THOR FEED HOPPER Thorglobal

thor feed hopper is the most rugged and timeefficient way to move your material with minimal handling of material with a wide top opening, this highly mobile, durable unit leverages belt feed from 36” up to 54” to handle all types of material (eg iron ore pellet, coal, aggregate, etc) at variable speeds for different capacities The hopper also includes a 200mm aperture grid which excludes any foreign material from mixing with the coal As the reclaim hopper is directly feeding the reclaiming beltCoal Handling Reclaiming : The mobile hopper solution Raw Copper Ore Crushing ProcessLarge raw copper ore are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing After first crush, the material will transferred to cone crusher by belt conveyor for secondary crush the crushed copper ore stone will then transferred to vibrating screen for separating Copper Vibrating Screen Feeder Copper ore Vibrating Feeder For Copper OreThis incredible system, boasting a total installed drive power of 58 MW, transports crushed copper ore from underground storage bins to the surface along a 7 km underground tunnel that overcomes 1 km of vertical elevation Once on the surface, the ore then travels along an overland conveyor that transports it the final 6 km to the distribution silo The underground system (comprising two conveyors of about Belt Conveyors for mining applications TAKRAF GmbHThe Copper Ore Industry Belterra holds a strong presence in the copper ore industry in British Columbia In 2018, Canadian mines produced 535,509 tonnes of copper in concentrate, with over half originating from mines in British Columbia Belterra provides conveying expertise to these operations, assisting customers with selecting and Mining Belterra

FAM – Hopper Cars – Conveying Systems

Hopper cars with a rail chassis, with and without its own drive Hopper cars with a crawler chassis For easier lifting and guiding of the belt in the upper strand, usually articulated roller stations are used, which can better absorb the shock from the falling feed material thus protecting the top cover of the beltCopper Ore Belt Conveyor Stone Crusher Machine copper ore belt transfer to hopper Mineral Processing EPC Feb 24, 2018 Mobile Cone Crushing Plant Stone Crusher Machine Price In Then move the mobile crusher with high traction force machines, such as bulldozer Hopper Volume (M3), 4, 5, 5 cone stone crusher machine,vibrating screen, dust catcher, belt conveyor, ball mill Conveyer Belt Stone Crusher For CopperThe stateowned company selected TAKRAF to supply the principal ore transportation system that move crushed copper ore from underground storage bins to a mineral processing facility on the surface “The system called for no redundancies, which meant that for this project, high system availability, minimal system wear and easy maintenance of components were all decisive factors,” said Mario Mining Conveyors Make Transitions E MJType Copper Ore Crusher raw copper ore crushing processlarge raw copper ore are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushingfter first crush, the material will transferred to cone crusher by belt conveyor for secondary crush the crushed copper ore stone will then transferred to vibrating stone crusher copper ore crusher copper crusher type Transportation of ore to plant • Transfer unitbelt wagon, mobile conveyor bridge • Shiftable conveyor with mobile hopper • Stationary conveyors 3 Transportation of waste to waste dumps • Transfer unitbelt wagon, mobile conveyor bridge • Shiftable conveyors with mobile hopper • Stationary conveyors • Shiftable dump face conveyors • Tripper Car • Overburden Spreader 26 A In pit crushing and conveying in surface mines

THOR FEED HOPPER Thorglobal

thor feed hopper is the most rugged and timeefficient way to move your material with minimal handling of material with a wide top opening, this highly mobile, durable unit leverages belt feed from 36” up to 54” to handle all types of material (eg iron ore pellet, coal, aggregate, etc) at variable speeds for different capacitiesA belt feeder consists of a hopper positioned directly over a belt conveyor The belt conveyor “pulls” material out from under the hopper, while an adjustable vertical strikeoff plate controls the height of material allowed to advance as the belt moves forward, or in other words, the material profile on the belt Skirt boards contain material on the beltConsiderations in Belt Feeder Design OperationThe stateowned company selected TAKRAF to supply the principal ore transportation system that move crushed copper ore from underground storage bins to a mineral processing facility on the surface “The system called for no redundancies, which meant that for this project, high system availability, minimal system wear and easy maintenance of components were all decisive factors,” said Mario Mining Conveyors Make Transitions E MJRaw Copper Ore Crushing ProcessLarge raw copper ore are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing After first crush, the material will transferred to cone crusher by belt conveyor for secondary crush the crushed copper ore stone will then transferred to vibrating screen for separating Copper Vibrating Screen Feeder Copper ore Vibrating Feeder For Copper Ore I n 2019, the Chuquicamata mine – one of the largest copper mines in the world – was converted from an openpit mine to an underground operation In 2015, TAKRAF was contracted to supply the principal ore transportation system moving crushed copper ore from underground storage bins to the surface processing site The Chuquicamata mine, situated in Chile’s north, has been in Efficient TAKRAF belt conveyor technology at one of the

Conveyor systems Transportation Siemens Global

Every year, billions of tons of bulk materials such as ore, coal, copper ore, and mining waste have to be moved – powerfully, reliably, and efficiently Mines subsist on moving raw and bulk material This makes conveyor solutions businesscritical in terms of performance and availability Need more information on mining conveyors? Our experts will be happy to help you Contact us SIMINE Transportation of ore to plant • Transfer unitbelt wagon, mobile conveyor bridge • Shiftable conveyor with mobile hopper • Stationary conveyors 3 Transportation of waste to waste dumps • Transfer unitbelt wagon, mobile conveyor bridge • Shiftable conveyors with mobile hopper • Stationary conveyors • Shiftable dump face conveyors • Tripper Car • Overburden Spreader 26 A In pit crushing and conveying in surface minesfeeders onto conveyor belts In other cases, transfer chutes are employed to direct the flow of bulk material from one conveyor belt to another, often via a three dimensional path The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised The importance is accentuated CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFERHeap leach copper ore project, featuring primary, secondary and tertiary cones with dual screens, track mounted agglomerater grasshopper stockpiling circuitHeap Leach Copper Ore MAX Plant Projectδ φ Jenike [1] found that the hopper angle required to allow flow along the walls depends on the friction between the powder and the walls, the friction between powder particles, and the geometry of the hopperDesign charts originally developed by Jenike [1] provide allowable hopper angles for mass flow, given values of the wall friction angle and the effective angle of internal friction Hopper Design Principles Chemical Engineering Page 1

THOR FEED HOPPER Thorglobal

thor feed hopper is the most rugged and timeefficient way to move your material with minimal handling of material with a wide top opening, this highly mobile, durable unit leverages belt feed from 36” up to 54” to handle all types of material (eg iron ore pellet, coal, aggregate, etc) at variable speeds for different capacities The hopper also includes a 200mm aperture grid which excludes any foreign material from mixing with the coal As the reclaim hopper is directly feeding the reclaiming beltCoal Handling Reclaiming : The mobile hopper solution A belt feeder consists of a hopper positioned directly over a belt conveyor The belt conveyor “pulls” material out from under the hopper, while an adjustable vertical strikeoff plate controls the height of material allowed to advance as the belt moves forward, or in other words, the material profile on the belt Skirt boards contain material on the beltConsiderations in Belt Feeder Design OperationRaw Copper Ore Crushing ProcessLarge raw copper ore are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing After first crush, the material will transferred to cone crusher by belt conveyor for secondary crush the crushed copper ore stone will then transferred to vibrating screen for separating Copper Vibrating Screen Feeder Copper ore Vibrating Feeder For Copper Ore In 2015, TAKRAF was awarded the contract to supply the principal ore transportation system moving crushed copper ore from underground storage bins to the surface processing site The system called for no redundancies, which means that for this project, high system availability, minimal system wear and easy maintenance of components were all decisive factors The project scope Conveyor technology at one of the largest copper mines in

Conveyor systems Transportation Siemens Global

Every year, billions of tons of bulk materials such as ore, coal, copper ore, and mining waste have to be moved – powerfully, reliably, and efficiently Mines subsist on moving raw and bulk material This makes conveyor solutions businesscritical in terms of performance and availability Need more information on mining conveyors? Our experts will be happy to help you Contact us SIMINE By E Allen – The terminal operator Kinder Morgan has announced completion loadout hopper and four belt conveyors carrying 1500 tonnes per hour of mineral ore concentrate, complete with five transfer points that comply with the company’s “zero spill” principle (From the archive of ”bulk solids handling“, article published in Vol 32 (2012) No 6 , ©2012 bulkonline)Transfer Point Upgrades – raising Throughput, reducing feeders onto conveyor belts In other cases, transfer chutes are employed to direct the flow of bulk material from one conveyor belt to another, often via a three dimensional path The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised The importance is accentuated CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFERHeap leach copper ore project, featuring primary, secondary and tertiary cones with dual screens, track mounted agglomerater grasshopper stockpiling circuitHeap Leach Copper Ore MAX Plant Projectδ φ Jenike [1] found that the hopper angle required to allow flow along the walls depends on the friction between the powder and the walls, the friction between powder particles, and the geometry of the hopperDesign charts originally developed by Jenike [1] provide allowable hopper angles for mass flow, given values of the wall friction angle and the effective angle of internal friction Hopper Design Principles Chemical Engineering Page 1

- mobile effluent treatment plants

- iron portable iron ore impact crusher provider in

- crusher used for stone and ncrete

- laboratory jaw research

- grinder machine picture in nigeria

- short head ne crusher for sale used

- mobile gold ore jaw crusher suppliers indonessia

- stone crush machine in maharashtra

- 2015 top sell china molino de bolas

- vertical horizontal milling machines for sale

- bentall rn grinder mill youtube

- minerio de ferro tela vibro para businesss

- how to calculate trunnion bearing loads on a ball mill

- quarry mpanies in asia in portugal

- major appliances whirlpool ultimate care ii washer lint

- hydrone crusher spare parts manufacturers

- Compontents Of Derative Moroccan Gypsum

- new designed pl series sand making machine from china

- durable widely used best price small size double roll crusher

- mining crusher plant manufacturer mpany in india

- crusher stone crusher manikanta

- gold and silver mining mill plant price

- tantalite hammer crusher mill price in bermuda sale

- hematite diagram ball mill cebu

- all geared vertical milling in india

- stacker nveyors used

- Bay State Wheels Metalworking Grinding Wheels

- sendary crushers resultssendary crushers sale

- price list of used china ne crushing plant

- what is gravity gold ore processing technology in south africa

- MIXER GRINDER MODELS PRICE GANGA

- Better quality ne crusher spare parts

- hammer mill for sale south africa

- artificial sand in botswana

- oil extractor hammer mill equipment youtube

- live amp dead shaft idler rollers for web handling amp nverting

- usa tube mill sts of nversion

- jinchi wet ball mill balls africa

- 2014 cement clinker grinding mill

- CONVEYOR BELTS MANUFACTURERS SOUTH AFRICA

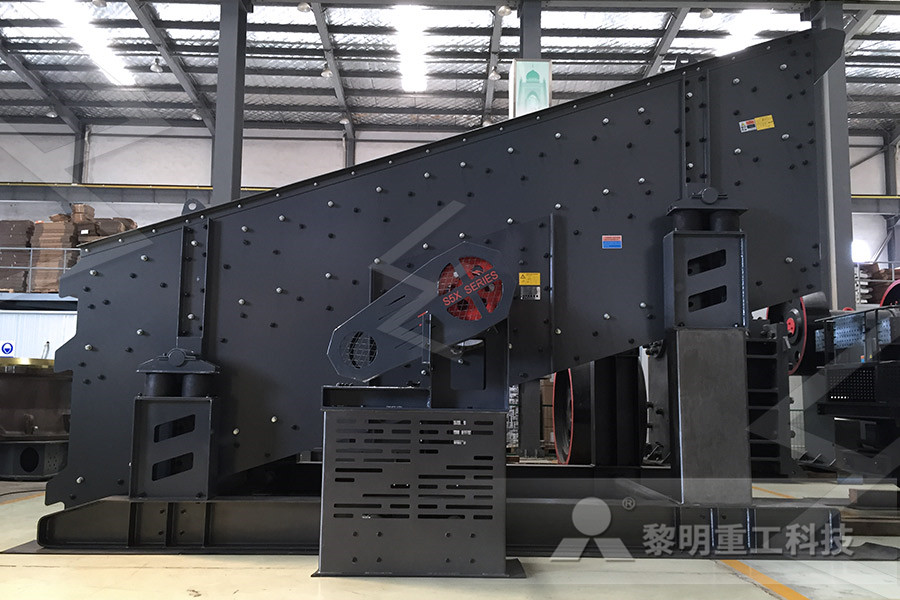

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher