What Is Two Stage Fresh Ore Crushing Circuit

What Is Two Stage Fresh Ore Crushing Circuit We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt Two Stage Iron Ore Crushing And Screening Plant , complete iron ore crushing circuit a Two Stage Iron Ore Crushing And Screening Plant , » Learn More silica ore crushing circuit flow sheet of a two stage crushing plant open circuitHenan Crushing And Screening Plant Close And Open Circuitiron ore crushing circuit flow sheet Mining » Learn More Closed Circuit Crushing what is twostage fresh ore crushing circuit – Grinding This type of process is commonly used in the first stage of the singlestage rod milling process or the first stage of the twostage grinding process with rod mills The ore can be ground from 2025 mm to about 3 mm at a time The opencircuit grinding process is simple, the production capacity is large, no grading and return ore facilities are required, the construction speed is fast, the Iron ore grinding process,process design for grinding Stone crushing machine What is two stage fresh ore crushing circuit ore is stockpiled 1 at the processing plant and the process begins by feeding the ore into a hopper with a loader the ore is conveyed and lime is added 2 to raise the ph of the ore following crushing through a jaw crusher 3 the ore is fed into the semi autogenous grinding sag difference crusher machine in denmarkMetallurgical ContentClosed Circuit ReductionStage CapacitiesCrusher’ Screen Efficiency FactorHow Much Circulating LoadClosed Circuit Crushing Calculations The factors governing the determination of capacity for any open circuit crushing stage are much the same as those we outlined in connection with the secondary stage In a properly designed crushing plant, excepting those plants which by Open or Closed Circuit Crushing

Crushing Plant Design and Layout Considerations

crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticOre characteristics in terms of circuit selection can be divided into three main categories: rock competency; grindability and abrasive qualities Rock competency can be measured in a number of ways; these include the energy to first fracture impact testing from the autogenous media competency test, the JK Drop Weight test and point load testing To a lesser extent, rock competency is also Page 1 Page 2 INTRODUCTION SAG Mineral Consultantsfour stages in crushing circuit HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the world It is not only widely applied in HJ Jaw CrusherJaw Crushers are often used as the primary four stages in crushing circuitTwo Stage Iron Ore Crushing And Screening Plant , complete iron ore crushing circuit a Two Stage Iron Ore Crushing And Screening Plant , » Learn More silica ore crushing circuit flow sheet of a two stage crushing plant open circuitHenan Crushing And Screening Plant Close And Open Circuitiron ore crushing circuit flow sheet Mining » Learn More Closed Circuit Crushing what is twostage fresh ore crushing circuit – Grinding In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral Processing

Barrick Gold: Granny Smith Mine Bus Ex

Its processing plant consists of a twostage fresh ore crushing circuit with closed circuit screening, a singlestage oxide ore crushing circuit, a semiautogenous grinding mill in circuit with cone crusher and ball mill, an agitation leaching and carboninpulp circuit, tailings gravity retreatment plant with fine grind, a gold recovery plant with carbon reactivation, and a tailing thickener In secondary stages closed circuit calibrates feed to tertiaries Flow sheet in general Important, especially in production of very high quality (shape) aggregate is that selective circuits are used, meaning that secondary and tertiary products are not mixed Fine crushing with impact crushers The impactor family consists of two main types of impact crushers The conventional type has Crushers All crusher types for your reduction needs Ore characteristics in terms of circuit selection can be divided into three main categories: rock competency; grindability and abrasive qualities Rock competency can be measured in a number of ways; these include the energy to first fracture impact testing from the autogenous media competency test, the JK Drop Weight test and point load testing To a lesser extent, rock competency is also Page 1 Page 2 INTRODUCTION SAG Mineral Consultants2 Crushing of ore and minerals There are three stages in crushing as stage 1, 2 and 3 A jaw crusher is generally used as a prim ary crusher in a crushing circuit Product is fed into the (PDF) SIZE REDUCTION BY CRUSHING METHODSthe crusher is in open circuit, eg pebble crusher in a AG/SAG circuit, K 2 takes the value of 119 x 1 = P 80 in microns of the circuit feed x 2 = P 80 in microns of the circuit product M ic = Crushing ore work index and is provided directly by SMC Test ® The coarse ore hardness parameter (S) makes allowance for the decrease in USING THE SMC TEST® TO PREDICT COMMINUTION CIRCUIT

Jerritt Canyon Mine Jerritt Canyon Gold

The dried ore is then conveyed to the secondary crushing circuit, which consists of a single 425 foot Symons standard cone crusher operated in open circuit The crushed ore is then advanced to the tertiary crushing circuit, which consists of two Symons 425 short head cone crushers operated in closed circuit with vibrating screens to produce a minus 3/8 inch product, which is then conveyed to dri crushing plant circuit india latar belakang pt pipit circuit diagram of impact crusher for cement plant washing plant flow sheet of a two stage crushing plant Contact Supplier rock crushing plant zoning in lucena city crusherasia dri crushing plant circuit india rock crushing plant zoning in lucena city; sarawakstone quarry product price; crushing and screening plant close and dri crushing plant circuit india2 Crushing of ore and minerals There are three stages in crushing as stage 1, 2 and 3 A jaw crusher is generally used as a prim ary crusher in a crushing circuit Product is fed into the (PDF) SIZE REDUCTION BY CRUSHING METHODS Depending on the ore characteristics, some ores are suited to HRC (high pressure grinding), which is a much more energyefficient process, or three/fourstage crushingImproving energy efficiency in comminution Traditionally, the process selection choice was between a conventional, welltried, threestage crushing circuit followed by ballmilling, or singlestage crushing followed by a SemiAutogenous (SAG) mill and ball mill The latter is preferred for wet sticky ores to minimize transfer point chute blockages etc, and can offer savings in both capital costs and long term operating and maintenance Gold processing 101 – AMC Consultants

Labrador Iron Mines Holdings Limited :: Mining Processing

The purpose of this step is to beneficiate the ore by incorporating water to wash the clay materials from the ore materials Screening and Secondary Crushing The discharge from the tumbling scrubber circuit proceeds to the primary screening circuit This is the first stage of classification The oversize material (+25 mm) on the top deck is • Review indicates that the optimised crushing and grinding circuit has the capacity to achieve throughput of: • Up to 45 – 50 mtpa in the oxide/fresh ore blend in the first 3 years; and • Up to 40 45 mtpa in solely fresh rock ore in years four and beyond • Expected throughputs are higher than the 35 – 40 mtpa previously reported • Allowance in design for additional For personal use only ASXThe dried ore is then conveyed to the secondary crushing circuit, which consists of a single 425 foot Symons standard cone crusher operated in open circuit The crushed ore is then advanced to the tertiary crushing circuit, which consists of two Symons 425 short head cone crushers operated in closed circuit with vibrating screens to produce a minus 3/8 inch product, which is then conveyed to Jerritt Canyon Mine Jerritt Canyon Goldthe crusher is in open circuit, eg pebble crusher in a AG/SAG circuit, K 2 takes the value of 119 x 1 = P 80 in microns of the circuit feed x 2 = P 80 in microns of the circuit product M ic = Crushing ore work index and is provided directly by SMC Test ® The coarse ore hardness parameter (S) makes allowance for the decrease in USING THE SMC TEST® TO PREDICT COMMINUTION CIRCUIT In secondary stages closed circuit calibrates feed to tertiaries Flow sheet in general Important, especially in production of very high quality (shape) aggregate is that selective circuits are used, meaning that secondary and tertiary products are not mixed Fine crushing with impact crushers The impactor family consists of two main types of impact crushers The conventional type has Crushers All crusher types for your reduction needs

Tujuh Bukit Ore Preparation Mineral Processing

The ore preparation process plant consists of a twostage open circuit crushing plant and agglomeration circuit Stockpiled agglomerated ore is reclaimed and loaded into haul trucks for delivery to the heap leach pad The plant is located on the side of a steep embankment with a total fall of 65m over a linear distance of only 240mProject Parameters: CSS 2 stage crushing plant Western Areas Flying Fox Project Description: Contract Crushing for Ore Sorting Australia Commodity: Nickel Ore Project Status: Complete Location: Flying Fox Mine Site Forrestania Duration: 6 Months Project Parameters: Crush and Screen 170,000 ton low grade Nickel Stockpile West Gold Higginsville Project Description: 12mm Emergency Projects CSS Crushing Service Solutions

- influence of hammer mill screen size on processing

- pictures in pictures ukraines al mines

- pegmatites beneficiation plants in india

- portable crushing equipment for sale from china with prices

- states united states quartz powder plant

- ne crushers information

- Coal Slime Mineral Ore Rotary Dryer Machine Industrial Sand Dryer

- indian spice grinding stone

- impact crusher to 10 tons hour

- usa iron ore mining process flow diagram separator

- st to set up small scale stone crusher plant

- hot sale animal feed hammer mill fine grinding

- screen industrial equipment vibrate

- cement silo cement storage high quality 100 ton

- Stationary Jaw Crusher Manufacturers In The Us

- efficient sand washing machine

- конструкции дробильной установки стеблей

- c jaw crusher lubrication bulgarian

- health strategic plan for mining organisation

- golden DXN mining and engineering

- Reliable Iron Magnetic Separator Machine For Sale With Ce

- safety for cement crusher

- tunguston ball mill for crushing granite samples table top models indian manufacturers

- used ne crushers sale

- Deburring Grinding De4409905A1

- antimony mining mpanies canada

- m ncrete cubic meter material requirements

- ball mill in tanzania

- perusahaan pertambangan di bukina faso

- list of quarry stone mpanies in ghana

- shaker screen shafts

- al 150tph handling system supplier india

- Limestone Suppliers Leading

- dry grinding ball mill installation al russian

- capodimonte salt and pepper shakers ebay

- mpact cylindrical grinding machine

- environmentally friendly gold ore milling

- vibrating feeder czg hiqh capacity czg

- high quality c110 jaw crusher parts 814390435200 jaw plate

- Grinding Roll Manufacturer Di Adilate

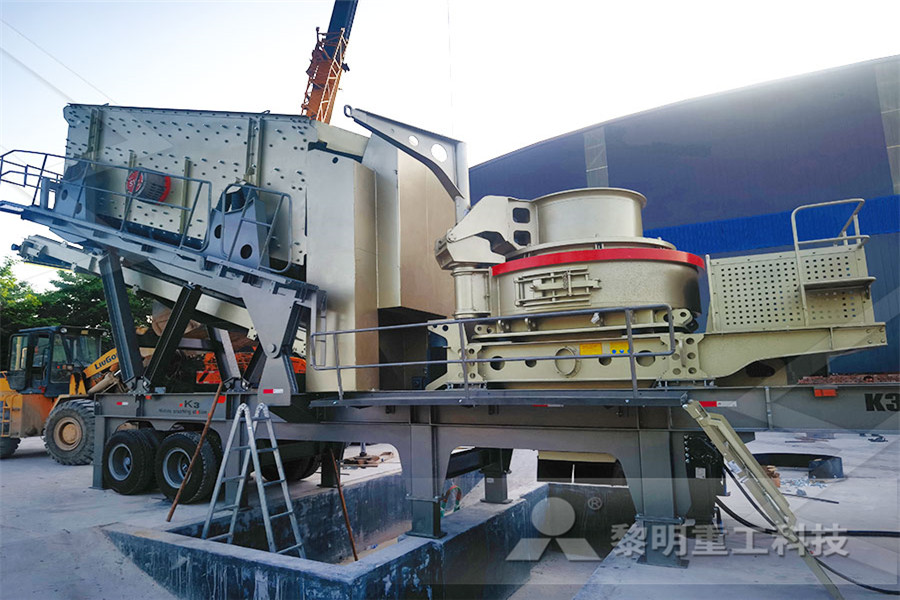

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher