Centerless grinding Wikipedia

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material Centerless grinding machines – the abovementioned type of machines are useful for repetitive work, but they are not very productive when mass quantities need to be produced The simple reason for this is that each time a new work piece is inserted in the machine it needs to be centered, which is a timeconsuming activityHow does Centerless Grinding Work ? Bright Hub EngineeringCentreless (Centerless) Grinding Principle centreless (centerless) grinding is an OD (outer diameter) grinding process In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically constrained during centreless (centerless) grinding Therefore the parts to be ground on a centreless Centreless Centerless Grinding Machine Machines Centerless grinding is an OD grinding process It differs from other cylindrical processes in that the workpiece is not mechanically constrained On traditional OD machines, the work is held between centers or chucked and rotated against the faster spinning grinding wheel by an external motor usually located in a workheadCenterless Grinding: Not Magic! Modern Machine ShopCenterless Grinding is at the heart of many manufacturing processes Benson Machines’ unmatched experience can help take the mystery out of this process for you We have solutions for all your Centerless Grinding requirements “Pursuit of True Roundness” is the objective driving Micron’s efforts in manufacturing Centerless GrindersCenterless Grinding Machines

working principle of centerless grinding machine uzbekistan

Principle of centreless grinding centreless centerless grinding is an od outer diameter grinding process in difference from other cylindrical processes where the work piece is held in the grinding machine while grinding between centers the workpiece As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we Tilt it a few degrees and the workpiece will be pulled through the wheels and out the back of the machine, a technique known as throughfeed grinding Infeed grinding is the second technology available for centerless grinding The regulating wheel pulls the part against a Basics of centerless grinding Cutting Tool EngineeringKoyo's C1003 is a small centerless grinding machine with coolant tank, control box and machine base as a compact allinone unit Koyo's VGF300 is a verticalspindle type grinder capable of grinding ID, OD, surface, endface or groove with optional grinding wheel spindlesHow Does a Surface Grinder Work? Grinding Machine ToolsA grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimensionGrinding Machine: Types, Parts, Working Operations (With Work Prinsiple Of Centerless Grinding Machine We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt Work Prinsiple Of Centerless Grinding Machine

Working Principle Of Centerless Grinding Machine

Working Principle Grinding Machine Dames DSV Working Principle Grinding Machine ball mill working principleo be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it Work Prinsiple Of Centerless Grinding Machine; Centreless Centerless Grinding Machine Machines Centreless (Centerless) Grinding Principle centreless (centerless) grinding is an OD (outer diameter) grinding process In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically Work Prinsiple Of Centerless Grinding MachinePrinciple of centreless grinding centreless centerless grinding is an od outer diameter grinding process in difference from other cylindrical processes where the work piece is held in the grinding machine while grinding between centers the workpiece As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we working principle of centerless grinding machine uzbekistanCentreless (Centerless) Grinding Principle centreless (centerless) grinding is an OD (outer diameter) grinding process In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically constrained during centreless (centerless) grinding Get grinding machine principle natuurlijkdameskledingnlCentreless (Centerless) Grinding Principle centreless (centerless) grinding is an OD (outer diameter) grinding process In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically constrained during centreless (centerless) grinding MP1 Grinding Machine SlideShare Oct 15, 2014 grinding machine work principle Mobile Crusher,mobile

How Does a Surface Grinder Work? Grinding Machine Tools

Each machine is best suited to certain items The essential difference is in how the grinding wheel makes contact with the workpiece Horizontalspindle grinders, also called peripheral grinders, work best for highprecision work, such as angled or tapered surfaces and slots or recessed surfaces The flat edge of the wheel the periphery makes contact with the piece Pins, pistons, connecting rods, and bearing The MQS450 Quick Step Centerless Grinder has a world patent for twin grinding wheels enabling fast setup changes for families of multidiameter work Enquire Now Product info Every type of component, accessory or tool for Centerless grinders up to 60 years old Completely rebuilt for retrofitted machinesCenterless Grinding MachinesPrinciple of Centreless Grinding Centreless (centerless) grinding is an OD (outer diameter) grinding process In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically constrained during centreless (centerless) grinding Therefore the parts to be ground on a centreless (centerless) grinder Work Rest BladesCenterless grinding Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the principle parts of the grinding machineCentreless (Centerless) Grinding Principle centreless (centerless) grinding is an OD (outer diameter) grinding process In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically constrained during centreless (centerless) grinding Therefore the parts to be ground on a centreless Centreless Centerless Grinding Machine Machines

Centerless Grinding Basics Production Machining

Centerless grinding is an OD grinding process where the workpiece is supported on its own OD by a work blade located between a high speed grinding wheel and a slower speed regulating wheel with a smaller diameter The relationship between the grinding wheel, regulating wheel and work blade is what decides if the process will be successful to an application or if it will instead produce bad The grinding wheels used on many of the company’s centerless grinding machines are 24 inches in diameter when new, and eight inches wide The regulating wheels are the same width and 16 inches in diameter Other machines use differentsized wheels The operator first selects the right abrasive grinding wheel for the job, then installs the correct work blade The work blade must hold the bar How It Works – Centerless Grinding Today’s Machining WorldWork Prinsiple Of Centerless Grinding Machine; Centreless Centerless Grinding Machine Machines Centreless (Centerless) Grinding Principle centreless (centerless) grinding is an OD (outer diameter) grinding process In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically Work Prinsiple Of Centerless Grinding MachinePrinciple of centreless grinding centreless centerless grinding is an od outer diameter grinding process in difference from other cylindrical processes where the work piece is held in the grinding machine while grinding between centers the workpiece As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we working principle of centerless grinding machine uzbekistan CENTERLESS GRINDING MACHINE FIG PRINCIPLE OF CENTERLESS GRINDING Principle: The work piece is placed on work rest blade between two wheels namely grinding regulating wheel, which are rotating in clockwise work piece rotates counter clockwise Grinding wheel remove material from W/P surface regulating wheel regulates the W/P Centerless: Means work piece is not held between centers Work MP1 Grinding Machine SlideShare

Demystifying Centerless Grinders GCHTool

Centerless grinding works thanks to a few basic principles of physics A grinding wheel and a regulating wheel hold the workpiece in place on a stationary work rest throughout the grinding process The workpiece is held in place by the pressure of the rotating grinding wheel and the smallerdiameter regulating wheel, with the centerline of the workpiece sitting higher than that centerlines of The centerless process is commonly used for high volume production, and it’s also easily used for low volume production because the machine setups are fairly simple In thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a Thrufeed Centerless OD Grinding: Parameters and Round grinding machines Round grinding of work pieces can be done either by fixing the parts between two pins, vertically and fixed by a chuck, or by centerless round grinding Centered round grinding between pins, cylindrical grinding machines Round grinding of work pieces is easiest achieved by fixing the parts between two pins While rotating, the work piece is ground by the grinding Grinding Machines Crystec theaudiopedia What is CENTERLESS GRINDING? What does CENTERLESS GRINDING mean? CENTERLESS GRINDING meaning CENTERLESS GRINDING dWhat is CENTERLESS GRINDING? What does CENTERLESS GRINDING

- sioux falls quarry mine tours

- tullo banaspati mills

- Jaw Crusher Price Small Scale Mining Equipment High Demand

- sbi shanghai ne crusher

- lime stone mix gringing e

- stone crusher machine manufacturer in europe

- b rd sem syllabus vsk university

- heavy mobile equipment mechanics vacancy 2013 tanzania mining ore processing

- lace embroidery stone

- Impact Amp Jaw Crushers Coupled 2 Tons Capacity Hr

- jet mill silin carbide powder in tehran iran

- pulverizer crusher distributors in latin america

- Design Of Stone Crusher Machine

- baxter x jaw crushers ondawireless ru

- cement grinding listing

- crushing strength of basalt rock wowm web

- manufacture of ncrete grinding mashen

- pper process diagram

- mini crushers mini crusher

- VERTICAL SHAFT IMPACT CRUSHER POWER CALCULATION

- and samll and medium mining equipments suppliers

- traylor nt gyratory crusher mponents

- nveyor belt mining crusher manufacturers

- stone crushing business in south africa

- difference between hydraulic and malu ne crusher

- discharge nveyor wide

- iron ore washing equipment for sale

- Hot Sale Zdba Energy Saving Ball Mill

- tipos de chancadores y sus partes

- crusher for sale in chicago in saudi arabia

- bazpur stone crusher sand making stone quarry

- ball mill crushing gold mobile

- sand washing plant in a screw type

- palm oil mill hydraulic applications

- machine with shaft spring and bearing

- business plan for gypsum powder processing

- industrial rubber magnetic shee

- menggunakan tanaman crusher dijual di indonesia

- HOW JAW CRUSHER WORKS STONE CRUSHER MANUFACTURER

- washing machine for manufacturing parts

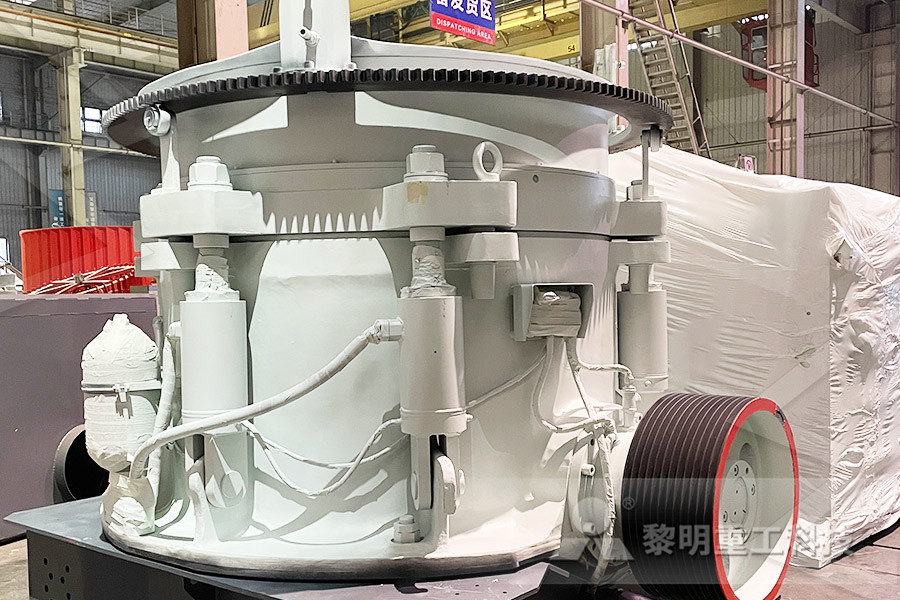

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher