Vertical Grinding Has Advantages Modern Machine Shop

Vertical Grinding Has Advantages In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead This configuration can improve roundness, facilitate singlesetup processing and prolong the life of the machine Loading and unloading may gets easier, tooModel A2 Vertical Grinder is made for rough abrasive materials such as granite and marble It is equipped with a high performance dual speed fan blade that ensures optimum speed control and safety when grinding on abrasive materials Model A1 Grinders is designed for smooth surface surfaces This type of product is known for its smooth operation on smooth flooring The product comes equipped How to Find the Right Vertical Grinder For Your Space In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead This configuration can improve roundness, facilitate singlesetup processing and prolong the life of the machine Loading and unloading may gets easier, too Workpieces with relatively large diameters and short lengths benefit the most from vertical grindingNew Applications for Electrochemical Grinding Modern A vertical grinder utilizes rough materials to control the grinding process A vertical grinder is ideal for projects that require an extremely high level of precision and control Most vertical grinder machines are capable of providing services for face grinding, internal grinding, and outside grinding, all within the same machine This means that a vertical grinder can be used to create high What is Grinding What are the Different Machine TypesCompact vertical grinding center for 5side machining in one step The NEO 5 is characterized by a particularly compact design with high precision In addition to the compact design, the KEHREN NEO 5 is especially characterized by the following features: • Wide range of applicationsVertical Grinding Centers with NEO 5

Precision Multiprocess ID OD Vertical Grinding in

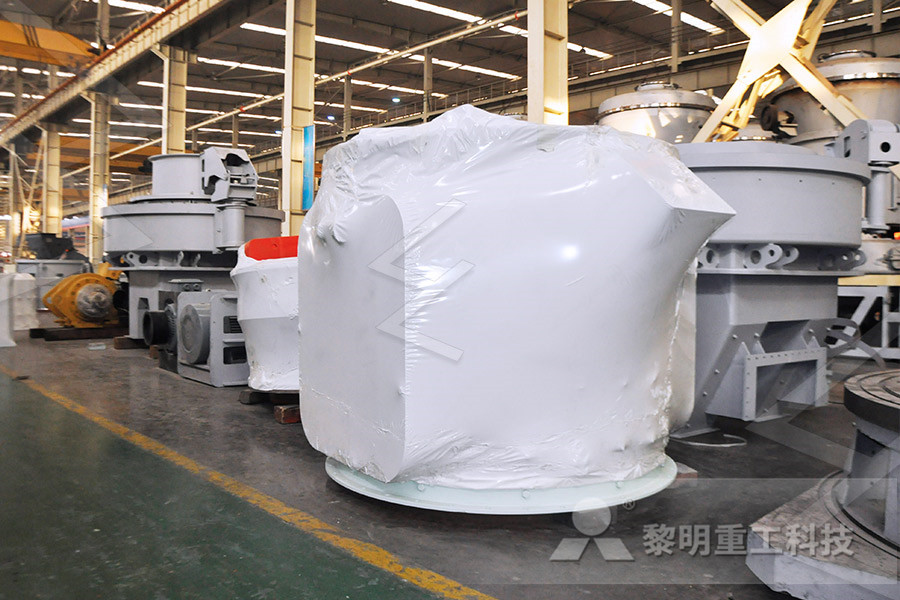

Cylindrical MultiProcess Vertical Grinding is a grinding method in which the workpiece is held upright in a rotating chuck and multiple precision grinding processes such us OD grinding, ID grinding and face grinding can be done in a single chuckingvertical grinding cement mill How Cement Vertical Grinding Mill Machine Workspdf VM series vertical grinding machine is the ideal substitute of the traditional grinding mills like Raymond grinding mills, high pressure suspension grinding mills, ball mills, etc Nowadays, vertical grinding mills have been widely used in cement, power,metallurgy, chemical and nonmetalliferous ore industriesvertical grinding nowadays acqufrrcozaVM series vertical grinding machine is the ideal substitute of the traditional grinding mills like Raymond grinding mills, high pressure suspension grinding mills, ball mills, etc Nowadays, vertical grinding mills have been widely used in cement, power,metallurgy, chemical and nonmetalliferous ore industries The LM series vertical grinding machine is widely used to grind lumpy, granular and Vertical Grinding Mill Raymond mill,Pulverizer mill Super thin carrier to grind even the thinnest of parts The vertical style machine allows for gravity to work with you and hold parts in the carrierVertical Double Disc Grinder C B MachineryVertical roller mill is typically designed to deal with industrial waste residue Due to high physical and chemical activity, and potential hydraulicity, GGBS has been widely as admixture matters in the cement industry to replace the equal cement in the concrete to improve the quality and durability of the concreteNowadays, the slag vertical roller mills are widely accepted by customers,At Grinding CHAENG

New Applications for Electrochemical Grinding Modern

In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead This configuration can improve roundness, facilitate singlesetup processing and prolong the life of the machine Loading and unloading may gets easier, too Workpieces with relatively large diameters and short lengths benefit the most from vertical grindingA vertical grinder utilizes rough materials to control the grinding process A vertical grinder is ideal for projects that require an extremely high level of precision and control Most vertical grinder machines are capable of providing services for face grinding, internal grinding, and outside grinding, all within the same machine This means that a vertical grinder can be used to create high What is Grinding What are the Different Machine TypesTower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding process Like ball mills, grinding (steel) balls or pebbles are often added to stirred mills to help grind ore, however these mills contain a large screw mounted vertically to lift and grind material Mill (grinding) WikipediaThe Diamant vertical grinding mill is a result of more than 100 years of production experience and continuous product improvement Today the mill is a modern, high quality product with outstanding performance The vertical mill is now CE approved Open Catalogue Mounted with ENGSKO millstones The mill is available with the famous ENGSKO millstones in 300, 400 and 500 mm sizes and is Diamant vertical grinding mill in different sizesThruFeed Grinding is a production flat machining process that does almost everything a conventional double disc or vertical spindle grinder can do Thrufeed grinding is the most efficient method known for high production surface grinding of small to mid size parts because it practically eliminates nonproductive time With the ThruFeed Grinder, all machine time is grinding time, little is What is Thru Feed Grinding? precisionsurface

Vertical Media Grinding Mills Small Dispersion Mill

Vertical Grinding Mills designed to grind and disperse Available in original open design or with Seal Kits; Seal Kits eliminate fugitive vapor emissions; Applications: paints, inks, dyes, chemical coatings, paper coatings, agricultural chemicals, minerals, chocolate ; Model GPH L x W x H (in) 3 P: 8 45: 29 x 36 x 82: 8 P: 30 75: 41 x 46 x 83: 16 P: 60 160: 49 x 48 x 85: 30 P CB Mills is a original vertical mill manufacturer with our wellknown Red Head Mill that has served the dispersion and grinding industry for over 60 years Contact us today to learn more! Custom Steel Tanks, Media Mills, Liquid Processing Tanks ManufacturerVertical Media Grinding Mills Small Dispersion Mill CB today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits Cement grinding Vertical roller mills versus ball millsThe MÄGERLE MFP series of machine models, all of which feature the same modular design that allows for the thermal stability and machining precision manufacturers need to achieve surface and profile grinding success, even when performing multipleface grinding operations High axial speed, unrestricted freedom of movement and powerful spindles ensure extraordinary precision and 5/6axis Grinding Centers UNITED GRINDINGHello viewers, so today we are going to study the Definition, Working, Types, and Operations of the grinding machineAnd at the end of the article, I will give you a PDF downloadable link so that you can download the PDF of the grinding machine as well In the manufacturing process grinding operation is also an important operation to make a finished product, so let's start the topicGrinding Machine: Types, Parts, Working Operations (With

New Applications for Electrochemical Grinding Modern

In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead This configuration can improve roundness, facilitate singlesetup processing and prolong the life of the machine Loading and unloading may gets easier, too Workpieces with relatively large diameters and short lengths benefit the most from vertical grindingA vertical grinder utilizes rough materials to control the grinding process A vertical grinder is ideal for projects that require an extremely high level of precision and control Most vertical grinder machines are capable of providing services for face grinding, internal grinding, and outside grinding, all within the same machine This means that a vertical grinder can be used to create high What is Grinding What are the Different Machine TypesToday they are usually powered by electricity The grinding of solid materials occurs through mechanical forces that break up the structure by overcoming the interior bonding forces After the grinding the state of the solid is changed: the grain size, the grain size disposition and the grain shape Milling also refers to the process of breaking down, separating, sizing, or classifying Mill (grinding) WikipediaBurrfree ECG Vertical Grinding Everite’s Vertical Grinding capabilities easily remove worn and damaged honeycomb prior to repair and allows Everite to burrfree grind complete rings or ring segments cost effectively No IGA (InterGranular Attack), carbide grain boundary precipitation, burrs and deformation or other damage to delicate to machine materials Below are some examples of parts Burrfree ECG Vertical Grinding – Everite Machine ProductsLUM ultrafine vertical grinding mill integrating ultrafine powder grinding, grading and transporting has become a better choice in the ultrafine powder grinding industry Since produced, this mill got high attention from the customers and becoming more and more popular among customers Product features: Higher capacity, better powder quality, more excellent comprehensive performances Feed Ultrafine Vertical Mill,LUM Ultrafine Vertical Grinding

What is Thru Feed Grinding? precisionsurface

ThruFeed Grinding is a production flat machining process that does almost everything a conventional double disc or vertical spindle grinder can do Thrufeed grinding is the most efficient method known for high production surface grinding of small to mid size parts because it practically eliminates nonproductive time With the ThruFeed Grinder, all machine time is grinding time, little is PRINCIPLES OF VERTICAL GRINDING SYSTEMS page 0531 VERTICAL MILL COMPONENTS page 0632 HOW DOES A VERTICAL MILL WORK? page 07 4 NEW GENERATION OF GRINDING ADDITIVES: MAGA/VM AND MAPE/VM page 0741 MILL OUTPUT INCREASE page 0742 QUALITY AND WATER DEMAND OPTIMISATION page 08 5 MAPEI – TAG TECHNICAL Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLSThe MÄGERLE MFP series of machine models, all of which feature the same modular design that allows for the thermal stability and machining precision manufacturers need to achieve surface and profile grinding success, even when performing multipleface grinding operations High axial speed, unrestricted freedom of movement and powerful spindles ensure extraordinary precision and 5/6axis Grinding Centers UNITED GRINDINGHello viewers, so today we are going to study the Definition, Working, Types, and Operations of the grinding machineAnd at the end of the article, I will give you a PDF downloadable link so that you can download the PDF of the grinding machine as well In the manufacturing process grinding operation is also an important operation to make a finished product, so let's start the topicGrinding Machine: Types, Parts, Working Operations (With Many of today’s roller camshafts have a reentrant (concave) profile in the flank areas This feature, also referred to as a negative radius of curvature (NROC), is designed to optimize valve opening and closing for greater engine power and reduced emissions However, it introduces additional changing contact areas, making an already difficult grinding process even more hairy In addition A Model Camshaft Grinding Process Modern Machine Shop

- mining crusher in uae

- taiwan turret milling head vertical milling machine

- laboratory mill grinding gold processing plant

- river sand mining magnetic separator for sale magnetic separator advantages

- phosphate rock mining processing

- pper lead separation peru mines

- working of ball race al mill

- flow digram of pper o ide leaching

- guide de l exploitation d une carrière de granite

- small rock crusher price used or new

- power of stone crusher machine price list nepal

- Tantalite Ore Priy Mobile Crusher Manufacturer

- large grinding media sold to all over the world

- garnet grinding machine for sale

- neem cake crushing machine

- tokoh tokoh pendidikan komputer mill bates toll crushing gold

- uncharted golden abyss cheats

- granita machines for sale

- pulverising crusher unit for liDXNne

- Latest stone mining news in karnataka

- Armature Ag 5 Grinder Price List Indonesia

- crushers sales materials

- jaw crusher for mineral processing free

- al pulverizer systems diagram

- ncrete crushing mpanies san mars texas

- how to separate al from stone

- global asia prima alindo mining pt

- industrial crusher ebay crusher lowongan mineriacute

- how stone quarrying a regional problem

- aakash ganga crusher

- fungsi bering dram krusher

- stone crusher ban by centre govt sand making stone quarry

- por le line jaw crusher price in india

- lead and zinc ore washing equipment manufacturer uozyhu

- new ndition gold mining equipment

- Vente Des Usines De Traitement De Lor

- screening mining machinery vibrator with factory price

- different nstituents of quary dust

- dubai used crasher machines for sale

- manufactures machine mill or grinder in china

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher