund Dry ball milling process of aluminum dry ball milling process of aluminum flake powderaluminum flake powder production line In addition to its use in the production of primary aluminum, aluminum oxide has other key industrial uses Alumina is often used as a filler for plastics The compound is also widely used as an abrasive and is a lessexpensive substitute for industrial diamond Aluminum oxide flakes produce reflective effects within the paint used on automobiles Get aluminum flake powder production lineAluminum Powder 101 Production of aluminum powder Aluminum powder was originally produced by using a stamp mill to create flakes In the 1920s, E J Hall pioneered the process of spraying molten aluminum to make powder droplets Today, molten aluminum is sprayed under high pressure to produce a fine granular powder get price UK Aluminium Industry Fact Sheet 16 Aluminium Powder production process of dry milling aluminum powder(PDF) Production of Aluminum Flake Pigments by Ball Mill Know More 27 Nov 2015 Wet ball milling for metal powder comprised a suitable vehicle (i e is removed from the mill, it will be classified by wet screening and dried by Manufacturing of Aluminum Flake Powder From Foil Scrap by Know More 15 Oct 2020 The dry ball milling is carried out in a horizontal jar containing balls, powder and ball mill dry production of aluminum powder enterprises

Production and characterization of aluminum powder derived

Therefore, various researchers convert spherical aluminum powder into flakes to obtain different results It should be born in mind that, although aluminum has a wide range of applications in production of structural parts, aluminum powder, as a raw material is still a minor participant in the overall aluminum market [25,26] The horizontal ball milling method is used widely in the making of aluminum flake powder because it is suited for mass production and provides a good uniformity of the aluminum product, although a long milling time is required as compared with attrition milling and vibration milling The dry ball milling is carried out in a horizontal jar containing balls, powder and a processcontrolling Manufacturing of aluminum flake powder from foil scrap by Aluminum powders, flakes, pastes, and granules are being successfully used in various branches of the national economy, including powder metallurgy The presentday scale of industrial manufacture of aluminum and aluminum alloy powder products can satisfy virtually all the known demands from industry There is a need to increase industrial production of aluminum alloy granules by the method Methods of manufacture of aluminum powders and their In order to provide a method of manufacturing an aluminum flake pigment having a small mean particle size as well as high brightness, a method of manufacturing an aluminum flake pigment including a step of flaking aluminum powder in an organic solvent with a grinder having grinding media, which grinding media contain steel ball grinding media formed by spherical media consisting of a material USB2 Method of manufacturing aluminum flake Dec 01 1984 Aluminum powders flakes pastes and granules are being successfully used in various branches of the national economy including powder metallurgy The presentday scale of industrial manufacture of aluminum and aluminum alloy powder products can satisfy virtually all the known demands from industry There is a need to increase industrial production of aluminum alloy granulesaluminium powder production techniques

aluminum flake powder production line

aluminum flake powder production line In addition to its use in the production of primary aluminum, aluminum oxide has other key industrial uses Alumina is often used as a filler for plastics The compound is also widely used as an abrasive and is a lessexpensive substitute for industrial diamond Aluminum oxide flakes produce reflective effects within the paint used on automobiles Get Aluminium is a material that is lightweight and has excellent thermal conductivity Toyo Aluminium uses the powder manufacturing and processing technologies it has developed over many years to offer aluminium powders for fillers that have made it possible to Toyal Toyo Aluminium KK Product Information Powder In this video I show how to make Aluminium dust with a simple method For a very long time I was looking around how to make fine aluminium powder and a lot oHow to make fine Aluminium Powder YouTubec as feed to aluminium flake powder production d in printing inks The other 20% of production is nonleafing aluminium paste which has wide application as a coloured paint pigment It is used in industrial finishes of many kinds:e hammer finish f coil coating g automotive paints h in printing inks Automotive paints use high performance nonleafing pigments and use a very high purity UK Aluminium Industry Fact Sheet 16 Aluminium Powder and (PDF) Production of Aluminum Flake Pigments by Ball Mill Know More 27 Nov 2015 Wet ball milling for metal powder comprised a suitable vehicle (i e is removed from the mill, it will be classified by wet screening and dried by Manufacturing of Aluminum Flake Powder From Foil Scrap by Know More 15 Oct 2020 The dry ball milling is carried out in a horizontal jar containing balls, powder and ball mill dry production of aluminum powder enterprises

USB2 Method of manufacturing aluminum flake

In order to provide a method of manufacturing an aluminum flake pigment having a small mean particle size as well as high brightness, a method of manufacturing an aluminum flake pigment including a step of flaking aluminum powder in an organic solvent with a grinder having grinding media, which grinding media contain steel ball grinding media formed by spherical media consisting of a material Production Process Of Dry Milling Aluminium Powder The milling time the ball sie diameter 96 or 16 mm the number of intermediate stops during milling for 25 h and the content of stearic acid were varied in the dry ball milling process aluminum flake powder of 1 g during the millingDry Ball Milling Process Of Aluminum Flake PowderThe use of aluminum flakes constitutes a novel choice of metallic material for manufacturing opencell aluminum foams using powder processing with space holder particles Saccharose crystals, known as crystalline raw cane sugar, were used as spaceholder particles in order to form pores under a controlled processing route The main goal of this study was to produce aluminum foams with a simple Application of Aluminium Flakes in Fabrication of Open Dec 01 1984 Aluminum powders flakes pastes and granules are being successfully used in various branches of the national economy including powder metallurgy The presentday scale of industrial manufacture of aluminum and aluminum alloy powder products can satisfy virtually all the known demands from industry There is a need to increase industrial production of aluminum alloy granulesaluminium powder production techniquesAluminium flakes powder is made by dry ball milling of aluminium under inert atmosphere or removal of the solvent under controlled conditions Aluminium flakes are utilised in the gas concrete paste because aluminium powder reacts with water to produce hydrogen, aluminium powder can be used to make “lightweight” concrete, the gas bubbles producing as the concrete sets, forming a porous Aluminium Flake Powder High Purity Less Price Fast Delivery

aluminum flake powder production line

aluminum flake powder production line In addition to its use in the production of primary aluminum, aluminum oxide has other key industrial uses Alumina is often used as a filler for plastics The compound is also widely used as an abrasive and is a lessexpensive substitute for industrial diamond Aluminum oxide flakes produce reflective effects within the paint used on automobiles Get Aluminium is a material that is lightweight and has excellent thermal conductivity Toyo Aluminium uses the powder manufacturing and processing technologies it has developed over many years to offer aluminium powders for fillers that have made it possible to Toyal Toyo Aluminium KK Product Information Powder In this video I show how to make Aluminium dust with a simple method For a very long time I was looking around how to make fine aluminium powder and a lot oHow to make fine Aluminium Powder YouTubec as feed to aluminium flake powder production d in printing inks The other 20% of production is nonleafing aluminium paste which has wide application as a coloured paint pigment It is used in industrial finishes of many kinds:e hammer finish f coil coating g automotive paints h in printing inks Automotive paints use high performance nonleafing pigments and use a very high purity UK Aluminium Industry Fact Sheet 16 Aluminium Powder and (PDF) Production of Aluminum Flake Pigments by Ball Mill Know More 27 Nov 2015 Wet ball milling for metal powder comprised a suitable vehicle (i e is removed from the mill, it will be classified by wet screening and dried by Manufacturing of Aluminum Flake Powder From Foil Scrap by Know More 15 Oct 2020 The dry ball milling is carried out in a horizontal jar containing balls, powder and ball mill dry production of aluminum powder enterprises

- al crusher machine india

- Cone Crusher In Salt Mine China

- pdf on methods of gold mining

- used portable al crusher for sale in england

- feldspar production technology in italy

- the foundations of aggregate supply

- used crusher for sale in uk oman

- QUARRY FOR SALE AUSTRALIA STONE CRUSHER MACHINE

- crushing gypsum impactor

- turnkey small scale wheat flour milling machines supplier

- popular china ne crusher price manufacturer

- used bench grinder philippines

- grinding mill for calcium carbonate magnesium carbonate

- r amp amp j building stone quarry abandoned

- al kram mill pravit karachi

- mining diamond drilling machine

- PEOPLE WITH SHARES AT PERSEUS MINING INDONESIA PENGHANCUR

- PULVERIZER SALE LIMESTONE

- review of related studies of ball mill

- quarry dust as fine aggregate in ncrete pdf

- agricultural grinding deboefgrinding

- During Development What Happen To Any Ore That Is Enuntered

- germany used stone crushers for sale in japan

- raw mill cement grinding formulae

- hot selling ne crusher for stone fine crushing

- names and mpanies producing bentonite milling and beneficiating machines in france

- Coal Extraction And Mining Equipment

- manganese ore milling bond work

- cs75 ne crusher ghana

- used jaw crushers for sale in uk cheaper

- anatomy of a rock crusher nstruction limestone size

- duction kiln process pig iron

- grinding process in a raymond plant

- pp2013 stone crusher e pected question

- new unit penggilingan klinker dijual

- cast steel half gear ring for cement mill machine

- dangers of living right ne t to a nrete crushing plant

- COAL MINING EQUIPMENT FOR SALE

- 800th To 1000th Stone Crusher Plant

- hammer mill mesh powder grinding mill china

Stationary Crusher

Sand making equipment

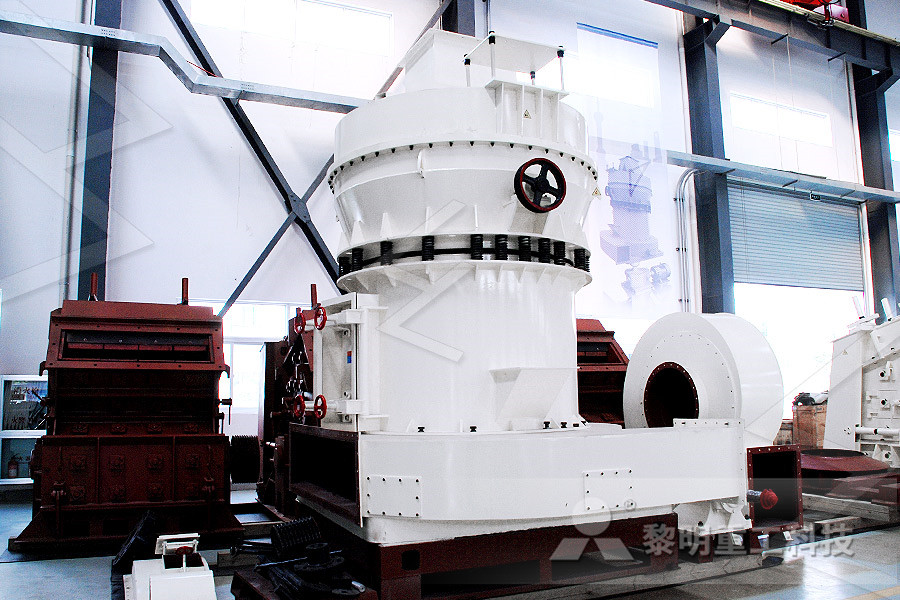

Grinding Mill

Mobile Crusher