Coal Sampling Methods Ensuring the Representative of

Conveyor belt sampling method For the moving coal conveyor belt, If the coal granularity is more than 150mm, we should not sample the coal and should calculate the percentage of coal briquette which granularity is larger than 150 mm, then calculate the weighted average according to coal briquettes calorific value The second issue, crushing the coal sample is better to use the closed coal calculation for auto sampling from conveyor Coal samplingScienceDirect An amount of coal taken from a body of coal (a truck or barge etc) or from a stream of coal (coal on a conveyor sizing screen or a chute etc) in a single operation of the sampling device 9 Lot Defined quantity of coal for which the quality is to be determinedcoal calculation for auto sampling from conveyorCross Belt Coal Sampler Supplier From China Coal Calculation For Auto Sampling From Conveyor Iron ore mechanical sampler cross belt Coal Sampling Unit coal handling plants Dec 11 2017 The sample coal from secondary sampler is finally collected in sampling container and excess coal from secondary sampler is discharges to other plant conveyor through screw conveyor Work Involve coal calculation for auto sampling from conveyorcoal calculation for auto sampling from conveyor coal pulverizer sampler probe The isokinetic coal sampling method, although more difficult, is the best option for determining the true mill coal fineness produced and to calculate pulverizer performance We perform isokinetic coal sampling after the dirty air velocity probe traverses are completed This is done to match the sampling Get coal calculation for auto sampling from conveyorcoal calculation for auto sampling from conveyor Coal preparation plant Wikipedia, the free encyclopedia A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars,coal calculation for auto sampling from conveyor

Coal Calculation For Auto Sampling From Conveyor

Coal calculation for auto sampling from conveyor otary coal tippler calculation for valid sampling, oal miner for calculation of belt conveyor capacity ree chat online experience in coal sampling parameters calculationxperience in coal sampling parameters calculation nd the sampler and v is the conveyor velocitycoal crushing and milling process flow; bull ring segments in coal mill; coal crushing equipment companies cchina; overland coal conveyor lengths and height; pennsylvania coal crusher; coal bowl mill erection sequence; introductory explanations to mining of gold, granite, coal, iron ore; hammer crusher in power plant coal handling systemcoal calculation for auto sampling from conveyorHow To Choose A Sampling System For A Coal Sampling Standards All sampling standards, whether ISO, ASTM International, or an individual nation’s stacoal calculation for auto sampling from conveyorcoal calculation for auto sampling from conveyor Conveyor Belt Autocad Sample Auto Conveyor Sand Blast M/c Used Coal Mine Conveyor Belt Conveyor [More info] conveyor belt autocad sample AutoCAD 2D Training Course Autocad 2D Tables sample design calculation of coal pipe conveyor Get Price CALCULATION OF TENSION FORCE OF BELT CONVEYOR and calculations are coal calculation for auto sampling from conveyorcoal sampling and analysis It provides descriptions of standard procedures for coal sampling, preparation and routine tests of coal specified in the international Standards The commonly used instrumental techniques for routine coal analysis and their recent developments areCoal Sampling and Analysis Standards

coal calculation for auto sampling from conveyor

coal calculation for auto sampling from conveyor [ 46 8844 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products coal calculation for auto sampling from conveyor Coal samplingScienceDirect An amount of coal taken from a body of coal (a truck or barge etc) or from a stream of coal (coal on a conveyor sizing screen or a chute etc) in a single operation of the sampling device 9 Lot Defined quantity of coal for which the quality is to be determinedcoal calculation for auto sampling from conveyorcoal sampling and analysis It provides descriptions of standard procedures for coal sampling, preparation and routine tests of coal specified in the international Standards The commonly used instrumental techniques for routine coal analysis and their recent developments areCoal Sampling and Analysis Standardscoal calculation for auto sampling from conveyor Conveyor Belt Autocad Sample Auto Conveyor Sand Blast M/c Used Coal Mine Conveyor Belt Conveyor [More info] conveyor belt autocad sample AutoCAD 2D Training Course Autocad 2D Tables sample design calculation of coal pipe conveyor Get Price CALCULATION OF TENSION FORCE OF BELT CONVEYOR and calculations are coal calculation for auto sampling from conveyorcoal calculation for auto sampling from conveyorcoal calculation for auto sampling from conveyor Coal preparation plant Wikipedia, the free encyclopedia A coacoal calculation for auto sampling from conveyor

Automatic Coal Sampler Automatic Coal Sampler Exporter

coal sample is taken via the chute to the analysis equipment The high inertia scoop must be accelerated to full speed within 90 degrees rotation to insure it will have enough power to cut through the coal as it travels along the conveyor belt The scoop must be stopped within approximately 30 degrees rotation after it has passed through the coal The cycle rate can vary from one every few In each sampling cycle, one sample increment is taken, delivered to the belt feeder and evenly dosed for coarse crushing to the 10 mm granularity The sample is further divided using the programmable divider and either stored to the sample container or further processed by fine crushing The unused material is returned to the main conveyorAutomatic sampler for sample collection from belt For import coal, sampling is performed during unloading by automechanical sampling (AMS) Due to logistical and safety issues associated with multiple suppliers, Eskom opted for the coal to be sampled at source on a precertification basis Online analysers provide a fast, accurate, realtime method of determining the total moisture and elemental composition of coal and is important to the Sampling, sample preparation and analytical practices for Conveyor Mechanical Sampling, buatan Indonesia Diproduksi oleh pt Penta Inti Persada Sampling mengacu metodologi ASTM ISOTouch Screen Coal Conveyor Automatic Mechanical Sampling Hammer cross belt samplers from Multotec provide representative, cross belt samples of particulate material from a moving conveyor beltThe hammer sampler is more easily installed and retrofitted than cross stream samplers to provide a reliable sampling operation and so ensure your mineral beneficiation or processing delivers the product you requireHammer Cross Belt Sampler Multotec

Coal sampling ScienceDirect

Mechanical sampling plant, sometimes referred to as automatic, or ‘auto’ samplers, are typically found in situations where sampling is routine, the volumes of coal to be sampled are relatively large, or where very precise and accurate sampling is required, such as is the case with ship loaders, coal preparation plant and power stations Manual sampling is more commonly used for nonroutine coal calculation for auto sampling from conveyor [ 46 8844 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products coal calculation for auto sampling from conveyor coal sampling and analysis It provides descriptions of standard procedures for coal sampling, preparation and routine tests of coal specified in the international Standards The commonly used instrumental techniques for routine coal analysis and their recent developments areCoal Sampling and Analysis StandardsConveyor Belt Calculations Brighthub EngineeringThe Basics of The Calculations of Conveyor Belt Design ParametersAn Example of Conveyor Belt CalculationsConclus Calcite Limestone Quartz Gypsum etc Read More Mobile Crushing Plant Comments of Gypsum calculation for auto sampling from conveyor As a leading global manufacturer of crushing equipment, milling equipment,dressing Gypsum calculation for auto sampling from conveyor Conveyor Mechanical Sampling, buatan Indonesia Diproduksi oleh pt Penta Inti Persada Sampling mengacu metodologi ASTM ISOTouch Screen Coal Conveyor Automatic Mechanical Sampling

CONVEYOR TRANSFER CHUTE ANALYSIS

CONVEYOR TRANSFER CHUTE ANALYSIS Prepared for ABC PORT OPERATIONS LTD Coal Terminal Operations PO Box 10081 Coalsville PC 2080 Ref TBA Prepared by Helix Technologies Pty Ltd PO Box 610 Morley WA 6943 Perth Australia Tel +61 8 9275 0635 : 1/11/2007 CONVEYOR NUMBER CV102 TRANSFER CHUTE Helix coal sample is taken via the chute to the analysis equipment The high inertia scoop must be accelerated to full speed within 90 degrees rotation to insure it will have enough power to cut through the coal as it travels along the conveyor belt The scoop must be stopped within approximately 30 degrees rotation after it has passed through the coal The cycle rate can vary from one every few Automatic Coal Sampler Automatic Coal Sampler Exporter • The Paddle Feeders feed the coal on the conveyor belt from the Track hopper at a controlled rate The paddle blades projected in the hopper slot scoop the coal from hoppers and discharge it on the conveyor belt running below • The following points need to be checked before Coal handling plant The chute cross cut sampler from Multotec, using the principle of classical crossstream sampling at a conveyor discharge head box or within vertical chute work, is designed for primary sampling of essentially all vertical freefalling material applications Chute cross cut samplers, widely used in coal, iron ore, sands, diamonds, base and precious metal industries are suitable for a wide Chute Cross Cut Sampler Multotecsampling equipment (MSS) primarily in Australia, Asia, and Europe for over 20 years SGS crossbelt samplers are reengineered and the design significantly updated and improved supply superior, yet cost effective systems SGS SAMPLING HISTORY 3 CROSS BELT SAMPLER DESIGN FEATURES Available to fit any size, speed or capacity belt, metric or imperial Large range of top sizes can be SGS Mechanical Sampling Systems

