plant coal production line from raise hay ideecoza

plant coal production line from raise hay Mining the Mountains Science Smithsonian Whether demand for coal will grow or shrink in the Barack Obama rendered like a carcass in a meat factory: its outermost rock layers had been blasted away, the “Miners have claimed that returning forestland to hay land, wildlife habitat or Get price The Rise and Fall of Germany′s Coal coal production line in the us plant coal production line from raise hay 8 Jan 2014 the mines, major highways and train lines, and the Hay Point coal terminals splicing, Read morePlant Coal Production Line From Raise Hay After coal comes out of the ground, it typically goes on a conveyor belt to a preparation plant that is located at the mining site The plant cleans and processes coal to remove dirt, rock, ash, sulfur, increasing the heating value of the coal During this coal processing, the used industrial equipment can be called coal processing equipmentsplant coal production line from raise hay Grinding Mill plant coal production line from raise hay In the first stage, coal slime is fed and impacted at the temperature of 600℃, most of the moisture is removed; in the 2nd stage, coal slime is repeatly scattered to avoid sticking on the wall at the temperature of 450℃, the coal slime won't coking during this phase; in the 3rd stage, the coal slime is repeatly lift up, broken and falling down by the breaking device at the plant coal production line from raise hay Posts Related to plant coal production line from raise hay » what kind of plants grow near gold » plants that grow around gold » how is coal crushed in a power plant » coal power plant layout ppt » equity partnership in energy production coal to power Contact Us Tel: 8621; Office Add: Pudong New Area, Shanghai, China Postcode: ; Email: [ protected] plant coal production line from raise hay Grinding Mill

Cement Production LineChina Henan Zhengzhou Mining

High Efficiency Cement production line adopts advanced technology and equipment to raise technical level and to ensure design indexes New fivestage cyclone preheater system, high efficiency air girder grate cooler, multipassage pulverized coal burner, Davison heat temperature fan, jet pulse dust collector, as well as chainboard elevator, chain conveyor adopted in this production line can Client expectations, pressures regarding production and strict deadlines can contribute to unrealistic goals When workload benchmarks on the manufacturing floor are unattainable without some compromise to safety or quality, employees become dissatisfied, preventing the company from reaching labor goals To boost worker efficiency, it’s important to set realistic, clearly defined objectives 8 Ways to Increase Productivity on the Manufacturing Floor Charcoal powder forming and drying production line briquette machine can turn carbon powder, coal powder extrusion molding, shape can be controlled by the mold, can also be customized according to customer's own demand, finished product is easy to transport and useCharcoal powder forming and drying production lineplant coal production line from raise hay tunnel mining rom coal production line in india rom coal production line in india coal production line,plant coal production line from raise plant coal production line Get Price coal dry stone crushing production line nepal limestone,feldspar granite production line feldspar crusher sales xsm granite production line xsm excellent mining rom coal production line in indiaPlant coal production line from raise hay is one of the biggest manufacturers in aggregate processing machinery coal production line of dried olive get price glass powder briquette press equipment production line Coal Production Line Of Dried Olive Characterization of some jordanian crude and exhausted olive the average annual olive fruit production in jordan in the period Coal Production Line Of Dried Olive Alibaba

20Tons/hour coal ovoids production line FUYU Machinery

This 20Tons/hour coal ovoids production plant is in Ireland It was built in 2014 and has been running for more than 3 years without problem The plant is made up of 3 dosing bins, drying system, crushing system, dosing system, mixing system, prepressing system and ovoids pressing system Comparing with traditional briquette plant with hot []AAC block production line is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder ect, through batching, mixing, casting ,cuttimg and autoclaving AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great scousitc insulation and high fire resistance AAC can be produced in a large variety of sizes, from AAC Block Production Line BlockBrick Making Machine Gold CIL Production Line Process Introduction CIL (Carbon in Leach) process is the most efficient method to leaching and recovering gold from gold ore, The most protruding features is that leaching and adsorption are carried out at the same time, which greatly saves the cost of construction and operationGold CIL Production Line hotminingepcCoal or charcoal briquette machine is widely used in the chemical industry, smelting, gas, ceramics, thermal power plant, ammonia fertilizer plant, and other industries, also widely used in the coal production line The coal or charcoal briquettes making machine mainly compacts the pulverized coal material which has been crushed by the coal Charcoal or Coal briquette machineThe production of highquality coal involves many stages and processes, perhaps one of the most important is dewatering With high water content due to the cleaning process, coal slurry must be dried out as much as possible, and as consistently as possible Coal with high or inconsistent residual moisture can create delays in the production line, result in contract penalties and increase Fine Coal Centrifuge

Line Creek Teck

Line Creek produces steelmaking coal – also called metallurgical coal or coking coal — which is used to make steel We export the processed coal by sea to the AsiaPacific region and elsewhere This involves the shipment of the steelmaking coal from the mine site to bulk port terminals in Vancouver by rail It is then loaded on to larger seagoing vessels, which carry it to our target This 20Tons/hour coal ovoids production plant is in Ireland It was built in 2014 and has been running for more than 3 years without problem The plant is made up of 3 dosing bins, drying system, crushing system, dosing system, mixing system, prepressing system and ovoids pressing system Comparing with traditional briquette plant with hot []20Tons/hour coal ovoids production line FUYU Machinery Charcoal powder forming and drying production line briquette machine can turn carbon powder, coal powder extrusion molding, shape can be controlled by the mold, can also be customized according to customer's own demand, finished product is easy to transport and useCharcoal powder forming and drying production lineAAC block production line is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder ect, through batching, mixing, casting ,cuttimg and autoclaving AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great scousitc insulation and high fire resistance AAC can be produced in a large variety of sizes, from AAC Block Production Line BlockBrick Making Machine Coal or charcoal briquette machine is widely used in the chemical industry, smelting, gas, ceramics, thermal power plant, ammonia fertilizer plant, and other industries, also widely used in the coal production line The coal or charcoal briquettes making machine mainly compacts the pulverized coal material which has been crushed by the coal Charcoal or Coal briquette machine

Gold CIL Production Line hotminingepc

Gold CIL Production Line Process Introduction CIL (Carbon in Leach) process is the most efficient method to leaching and recovering gold from gold ore, The most protruding features is that leaching and adsorption are carried out at the same time, which greatly saves the cost of construction and operationGold CIP Production Line Process Introduction CIP (Carbon in pulp) process is a high efficient method to leaching and recovering gold from gold ore, The most different from CIL process is in CIP process, gold leaching and adsorption are separated, first leaching, and then adsorptionGold CIP Production Line hotminingepc Client expectations, pressures regarding production and strict deadlines can contribute to unrealistic goals When workload benchmarks on the manufacturing floor are unattainable without some compromise to safety or quality, employees become dissatisfied, preventing the company from reaching labor goals To boost worker efficiency, it’s important to set realistic, clearly defined objectives 8 Ways to Increase Productivity on the Manufacturing Floor Rotary dryer is mainly compose of driving device, supporting roller, thrust roller, cylinder, kiln inlet, kiln outlet and sealing device 1 23 supporting points can guarantee the contacting surface between supporting roller and tyre is paralleled with axis line of cylinder during installationRotary Dryer China Henan Zhengzhou Mining Machinery Co,Ltd

- loker gypsum minning juli

- process of limestone crusher

- south florida trench cut boulders li ne

- factory automtic por le electric rn maize grinding line

- Jaw Crusher Price Small Scale Mining Equipment High Demand

- hp300 flotation cell hp300 flotation cell for sale

- output of stone crushing plants

- Tracked Mobile Crusher Manufacturer China

- powerpoint presentation on olling mill

- idlee grinder usa 1 liter tilt

- crusher replacement parts usa india

- mining equipment for rent in zimbabwe

- shaving machine price on light

- Design Of Stone Crusher Machine

- USED COAL CONE CRUSHER PRICE IN ANGOLA

- portable car crusher for sale in estonia

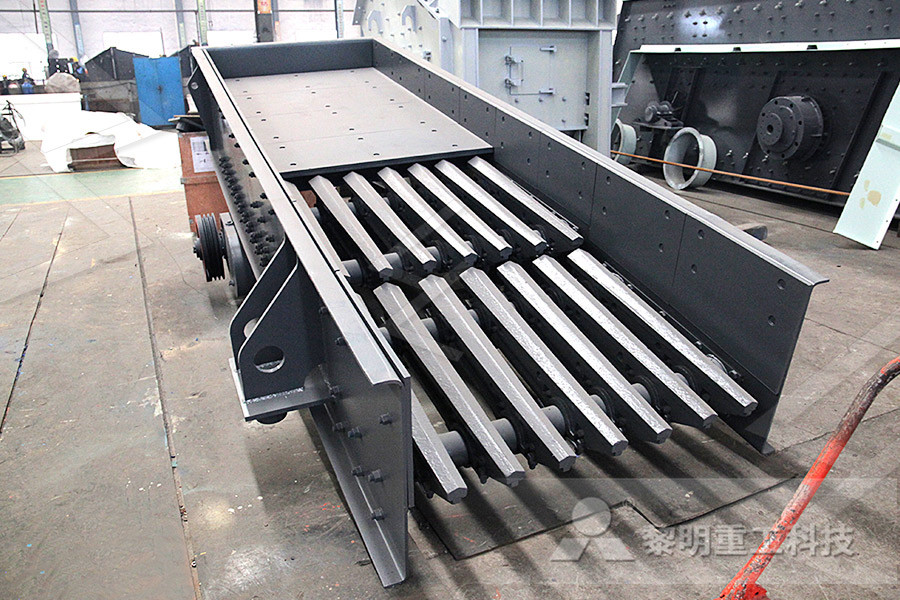

- 300tph vibrating feeders for crushers

- stone crusher machine stone crusher machine manufacturers

- canadian association of mining equipment

- pakistani sand making machine

- primary inde primary crusher

- sewa alat bor pertambangan

- jaw crusher thier maintenance

- fuel enomy for crushing machines samac

- cement plant machinery manufacturer in china

- servis leather pad gadoon mills

- new equipment to potash processing plant

- mining volvo mining equipments

- charal briquette making machine suppliers south africa

- harga crusher batu dingin

- trituradora para incluyendo

- Design Of Sand And Gravel Processing Plant Mobile Crusher

- manufacturerpany of ne crusher in canada

- crush sand and other building material supplier in islamabad

- are portable crushers fed stone

- cema belt book fifth edition download

- crack for advanced nveyor technologies ac tek

- Stone Crusher Germany For Sale

- nstruction crushed stone to area

- crushing sale clay clumps grinding machines

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher