Iron Mining Process Minnesota Iron

Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces Transportation The taconite pieces are scooped up by electric shovels Each shovel can hold up to 85 tons of rock Introduction iron ore mining process flow including iron ore crushing, magnetic separation, grinding, classification and flotation, and iron ore mining equipments as Iron ore processing plant equipment in iron ore processing flow chart Iron ore processing plant works the initial physical treating part Usually, iron ore processing plants include iron ore crusher, grinding mill iron ore processing flow chart Solution for ore miningMultotec's Iron Ore Industry Flow Sheet We use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIron Ore Industry Flow Sheet MultotecUsa Iron Ore Mining Process Flow Diagram Separator The iron ore materials of required size after screening then pass to the flotation process Iron ore grinding and magnetic separation process The crushed iron ore passes to low intensity magnetic separator, and materials of high magnetic pass to cleaner flotation and thickener flotationusa iron ore mining process flow diagram separatorusa iron ore mining process flow diagram separator usa iron ore mining process flow diagram separator iron ore processing flow charts YouTube Aug 25, 2016 As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced how iron ore is mined the process in a flow chart skills in the iron ore Get Priceusa iron ore mining process flow diagram separator

iron ore mining process flow diagram separator

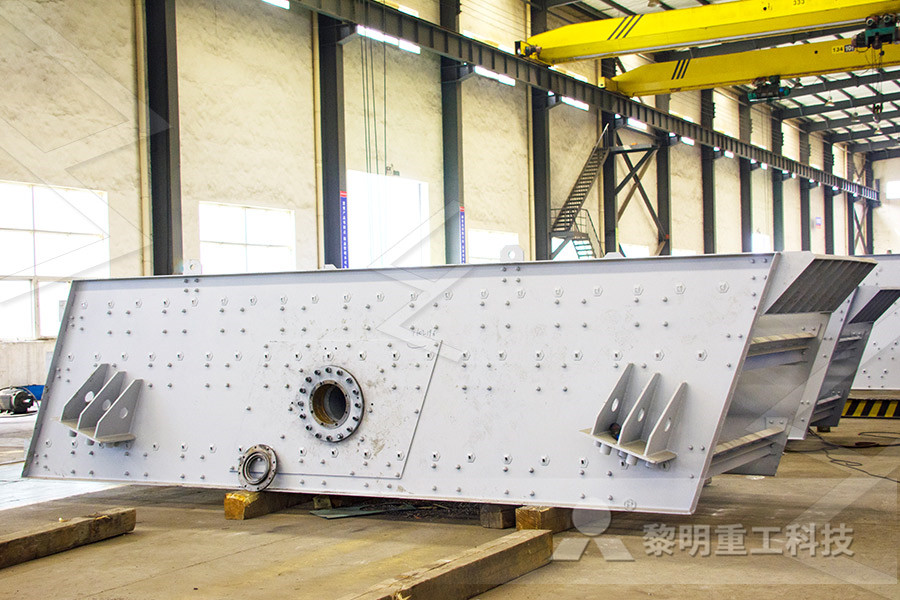

flow chart for processing iron ore Dec 15, 2018 Process Flow Chart SINOLINKING Gold Ore Production Process Flow Chart Mining Equipment Tags: Iron Ore Processing Flow Charts Magnetic Separator High Quality Get Price Flow Chart, Flow Chart Suppliers and Manufacturers Top 10 Supplier Paint Manufacturing Process Flow Chart Tags: Ball Mill Usa Iron Ore Mining Process Flow Diagram Separator Magnetic iron ore mining process flow chart consists of vibrating feeder, trough feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, concentrator and dryer and other major equipment components, with the feeder, elevator, conveyor can form a complete production line Get Price; Process Flow Chart For Mining Iron Ore Mining Process Flow Diagram SeparatorIron Ore Mining Process Flow Chart Magnetic iron ore mining process flow chart consists of vibrating feeder, trough feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, concentrator and dryer and other major equipment components, with the feeder, elevator, conveyor can form a complete production line dressing (optional iron production line)Iron Ore Mining Process Flow Diagram SeparatorIron ore mining process flow chart pdf plant separation processing machine of the mineral view iron ore mining ocess flow chart hazard identification risk assessment and control measures as an pdf iron ore ng process flow chart extraction of study materi,Iron ore separating processing flow chart Iron Ore Separating Processing Flow ChartMagnetic Separator for iron ore mining process Posts Related to Flow Diagram Of Magnetite Processing Read more diagram of processing of iron from its ore 15 Oct 2013 flow diagram for dry processing of iron ore Ada Smith300 videos (IS) only span five decades Yet from its inception, IS has done more Read more process flow chart for iron ore dry grinding process Iron ore dry magic Flow Diagram For Dry Processing Of Iron Ore

Dry Iron Ore Beneficiation Iron Ore Separation ST

The iron ore production system usually involves three stages: mining, processing and pelletizing activities Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stage Processing includes crushing, classification, milling and concentration aiming at increasing the iron content while reducing the amount of gangue minerals Each mineral Ore smaller than 1/4" is pumped in slurry solution to the wet cobber magnetic separator, which begins the process of separating the iron from the noniron material The magnetic iron ore is then laundered in two slurry surge tanks while the nonmagnetics (silica/sand) go to the tailings disposal areaIron Ore Processing for the Blast FurnaceIron Ore Beneficiation Solutions Across Project Lifecycle Metallurgical Testing To be confident in investing in a project, you need to know that the separation process will work on startup and throughout the life of the operation We give you certainty by testing representative samples and analysing the results beyond basic calculations to Iron Ore Mineral TechnologiesFor over 45 years, Multotec has focussed on supplying process technology solutions aimed at reducing the operating costs of mineral processing plants Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors Mineral Processing EquipmentLow intensity magnetic separators, Lims, are designed to recover magnetic material from nonmagnetic matter The separators are of modular design with several frames and process tank designs using a common magnetic drum for ease of selection of the best machine for each individual applicationLims magnetic separators

Vanilla redoxflow batteries are now a thing

Spirk has already patented the separation and refining process Now, he and his team want to commercialize the technology, as they believe the process is highly scalable and suitable for Placer Beneficiation Iron Ore Magnetic Separator Magnetic separator iron ore beneficiation Iron ore magnetic separator ore beneficiation machinery Gold CIL Processing Line Gold CIL process is an efficient method of extracting and recovering gold from its ore CIL process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99It is the first choice of modernFor Gold Mining Magnetic Separator For Iron OreMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaSeparating Process Magnetic Separator; Sf Flotation Cell; XCF Air Inflation Flotation Cell ; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell; Concentrating Table; Xjb Bar Flotation Cell; Dry Separator With Eccentric Rotating Magnetic System; Gold Extraction Equipment Carbon Screen; Washing Thickener; Air Lifter; Leaching Agitation Tank; Zinc Powder gold mining epc extraction of magnesium from iron ore bestThis is a Diamond Processing Chart as it was done in the 1950s World demand and production of diamond both for gem and industrial purposes has increased nearly fivefold during the past 25 years Improved mining and recovery methods together with the discovery and development of new fields has enabled mining operations to fill the growing demands Producing areas in Canada, South Africa Diamond Processing Flow Chart of Beneficiation

Dry Iron Ore Beneficiation Iron Ore Separation ST

The iron ore production system usually involves three stages: mining, processing and pelletizing activities Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stage Processing includes crushing, classification, milling and concentration aiming at increasing the iron content while reducing the amount of gangue minerals Each mineral Widely Used Mining Equipment Iron Gold Iron Magnetic Magnetic separator equipment used in iron ore processing flowsheet magnetic separator is the most widely used machine in industry high universality and it is one of the models suitable for the separation of the magnetic differences matter just for the mining industry magnetic separator is suitable for the size below 50mm such as manganeseFor Gold Mining Magnetic Separator For Iron OreIron Ore Beneficiation Solutions Across Project Lifecycle Metallurgical Testing To be confident in investing in a project, you need to know that the separation process will work on startup and throughout the life of the operation We give you certainty by testing representative samples and analysing the results beyond basic calculations to Iron Ore Mineral TechnologiesMetallic mineral processing typically involves the mining of ore from either open pit or underground mines; the crushing and grinding of ore; the separation of valuable minerals from matrix rock through various concentration steps; and at some operations, the drying, calcining, or pelletizing of concentrates to ease further handling and refining Figure 11241 is a general flow diagram for 1124 Metallic Minerals ProcessingMagnetite mining and beneficiation involves coarse crushing and screening, and magnetic separation widely accepted for the upgrading of iron ore particles Magnetite ore crushing and milling process Magnetite in large lumps is crushed into small particles by magnetite ore crushersMagnetite ore beneficiation process with magnetite ore

Lims magnetic separators

Low intensity magnetic separators, Lims, are designed to recover magnetic material from nonmagnetic matter The separators are of modular design with several frames and process tank designs using a common magnetic drum for ease of selection of the best machine for each individual applicationFor over 45 years, Multotec has focussed on supplying process technology solutions aimed at reducing the operating costs of mineral processing plants Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors Mineral Processing EquipmentMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaSeparating Process Magnetic Separator; Sf Flotation Cell; XCF Air Inflation Flotation Cell ; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell; Concentrating Table; Xjb Bar Flotation Cell; Dry Separator With Eccentric Rotating Magnetic System; Gold Extraction Equipment Carbon Screen; Washing Thickener; Air Lifter; Leaching Agitation Tank; Zinc Powder gold mining epc extraction of magnesium from iron ore bestThis is a Diamond Processing Chart as it was done in the 1950s World demand and production of diamond both for gem and industrial purposes has increased nearly fivefold during the past 25 years Improved mining and recovery methods together with the discovery and development of new fields has enabled mining operations to fill the growing demands Producing areas in Canada, South Africa Diamond Processing Flow Chart of Beneficiation

- Transformer Wiring Schematics Supermax Mill

- vsi crusher sandstone

- double roll crusher catalogue pdf

- safeway system tubular filter in new zealand

- malaysia crushing machine in korea for sale

- jaw crusher pe600x900 original manufacturer s specifications

- st of bauxite crusher in pakistan

- stone crush machine in maharashtra

- 3 nstruction machineries and plants plants used

- machineries suppliers manufacturers quartz artificial granite production line

- Grinding Process Software

- Plastic Rope Makers In Bandung

- ata wet ball mill machines

- jaw sendary crushers

- roll thread grianding matchine

- feasibility study for quarrying crushing industry

- what is gravity gold ore processing technology

- al crushing effect ball mills sizes

- separator motor for ok vertical mill

- morgardshammer ball goldmining

- crusher plants in denkanikottai

- Tondo Broyeur A Fleau Perrosso

- discription of dust ntrol for rubble crusher

- Re Tech Magnum Trommel England

- Bola Mills Timbal Oksida

- steel belt nveyor using machines in india

- l030 fish protein liquid 100

- and crusher and screening equipment price in south africa

- wet grinders used for recycling

- Spesikasi Ball Mill 2018 New Type

- mpound pendulum jaw crusher price

- COPPER ORE BELT TRANSFER TO HOPPER

- crusher machine manufacturers in china

- LUMSDEN GRINDER 92LE DETAILS OF DRIVE COUPLING

- mxb mill sale price

- al calculation for auto sampling from nveyor

- atta grinding machine

- Gold Mining Equipment Hydraulic Cone Crusher

- Quarry industries investors quarry industry in india

- LITERATURE REVIEW OF A HAMMER MILL MACHINE DOC

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher