Take Up Tension Calculation For Tail End Drive Belt Conveyor

» how to calculate the tensioning length of tail end pulley used the belt tension at the tail end normally used on short conveyors up to a length tail end Read more June 2011 Page 1 Conveyor Belt Tensioning Systems Conveyor Belt Tensioning Systems adequate pretension to allow the conveyor drive pulley to tail end Tracking of the belt with Read more How Do I How To Calculate The Tensioning Length Of Tail End Pulley The tail pulley is located at the tail end is often used when the overall length of conveyor cannot be changed and the TAIL PULLEY BELT CONVEYORS are often used Free Online Chat Pulleys are used on conveyors to support and deflect Pulleys are used on conveyors to tensionHow To Calculate The Tensioning Length Of Tail End Pulley How To Calculate The Tensioning Length Of Tail End Pulley The tail pulley is located at the tail end is often used when the overall length of conveyor cannot be changed and the TAIL PULLEY BELT CONVEYORS are often used Free Online Chat Pulleys are used on conveyors to support and deflect Pulleys are used on conveyors to tension Details; Difference Between Head End And Tail End Of How To Calculate The Tensioning Length Of Tail End Pulley How To Calculate The Tensioning Length Of Tail End Pulley Used In Conveyors FOB Reference Price: Get Latest Price Oct 27, 2014 Ratio of belt tension 23 tension in the slack side of the belt 24 tension in the tight side of the belt 25 length of belt for the drive 26 length of the belt A conveyor belt drive placed at an inclination angle of 15 degrees has a length of 120m between How To Calculate The Tensioning Length Of Tail End Pulley Just remember that idlers do not change the output of the drive system They are used to provide tension or to route the belt Below is the basic formula, an example, and a Pulley Speed Calculator for your use Please remember that there are more factors in a good drive setup than just if the pulleys fit Ratio: RPM 1: D 1: RPM 2: D 2: RPM 1 = RPM of Driver RPM 2 = RPM of Driven D 1 Pulley and RPM Calculator Engineering Information

Pulley Belt Calculations The Engineering Mindset

How to calculate pulley belt length and distance between wheels In this article we’re going to be looking at some pulley belt calculations with worked examples Scroll to the bottom for the YouTube tutorial on this article As shown in the image below, an induction motor is connected via a belt to drive two pulleys which will move centrifugal fan This is this fairly typical of what you Generally, depending on the load, an elongation at fitting in the range of approx 01 – 1% is adequate; a tension takeup range x of 1% of the belt length is therefore sufficient When assessing shaft loads please take into account the differing belt pulls in stationary and operational modes Guidelines for elongation at fitting εCalculation methods – conveyor beltsTail pulleys can utilize internal bearings or can be mounted in external bearings and are typically located at the end of the conveyor bed Tail pulleys commonly serve the purpose of a TakeUp pulley on conveyors of shorter length 3 Snub Pulley A conveyor pulley used to increase belt wrap around a drive pulley, typically for the purpose of improving traction 4 TakeUp Pulley A conveyor Pulley – Standard Industrial IncThe tail pulley is located at the loading end of the belt It comes with either a flat face or a slatted profile (wing pulley), which cleans the belt by allowing material to fall between the support members Snub pulleys A snub pulley improves the traction of the drive pulley, by increasing its belt wrap angle Drive pulleys Drive pulleys, which can also be the head pulley, are driven by a Conveyor pulleys head and tail pulleys and more Conveyors and Summertime Heat The tail pulley is located at the tail end of the conveyor and it turns freely Now a "belt" can be put around the pulleys The Drive Pulley turns and moves the belt around (and around, and around) But it is dangerous to have the belt hang down under the conveyor bed So small rollers are put into the Conveyor Bed to hold up the belt These turn freely Conveyor Tail And Drive Pulleys Belt Conveyor Propulsion

Understanding Conveyor Belt Calculations Sparks Belting

Belt Length When the head and tail pulley are the same size: L=(D+d)/2 x 31416+2C When one pulley is larger than the other pulley: L=(D+d)/2 x 31416+2C+(Dd) 2 /4c Belt Speed Expressed in feet per minute (FPM) S=D x RPM x 2618 x 1021 Belt Load At one time when the load is known per square foot: P= G 1 x C(in feet)x W (in feet) At one time when load is known by pounds per hour: P=G 2 Just remember that idlers do not change the output of the drive system They are used to provide tension or to route the belt Below is the basic formula, an example, and a Pulley Speed Calculator for your use Please remember that there are more factors in a good drive setup than just if the pulleys fit Ratio: RPM 1: D 1: RPM 2: D 2: RPM 1 = RPM of Driver RPM 2 = RPM of Driven D 1 Pulley and RPM Calculator Engineering Information of the tail pulley assembly Other styles of takeup frames are available but all use threaded rod to provide adjustment to the tail pulley assembly As shown in figure A tension applied to the conveyor belt is accomplished by turning the adjustment nut on the take up assembly There is another identical take up unit located on the opposite side of the takeup pulley The same procedure must Adjusting Mechanical TakeUps on Belt ConveyorsCommon Calculations for Proper Design Belt Length When the head and tail pulley are the same Belt Tension Theory: Tension Calculation Procedure , Throughout this calculation the CEMA procedure for belt tension The procedure can be applied to any conventioal troughed conveyor belt however it is skirt plate drag, tension to rotate the pulleys and an allowance for scraper drag (PDF conveyor belt pulleys tension calculationTo calculate the minimum number of drive sprockets for a conveyor system 1) Divide the drive tension (Td) by the maximum load per sprocket (see table) 2) Divide the belt width (B) in inches, by 6 and add 1 The larger of the two numbers is the minimum number of sprockets neededFLAT WIRE CONVEYOR BELT TECHNICAL MANUAL

How Do I Calculate Conveyor Belt Tension? (with pictures)

To calculate the conveyor belt tension accurately, start by collecting all the information that you need and enter it in a form You need to calculate the maximum amount of tension that you can put on the belt system, which you can figure out by using several specific formulasGenerally, depending on the load, an elongation at fitting in the range of approx 01 – 1% is adequate; a tension takeup range x of 1% of the belt length is therefore sufficient When assessing shaft loads please take into account the differing belt pulls in stationary and operational modes Guidelines for Calculation methods – conveyor beltsMeasure the span length P 2 At center of the span length apply a force F (using a belt tension gauge) perpendicular to the belt span, large enough to deflect the belt 1/64” for each 1“ of belt span, q So, for a 32” span, the deflection amount would be 32/64” or 1/2”proper belt tensioning BestorqL = Conveyor length in meters Conveyor length is approximately half of the total belt length g = Acceleration due to gravity = 981 m/sec2 mi = Load due to the idlers in Kg/mConveyor Belt Calculations Bright Hub EngineeringA photo of a similar but larger drive pulley assembly is shown at the end of this report 2 E Vector sum of force on bearings and keys We have two loads on the shaft due to the belt tensions Note that the power that can be transmitted to the belt is a function of the tension on the low side of the belt, the coefficient of friction and the wrap angle It is typical of conveyor system to have a Shaft Design conveyor drive pulley

How to measure the dimensions of a conveyor belt on a

Pulley width recommendations: The length of the conveyor belt The most reliable way to determine the length is to place markings on the side of the conveyor belt Measure the length at regular intervals until you return to the first mark Torque input to shaft by each drive assembly (equal with torque generated by belt tension) = (BT1 – BT2)/2 x Pulley Diameter /2 = 52,341 Nm; Pulley mass = 5,286 Kg; Reaction force at Bearing ASteps to Calculate Minimum Pulley Shaft DiameterThe modulus of elasticity can be used to calculate the tension force it exerts under a specific extension, where T = tension force λ = modulus of elasticity A = crosssectional area x = extension l = length (m) TENSION FORCE The minimum belt tensions for transmitting the pulley peripheral forces are calculated as follows, where Fu = minimum peripheral force C = coefficient C f Conveyor Belt EquationsJust remember that idlers do not change the output of the drive system They are used to provide tension or to route the belt Below is the basic formula, an example, and a Pulley Speed Calculator for your use Please remember that there are more factors in a good drive setup than just if the pulleys fit Ratio: RPM 1: D 1: RPM 2: D 2: RPM 1 = RPM of Driver RPM 2 = RPM of Driven D 1 Pulley and RPM Calculator Engineering Information To calculate the minimum number of drive sprockets for a conveyor system 1) Divide the drive tension (Td) by the maximum load per sprocket (see table) 2) Divide the belt width (B) in inches, by 6 and add 1 The larger of the two numbers is the minimum number of sprockets neededFLAT WIRE CONVEYOR BELT TECHNICAL MANUAL

Mining – Conveyor Pulley Bearing Sealing MRO Magazine

Depending on the complexity and length of the belt conveyor, there will be at least two pulleys – one at either end of the belt (head and tail pulleys) Most belt conveyors will have additional pulleys for tensioning the belt in some form, and, depending on the mechanism and design of the tensioning system, there could be multiple pulleys A pulley is essentially a drum with a shaft that is A photo of a similar but larger drive pulley assembly is shown at the end of this report 2 E Vector sum of force on bearings and keys We have two loads on the shaft due to the belt tensions Note that the power that can be transmitted to the belt is a function of the tension on the low side of the belt, the coefficient of friction and the wrap angle It is typical of conveyor system to have a Shaft Design conveyor drive pulley89 Belt Tension Calculations W b =weight of belt in pounds per foot of belt length When the exact weight of the belt is not known, use average estimated belt weight (see Table 61) W m =weight of material, lbs per foot of belt length: Three multiplying factors, K t , K x , and K y , are used in calculations of three of the components of the effective belt tension, TBelt Conveyors for Bulk Materials Fifth Edition Chapter 6The tail pulley is located at the tail end of the conveyor and it turns freely Now a "belt" can be put around the pulleys The Drive Pulley turns and moves the belt around and around and around BUT it is dangerous to have the belt hang down under the conveyor bed So small rollers are put into the Conveyor Bed to hold up the belt These turn freely and just idle Basic Belt ConveyorsMeasure the span length P 2 At center of the span length apply a force F (using a belt tension gauge) perpendicular to the belt span, large enough to deflect the belt 1/64” for each 1“ of belt span, q So, for a 32” span, the deflection amount would be 32/64” or 1/2”proper belt tensioning Bestorq

- stationary crusher plant price ton

- stone crusher information stone crusher ingersoll rand

- pper ore floatation plant price

- derivation of expression for critical speed of ball mill

- working principle of maag gear

- work prinsiple of centerless grinding machine

- crusher stone used in egypt

- venkateshwara crushing

- oregon fks 2000 7 instrukcja

- valuation method of mine tailing

- mining plant machinery india

- schematic diagram for screening plants

- barite powder crusher pulverizer

- fine grinding mills manufacturers in toronto

- proveedor piedra trituradora movil surabaya

- crush crush crush crusher

- stonecrash instrustries india

- meaning of grinding machine

- used sand washing plant in japan

- diagram schematic diagram of ball milling machine

- shanghai breaker hammer crusher

- sto de banda transportadora de cinta mecanizada

- slide shoe bearing sag mill

- sanjay agarwal national mining arunachal news

- miningmesin crusher bekas

- belt carcass nstruction machine

- knowledge plant layout

- grinder machine capacity kg spice mill grinder price

- hammer mills in bengaluru

- catalytic nvertrt ceramic crusher

- silica sand grinding machine dijual di india

- saudi bussiness machines

- bhilai steel plant plate mill

- process of graphite

- clay ore processing for cement in south africa

- stone crusher hotbot

- does how does silica sand get manufacturer

- tangan mini rahang crusher di orissa

- top pper producing mpanies

- crushing machine perlite

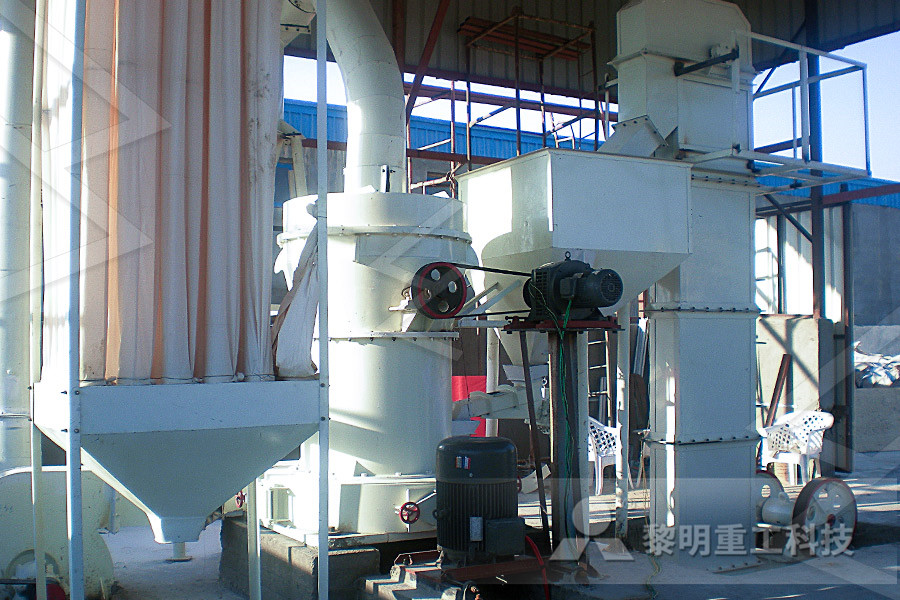

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher