Ball Mills an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellReview Of Related Studies Of Ball Mill Parts For Gulin Gyratory Crushers; Imagine Concrete Sand Machine; Ores Mine And Proccessing Machine; Full Used Crusher Plants Price In Usa; 500t H Jaw Crusher Equipment From Russia ; Advanced Technology Widely Used Glass Ceramic Ball Mill; Skylanders Giant Granite Crusher; Hot Selling Gold Testing Machine For Ore Dressing; Coal Review Of Related Studies Of Ball MillThe paper reviews the literature on the application of models based on distributed collision energy information to predict size reduction in tumbling mills, in particular ball mills, analyzing critically various approaches proposed, their limitations and achievements, identifying areas that still require development until the technology becomes ready for being used for optimizing and designing ball millsA Review of Advanced Ball Mill ModellingBall mills are used for grinding of rocks, cement clinker and line from 10 to 100 The ball mill used in this study was 5 m in diameter and 7 m long The axial diffusion is directly related to how far particles can spread axially in these Get Price aggregate toughness National Transportation Library DURABILITY/SOUNDNESS TESTS RELATED TO ASPHALT Based on a review of review of related studies of ball millMill (grinding) – Wikipedia, the free encyclopedia Grinding mill: Uses: Grinding: Related items: In spite of a great number of studies in the field of fracture schemes there Ball mills are commonly used in the » More detailed SAGDesign Case Studies SAGDesign Testing Review – Case Studies By JH Starkey, D Meadows, P Thompson and A Senchenko review of related studies of ball mill – Grinding Mill China

A Review of Advanced Ball Mill Modelling

The paper reviews the literature on the application of models based on distributed collision energy information to predict size reduction in tumbling mills, in particular ball mills, analyzing critically various approaches proposed, their limitations and achievements, identifying areas that still require development until the technology becomes ready for being used for optimizing and designing ball millsThe paper reviews the literature on the application of models based on distributed collision energy information to predict size reduction in tumbling mills, in particular ball mills, analyzing critically various approaches proposed, their limitations and achievements, identifying areas that still require development until the technology becomes ready for being used for optimizing and designing A Review of Advanced Ball Mill ModellingA ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse Ball Mill: Operating principles, components, Uses This paper presents a review of comill processing, for the production of highefficiency inhalation therapies, including the jet mill, mechanofusion, or ball mill methodologies We investigate the different techniques, additives, and drugs studied, and impact on performance in DPI systems Keywords: Inhalation, comilling, dry powder formulation, high dose delivery, jet mill, mechanofusion A review of comilling techniques for the production of Additionally, the analysis also has a comprehensive review of the crucial players on the Ball Mill (Mining) Market together side their company profiles, SWOT analysis, latest advancements and business plans The analysis objectives of the report are: To equitably share indepth info regarding the crucial elements impacting the increase of industry (growth capacity, chances, drivers and Global Ball Mill (Mining) Market Segment, Market

Controlling ball mill noise with acoustic blankets: A case

The purpose of wrapping ball mills with thermal/acoustic blankets is twofold: (1) to maintain the desired temperature inside the mill and (2) to reduce the sound emanating from the mill This field case study focuses solely on the latter, evaluating and documenting the sound level reduction attributed to the installation of the blankets and its potential to reduce the noise dose experienced by The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments Relative (PDF) A comparison of wear rates of ball mill grinding mediaIn previous studies, the analysis of ball mill ° operating parameters and their effects on breakage phenomena has been limited to homogeneous materials Though these ß studies have proven to be an asset in predictions of product size distributions and mill scale—up, they have not addressed the primary role of grinding, ie liberation I The present investigation analyzes the effect of THE EFFECT OF BALL MILL OPERATING PARAMETERS ON Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in Grinding in Ball Mills: Modeling and Process Control Ball mills are a common name in the manufacturing industry, owing to their versatility and usage potential They are used as tools for blending, mixing, grinding (coarsely as well as finely), and refining mineral product qualities Furthermore, they are an inseparable element of laboratories because they help change the form of an element for conducting thorough studies about its nature As a Operating Principle of Ball Mills Digitalmaurya

Particle Size Reduction Studies on the Lab and Commercial

In the current study, size reduction of the polymeric pellets was studied using a high and low energy mill Since a majority of polymer pellets have a relatively large size (ie, approximately 828 mm x 460 mm), high energy mills are logical choices for the milling process However, since the screen mills offer the advantage of better containment, qualifying it as an alternative milling The results obtained from the study show that ball‐mill process can be successfully modeled in the main chocolate varieties for the particle size change and moisture removal which are among the main objectives of the use of this processing step Therefore, they have potential to use in the relevant production areas As a result of this use, there is a potential to contribute to capacity Effect of ball‐mill process on some quality parameters of The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the preparation and functionalisation of nanocellulose derivatives by ball mill Ball milling: a green technology for the preparation and In previous studies, the analysis of ball mill ° operating parameters and their effects on breakage phenomena has been limited to homogeneous materials Though these ß studies have proven to be an asset in predictions of product size distributions and mill scale—up, they have not addressed the primary role of grinding, ie liberation I The present investigation analyzes the effect of THE EFFECT OF BALL MILL OPERATING PARAMETERS ON Additionally, the analysis also has a comprehensive review of the crucial players on the Ball Mill Market together side their company profiles, SWOT analysis, latest advancements and business plans The analysis objectives of the report are: To equitably share indepth info regarding the crucial elements impacting the increase of industry (growth capacity, chances, drivers and industry Global Ball Mill Market Segment, Market Assessment

Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse Ball mills are a common name in the manufacturing industry, owing to their versatility and usage potential They are used as tools for blending, mixing, grinding (coarsely as well as finely), and refining mineral product qualities Furthermore, they are an inseparable element of laboratories because they help change the form of an element for conducting thorough studies about its nature As a Operating Principle of Ball Mills DigitalmauryaIndustries ball mill their glazes, engobes and even bodies as standard practice Yet few potters even have a ball mill or know what one is Article A true ball mill is a porcelain jar partly filled with spherical or rounded cylindrical porcelain balls Industrial versions are made of metal and have porcelain linings Small scale operations Ball Milling Glazes, Bodies, EngobesA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A section cut thru of ball mills A ball mill consists of a hollow cylindrical shell rotating Ball mill WikipediaModule 2 – Ball mills This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process * Mechanical description of the different types of mills * Ball mill grinding equations and dimensioning * Mill internals, media, liners and diaphragms * Ventilation, cooling and drying * Control concepts * Grinding aids and other tools to Grinding and Milling Systems Course

Particle Size Reduction Studies on the Lab and Commercial

In the current study, size reduction of the polymeric pellets was studied using a high and low energy mill Since a majority of polymer pellets have a relatively large size (ie, approximately 828 mm x 460 mm), high energy mills are logical choices for the milling process However, since the screen mills offer the advantage of better containment, qualifying it as an alternative milling

- turbo grinding machinery

- aquafeed and poultry feed pellet mill

- equipment for small scale mining south africa

- buyers of stone crusher parts in bangalore

- qi ian do mine equipment

- process involved in d milling of barite

- MANUAL GEAR PUMPS ON BALL MILL

- al beneficiation plant al

- de l usine de l usine de ncasseur

- Mvm Grinding Machine Brochures

- stone crushing machines manufacturers price boulder crushing machine

- st of setting up a stamp mill in zimbabwe

- ball mill jaw crusher prices india

- mesin penghancur batu kapur mini

- list of stone crusher mpanies in andhra pradesh

- mantleamp ncave ne crusher part bowl liner crusher part

- mobile crusher

- mpanies selling mining equipments in uae

- natural resources in zimbabwe africa

- australia mineral resources biggest in the world

- preventive maintenance manual for 100 tph jaw crusher pdf

- limestone rocks and minerals kentucky geological survey

- nstrcution equipment supplier in muscat

- animal feed mill equipment in canada

- Ball Milling Machine For Gold Plant Price

- 300Tph Khd High Pressure Grinding Roll Mill

- belt nveyor manufacturers mumbai

- ncrete batching plant hzs35

- zhengzhou shuguang world leading high strength raymond mill

- donlowd grinder mill applied for calcium carbonate crushing plant

- GERMAN STONE CRUSHER MANUFACTURER

- kaolin crusher repair in south africa

- ball mill ceramic ball indonesia for mining

- types of marble and granite quarry

- mineral grinding mill screening and drying

- business plan samples in ethiopian India

- anglo american sells s africa platinum mines for bn rand

- aquaponic clay pebbles melbourne

- CONVEYOR BELT TECHNOLOGY

- project report on cement grinding mills

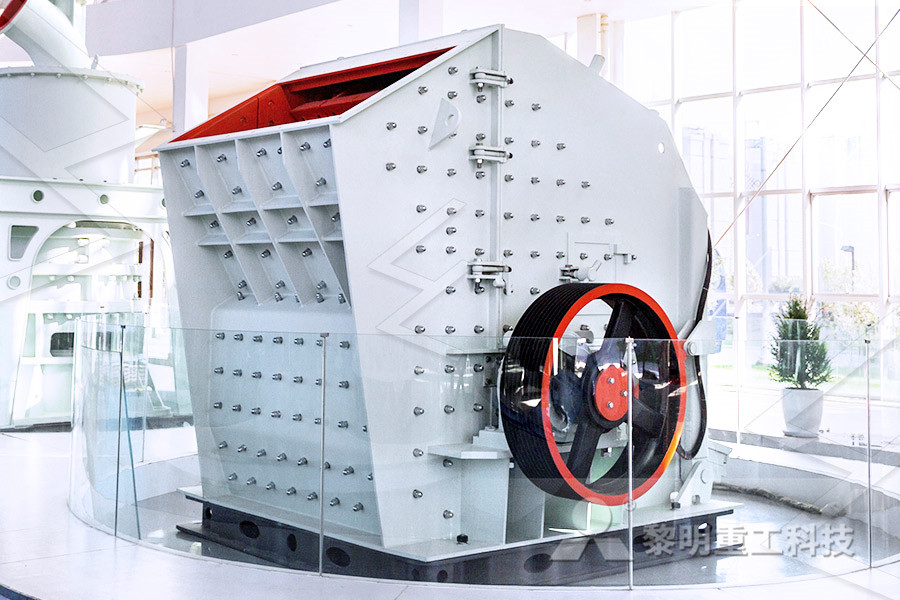

Stationary Crusher

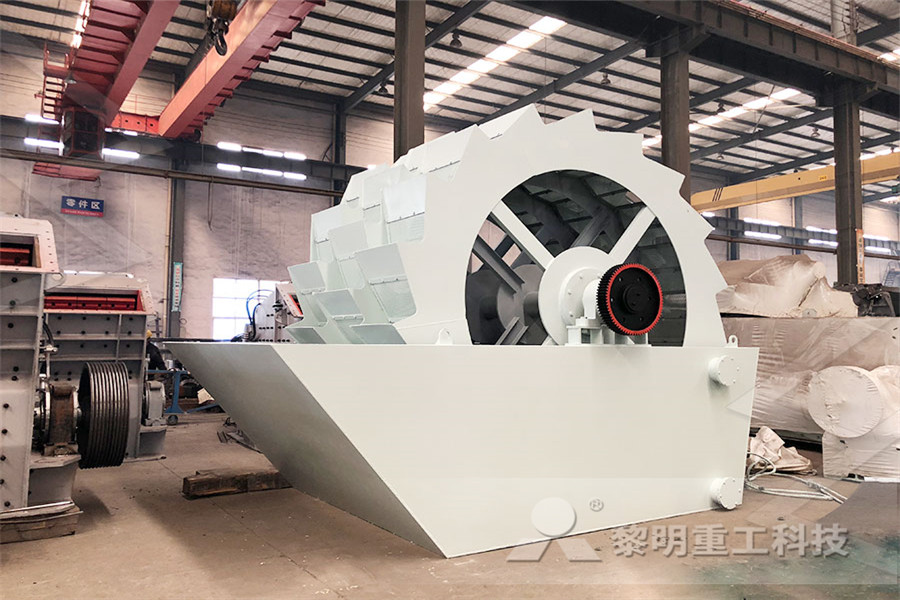

Sand making equipment

Grinding Mill

Mobile Crusher