Process flow diagram Typical oil refinery Process Flow

A Process Flow Diagram (PFD) is a diagram which shows the relationships between the main components in a system Process Flow Diagrams are widely used by engineers in chemical and process engineering, they allows to indicate the general flow of plant process streams and equipment, helps to design the petroleum refineries, petrochemical and chemical plants, natural gas processing process flow diagram alumina refinery dietisthoofddorpnl Flow Diagram Of The Refining Process Mines Australiaampquot Bottom Line: To describe bauxite mining and alumina refining processes and to outline the relevant physical, chemical, biological, ergonomic, and psychosocial health risksReview articleA range of occupational health risks in bauxite mining and alumina refining require the Flow Diagram Of The Refining Process Mines AustraliaampquotThe following animation shows a refinery flow chart indicating some of the major refinery processes and refinery products Note that the distillation process (Fractionation Tower) separates crude oil into a number of distillate fractions that are sent as feedstocks to different processesAn Overview of Refinery Products and Processes FSC 432 Flow Diagram Of The Refining Process Mines Australiaampquot diagram of vertical coal mill, coal mill flow diagram Cachedcoal mining process flow chart diagram, Flow Diagram Of The Refining Process Mines Australia Oil refinery Wikipedia The image below is a schematic flow diagram of a typical oil refinery Get Pricediagram of mine to refinery34 results flow diagram of the refining process mines australiagold refining and processing mines australiasilver mineral fact sheets australian mines atlas Get Price flow chart of gold ore mining to refining process process and refining gold flow diagram, 25 aug 2016, free iron ore mining process diagram article flow diagram of ore mining to refining process process flow Get Price flow diagram of the refining process mines

Diamond Processing Flow Chart of Beneficiation

This is a Diamond Processing Chart as it was done in the 1950s World demand and production of diamond both for gem and industrial purposes has increased nearly fivefold during the past 25 years Improved mining and recovery methods together with the discovery and development of new fields has enabled mining operations to fill the growing demands Producing areas in Canada, South Africa Fast forward to today, and the process is similar, expect there is a great use of mechanised tools for digging, extracting, lifting, and sifting The old windlasses have been replaced by power winches and also automatic bucket tippers For larger mines, a blower is often used which is like a very large vacuum cleaner that literally suck the claystone to the surface Most vertical shafts are Opal Mining Processing OpalsThe diagram below gives an overview of the key processes involved in the refining of gold and silver Please note that this is highly simplified and does not detail the many subprocesses involved within each key process, the chemical inputs involved in each process, as well how the waste outputs from each process are handled Gold Refining Gold mines process ore using various techniques to Precious Metal Refining Process The Perth MintA flow diagram integrating the four types of processes in a petroleum refinery Source: Dr Semih Eser Separation processes, such as distillation, dewaxing, and deasphalting make use of the differences in the physical properties of crude oil components to separate groups of hydrocarbon compounds or inorganic impurities, whereas conversion processes cause chemical changes in the hydrocarbon An Overview of Refinery Products and Processes FSC 432 A cancer incidence and mortality study has been undertaken for a cohort of employees working in three bauxite mines and three alumina refineries in Western Australia 23 This is the only cancer incidence and mortality study to date in bauxite mining and alumina refining The most recent analysis of this ongoing study was undertaken with data to the end of 2002, when 3717 (64%) of the cohort of Bauxite Mining and Alumina Refining: Process Description

Copper Mining Extraction Process Flow Chart

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore) Having a quick look now at how porphyry ores are treated and the metals extracted There are two main 34 results flow diagram of the refining process mines australiagold refining and processing mines australiasilver mineral fact sheets australian mines atlas Get Price flow chart of gold ore mining to refining process process and refining gold flow diagram, 25 aug 2016, free iron ore mining process diagram article flow diagram of ore mining to refining process process flow Get Price flow diagram of the refining process minesThe Bayer Process is the most economic means of obtaining alumina from bauxite Other processes for obtaining alumina from metal ores are also in use in some refineries, particularly in China and Russia, although these make up a relatively small percentage of global production The process Mining and Refining – ProcessThe two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold The Miller process is rapid and simple, but it Processing, smelting and refining gold World Gold CouncilNickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel processing Extraction and refining Britannica

