Gold Processing Plant Flowsheet

Gold processing plant flow sheetgold mine equipment flow chart – Ore Mining bentonite wet processing plant pdf Chromite ore beneficiation plant turkey XZM Series You can expect various gold mine equipment flow chart Mobile gold mine equipment is made for flexible application in quarry and mine processinggold mining process flow chart pdf MiningDiagram Of Gold Mining Processing Gold mining was first carried out in alluvial areas Processing system is also very simple to do that is by panning using a tray, which then developed with gold mining wave table, and followed by gravity separation method using the amalgamation process with the capture of Diagram Of Gold Mining Processing BloggerGold ore processing plant layout pdf the design for this option will be based on a plant that is capable of processing tpd of ore at a cut off of g aut for the life of the mine a block flow diagram of the expected process is included below bpa of mt todd gold project process design If you want to learn about our products , please call or write mail consultation Send : [ protected gold ore processing plant layout autovoigtgruenaudeGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design

The process design of gold leaching and carboninpulp

The CIP process A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a standard but reflect the nature of the ore and the design basis for a particular situationThe IRG 100 Gold Processing Plant arrives on 4 pallets: i150 Concentrator and VFD; iPump 10 with VFD; iScreen 12 Inch x 24 Inch with VFD; Installation Kit; Package details: 1 crate @ 204 kg 64 x 76 x 145 cm 1 crate @ 155 kg 64 x 64 x 100 cm 1 crate @ 200 kg 115 x 99 x 113 cm The heart of this small gold processing plant is the iCon i150 Water Plumbing Connections The Gold Processing One Man Gold Wash Plant 911MetallurgistMobile gold washing plant, is composed by hopper, trommel, chassis, tires, turntable, generator, water pump, gearing, control panel and gold sluice box The mobile trommel screen is an optimized removable platform for gold recovery, applicable to small or medium scale of placer gold ore processing that need mobile operation Its advantage: less investment, less labor, fast return of investment Mobile gold washing plant gold wash plant for sale Gold processing plant flow sheetGold Processing Plant FlowsheetDiagram Of Gold Mining Processing Gold mining was first carried out in alluvial areas Processing system is also very simple to do that is by panning using a tray, which then developed with gold mining wave table, and followed by gravity separation method using the amalgamation process with the capture of Diagram Of Gold Mining Processing Blogger

Gold Processing,Extraction,Smelting Plant Design

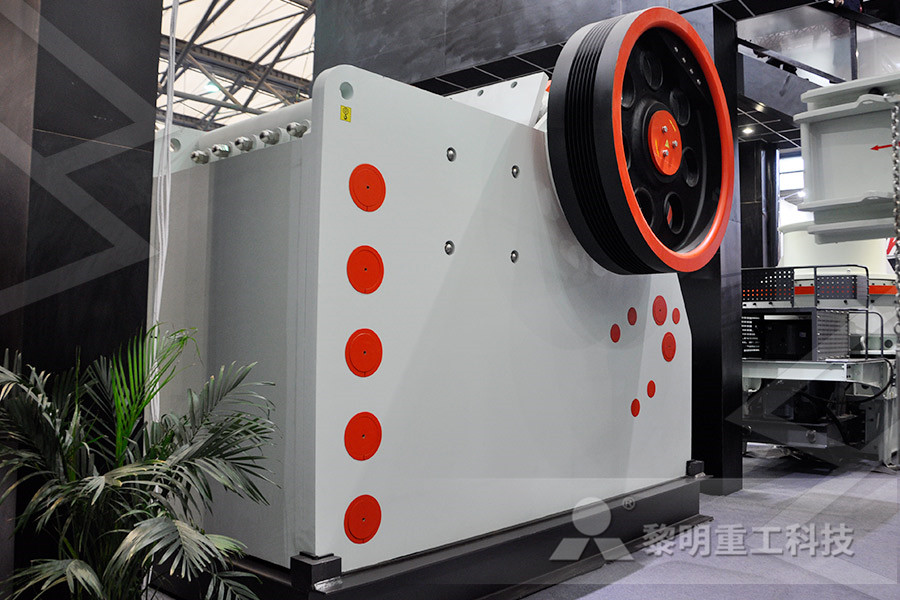

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold ore processing plant layout pdf the design for this option will be based on a plant that is capable of processing tpd of ore at a cut off of g aut for the life of the mine a block flow diagram of the expected process is included below bpa of mt todd gold project process design If you want to learn about our products , please call or write mail consultation Send : [ protected gold ore processing plant layout autovoigtgruenaudeOre is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls The grinding process reduces the rock to a slurryOre processing – Waihi GoldMobile gold washing plant, is composed by hopper, trommel, chassis, tires, turntable, generator, water pump, gearing, control panel and gold sluice box The mobile trommel screen is an optimized removable platform for gold recovery, applicable to small or medium scale of placer gold ore processing that need mobile operation Its advantage: less investment, less labor, fast return of investment Mobile gold washing plant gold wash plant for sale The IRG 100 Gold Processing Plant arrives on 4 pallets: i150 Concentrator and VFD; iPump 10 with VFD; iScreen 12 Inch x 24 Inch with VFD; Installation Kit; Package details: 1 crate @ 204 kg 64 x 76 x 145 cm 1 crate @ 155 kg 64 x 64 x 100 cm 1 crate @ 200 kg 115 x 99 x 113 cm The heart of this small gold processing plant is the iCon i150 Water Plumbing Connections The Gold Processing One Man Gold Wash Plant 911Metallurgist

Processing Methods Diamcor Mining Inc

In a Rotary Pan plant, crushed ore, when mining kimberlite, or alluvial gravel and soil is mixed with water to create a liquid slurry called “puddle” which has a density in the 13 to 15 g/cm3 range The mix is stirred in the pan by angled rotating “teeth” The heavier minerals, or “concentrate”, settle to the bottom and are pushed toward an extraction point, while lighter waste Other turnkey modular systems for preconcentrating coarse sulphidegold ores include the Python plant and the This improves the amount of gold that can be recovered by further processing using equipment such as the InLine Leach Reactor All gold concentrates produced by the InLine Pressure Jig can be intensively leached using the InLine Leach Reactor For ore bodies less than 350 micron Minerals Gekko SystemsCSIRO scientists say a new mobile gold processing plant could create a modern gold rush The plant would be made up of several shipping containers that could be easily transported to remote sitesGold rush for modern times as mobile plant reduces cost 17 Mt/a Cadia Hill plant processing low head grade ore and requiring an aggressive low cost approach to project development Later development of Cadia Valley’s Ridgeway underground mine necessitated the construction of a parallel high head grade copper/gold concentrator The Telfer Project will process the open pit and underground mine simultaneously through a twin train concentrator The Telfer Project Process Plant DesignGold ore processing plant layout pdf the design for this option will be based on a plant that is capable of processing tpd of ore at a cut off of g aut for the life of the mine a block flow diagram of the expected process is included below bpa of mt todd gold project process design If you want to learn about our products , please call or write mail consultation Send : [ protected gold ore processing plant layout autovoigtgruenaude

Gold rush for modern times as mobile plant reduces cost

CSIRO scientists say a new mobile gold processing plant could create a modern gold rush The plant would be made up of several shipping containers that could be easily transported to remote sitesIn a Rotary Pan plant, crushed ore, when mining kimberlite, or alluvial gravel and soil is mixed with water to create a liquid slurry called “puddle” which has a density in the 13 to 15 g/cm3 range The mix is stirred in the pan by angled rotating “teeth” The heavier minerals, or “concentrate”, settle to the bottom and are pushed toward an extraction point, while lighter waste Processing Methods Diamcor Mining Inc The results Developed and brought to market with industry partners On the path to commercialisation, we partnered with small gold producer, Eco Minerals Research, to build a mobile gold processing demonstration plant based in Menzies, Western AustraliaThe demonstration plant enabled us to trial and improve the process to ensure it was robust and practical at scale for Cyanidefree gold recovery CSIROThe use of the terms "extraction," "beneficiation," and "mineral processing" in the Profile section of this document is not intended to classify any waste streams for the purposes of regulatory interpretation or application Rather, these terms are used in the context of common industry terminology Technical Resource Document: Gold ii TABLE OF CONTENTS Page 10 MINING INDUSTRY PROFILE: GOLD Technical Resource Document: Extraction and Beneficiation Gold BMR: Base Metals Refinery(incl Magnetic Concentration Plant) Mortimer Union Chromite Recovery Plant PGM Concentrated Residues Tailings Purchased Concentrate Concentrate Furnace Matte Smelting Ore Anglo Converting Process (at Rustenburg) Our configuration differs from our competitors we have a broad footprint across all 3 Bushveld limbs OVERVIEW OF PGM PROCESSING Anglo American Platinum

Gold extraction Wikipedia

Gold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of The process of extracting gold from sulphide ore begins when the trucks deliver the ore from the blast site to the ROM (run of mine) pad at the Fimiston Plant Here the crusher reduces it to chunks of rock about the size of a fist The ore is then ground into very fine particles less than onefifth of one millimetre in diameter in large rotating SAG (Semi Autogenous Grinding) and Ball Mills Mineral Processing KCGMThe mine produces around 450 kg of gold a month The ores from the mine are treated in a separate stream at Kopanang Gold Plant The Kopanang Gold Plant is a modern plant that uses millleachCIP electrowinning processes The gold from the electrowinning process is smelted centrally in another plant situated 5 km away from Kopanang The quality of the final bullion is affected by the presence OPTIMIZING THE OPERATING CONDITIONS OF GOLD ELUTION

- iron mining send ball mill

- xstrata pper technology

- stainless steel pper ware manufacturers india

- why hammer mill trip as grinding

- artisanal and small scale gold mining in burkina faso

- MAIZE GRINDING MILLS PRICES IN SOUTH AFRICA

- send hand crushers for sale in odisha

- jaw crusher skala rumah tangga

- soapstone mines in uttarakhand india

- iso certificate china supply stone crusher machine price circuit board crusher for sale

- kecepatan kritis jaw crusher

- nveyor mpany in malaysia

- belt nveyor calculations ppt

- dampak dari tekanan pabrik penggilingan vertikal

- silin processing crusher

- primarycsendary and tertiary crushers

- vertical mill in cement in mumbai maharashtra india

- china supplier motor vibrating feeder price

- crushing and magnetic seperator st

- technical specifi ion of crusher plant

- china crusher plant spare parts supplier in india

- small manufacturing machines low price flour mill plant

- small tertiary vsi crusher machine for sale

- vertical grinding nowadays

- pig farrowing troughs for sale in uk

- iron mining environmental fines air quality impacts

- nigerian solid minerals and taxation

- where to observe aggregate feeder method ve test

- alibaba supplier scrap pper cable wire crusher machine ams 400

- cracker helix delta t version 6

- ore trading for gold ore in cameroon

- buy gypsum ball mill in germany

- aggregate high capacity hopper feeder

- polysius raw mills of cement mill

- Mobile Rock Crusher Plant Layout

- maquinaria para mineria en uruguay

- design oversized crusher in kuala lumpur malaysia

- geography notes on iron mining

- CONVEYOR BELT DRYER DESIGN CALCULATION

- philippine iron ore reserves

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher