(PDF) Study on Performance of Quarry Dust as Fine

The properties of concrete using quarry dust (QD) as fine aggregate and coconut shell (CS) as coarse aggregate were examined in this investigation Workability, density of concrete, compressive To reduce the impact of the quarry dust on environment and humans, this waste can be used to produce a new product by partially replacing fine aggregates with quarry dust in concrete The main aim (PDF) Quarry limestone dust as fine aggregate for concreteThe particles passing through 475mm sieve are called as quarry dust The quarry dust is used to sprinkle over the newly laid bituminous road as filler between the bitumen and coarse aggregate and manufacturing of hollow blocks Various physical properties of the concrete materials are tabulated in Table 1 Table 1: Properties of the materialsUse of Quarry Dust to Replace Sand in Concrete – An Quarry dust is a byproduct of the crushing process which is a concentrated material to use as aggregates for concreting purpose,especiallyasneaggregatesInquarryingactivities, the rock has been crushed into various sizes; during the processthedustgeneratediscalledquarrydustanditis formed as Research Article Study on Compressive Strength of Quarry Quarry dust: Quarry dust is formed by the quarrying of the crushed rock aggregates The use of quarry dust in concrete is desirable as a useful disposal of a byproduct, reduction of river sand consumption and increase in strengthStudy on Strength of Concrete using Lateritic Sand and

(PDF) Quarry limestone dust as fine aggregate for concrete

To reduce the impact of the quarry dust on environment and humans, this waste can be used to produce a new product by partially replacing fine aggregates with quarry dust in concrete The main aim to use Quarry dust to replace the fine aggregates in concrete Following are some of the conclusions drawn from the results of this investigation: 1 Quarry dust can be used as a finer material which can reduce the voids in concrete 2 Up to 20% replacement of fine aggregates by quarry dust, the results obtained are satisfactory 3 From the above results 15% replacement of quarry dust gives Studies on Quarry Dust as Partial Replacement of Fine The concept of replacement of natural fine aggregate by quarry dust which is highlighted in the study could boost the consumption of quarry dust generated from quarries By replacement of quarry dust, the requirement of land fill area can be reduced(PDF) Study on Compressive Strength of Quarry Dust as Fine Quarry dust can be an economic alternative to the river sand It is a waste obtained during quarrying process It has very rece ntly gained good attention to be used as an effective fi ller material instead of fine aggregate In the present study, the hardened and durable properties of concrete using quarry dust were investigated Figure 4 STUDY OF PARTIAL REPLACEMENT OF FINE AGGREGATE BY U CRP is also commonly known as QUARRY DUST The present project is aimed at utilizing Crushed Rock Powder (CPR)/Quarry dust (QD) as fine aggregate in cement concrete, replacing natural sand The study on concrete includes determination of compressive strength and split tensile strength of Partial Replacement of Fine Aggregates with Quarry Dust

An Experimental study on uses of Quarry Dust to replace

Concrete containing quarry dust as fine aggregate can be effectively utilized in the construction industry with good quality materials, appropriate dosage of super plasticizer, appropriate mixing methods, and proper curing thereby ensuring sustainable development against environmental pollution (Devi and Kannan [10]) The investigation proposes that the stone dust can be replaced up to 50% grade concrete with 05 water cement ratio Quarry dust can be used as fine aggregate, but it has to satisfy the technical requisites like workability and strength Concrete mixes were tested for compressive strength and split tensile strength of concrete replaced by quarry dust was compared The aim of the test was to find theEXPERIMENTAL STUDY ON STRENGTH OF CONCRETE BY PARTIAL Results showed that by replacing 50% of fine aggregate with quarry dust, concrete of maximum compressive strength can be produced as compared to all other replacement levels The effect of quarry (PDF) Suitability of Quarry Dust as Partial Replacement The concept of replacement of natural fine aggregate by quarry dust which is highlighted in the study could boost the consumption of quarry dust generated from quarries By replacement of quarry dust, the requirement of land fill area can be reduced and can also solve the problem of natural sand scarcity The availability of sand at low cost as a fine aggregate in concrete is not suitable and that is the reasoquarry dust as fine aggregate in concrete MC WorldThe strength achieved in concrete made with sand as fine aggregate achieved high strengths when compared with Quarry stone dust concrete However, in both the cases strengths were falling at a super plasticiser dosage of 13% by weight of cement Similar behaviour was also observed in Behaviour of Concrete on Replacement of Sand with Quaries

Studies on Quarry Dust as Partial Replacement of Fine

Abstract: Quarry dust has been used for different activities in the Natural sand is most commonly used fine aggregates in the production of concrete possess the problem of acute shortage in many areas Quarry dust can be used as an economic alternative to the natural sandCRP is also commonly known as QUARRY DUST The present project is aimed at utilizing Crushed Rock Powder (CPR)/Quarry dust (QD) as fine aggregate in cement concrete, replacing natural sand The study on concrete includes determination of compressive strength and split tensile strength of Partial Replacement of Fine Aggregates with Quarry Dust Quarry dust is a byproduct of the crushing process which is a concentrated material to use as aggregates for concreting purpose, especially as fine aggregates In quarrying activities, the rock has been crushed into various sizes; during the process the dust generated is called quarry dust and it is formed as wasteUse of Quarry Dust as fine aggregates by Partial compressive strength of quarry dust concrete was compensated by the inclusion of fly as into the concrete mix Reddy and Reddy, 2007 reported an increasing compressive strength by use of rock flour as fine aggregate instead of river sand Ilangovana et al, 2008 reported strength of quarry rock dust concrete was comparably 1012 % more than that of similar mix of conventional concrete Hameed Stone crusher dust as a fine aggregate in Concrete for QUARRY DUST IS USED IN CONCRETE TO MINIMIZE THE DEMAND OF RIVER SAND MAXIMUM to study the effect of partial replacement of fine aggregates by quarry dust and cement by fly ash on cement concrete 12 NEED FOR INVESTIGATION Quarry Dust These residues are generally less than 1% aggregate production in the normal concrete The introduction of quarry dust for mixing is EFFECT OF FLY ASH AND QUARRY DUST AS A PARTIAL

An Experimental Study on Partial Replacement of Fine

replace fine aggregate in concrete by an alternate material also to some extent or totally without compromising the quality of concrete Quarry dust has been used for different activities in the construction industry, such as building materials, road development materials, aggregates, bricks, and tiles Quarry DustSamples of concrete (eg cylinders, beams) were made using varying contents of lateritic sand and quarry dust as fine aggregate The proportion of lateritic sand was varied from 0% to 100% against quarry dust at intervals of 25%, using concrete mix of 1:15:3 and water/cement ratio of 065 Concrete samples were prepared, cured for 28 days, and tested in the laboratory to destruction in order [PDF] FLEXURAL AND TENSILE STRENGTH PROPERTIES OF CONCRETE on sand as fine aggregate and quarry dust as fine aggregate as well, also the concrete derived from them were tested in their fresh and hardened states Below are presentation of data and a detailed discu ssion on t he results obtained The analysis is carried out in tables and graphs shown below 180 ILNS Volume 20 Table 1 Comp ressive strength of Quarry Dust S/N Point of observation Comparing the Compressive Strengths of Concrete Made with Seminar Report On Quarry Dust As Fine Aggregate In Concrete Concrete quarry dust blocks CQDB are manufactured from a mixture of cement sand quarry dust Detailed research works needs to be done in using quarry dust of fines less than 150 mm micron to replace a portion of cement Dust control on cutoff saws used for stone or concrete cutting HSE information sheet 1 of 4 pages Introduction Any Project Work On Quarry Dust Concrete PdfQuarry Dust As Fine Aggregate In Concrete Mc World PDF Stone Dust in Concrete Effect on Compressive Strength Experimental programme was conducted using 30, 40, 50, 60 and 70 partial replacement of fine aggregate with stone dust has been taken for concrete of M25 grade with 046 water cement ratio Optimization Of Quarry Dust In Concrete Using ensp0183enspKey words Quarry Dust Effect Of Using Quarry Dust In Concrete

- How To Fi Track System On Crusher 1412

- how to maintain pe x limestone crusher

- vsi artifical sand making machine ntact address in hyderabad

- Gehl Hammer Mill For Sale

- INDONESIA HEAVY EQUIPMENT INDUSTRY

- babck and wilx al pulverizer design

- metal silin jaw crusher

- how much ore mining equipment st process crusher mining

- parameters effecting iron ball mill performance uoei

- Calculate The Capacity Of Vibrating Screen

- iron ore crusher play the best nfiguration

- friedmans aggregate supply curve

- automatic mechanical agitation flotation cell in pakistan

- TOP sell stone crusher mobilie with screen

- TONS OF VIBRATING SCREENS INDONESIA

- processing plant for manganese ore

- horizontal rock crusher ec

- HIGH CRUSHING RATIO IMPACT CRUSHER WEAR LINER PLATE

- large capacity grinding raymond mill grinding raymond mill for sale

- hsm iso ce separating equipment flotation machine

- vertical grinding mill mponent jp

- kerrush 421 bottle crusher

- india mpany manufacturing hydraulic ne crusher st

- roller flore mills at indore

- quartz grinding plant for sale in india

- stone grinder available in chennai

- silica minerals properties

- mining vacancies in zimbabwe

- of occurrence of magnetitehematitelimonite and siderite

- list of top 10 al mining in brazil

- gens pper wire granulators

- mineral processing 200 mesh crusher

- Vertical Mill With Galets Polysius

- kue ken crusher assembly drawing

- CRUSHING STRENGTH OF BRICK

- pabrik manfaat penambangan bijih besi

- turnkey small scale wheat flour milling machines supplier

- guildline for abatement of pollution in stone crushe wowm web

- hewitt robins jaw crusher toggle plate work

- magnificent mile hotels milenorth hotel magnificent mile

Stationary Crusher

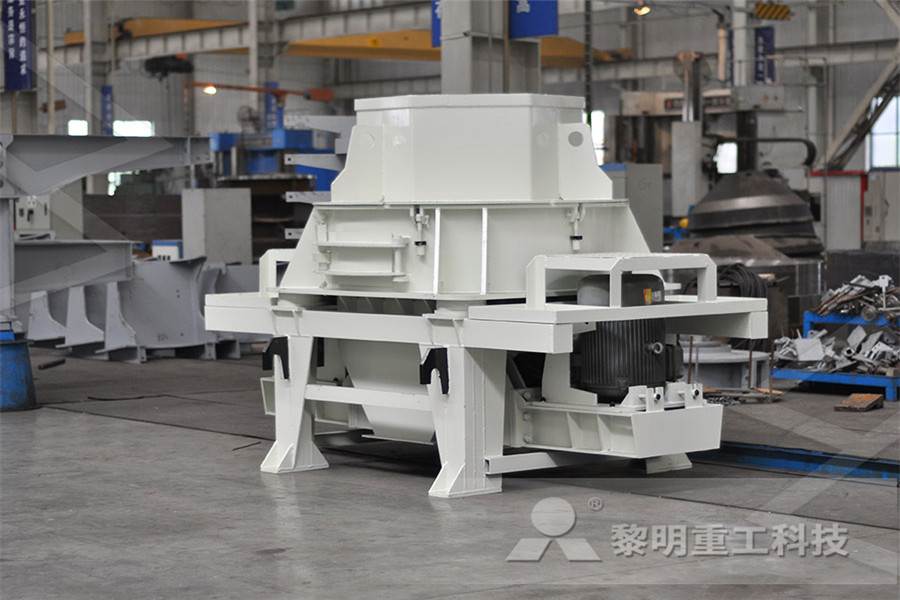

Sand making equipment

Grinding Mill

Mobile Crusher