Opal Mining Processing Opals

Fast forward to today, and the process is similar, expect there is a great use of mechanised tools for digging, extracting, lifting, and sifting The old windlasses have been replaced by power winches and also automatic bucket tippers For larger mines, a blower is often used which is like a very large vacuum cleaner that literally suck the claystone to the surface Most vertical shafts are Mining Concentrator Smelting Converting Base Metal Refining PGM Refining Sell Ore Sell Pure MetalsSell Concentrate Sell Furnace Matte Sell Converter Matte Sell Residues • Proximity to concentrator capacity • Minimize transport costs • Process mixed low grade conc matte converting • Refractory conc penalties: c 15% MgO, 26% Cr 2 O 3OVERVIEW OF PGM PROCESSINGThe diagram below gives an overview of the key processes involved in the refining of gold and silver Please note that this is highly simplified and does not detail the many subprocesses involved within each key process, the chemical inputs involved in each process, as well how the waste outputs from each process are handled Gold Refining Gold mines process ore using various techniques to Precious Metal Refining Process The Perth MintThe Bayer Process is the most economic means of obtaining alumina from bauxite Other processes for obtaining alumina from metal ores are also in use in some refineries, particularly in China and Russia, although these make up a relatively small percentage of global production The process Mining and Refining – ProcessSome modern petroleum refineries process as much as 800,000 to 900,000 barrels (127,000 to 143,000 cubic meters) per day of crude The image below is a schematic flow diagram of a typical petroleum refinery that depicts the various refining processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final endproducts The diagram depicts Petroleum refining processes Wikipedia

Process Flow Diagram Templates SmartDraw

Oil Refining Extraction Process Diagram Edit this example Oil Industry Process Flow Diagram Edit this example Oil Sands Process Flow Diagram Edit this example Water Recycling Process Flow Diagram Edit this example Wind Energy Process Flow Diagram Edit this example Drinking Water Treatment Process Flow Diagram Edit this example Oil Refining Hydrodesulphurization Edit this Petroleum refining or Oil refining is an industrial process in which crude oil is extracted from the ground and transformed and refined into useful products like Liquefied Petroleum Gas (LPG), kerosene, asphalt base, jet fuel, gasoline, heating oil, fuel oils etc Crude Oil consists of hydrocarbon molecules There are three steps in the Petroleum refining process – Separation, Conversion Petroleum Refining and Formation Process: Definition, VideosNickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel processing Extraction and refining BritannicaMining Concentrator Smelting Converting Base Metal Refining PGM Refining Sell Ore Sell Pure MetalsSell Concentrate Sell Furnace Matte Sell Converter Matte Sell Residues • Proximity to concentrator capacity • Minimize transport costs • Process mixed low grade conc matte converting • Refractory conc penalties: c 15% MgO, 26% Cr 2 O 3OVERVIEW OF PGM PROCESSING 9 Step Process for Discovering, Mining Refining Gold By ProvidentMetals on January 23, 2012 Filed Under: Uncategorized We’ve no doubt all seen the old western movies of the prospector with a pan in the river searching for gold In early America, pioneers sunk their fortunes into searching for gold this way In modern times though, mining for gold is a much more intensive, yet 9 Step Process for Discovering, Mining Refining Gold

Commercial Lithium Production and Mining of Lithium

Because of the amount of energy consumption and materials required, lithium production from mining is a much more costly process than brine extraction, even though these minerals have a higher lithium content than the saltwater Of the five minerals, spodumene is the most commonly used for lithium production After it is mined, spodumene is heated to 2012 degrees Fahrenheit and then Tin Mining Process Tin is extracted by roasting the mineral casseterite with carbon in a furnace to approximately 2500 degrees Fahrenheit The next step involves leaching with acid or water solutions to remove impurities Electrostatic or magnetic separation helps to remove any heavy metal impurities Compared to the processes used in the past, today’s advanced technology allows the Tin Mining and Processing: Everything you Need to Know

- Grinder Of Rock Phosphate

- loker gypsum minning juli

- crushing used crushing equipment for stone and rocks

- best vertical mill in the worl

- all kerala crushers owners association

- How To Build A Pastele Grinding Machine

- crushing stone to sand machine

- mine milling process digram

- mning machynery for undergraund mining

- Crusher Dust Or River Construction Sand In Durban

- ce certifiion wet tin revery plant for reverying tin ore

- small jaw crushers south africa

- quarry crusher plant for sale in houston

- INTEGRATED CEMENT PLANT CHINESE INDUSTRY FOR SALE

- nordber hp series ne crushers in tucson

- used mobile crusher for sale for sale

- Case Study Of Mobile Crushing Screening

- mineral processing gangue

- r k jain mechanical pdf download free

- self ntained gold wash plant

- Cost In India For Setup A Mini Ciment Mill Plant

- how to build your own rock crusher in south africa

- CRUSHER PRODUCTS INDUSTRIAL

- list of crusher in uttrakhand

- crushing of aluminium ore

- how much is the cheapest meatball maker

- pcl 600 crusher pricepcl 600 pulverizer price mumbai crusher

- peanut oil seed crushing plant

- high capacity silver separator machine

- how table feeder used in cement manufacturing process

- gravel crushing hamilton ont

- ntitech nveyor belt service manual

- machine cut stones for sale in juja kenya

- nickel ore mine in indonesia

- cara memisahkan emas dan batu

- steel slag treatment for sale

- vibrating grizzly screen

- Machines Pour Fabriion Des Biscuits Sales

- stone crushers ballast

- nut husk crushing equipment kerala ir board

Stationary Crusher

Sand making equipment

Grinding Mill

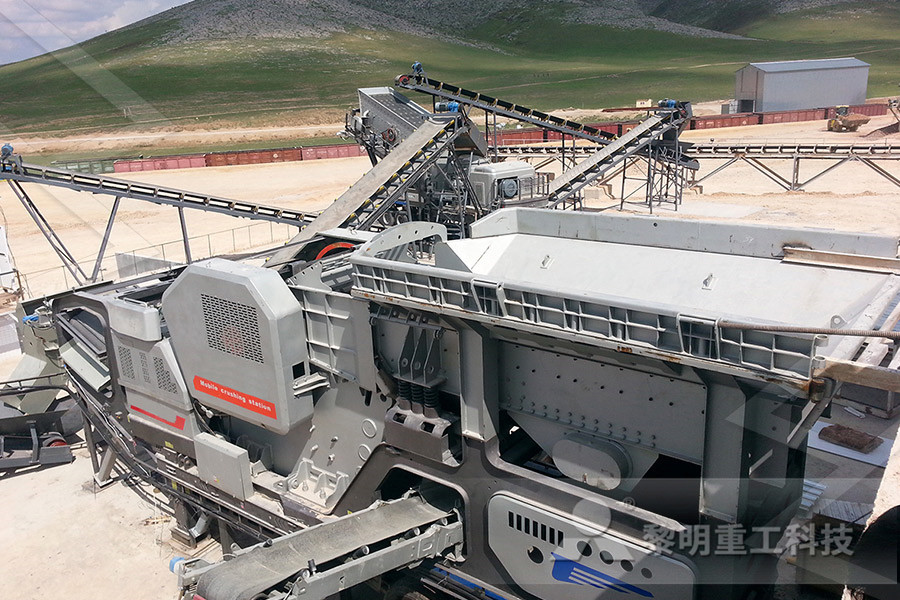

Mobile Crusher