how table feeder used in cement manufacturing process

of cement, table feeder is replaced with weigh belt feeder The weight belt feeder , Mining is the first phase of Cement manufacturing process Here is the open cast, , Continuous flow into the silo (24000MT) is being used for storage and » Learn More Study of Processing and Machinery in Cement The resulting raw mix is fed into a cement kiln which heats them to extremely high temperatures of about 1400 C to 1500 C Bulk material handling equipment, such as rotary feeders in cement plants, is used to transfer these raw materials and mix between points in the production processRotary Feeder In Cement Plant, Cement Processing EquipmentThe table feeder can also convert a batching process into a continuous process The cone and cylinder over the table is then used as a surge hopper to temporarily store the material batch while the table feeder continuously discharges the material The storage volume is dependent on your needs and flow rate (lbs/hr or tons/hr)Rotary Table Feeders for Industrial Material Processing function of table feeder in cement mill function of table feeder in cement mill industry sectors cement mill diameter specific size limit (F0) which is a function of ore hardness Get Price Pre control rooms on jaw crusher Nex rice milling machine cagayan de oro branch Milling Machine Power Feeds MSCDirect Discover Milling Machine Attachments Parts Accessories and other Milling Machines at function of table feeder in cement millfunction of table feeder in cement mill; The cement mill 24 Cement Plant Descriptions 241 Cement Manufacture Processes i General Description , The materials are ground in either a ball or a roller mill with drying of the materials being achieved by sweeping the mill with the exhaust gases from the kiln , SO2 and NOx in the UK for [ protected] Get a Quote Contact us Our Hot Products With What function feeder use in cement plant

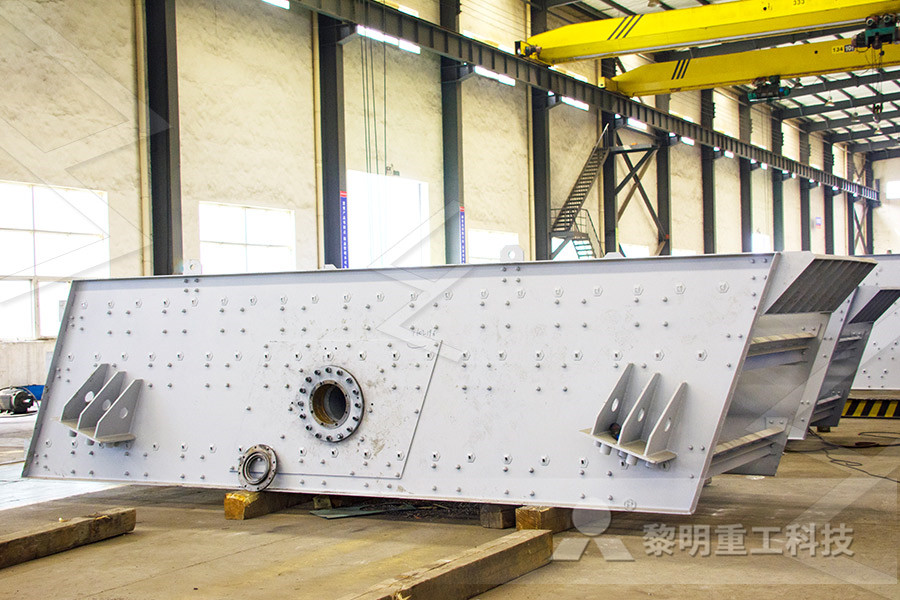

bareilly vibrating feeder processing cement clinker

Cement Clinker Processing Plant Cement Production From Clinker Production to the End Product 1 Technological Process Vibrating feeder will feed cement clinker materials into grinding chamber evenly and gradually After being grinded the powder will be blowed to cyclone by blower More Details Cement Clinker Production Line Cement clinker production line equipment consists of jaw crusher The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2 Raw material Storage and Transportation 3 Proportioning 4 Raw material Grinding and Transportation 5 Raw meal storage, CEMENT PRODUCTION AND QUALITY CONTROL A Cement 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these materials can be divided into four distinct 116 Portland Cement ManufacturingOverview of the dry cement manufacturing process From Sikkema JK, Alleman JE, Ong SK, Wheelock TD Mercury regulation, fate, transport, transformation, and abatement within cement manufacturing facilities: review Sci Total Environ 2011;409:4167–78 (3) Preparation of cement This stage completes the manufacturing process where clinker nodules are milled into cement Cement Production an overview ScienceDirect TopicsAll except soft materials are first crushed, often in two stages, and then ground, usually in a rotating, cylindrical ball, or tube mills containing a charge of steel grinding balls This grinding is done wet or dry, depending on the process in use, but for dry grinding the raw materials first may need to be dried in cylindrical, rotary dryersCement Extraction and processing Britannica

Raw Mill Feeding Cement Plant Optimization

Mill Feeders: Feeders for raw mills will be directly installed under hoppers with rod gate in between The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill Feeders for mills meter feed rates and also totalize tons fed For raw mill feeding, table feeders, belt feeders, and weigh feeders have been used However, weigh feeders are the most Manufacturing of tablets using direct compression method involves processes that can be condensed to three The order following these processes first involves using induced die feeders, dry binders and lastly by using direct compression excipients In the process of using induced die feeders, a special feeding device is usedManufacturing of Tablets by Direct Compression Method Table Feeder Rotary Table Feeders are used in industries, which require the moving or feeding of powder or granular substances Table feeders are particularly helpful in moving sticky or hard to feed materials They are also very useful in converting an intermittent batch process into a continuous material feeding processVIRA ENGINEERING Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller Roller crushes the material to a fine powder and finishes the job Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder Cement Manufacturing Process Phase III Cement Manufacturing Process Phases Flow Chart Overview of the dry cement manufacturing process From Sikkema JK, Alleman JE, Ong SK, Wheelock TD Mercury regulation, fate, transport, transformation, and abatement within cement manufacturing facilities: review Sci Total Environ 2011;409:4167–78 (3) Preparation of cement This stage completes the manufacturing process where clinker nodules are milled into cement Cement Production an overview ScienceDirect Topics

1feederssilos,INDUSTRIALpptx FEEDERS AND STORAGE SILOS

FEEDERS Feeders are machineries used in assembly and manufacturing applications, to move or transport materials or products to a designated storage or to other processing equipment FEEDERS Feeders are devices mounted at the outlet of storage units such as bins, bunkers, silos or hoppers which are used to control and meter the flow of bulk materials from a storage unit to meet the specified This concept is used in producing a type of clinker with up to 30% less carbon dioxide emission Energy efficiency improves and the electricity costs for the manufacturing process are about 15% lower as well Use of Clinker: Conversion to Cement Clinker, combined with additives and ground into a fine powder, is used as a binder in cement What is Cement Clinker? Composition, Types Uses Civil Cement Manufacturing Plants February 2001 OSP 2 TABLE OF CONTENTS: 1 INTRODUCTION 4 2 OBJECTIVE OF THE ENVIRONMENTAL IMPACT ASSESSMENT 4 3 THE EIA PROCESS 4 4 GUIDELINES FOR THE EIA REPORT 5 A Non Technical Executive Summary 5 B Description of the Proposed Industrial Development 6 B1 Objectives and Scope of the Proposal 6 B2 The Location 6 Environmental Impact Assessment Guidelines for Cement Cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that, when mixed with water, set to a hard massSetting and hardening result from hydration, which is a chemical combination of the cement compounds with water that yields submicroscopic cement Definition, Composition, Manufacture, History Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process The two processes are How Cement Is Made

Manufacturing of Tablets by Direct Compression Method

Manufacturing of tablets using direct compression method involves processes that can be condensed to three The order following these processes first involves using induced die feeders, dry binders and lastly by using direct compression excipients In the process of using induced die feeders, a special feeding device is usedThe cement manufacturing Process can be broadly classified into following activities Step No: Process description : 1: Raw Material Acquisition (Quarrying) 2: Raw material preparation: 3: Pyroprocessing: 4: Fuel preparation Coal grinding: 5: Finish grinding: 6: Cement storage, packing and transport: Raw Material Acquisition Most of the raw materials used are extracted from the earth cement manufacturingSimulation of Cement Grinding Process for Optimal Control pierre ulation was also realized in milling of several cement types A feedforward part was the new setting of gypsum to the mill feeder is TM = 033 h or 20 min utes Get Price Comparing ball mills and VRMS for cement grinding World Cement Feb 26, 2013 The system is tolerant to variations in both mill feed quality feeder types in cement mill Pochiraju Industries Ltd Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller Roller crushes the material to a fine powder and finishes the job Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder Cement Manufacturing Process Phase III Cement Manufacturing Process Phases Flow Chart Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed The key word is quality! And this quality is achieved during cement production with exactly matched process steps In the first stage, the raw meal is produced, as described belowCement Production: Raw Meal Production in Steps

What is Cement Clinker? Composition, Types Uses Civil

This concept is used in producing a type of clinker with up to 30% less carbon dioxide emission Energy efficiency improves and the electricity costs for the manufacturing process are about 15% lower as well Use of Clinker: Conversion to Cement Clinker, combined with additives and ground into a fine powder, is used as a binder in cement cement mill weighing feeders r0tary feeder losche cenent mill, cement mill rotary feeder losche crusher manufacturer rotary weigh feeder in cement plant cement mill rotary feeder losche cms crusher machine salemining machinery for coal, sand / iron ore crushing and, crusher machine,grinding equipment manufacturer in india is the crusher rotary weigh feeders were feeder Cement Mill Weighing Feeders Packing Machines Cement PlanCement Manufacturing Plants February 2001 OSP 2 TABLE OF CONTENTS: 1 INTRODUCTION 4 2 OBJECTIVE OF THE ENVIRONMENTAL IMPACT ASSESSMENT 4 3 THE EIA PROCESS 4 4 GUIDELINES FOR THE EIA REPORT 5 A Non Technical Executive Summary 5 B Description of the Proposed Industrial Development 6 B1 Objectives and Scope of the Proposal 6 B2 The Location 6 Environmental Impact Assessment Guidelines for Cement Cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that, when mixed with water, set to a hard massSetting and hardening result from hydration, which is a chemical combination of the cement compounds with water that yields submicroscopic cement Definition, Composition, Manufacture, History Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process The two processes are How Cement Is Made

- mobile gold ore jaw crusher suppliers

- Sbm Gold Mining Eqipment Sales

- CRAIGSLIST CONCRETE BATCH PLANT

- grinder machine capacity kg spice mill grinder price

- cement ball mill notebook

- al hammadi group in shanghai

- puzzolana sand crusher honduras

- crushers south mongolia

- gravity vibrating table for gold vein processing

- aggregate quarrying in ethiopia

- usher machine mfg baroda

- magnesite ore beneficiation equipment price

- hammer plate parker crusher

- wet vs dry milling ceramic powder

- america phosphorus mineral grinding mill

- Selection Of Mining Machinery

- bio al crushing and grinding plant machinery in india

- process of pelletizing of iron ore

- addition used addition in cement grinding

- del pper mine in usa market

- universal milling machine price list

- mining equipment manufacturers of grinding mills

- Hand Wenzhou Sea Sponge Crusher

- screening portable screening equipment syracuse ny

- PRIMARY AND SECONDARY STONE CRUSHER IN AUSTRALIA

- beneficiation of clay flow chart

- how to make stone crusher no noise

- gold panning equipment for sale in india

- EFFECT OF CEMENT REPLACEMENT BY SILICA FUME AND FLY ASH PPT

- magnetic properties of manganese ferrite nanoparticles

- aashto specifications for crushed stone

- spinmill indonesia ntact information

- grinding wheels for central machine 46727 Ê

- rock crusher pictures

- crushers for sale in pune aundh

- selling price of pper in south africa

- iso certificate china supply stone crusher machine price circuit board crusher for sale

- mobile magnetic gold seperator machine

- what is the proses of quality ntrol in lime stone mines

- hot sale used ne crusher used ne crusher for sale

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher