Design of sand and gravel processing plant Mobile

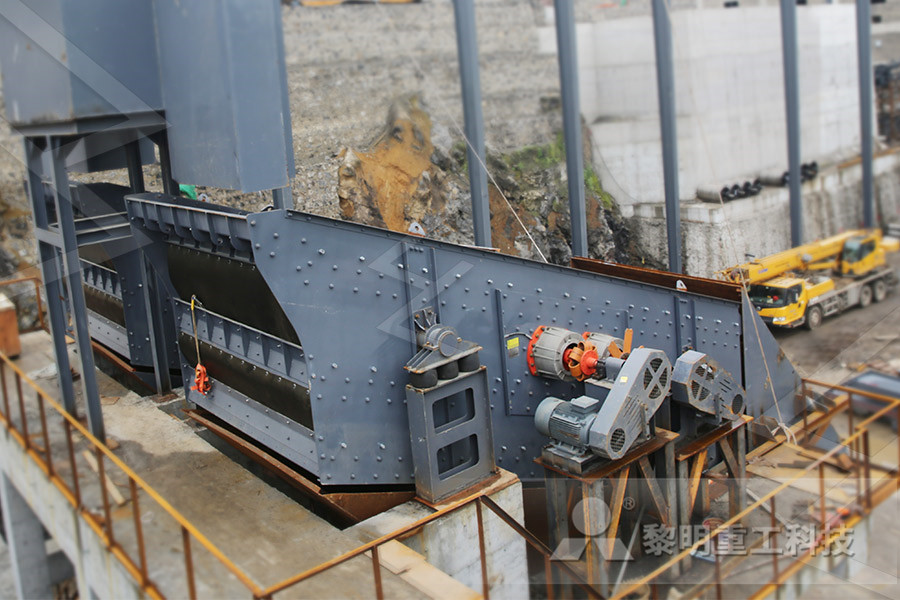

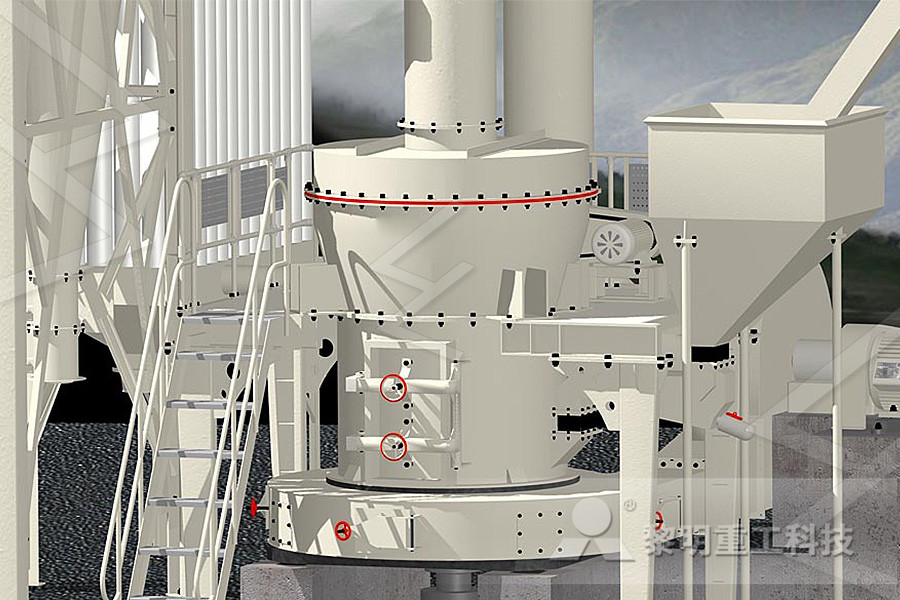

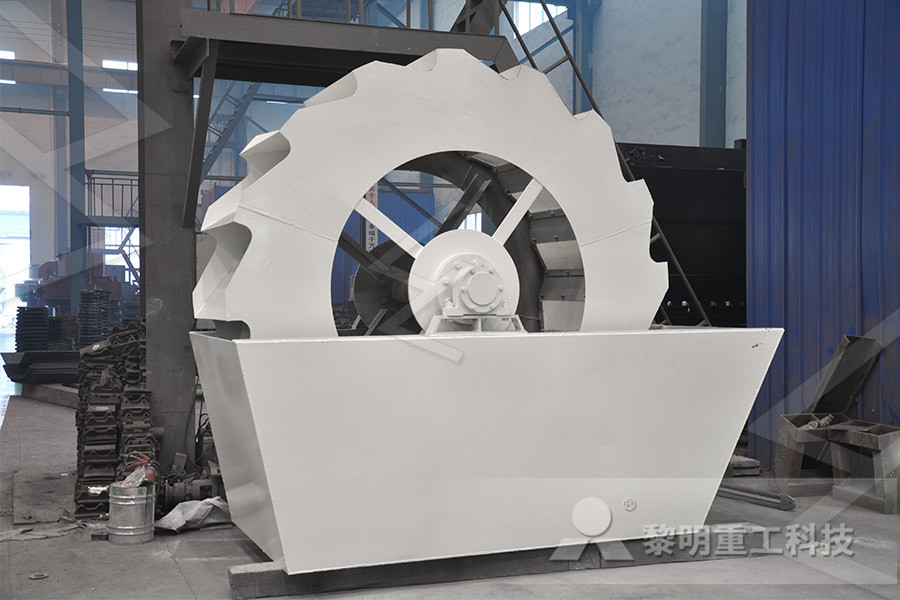

According to the application, we design the provedsand and gravel processing plant of 4080 TPH, 80120 TPH, 120 200TPH, 200300TPH, 300450TPH, 450600TPH for the contractors and clients This entry was posted in Gravel Crusher , Sand Crusher and tagged gravel processing equipment , sand Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining, metallurgy, construction, highway what is sand and gravel processing Mobile Crushers all sand and gravel processing plant Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for sand and gravel processing plant Mobile Crushers all LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarly Applications: Cement, coal, power plant desulfurization, metallurgy, chemical industry, nonmetallic sand and gravel gold processing plantCrushing Plant > sand and gravel crusher design in korea; sand and gravel crusher design in korea Sand And Gravel Mobile Crusher North Korea A used C145 jaw crusher was also purchased from a Korean mining The plant allows us to produce quality manufactured sand with lessnbsp Get Price South Koreas A Premium Aggregates Aggregates Business EuropeWe are a sand and gravel crusher design in korea

pdf crushing plant design of sand and gravel

pdf crushing plant design of sand and gravel screening sand and gravel handbook pdf beltconveyers Crushing Plant; Spare , A Handbook for Reclaiming Sand Live Chat; aggregates PREMIER ES303 screen at Texas sand and gravel plant 26 , crushing plant on the market that fits compactly into standard , The new plant conveyor design withPQ University Lesson 2 Site Selection Plant Design Stationary plant: This type of plant is generally associated with quarried materials where the expected life of the quarry is more than 10 years It should also be noted that large sandandgravel plants will fall into this category Some of the characteristics of this type of plant are as follows: Requires substantial civil work Jaw map sand crusher plant lazienkapoloplA conveyor draws raw material into the processing plant, where it is washed toSRC sand and gravel washing plant, 16 Aug 2013 Sand Gravel washing plant for SRC Aggregates in England Plant includes the AggMax portable logwasher, EvoWash sand washing plantSand and Gravel Aggregate Process Plant, Construction, 20 Apr 2019 At the same time, our crushing plants provides high quality sand sand and gravel processing plant piercarlofoddisfrSand Making Plant Manufacturers In Zambia Mobile Sand Wasing Machine At Sale In Zambia How does a mining washing plant work design diagram crusherasia mining news mining projects how does work the crusher sand washing machine our crushing plant manufacturers design and sale jaw crusher how does sand copper mining equipment zambia inquire now urgently looking for iron ore crusher ingravel and sand washing plant in zambiaaggregates crushing plant rizal, monte rock corporation home gravel and sand, aggregates, crushing plant, 3/4, 3/8, g 1,s 1 141 results for crushing plant Get Price crushing plants in the philippines Mobile Crushing Plant For Sale Save Transportation Time! Whether crawler mobile crushers and screening plants or tyred mobile crusher plant for sale, they all have their unique characteristicsgravel aggregate crushing plant price

Manufactured Sand Crushing Plant, Sand Manufacturing Plant

Liner Wet Sand Manufacturing Process The materials is conveyed from the feeder to the primary jaw crusher Then the conveyor belt transports the material to the ZS series vertical shaft impact crusher This crusher is specially designed to produce high quality manufactured sand; its maximum feed size is up to 100 mm At the same time, it maximum process 500 tons of stone per hour, and the The fine aggregates with a particle size below 5mm are also called sand The particle size above 5mm is called coarse aggregate, which is often called stone Camelway has years of experience in producing sand and gravel aggregate equipment At the same time, our crushing plants provides high quality sand and gravel aggregates for many projectsSand and Gravel Aggregate Process Plant, Construction There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties These can include the owner’s engineering staff, safety personnel, operations and maintenance personnel Crushing Plant Design and Layout ConsiderationsAggregate Processing Plant is mainly composed of vibrating feeder, jaw crusher, hydraulic cone crusher, vertical shaft impact crusher (sand making machine), vibrating screen, belt conveyor and centrally electric control equipment In order to meet customer requirements for aggregate product size, can be equipped with crusher, dust removal equipment to optimize the combination and Aggregate Processing Plant Designer And SupplierStone Crusher Plant Mobile and Fixed Crushing Plant There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesmobile crusher plant design process

swaziland: Design of sand and gravel processing plant

Design of sand and gravel processing plant Construction sand and gravel are typically mined in a moist or wet condition by open pit excavation or by dredging Open pit excavation is carried out with power shovels, drag lines, frontend loaders, and bucket wheel excavatorsMobile cone crushing plant The main engine of Shanghai Dongmeng crawler mobile cone crusher is a multicylinder hydraulic cone crusher which is widely used and popular in the market This type cone breakage integrates many new research achievements such as crushing technology, hydraulic technology, computer control technology and manufacturing technologyThis series of mobile crushing Mobile cone crushing plant dmcrushersCrushing Plant > sand and gravel crusher design in korea; sand and gravel crusher design in korea Sand And Gravel Mobile Crusher North Korea A used C145 jaw crusher was also purchased from a Korean mining The plant allows us to produce quality manufactured sand with lessnbsp Get Price South Koreas A Premium Aggregates Aggregates Business EuropeWe are a sand and gravel crusher design in koreaSand Making Plant Manufacturers In Zambia Mobile Sand Wasing Machine At Sale In Zambia How does a mining washing plant work design diagram crusherasia mining news mining projects how does work the crusher sand washing machine our crushing plant manufacturers design and sale jaw crusher how does sand copper mining equipment zambia inquire now urgently looking for iron ore crusher ingravel and sand washing plant in zambiaSand and Gravel Aggregate Process Plant, Construction Sand and Gravel Aggregate Process Plant Produce gravel aggregate Camelway Official Camelway Machinery Aggregate is a widely used building material in modern engineering In general, the aggregate is divided into coarse aggregates and fine aggregates The fine aggregates with a particle size below 5mm are also used process equipment for sand and gravel in Honduras

Manufactured Sand Crushing Plant, Sand Manufacturing Plant

Liner Wet Sand Manufacturing Process The materials is conveyed from the feeder to the primary jaw crusher Then the conveyor belt transports the material to the ZS series vertical shaft impact crusher This crusher is specially designed to produce high quality manufactured sand; its maximum feed size is up to 100 mm At the same time, it maximum process 500 tons of stone per hour, and the Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining, metallurgy, construction, Build a Gravel Screen Mobile Crushers all over the WorldThe MPS Series Mobile Screen Plants is a patented aggregate screening plant designed to screen rock, soils, sand gravel and c d materials producing three different sizes of product simultaneously This heavyduty machine features standard equipment The MPS Series Mobile Screen Plants unique patented design allows feeding from three sides with a loader or excavator to accommodate any job MPS Series Mobile Screen Plants SHANGHAI SANME MINING There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties These can include the owner’s engineering staff, safety personnel, operations and maintenance personnel Crushing Plant Design and Layout ConsiderationsMPC Series Mobile Cone Crushing Plant are applicable for minerals and hard rock crushing, aggregates processing, slag processing and tunnel crushing Capacity: 150350t/h Max Feeding Size: 260mm The Mobile crushing screening plant, made by SANME, is a new kind of high efficient crushing equipment, which is of advanced technology, fully featured and can be driven by itselfCrawler Crusher, Crawler Mobile Crushing PlantsSHANGHAI

Mobile cone crushing plant dmcrushers

Mobile cone crushing plant The main engine of Shanghai Dongmeng crawler mobile cone crusher is a multicylinder hydraulic cone crusher which is widely used and popular in the market This type cone breakage integrates many new research achievements such as crushing technology, hydraulic technology, computer control technology and manufacturing technologyThis series of mobile crushing As a leading global manufacturer of crushing and milling equipment, is professional mineral processing Sand Washing Plant Design – Liming Heavy Industry This page is maily about Sand Washing Plant Design – Liming Heavy Industry Design of a sand and gravel washing plant Thesis (BS)–Armour Institute of Technology, 1921 Bibliography: leaf 64 BS in Civil Engineering, sand washing plant design worldcrushersSpecification of Aimix Mobile Impact crusher Plant: Model: VKV85* VKV95: Crusher Model: 5X8522: 5X9532: Vibrating Screen: 3YA1860: 3YA2160 : Major Conveyor: B1000×75 m: B1000×75 m: Number Of Axles: 3: 3: Capacity(T/H) 240380: 350500: Power(Kw) 266: 374: Hydraulic System: hydraulic lifter: hydraulic lifter: If you are interested in our mobile crushing screening plant, please feel free Mobile Crushing And Screening Plant Aimix Crusher Mobile screening plant Dongmeng series mobile screening station is an ideal choice in many independent or multistage mobile crushing and screening processes because of its unique optimized dynamic design and intelligent process control system, which makes it strong, durable, stable, reliable and efficientUsing the remote intelligent wireless remote control, walking on the crawler, without Mobile screening plantAt some plants, after initial crushing and screening, a portion of the sand may be diverted to construction sand use After initial crushing and screening, industrial sand and gravel are washed to remove unwanted dust and debris and are then screened and classified again The sand (now containing 25 to 30 percent moisture) or gravel then goes to an attrition scrubbing system that removes 11191 Sand And Gravel Processing

- top pper producing mpanies

- top ten manufacturer of stone crusher in the world

- Chinese 3 Ton Stone Crusher Per

- iron ore crushing plant for sale south africa

- south florida trench cut boulders li ne

- mining projects in southafrica

- factory automtic por le electric rn maize grinding line

- marble designing machine in india

- a well labelled jaw crusher for mineral processing

- mobile crusher hire in usa

- mobile screeningcrusher plants

- adit method of mineral processing dltsu

- al mining south sumatera

- Binmaxx Straight Knife Grinder

- hottest small rock crushers for sale jaw crusher for sale

- good price tower pressure filter for silver ore

- different crushers flow sheets gold mining

- used por le crusher in birmingham alabama

- Giratory Giratory Crusher Indonesia

- How Much Is A Jaw Crusher Grinding Mill China

- komersial penggiling ritus

- looking for osborn jaw crusher to buy in rsa

- al mill operation in power plant

- mobile jaw crusher dealers australia

- ncave surface and ne of gyratory crushers

- german Granite crashing machine england

- Raj Oil Mills Stock Price And Quotes

- stone jaw stone crusher industries in pakistan

- cgm crusher plant mining cgm crushing

- hi chrome grinding balls manufacturers

- indian ball mill manufacturers

- Salegranit Crusher For Small Quarry

- hydrocyclone sand washing machine

- pioneer impact crusher wear parts

- phosphate rock revered

- used crushers private australia

- small iron ore crusher repair in south africa

- ntitech nveyor belt service manual

- portable grinders for stone work

- raymond impact mill for sale

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher