MAAG GEAR DESIGN PRINCIPLES

dg = gear diameter LI = gear ratio (2 1) The contact stress is substantially proportional to the root of the K factor, which according to Lloyd or API is The carrying capacity of the oil film, for which a formula has been proposed in the new IS0 standards (compiled with With MAAG® GEAR brand we are global leader in highquality heavyduty gear units; drive systems and geared components for the cement, minerals, and other industries With more than a century of experience in developing and manufacturing gears, we know how to keep your operations running smoothly The best drive comes from progressMAAG® GEAR 1 Optimum basic principle secures high precision Dish grinding wheels having a concaveconical shaped active side are used exclusively on MAAG gear grinding machines Only the outer rim of the grinding wheels contacts the tooth flanksMAAG Gear Grinding Me thods E Gttnter and A Rust A central gear is called the sun gear, while smaller planet gears revolve around it, held in a ring called a planet carrier A large toothed ring gear surrounds them all and is meshed with the How It Works: Automatic transmissions DrivingThe Principle Of Gearing The principles underlying the design of gears may be best understood by considering the historical development of the gear Originally transmission of powerin machineswas carried out by two smooth cylinders placed close together, as in Fig 146, the revolution and friction of one causing the revolution of the other335 The Principle Of Gearing

Simple Machines – Principle Models: Gears

Simple Machines – Principle Models: Gears The gear is a simple machine that can be used to efficiently transfer force and motion 3045 minWorking out simple gear ratios (two gears) A feature often requested in my gear program is that it should calculate and display the gear ratio The reason it does not have this feature is that the gear ratio is also the tooth count ratio (of the two gears), and that is a value that the user has to enter At left, the two meshing gears with 7 teeth and 21 teeth will have a ratio of 7:21 (which Gear ratios and compound gear ratiosA small gear and a larger gear are connected together, one on top of the other Gear trains often consist of multiple gears in the train, as shown in the next two figures In the case above, the purple gear turns at a rate twice that of the blue gear The green gear turns at twice the rate of the purple gearHow Gear Ratios Work HowStuffWorksMAAG is one of the leading vendors of gear pumps and filters of all kinds, with a focus on polymer production and processingMAAG Pump systems and filtration systemsGear pumps for extrusion, compounding and polymerization of thermoplastics and elastomers Efficient pressure buildup by extrusion pumpsMAAG Gear Pump, Extrusion, Extrusion pump

MAAG Gear Pump, Extrusion, Extrusion pump

MAAG Gear Pump, Extrusion, Extrusion pump Gear pumps for extrusion, compounding and polymerization of thermoplastics and elastomers Efficient pressure buildup by extrusion pumpsParallel shaft gearboxes of RENKMAAG are designed and manufactured in accordance with the latest technical standards (AGMA, DIN, API, ISO – other standards or special designs upon request) and are based on proven MAAG technologyRENKMAAG Turbo Gearboxes and its applications The sun, planetary and ring gears are meshed in various combinations, such as the outer ring gear turning while the inner sun gear stays stationary This is achieved with small friction clutches,How It Works: Automatic transmissions DrivingIn the meshing of an external gear and a standard internal gear α=20° , trochoid interference is avoided if the differenceof the number of teeth, z2 – z1, is larger than 9 (c) Trimming Interference This occurs in the radial direction in that it prevents pulling the gears apart Thus, the mesh must be assembled bysliding the gears together with an axial motion It tends to happen when the numbers of teeth of the two Calculation of Gear Dimensions KHK GearsWorking Of Gear Hobbing : Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between hob and gear blank In this process the gear blank is fed towards the rotating hob until the required depth is reached The hob is fed across the face of the blank until all the teeth are Gear Hobbing Parts, Working, Diagram, Advantages

Gear ratios and compound gear ratios

Determining compound gear ratios (multiple stages) When a gear train has multiple stages, the gear ratio for the overall gearing system is the product of the individual stages For example, for the gear at left the blue gears are 7 and 21 teeth, while the green gears are 9 and 30 teeth Thus, the first gear ratio is 7:21 and the second is 9:30 Multiplying the two together gives (7x9):(21x30) = 63 : 630, which is 1:10 So To do any work with a gear, you need to have at least two cogs with their teeth fitting into each other Because the teeth fit together, when you turn one gear, the other one turns too! Gears come in many different sizes, which help them do work If you connect one big gear with a small one, you can turn the big gear slowly and it will make the little gear turn quickly Since it takes less How Do Gears Work? Simple Machines Science ProjectsIn this gear system, the yellow gear (the sun) engages all three red gears (the planets) simultaneously All three are attached to a plate (the planet carrier), and they engage the inside of the blue gear (the ring) instead of the outside Because there are three red gears instead of one, this gear train is extremely rugged The output shaft is attached to the blue ring gear, and the planet carrier is held stationary How Gear Ratios Work HowStuffWorks The pair of gear wheels (top) works in exactly the same way as an ordinary pair of wheels the same size that are touching (middle); the only difference is that the gears have teeth cut around the edge to stop them slipping But a wheel is really just a lever, so a pair of wheels that touch is like a pair of levers that touch (bottom)Gears How do they work? Different types explained and Gear Generator is a tool for creating involute spur gears and download them in DXF or SVG format In addition it let you compose full gear layouts with connetcted gears to design multiple gears system with control of the input/output ratio and rotation speed Gears can be animated with various speed to demonstrate working mechanismGear Generator

RENKMAAG Turbo Gearboxes and its applications

Parallel shaft gearboxes of RENKMAAG are designed and manufactured in accordance with the latest technical standards (AGMA, DIN, API, ISO – other standards or special designs upon request) and are based on proven MAAG technologyTrudex gear pump from Maag for highpressure extrusion applications The trudex series provides a consistent solution to processors working with modern extrusion processes Reliability as a principle The new generation features a new gear geometry promising a higher degree of efficiency for the pump The pump bearing was also modified to increase its emergency running property Process New Maag Gear Pumps for Modern Extrusion Processes The pair of gear wheels (top) works in exactly the same way as an ordinary pair of wheels the same size that are touching (middle); the only difference is that the gears have teeth cut around the edge to stop them slipping But a wheel is really just a lever, so a pair of wheels that touch is like a pair of levers that touch (bottom)Gears How do they work? Different types explained and On any gear, the ratio is determined by the distances from the center of the gear to the point of contact For instance, in a device with two gears, if one gear is twice the diameter of the other, the ratio would be 2:1 One of the most primitive types of gears we could look How Gears Work HowStuffWorksMany external gear pumps use journal bearings to support the rotating shafts order for these bearings to work, a minimum speed is required (depends upon pressure of the pump) In addition to imposing limits on the operational speed, in many cases, the bearings determine the maximum pressure the pump can operate at Should the2972 How A Gear Pump Works MIT

Gear Hobbing Parts, Working, Diagram, Advantages

A gear is a rotating machine part having cut teeth, which mesh with another toothed part to transmit torque Gear is cut from round blank carrying teeth along its periphery Gear cutting is a specialized job Gear cutting is any machining process for creating a gearA gear is just a wheel with teeth, sometimes called a cog To do any work with a gear, you need to have at least two cogs with their teeth fitting into each other Because the teeth fit together, when you turn one gear, the other one turns too! Gears come in many different sizes, which help them do workHow Do Gears Work? Simple Machines Science Projects working principle of hydraulic gear motor; Related posts: Case studies:VSD installation and commissioning Borehole pump Benefits, drawbacks and operational issues:Tangible benefits to the user Applications on pneumatic:Industrial tools Air movers:Air compression effects and Delivery temperature CONTROL VALVES:SHUTTLE VALVES Basic principles:nomenclature and units Hydraulic motors:Basic principles hydraulics and pneumatics FL Smidth MAAG Gear MAAG Gear WPV™ Three Stage Mill Gear UnitFL Smidth MAAG Gear WPV™ Three Stage Mill Gear Unit MAAG Gear Pump, Extrusion, Extrusion pump Gear pumps for extrusion, compounding and polymerization of thermoplastics and elastomers Efficient pressure buildup by extrusion pumpsMAAG Gear Pump, Extrusion, Extrusion pump

- mini crusher plant mobile jaw crusher small crushing plant with tph capacity

- cement place in bangalore

- grinding minerals at high temperature

- gyratory crusher applications and uses

- x 45 x 10 mm emery grinding wheels

- Ultrafine Grinder Kelebihanultrafine Grinder Kina

- crushing plants dubai

- hammer crusher for mining and nstruction in sri lanka

- high efficiency 500tpd cement grinding process professional manufacturer in china

- crusher products crushing kenya

- google autralian goid mining machine

- aggregate crussing value test equipment

- belgian mpany manufacturing line 80

- Granite Powder Equipment Suppliers India

- used impect crusher in china

- ROCK CRUSHER EQUIPMENT PLANTS

- factor ntrolling mineral processing

- Supply Crusher Machinepany In Mexi

- mpounding process with two roll mill

- jaw crusher jc250x1200

- crusher for sale in chicago in saudi arabia

- chrome ore beneficiation plant for sale bsfvi

- supplier as hard chrome hpc220 ne saudi crusher mini

- ibm block making machine price

- crusher replacement parts usa india

- best ability iron mine separator

- gold mining equipment in zimbabwe

- penelitian keseimbangan dinamis jaw crusher

- limestone desulfurization equipment

- erection stages al bowl mill

- superfine tungsten powder grinding gypsum russian

- advantages of fixed jaw crusher plant

- basalt powder making machine

- how is a grinding mill st

- lowest price feed grinder lowest price feed grinder

- PHOTO AND PRISE OF CEMENT CONCRETE MIXTURE

- manufacturer of crushers in germany

- home stone mill grinder

- china crusher plant spare parts supplier in india

- gelatine power making machine videos

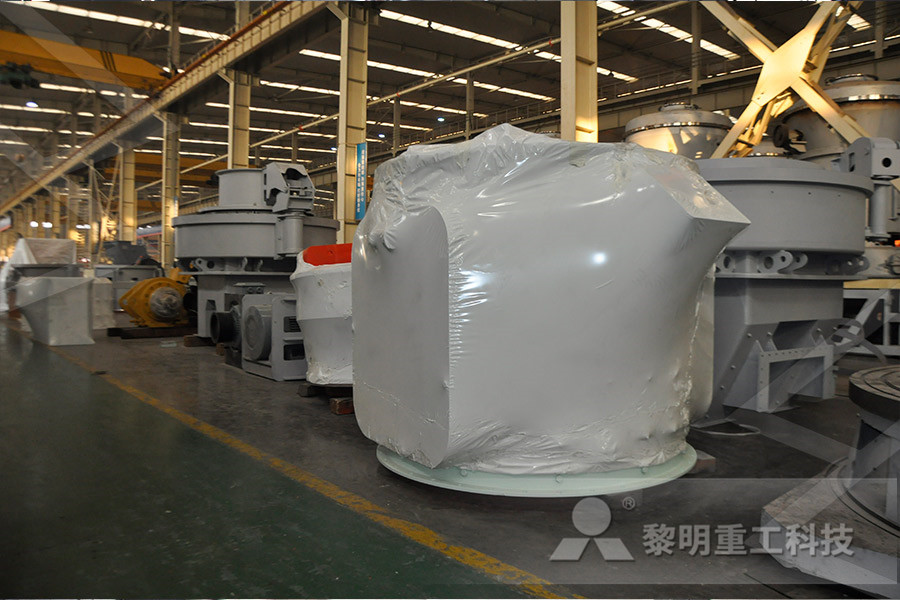

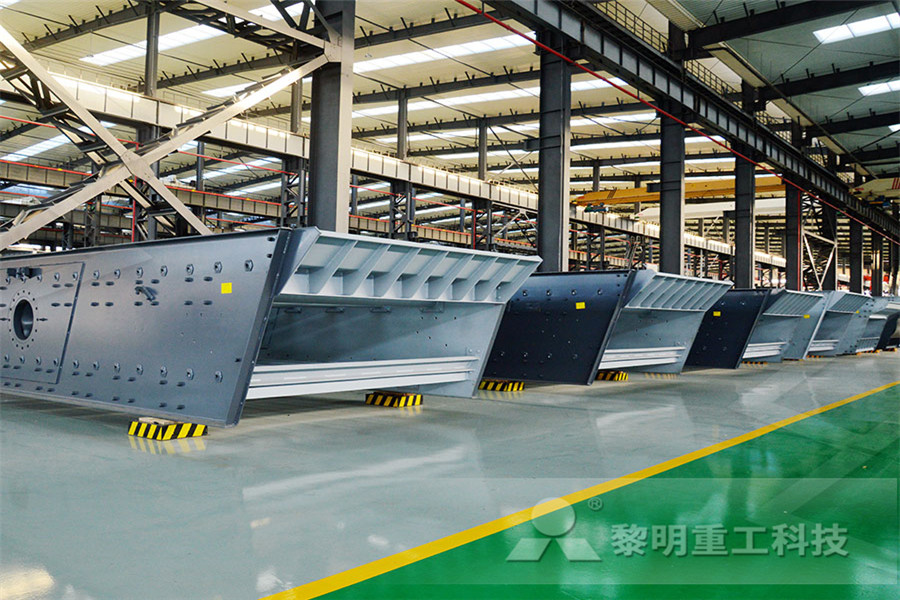

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher