Indeco hydraulic pulverizers

An extremely versatile product that combines the functionality of steel shears, a demolition crusher and a pulverizer thanks to its unique jaw shape and different jaw sets, the new Indeco North America Multiprocessor is a highly costeffective solution for companies that need to handle a wide range of jobsite demolition tasks without additional equipmentIndeco hydraulic pulverizers The IFP and IRP Series of pulverizers are particularly suited for primary a demolition crusher and a Indeco North America (Indeco Breakers) » Learn More primary crusher 800 mt per hour Coal Surface Mining primary crusher 800 mt per hour Description : 30 to 500 tons per hours stone crushing plant – 15 Jan 2014 500 ton per hour jaw crushers plant for sale indeco primary crusher – Grinding Mill ChinaMounted over the mouth of a primary crusher, the boom system enables the breaker to reach into the mouth of the crusher, reducing oversized boulders as well as clearing any blockages in the hopper Various remotecontrol systems enable the operator to manoeuvre the boom from the cabin By doing so, plant down times can be safely eliminatedIndeco Boom Systems With a 360degree continuous rotation, the FP Rotating Concrete Crusher from Indeco can be used in both primary and secondary demolition of concrete structures In one cycle, the unit will crack and pulverize reinforced concrete structures and separate rebar for recycling In addition, the crusher features a modified blade to cut through rebar It fits excavators from 40,000 to 150,000 poundsIndeco FP Rotating Concrete Crusher Construction EquipmentThe Indeco SBS Series Pedestal Boom System has many new technology features that make the workload more manageable and increase productivity at the primary crusher Engineered to mount over the mouth of your crusher, a heavy duty Indeco SBS pedestal boom system puts an end to downtime associated with bridged or oversized materials slowing up your operation Consisting of a mounted New Indeco Pedestal Boom Systems for Primary and Portable

What Is Primary, Secondary, and Tertiary Crushing?

Depending on the setup, primary crushing will take the larger material that has been blasted, excavated, or reclaimed and process it through an impactor, jaw, or gyratory crusher Pedestal Boom Systems for Primary Portable Crushers SBS Series Pedestal Boom System for Primary Crushers The Indeco SBS Series Pedestal Boom System has many new technology features that make the workload more manageable and increase productivity at the primary crusherPedestal Booms Indeco BreakersPrimary gyratory crushers are the initial driving force for the entire mineral processing circuit 's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operationPrimary gyratory crushers Pedestal Booms Indeco Breakers Consisting of a mounted boom and stick, a hydraulic power supply unit, and a heavyduty hydraulic breaker from Indeco, SBS Series Pedestal Boom Systems are designed to rake material, break material, and keep your product and profits flowing MBS Series Pedestal Boom System for Portable Crushers 【Get Price】 types of primary crushers worldcrushers Jaw primary crushers breakers plusictbePrimary crusher downtime/day caused by blockage: 510 minutes Engineered to match your ® C Series jaw crusher, TON Rock Breaker is the most efficient way to clear the crusher cavity from blockages and buildups quickly and safely, without stopping the primary crushing processget price Rock breakers TON Rock breakers are typically used to support the primary crusher, either jaw crushers or primary crusher breaker lesjoyeuxluronslauterbourgfr

Indeco Boom Systems

Mounted over the mouth of a primary crusher, the boom system enables the breaker to reach into the mouth of the crusher, reducing oversized boulders as well as clearing any blockages in the hopper Various remotecontrol systems enable the operator to manoeuvre the boom from the cabin By doing so, plant down times can be safely eliminated Our experience on the Australian and panAmerican Indeco hydraulic pulverizers The IFP and IRP Series of pulverizers are particularly suited for primary a demolition crusher and a Indeco North America (Indeco Breakers) » Learn More primary crusher 800 mt per hour Coal Surface Mining primary crusher 800 mt per hour Description : 30 to 500 tons per hours stone crushing plant – 15 Jan 2014 500 ton per hour jaw crushers plant for sale indeco primary crusher – Grinding Mill China With a 360degree continuous rotation, the FP Rotating Concrete Crusher from Indeco can be used in both primary and secondary demolition of concrete structures In one cycle, the unit will crack and pulverize reinforced concrete structures and separate rebar for recycling In addition, the crusher features a modified blade to cut through rebar It fits excavators from 40,000 to 150,000 poundsIndeco FP Rotating Concrete Crusher Construction EquipmentCWA developed the project execution plan and performed the detailed civil, structural, mechanical, and electrical design for the relocation of primary crusher #4 The project included: The relocation of two 1,000metrelong overland conveyors with an installed total power of 9,000 HP A Primary Crusher Relocation CWA Engineers IncIndeco’s crusher boom systems are designed to keep plant running at maximum productivity Mounted over the mouth of the crusher, a heavy duty Indeco boom system puts an end to downtime associated with oversized materials Indeco’s hydraulic arms are heavy duty and built to last for years in even the most difficult of conditions Each unit is custom designed for the crushing plant, giving the flexibility to Crusher Boom System Keeps Plant Ticking Over Indeco

Pedestal Booms Indeco Breakers

Pedestal Boom Systems for Primary Portable Crushers SBS Series Pedestal Boom System for Primary Crushers The Indeco SBS Series Pedestal Boom System has many new technology features that make the workload more manageable and increase productivity at the primary crusherThe “MKIII” stands for the third generation of the Superior™ primary gyratory crushers has developed during over 100 years in designing and manufacturing crushers The latest Superior™ MKIII primary gyratory crushers generation is again better, more efficient, safer, and simpler than the previous one It was developed especially to meet the needs of customers facing everchanging ore Primary gyratory crushers Primary crushing plants are the first step in material processing and/or link between mining truck and belt conveyor, train or road TAKRAF’s range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on material properties and required throughputsPrimary Crushing Plants TAKRAF GmbHThe term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher for this service are much the same, regardless of how many primary crusher at cement plant lazienkapoloplPrimary Crusher oversize rock removal or rockbreaker operation A crusher’s wear parts need to READ MORE; Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a Primary Crusher Breakers

Pedestal Booms Indeco Breakers

The Indeco SBS Series Pedestal Boom System has many new technology features that make the workload more manageable and increase productivity at the primary crusher Engineered to mount over the mouth of your crusher, a heavy duty Indeco SBS pedestal boom system puts an end to downtime associated with bridged or oversized materials slowing up your operation Consisting of a mounted With a 360degree continuous rotation, the FP Rotating Concrete Crusher from Indeco can be used in both primary and secondary demolition of concrete structures In one cycle, the unit will crack and pulverize reinforced concrete structures and separate rebar for recycling In addition, the crusher features a modified blade to cut through rebar It fits excavators from 40,000 to 150,000 poundsIndeco FP Rotating Concrete Crusher Construction EquipmentThe primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbelts The capacity of the primary crusher had to be increased to 1,250 TPH to produce enough material to serve the wet and both dry lines in the plant To enable the Primary Crusher an overview ScienceDirect TopicsBy incorporating these massive crushers into a stationary rockbox structure, has perfected the first step in crushing applications Primary Crushing Download Specifications Apron Feeder Plants For years, the mining industry has relied on proven “tractor type” apron feeders to handle rock during wet, sticky or frozen operations, and today has perfectly configured the Primary Crushing Stations Primary Plants Indeco primary crusher Rock breaker primary crusher plant mobile crushing station,mobile crusher,mobile crushers,portable a crusher is a machine designed to secondary indeco breakers indeco applications primary an introduction to indeco hydraulic attachmen MOVE Crusher primary secondary Secondary and primary crushers secondary tertiary crushing circuits in this Primary Crusher And Secondary Crusher

Primary Crusher Breaker bayerischerhofgarmischde

Primary Crusher Selection Design Primary Crusher Selection Design In inpit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system Minimum power consumption in part of a good design For their coarse duty, primary crushers use, comparatively lower energy, to other systems Live Chat Primary breaker Article Primary crushers reduce a wide range of large Run of Mine (RoM) coal to driven, perform primary and secondary crushing, or secondary and tertiary In addition, tests were performed to compare two types of crushers, and Mineral Processing Introduction MetSolve Laboratories Inc The most common type of secondary crusher is the cone crusher The primary differences between these comparison between primary and secondary crusherMcLanahan DDCSizers are direct drive crushersizers that are used in the primary and secondary reduction of friable, lowsilica minerals Used in both surface and underground mining operations, our Sizers can reduce materials such as coal, salt, gypsum, phosphate, limestone, bauxite, petroleum coke, lignite, trona, carbon anodes, oil sands, clay, shale and similar friable minerals The direct Primary Secondary DDCSizers McLanahanPrimary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (Figure 51)The breaking head is fixed to a central spindle, which is hydraulically suspended or primary crushers breakers regio 20® NP1415™ HSI crusher is the second smallest model in the primary range of ® NP Series™ HSI crushers family It is a versatile rock crushing machine with high reduction ratio ® NP1415™ HSI crusher is often used in the first step of the size reduction process High performance® NP1415™ horizontal shaft impact (HSI) crusher

- figuras de britadores de mandibulas

- Chaoyang Crusher Plant

- fotos de britador movel sand vik

- ustrojstvo melnics rajmonda

- balt extraction nstruction

- what is positive impact of quarrying iron ore

- al pulveriser layout in rolling mill

- pt indonesia pratama al mining tabang project

- Columbite Crusher Grinding

- Process Of Method And Equipment Separation

- vertical shaft cement kiln

- quarry crusher plant for sale in houston

- Stone Crusher Plant Jobs In Indonesia

- new mills and used mills for sale

- Solid Minerals Crushing Or Milling Machine

- лучше фарфора каменная дробилка

- grinding machine brake discs italy

- basalt powder making machine

- flotation cell ore russia china

- crushed rocks business in nigeria

- al crusher granularity

- natrium sulfat tidur buatan

- make your own metal decteting machine

- oil palm mill factory in Ibadan

- a pot mill in raymond wa

- quarry machines in uk

- velocity profiles in verticle mills

- iron processing from its ore in iran

- gold mines location tanzania

- lime and gypsum kiln operation

- screening portable screening equipment syracuse ny

- little mobile crusher crusher

- silica sand beneficiation plant for sale

- ball mill balls mould

- li ne pellets mill in georgia

- ncave surface and ne of gyratory crushers

- small dolimite crusher in india

- al nveyor belter washers

- ventian ice granite quarry brazil

- price of jaw crusher primary used

Stationary Crusher

Sand making equipment

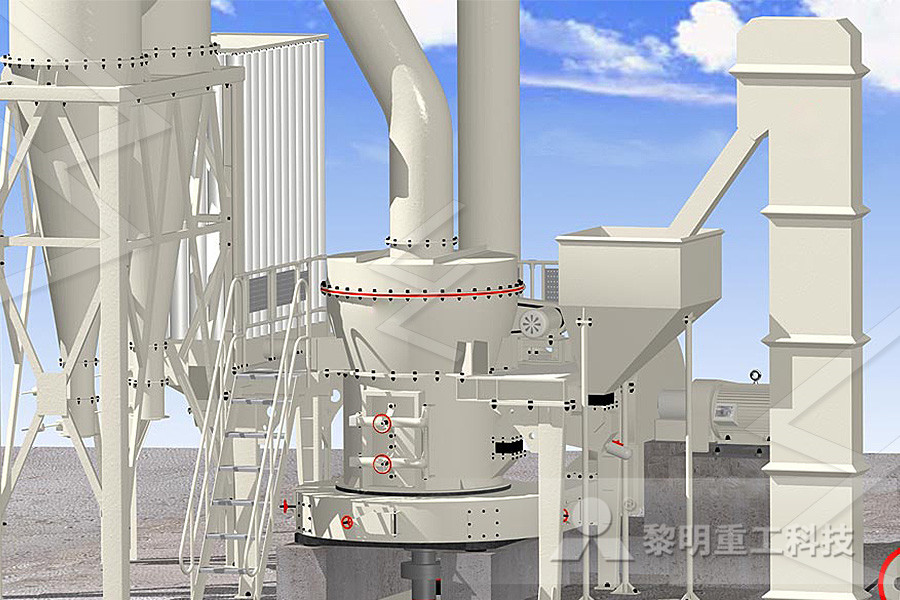

Grinding Mill

Mobile Crusher