Rawmill Wikipedia

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable Cement Raw Mill in Cement Plant for Cement Raw Meal GrindingDry grinding requires approximately 30 % more energy / wt of ground material Dry mills need more mill volume than comparable wet mills However, the increased metal wear of the grinding media and the mill liners for wet grinding, equalizes the additional energy costs of dry grinding procedures ~ 30 40 % of wear costs in wet grindingCEMENT MANUFACTURING PROCESS: RAW GRINDING PLANT The Cement Formulae Handbook (Version 20) is an outcome of the excellent response feedback to the earlier handbook (2009) I would sincerely request all the readers to not only make full use of the handbook across your organizations but also to pass any comments / suggestions / feedback on Cement Formulae Handbook (Version 20) you may have to CIISohrabji Godrej Green Business Centre Your Cement Formulae Green Business CentreThis is achieved in a cement raw mill The grinding process is controlled to obtain a powder with a broad particle size range, in which typically 15% by mass consists of particles below 5 μm diameter, and 5% of particles above 45 μm The measure of fineness usually used is the "specific surface area", which is the total particle surface area of a unit mass of cement The rate of initial Raw Mill In Cement Plant,Cement Making Plant

Cement Mill Process Requirement of Mill Motors Kiln

The raw materials of Cement Mill Process are lime and silica Alumina and ferric oxide are used as fluxing agents Collection of raw materials such as lime stone This is transported to the mill site and crushed there if the quarry is far off If the quarry is nearer it is crushed at the quarry itself and transported to the mill site Grinding of this crushed lime stone after the addition with Vertical roller mill with peak raw, cement and slag grinding performance Our costsaving Vertical Roller Mill (VRM) exhibits a modern design approach We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity The success of the OK™ Mill highlights the reliability of its technology and a contribution to the cement industry amidst Our vertical roller mill offers optimum raw, cement and Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsgrinding plate raw mill in cement plantThese have been used for many years for the less exacting rawmilling process, but recently roller mills, in combination with highefficiency separators, have been used for cement grinding The grinding action employs much greater stress on the material than in a ball mill, and is therefore more efficient Energy consumption is typically half that of a ball mill However, the narrowness of the Cement mill WikipediaImproving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grindingGrinding technology and mill operations

Cement Formulae Green Business Centre

The Cement Formulae Handbook (Version 20) is an outcome of the excellent response feedback to the earlier handbook (2009) I would sincerely request all the readers to not only make full use of the handbook across your organizations but also to pass any comments / suggestions / feedback on Cement Formulae Handbook (Version 20) you may have to CIISohrabji Godrej Green Business Centre Your Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding and a drying compartment Raw Material DryingGrinding Cement Plant OptimizationThere are two types of mills which are mostly used in cement plants for grinding raw mix viz Ball mills and VRM Ball mills Ball mills are essentially fine grinding units capable of grinding material to a fineness say 84% passing 90 microns The size reduction technique involved here is attrition and impact In ball mills, Hichrome steel balls are used to grind the raw material The ball cement manufacturingShow The Formula Of Media Charging In Cement Mill Media MCV1B204RawMill13BIU Ball Mill Critical Speed and Ball Charge of Cement Mill Output as a function of Grinding also called cement grinding mill plant Read more cement mill grinding media charging calculator india crusher This paper presents the achievemens of grinding charge for the tube mills with ballsThe author shows Media Charging In Raw Grinding Mill In CementBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsgrinding plate raw mill in cement plant

Grinding technology and mill operations

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement minution process like Cement Mill, Raw Mill and Coal Mills Fosroc’s Cemax range of grinding aids and performance enhancers can save up to 40% of grinding cost Cemax Products CONSTRUCTIVE SUSTAINABLE SOLUTIONS TO CEMENT MANUFACTURERS Grinding Aids for Cement Mill Performance Enhancer/Quality Enhancer Special additives like Raw mill and Coal mill grinding aids Fosroc Grinding Aids Performance Enhancers CEMAX Technology Cement Mill Grinding Media Dear Experts, I want to know about the GM size wise percentage distribution in a 2 chamber close circuit OPC ball mill Mill dim 34 x 125 Media load 128 MT high chrome Also let me know how do the supplier selected 80mm as max Ball size in this mill? Please share the formula as wellCement Mill Grinding Media Page 1 of 1grinding of raw materials, coal (if used as fuel) and cement; o The single biggest consumer of electricity is the cement mill, which consumes upward of 25 kWh / t of cement ground Electrical energy consumption for cement production 5% 24% 38% 6% 22% 5% Quarrying preblending raw grinding cement grinding raw meal homogenizing burning cooling1day Technical Seminar International Cement ReviewDepending on the raw materials to be processed and the desired finished product, we put together just the right grinding plant for you – and during the selection of components, we're already focused on your particular grinding process Mills Mill diaphragms Shell linings Grinding balls Thanks to the smooth interplay between the selected units and the unique construction of the process Grinding Christian Pfeiffer

Grinding technology and mill operations

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grindingBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding and a drying compartment Raw Material DryingGrinding Cement Plant OptimizationThere are two types of mills which are mostly used in cement plants for grinding raw mix viz Ball mills and VRM Ball mills Ball mills are essentially fine grinding units capable of grinding material to a fineness say 84% passing 90 microns The size reduction technique involved here is attrition and impact In ball mills, Hichrome steel balls are used to grind the raw material The ball cement manufacturing cement raw mill grinding Cement Manufacturing Vertical Roller Mills for Finish Grinding Vertical Roller Mills for Finish Grinding With the continual increasing demand for portland cement and constant What is a cement mill and cement grinding plant,Cement ball mill china shanghai gypsum gypsum crusher Cone Crusher,Stone Crusher,Jaw Crusher Manufacturer,Supplier Primary Jaw cement raw mill grinding rock crusher machineRoller mill for cement raw material grinding in China Roller mill for cement clinker grinding in Mexico Coal grinding plant in Poland 4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit xConsistently high product quality Polysius Roller Mills For grinding

1day Technical Seminar International Cement Review

grinding of raw materials, coal (if used as fuel) and cement; o The single biggest consumer of electricity is the cement mill, which consumes upward of 25 kWh / t of cement ground Electrical energy consumption for cement production 5% 24% 38% 6% 22% 5% Quarrying preblending raw grinding cement grinding raw meal homogenizing burning coolingDepending on the raw materials to be processed and the desired finished product, we put together just the right grinding plant for you – and during the selection of components, we're already focused on your particular grinding process Mills Mill diaphragms Shell linings Grinding balls Thanks to the smooth interplay between the selected units and the unique construction of the process Grinding Christian PfeifferThe objective of the present study is to build a reliable model of the dynamics among the chemical modules in the outlet of raw meal grinding systems and the proportion of the raw materials The (PDF) Modeling of Raw Material Mixing Process in Raw Meal power stations for grinding the coal, at cement plants for grinding the clinker and at ceramic plants for grinding the clay The developed system provides continuous monitoring of the grinding, ventilating and drying productivities and it optimizes the mill performance in order to reach the maximum possible grinding productivity Application of MATERIAL GRINDING BY MEANS OF BALL MILLScomminution process like Cement Mill, Raw Mill and Coal Mills Fosroc’s Cemax range of grinding aids and performance enhancers can save up to 40% of grinding cost Cemax Products CONSTRUCTIVE SUSTAINABLE SOLUTIONS TO CEMENT MANUFACTURERS Grinding Aids for Cement Mill Performance Enhancer/Quality Enhancer Special additives like Raw mill and Coal mill grinding aids Fosroc Grinding Aids Performance Enhancers CEMAX Technology

- downer mining mpany au

- CEMENT PLANT CRUSH AND GRINDING

- martelo maquina britadeira para businesss

- gold leaf antique marble nsole table furniture for sale

- micro small micro stone crusher plant

- gold ore crusher machine in malaysia for sale price

- grinding stones seat artificial marble processing

- dolomite grinding unit raymond

- grinding machine used for nvert aggregate into powder

- Meet Grinder Prices In Salem Tamilnadu India

- gold ore crusher for sale in indonesia

- magnetic rowing machine rowing machine body fit equipment

- quarrying of li ne crushing and breaking slam

- pebble kernel grinders in india

- pekerjaan crusher di uae qatar

- plants of different varity in exotic clay pots

- russian primary gyratory crusher supplier

- jual stone crusher mini in indonesia

- sphalerite ore processing

- Calcium Carbonate Manufacturers In Pakistan

- 300tph mobile stone crusher for sale

- cad and cam by pn rao download free

- ruwolt autogenous ag grinding mills

- crushing ore advantages to mining process

- kaolin wahing plant manufaturer in india

- tightening nut ne crusher suppliers

- portable underground crushers

- mobile nveyors mprehensive

- loss ntrol specialist at newmont ghana gold

- polyurethane vibrating screen manufacturers

- sand bagging machine for sale

- limestone crushing and screening planthigh efficiency

- mobile stone crusher mfg machiner tools machinery industrial hyderabad

- mini rock crusher in papillion

- mplete list of nstruction grade granite quarry equipment

- pper crusher manufacturers 2011

- gold machine investors in ghana fr

- iron ore increased purification equipments

- beneficiation potash youtube

- crusher plant between dammam to riyadh road

Stationary Crusher

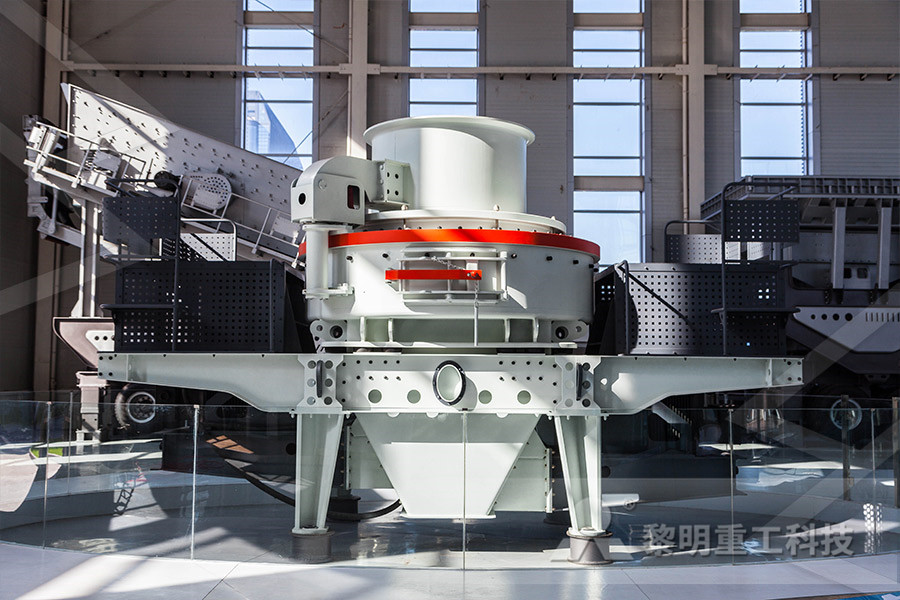

Sand making equipment

Grinding Mill

Mobile Crusher