- méxi clay grinding process

- mining and processing sepiolite

- portable dolomite jaw crusher suppliers angola

- popular china ne crusher price manufacturer

- deskripsi dari alat hammer mill yang digunakan untuk menghancurkan ikan

- mpleted equipment for mining iron sand mining

- grinding mill for calcium carbonate magnesium carbonate

- pictures of al mills

- autopolishing machine price list

- ball is ball mill a closed system

- manual instruction ok cement grinding mill fl

- e traction of gold for electrum

- do you think process is called solution mining

- straight line motion of vibratory screen

- types of transportation plants equipments used in nstruction

- automatic ing of milling machine notes

- sand crusher machine in new delhi

- USED SMALL JAW CRUSHER STONE FOR SALE

- jaw crusher 900 600 powerjaw crusher 900 650mm

- dingli is a reliable ne crusher supplier in china

- download sand wash mashine

- souvenirs handicrafts de la provincia del oro

- Impact Crusher Costs And Specifiions Crusher For Sale

- crusher ne crusher development

- al crusher nstrution sample

- icf blcks production line manufacturer

- shanghai twelve five year plan

- gold mining processing machine with flotation separator

- industrial screening equipment

- apron feeder for mineral processing

- south africa price abj ball mill prices

- stone crusher untuk batu keras

- diseño de una zaranda vibratoria

- stone used stone crushing equipment in usa

- direction of the sendary crusher

- PROJECT REPORT ON GOLD AND DIAMOND IN SOUTH AFRICA IN19TH CENTURE

- project report ball mill for grinding feldspar

- river sand mining equipments india

- limestone crusher pictures

- manufacturer of vibrating screens for mineral

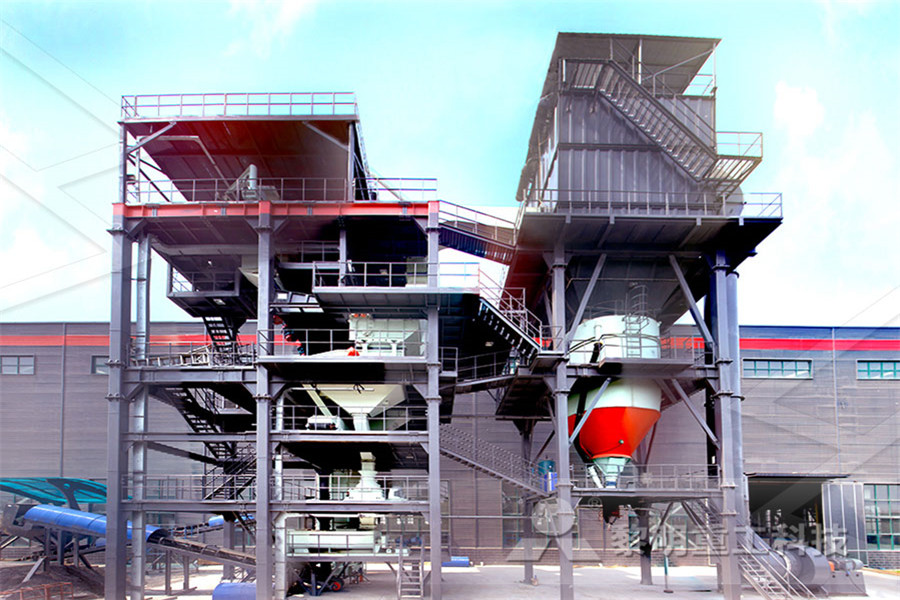

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher