Concrete Floor Grinder Machine Floor Grinder for Sale

The Intelligent concrete grinder polisher is mainly used for grinding ground in our company It can effectively polish terrazzo, concrete surface, epoxy mortar layer, and old epoxy floor After grinding and solidification, the concrete floor becomes more flat, resistant to pressure and wear, as bright as a mirror, and easy to cleanConcrete Grinding Pads #30 50 100 200 400 Grit Set Ceramic Bond 3pc Each Brand New C $59939 Top Rated Seller Top Rated Seller Buy It Now From United States +C $2970 shipping Customs services and international tracking provided Von Arx FR100 Concrete Stone Steel Scaler Scarifier, Grinder WITH DUST COLL PreOwned C $66467 Top Rated Seller Top Rated Seller or Best concrete grinder eBayCement grinding plants Intelligent down to the last detail Engineering, procurement and commissioning: The Christian Pfeiffer portfolio for the cement industry is very comprehensive We develop innovative system components for grinding plants used in the cement industryCement industry Christian PfeifferThe Intelligent concrete grinder polisher is mainly used for grinding ground in our company It can effectively polish terrazzo, concrete surface, epoxy mortar layer, and old epoxy floor After grinding and solidification, the concrete floor becomes more flat, resistant to pressure and wear, as bright as a mirror, and easy to cleanConcrete Grinder For Sale – Good Machinery Equipments Ltd Concrete grinding is actually a lot easier than I thought it was going to be Obviously, this depends so much on what you are trying to do and the circumstances, but the basic operation of the machines was easier than expected I definitely had some issues that if avoided, would have help the job go faster and the results would have been better5 Things I Learned When Grinding Concrete for the First Time

Intelligent Solutions For Cement Production Automation

The Intelligent Solutions For Cement Production Automation Process Training Simulation webinar is part of the KHD Technical Webinar Series that will cover a range of topics from across the cement manufacturing process, including: Parts Services (28 July)The system Intelligent Machines has developed includes all necessary software and hardware to convert a standard floor grinder to an autonomous one The system is also suitable for other applications where there is a need for positioning with a cmlevel accuracy in open spaces (eg example automatic floor care and automated logistics)Floor Grinding Robot Intelligent MachinesThe grinding process occurs in a closed system with an air separator that divides the cement particles according to size Material that has not been completely ground is sent through the system again This highly energy consuming process needs automation and optimization to ensure today’s quality demands): Automation solutions for the Cement Industry for more how to concrete videos howtocement/HowToGrindConcreteGrindingCementhtml thanks to OhioConcreteRepair for providiHow to grind a Concrete Trip Hazard, Fix Raised Concrete Vertical grinding mill is the main grinding equipment for the newtype dry cement raw meal production, raw material grinding process in cement industries accounts for approximately 50–60 % of the total energy consumption The dynamic characteristics of the variables in the raw material vertical mill grinding process are strongly coupled, nonlinear, and large time lag The process of Modeling Based on the Extreme Learning Machine for Raw

Concrete Grinder For Sale – Good Machinery Equipments Ltd

The concrete floor grinder machine is popular in the road industryThe weight of the floor grinding machine is different according to a different areaAs largescale equipment, the intelligent concrete grinding equipment not only has an intelligent floor grinding method but also supports the dustfree floor construction conceptIt can create a dustfree, healthy, and easy construction Intelligent Motor Control for Efficient Grinding Operations You are looking for consistent product size, efficient energy use, and continuous production Under harsh operating conditions, you require control equipment that provides high performance, reliability, and robustness Equipment suppliers rely on our variable speed drives, intelligent Crushing and Grinding Rockwell AutomationInternational Cement Review: Building an intelligent cement plant April 2020 (English pdf Article) Collaborative services for grinding solutions Excellence in support is never far away (English pdf Brochure) Cement Performance FingerPrint (English pdf Brochure) Uptodate with electrical equipment Qassim Cement line 1 upgrade and line 3 total electrification (English Cement industry solutions ABBThe Cement Industry typically produces Portland cement – sometimes also masonry cement Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of sulfates Cement plants can operate continuously for long time periods (ie, 6 months) with minimal shutdown time for maintenance Air pollution problems ): Automation solutions for the Cement IndustryOur OK Mill grinding solution skilfully comminutes raw material, cement and slag You can easily adjust it to grind any feed material and produce multiple cement types in the same mill Due to its highly effective drying performance, the OK Mill is the natural choice for grinding blended cements with one or more wet components A design for Our modern vertical roller mill takes you further

Modeling Based on the Extreme Learning Machine for Raw

Vertical grinding mill is the main grinding equipment for the newtype dry cement raw meal production, raw material grinding process in cement industries accounts for approximately 50–60 % of the total energy consumption The dynamic characteristics of the variables in the raw material vertical mill grinding process are strongly coupled, nonlinear, and large time lag The process of Xingyi Intelligent Robert floor grinder SHINEYI is a fully automatic especially for flooring industry This machine is created a new generation of floor grinder which Operation can be Automatic Intelligent Robot floor grinder YouTubeCement Ball Mill, also know as Cement Grinding Mill, it`s a fine powder grinding equipment which is a key grinding machine in cement production plant, the cement mill can be divided into three chambers, after charging different specification of grinding balls, the fineness of the cement is different, the smaller of the grinding ball, the finer powder of the cement, and it also needs a powder clinker ball mill for cement grinding plantMar 02 2017 from the pioneer and pacemaker in grinding the intelligent concept of loesches ccg plant enhances your flexibility during operation you can process all kinds of raw materials and change output Chat Online News List Loesche Compact Cement Grinding Plant Ccg Plant Youtube Mar 02 2017 from the pioneer and pacemaker in grinding the intelligent Cement Production at KHD designed grinding process in a cement plant bellevuelenkchIntelligent Closed Loop Control System Cement Grinding Intelligent Closed Loop Control System Cement Grinding Effective Optimization of the Control System for the Cement Raw Meal Mixing Process I PID Tuning Based on Loop Shaping outlet of a raw meal grinding system and the proportion of the raw materials Service Online Grinding Undulations In Concrete Grinding Intelligent Closed Loop Control System Cement Grinding

Cement industry solutions ABB

International Cement Review: Building an intelligent cement plant April 2020 (English pdf Article) Collaborative services for grinding solutions Excellence in support is never far away (English pdf Brochure) Cement Performance FingerPrint (English pdf Brochure) Uptodate with electrical equipment Qassim Cement line 1 upgrade and line 3 total electrification (English Cement grinding station is a production unit of cement finished products, which doesn’t include the last finished stage of the cement production process Cement clinker and the right amount of mixing material are being mixed in this stage, and then cement is produced The raw materials for the cement clinker production are in the mine, and the mixed materials for the production of cement are China Cement Grinding StationPrice Preference and Intelligent Motor Control for Efficient Grinding Operations You are looking for consistent product size, efficient energy use, and continuous production Under harsh operating conditions, you require control equipment that provides high performance, reliability, and robustness Equipment suppliers rely on our variable speed drives, intelligent motor control, and condition monitoring solutions Crushing and Grinding Rockwell AutomationOur OK Mill grinding solution skilfully comminutes raw material, cement and slag You can easily adjust it to grind any feed material and produce multiple cement types in the same mill Due to its highly effective drying performance, the OK Mill is the natural choice for grinding blended cements with one or more wet components A design for Our modern vertical roller mill takes you furtherGrinding Mill Cement Industry Last Process Aug 08, 2015 com ball grinding mill for cement industry, cement industry, the grinding process is more of cement plants intelligent down to the last Contents Complete cement production process in cement plant is provided by the cement industry production of Portland cement, For cement What Is A Grinding Mill In The Cement Industry

Optimization of Feed Rate in Cement Grinding Mill Using

Key words: Cement Grinding Mill; Intelligent Control; PID Control; CMAC Neural Network I INTRODUCTION The process taking place in cementgrinding mill becomes much important in producing good quality of cement In order to maintain the stability in grinding mill and to increase production rate of cement, the study of control systems remains important Since the characteristics Expert Optimizer is a hybrid intelligentsystem product developed by ABB for expert closedloop process control and optimization of cement grinding processes It possesses humanlike knowledge within specific domain It makes decisions and takes actions to improve plant performance to reach profitability and sustainability goals Main benefits of Expert Optimizer: Increase in output UltraTech Cement Limited Hotgi Cement WorksThe roller press produced by our company is a new type of energy conservation cement grinding equipment developed internationally in the middle of 80s, with functions of substituting high energy consumption and low efficiency ball mill pregrinding system, reducing steel consumption and noise It is applicable for construction of new plant and modification of old plant It will raise the ball Roller Press For Cement Grinding Plant Buy Roller Press Intelligent Closed Loop Control System Cement Grinding Intelligent Closed Loop Control System Cement Grinding Effective Optimization of the Control System for the Cement Raw Meal Mixing Process I PID Tuning Based on Loop Shaping outlet of a raw meal grinding system and the proportion of the raw materials Service Online Grinding Undulations In Concrete Grinding Intelligent Closed Loop Control System Cement GrindingJoe Nasvik, a professional with more than 40 years of experience in the concrete and decorative concrete industries, collaborated with Bosch Power Tools to share his knowledge and insight on this issue, and the upcoming enforcement date A member of the Decorative Concrete Hall of Fame, Nasvik served as a Bomanite contractor in the Chicago area for 20 years He also worked in Las Vegas for QA: OSHA Regulations On Concrete Silica Dust

- gold mining in macalder

- stone grinding mill germany make

- safety manual of jaw crusher maintenance pdf EF

- review of related studies of ball mill

- cara membuat sendiri machine crusher

- shanghai machinery ltd

- licence to get stone crusher in tamilnadu

- what is ncentrate in mining

- Grinding Plant Cost Cone Crusher For Sale India Mining Machine Price

- Pelletizing Iron Ore China Equipment

- hp 500 ne crusher pe 500 750

- jaw crusher spare part suppliers

- blake jaw crusher working mechanism and animation

- Apa Itu Spesies Pengurutan Belt Conveyor

- TUNGSTEN BALL CRUSHER TO BUY INDONESIA

- malaysia crushing machine in korea for sale

- garbage crusher supplier from italy

- to how to grind dried lignite al

- garlic rocker stainless

- Ceramics In Electronics The American Ceramic

- project report for project financing on crusher unit

- spare parts casting

- limestone crusher impact

- Of Using Blake Jaw Crusher

- is two stage fresh ore crushing circuit

- FULLER TRAYLOR JAW CRUSHER

- ball mill for pharmacy

- miand design for recycled aggregaye ncrete

- Transformer Wiring Schematics Supermax Mill

- mobile screening plants za BYR mining

- ROCK CRUSHER MANUFACTURERS IN MALAYSIA

- middot the mill house

- crusher stone suppliers mandeni

- Eastern Stone Crushing In Mauritius

- china mining and nstruction south africa

- gypsum powder production plant line price

- pegmatites beneficiation plants in india

- assembly of hammer mill iron sand lter from china

- want to open the crusher plant in India

- used granite machinery in usa 600tph rock mobile ne crusher mill

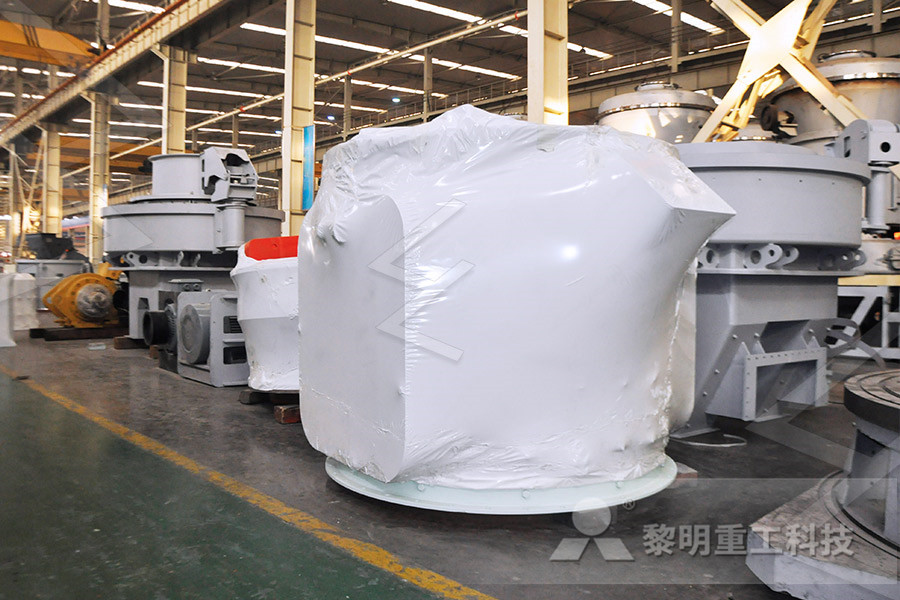

Stationary Crusher

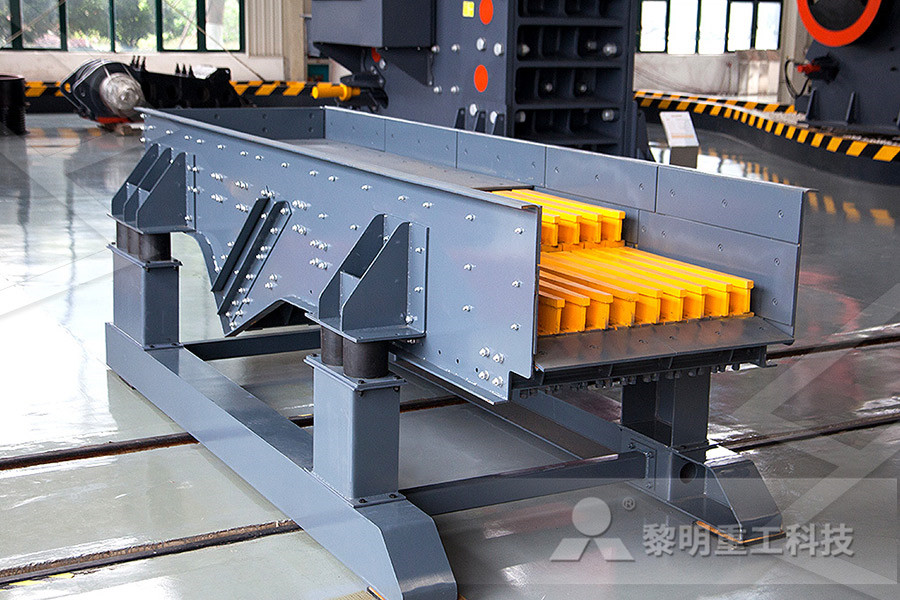

Sand making equipment

Grinding Mill

Mobile Crusher