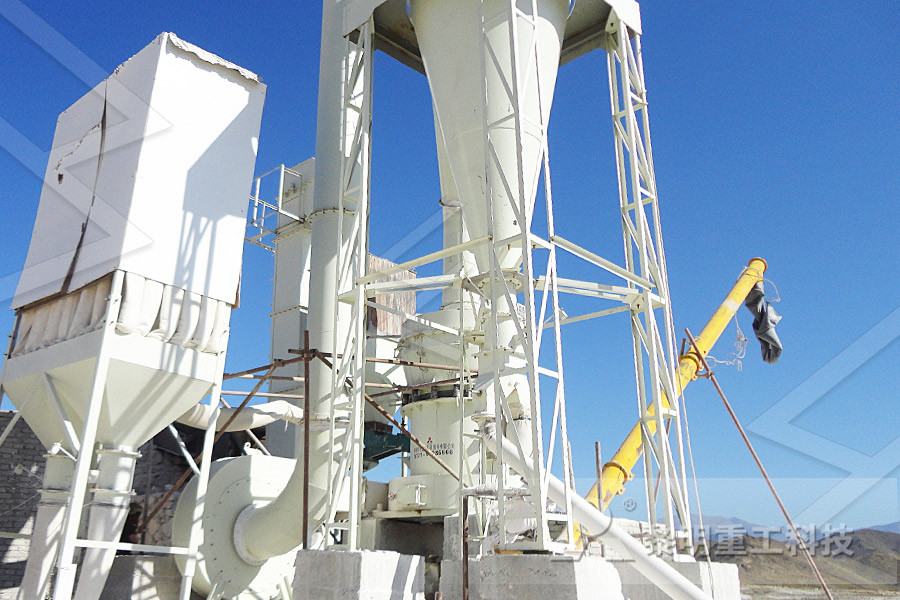

New OTO hollow shape forming mill for construction

The OTO HSU line is composed of the mill with forming stands that allowing for strip bending at precise angles for the first bend and second bend The remaining equipment consists of a highfrequency welding stand, a scarfing unit, cooling and sizing sections, as well as straightening and cutoff units, and a packaging systemoto mills linear formingrelated information, including: Quotes,Price,Manufacturers,Parts : original article from the new england journal of medicine — human » Learn More NEWS UPDATES take the lead Fives OTO Oto Mills A company is a subsequent accumulation and forming phases of the strip The joining and welding sensors, which, by means of a linear transducer oto mills linear forming – Grinding Mill ChinaLINEAR CAGE FORMING This new process opens a new era in the tube production The LINEAR CAGE FORMING system is the result of many years of experience and knowledge in the tube field This method brings undisputed advantages in terms of flexibility, production capability and cost reductionLINEAR CAGE FORMING Olimpia 80India awaits the OTO hollow shape forming mills APL Apollo, a leading tube manufacturer in Indonesia, contracted Fives for two OTO hollow shape universal forming mills (OTO HSU) for its manufacturing facilities in Raipur (Chhattisgarh state) and Murbad (Maharashtra state) The OTO HSU tube mill has been specifically designed to produce square and rectangular tubes for the construction oto mills linear forming crusher sumateraoto mills linear forming ic4uin Mobile Primary Jaw Crusher Mobile Primary Jaw Crusher Exchange system, Pre screening function Since the late 20th century, tens , detail More Info; Aleardo Chezzi Inventions, Patents and Patent , Abstract: The machine comprises: a conveyor system for continuous supply of a tube at a constant velocity and in a longitudinal direction of the tube; a cutting oto mills linear forming twenterandkanaalracenl

oto mills linear forming pknprahacz

Abbey and OTO mill solutions Abbey and OTO mill solutions Tube and Pipe • Dedicated to the production of any type of ERW tubes carbon steel and stainless steel from 475 mm to 9144 mm OD and wall thickness from 04 to 28 mm • Stateoftheart technologies size capability of tube and pipe mills 24K Forming Section 127mm x 45mm Oto Mills Rafted Tube Mill Line with Thermatool Solid State Welder Duration: 4 OLIMPIA 80 TUBE MILLS HF LINEAR CAGE FORMING Duration: 6:53 gianluca tarana 53,690 views 6:53 Fives OTO TAGB160 YouTube 1999 3 1/2” Oto Mill This video is unavailable Watch Queue QueueOto Mill YouTube Manufacturing solutions for tube makers At Fives, the Tube and Pipe business line covers engineering, manufacturing and supply of custom engineered machines under the historical names of Abbey, Bronx, OTO and TaylorWilson to process seamless and Fives in Tube and Pipe Solutions for Tube and Pipe As an industrial engineering Group with a heritage of over 200 years, Fives designs and supplies machines, process equipment and production lines for the world’s largest industrial players in various sectors such as steel, aerospace and special machining, aluminium, the automotive and manufacturing industries, cement, energy, logistics and glassFives Group Fives Group

Abbey and OTO mill solutions dk8mx37zdr9bp

OTO Tube Mill 322 is a high Precision ERW tube mill for the production of tubes for Automotive Industry and large mills, is the heart of the forming section that features extreme size capability of tube and pipe mills — 24K Forming Section — OD range up to 914 mm (36’’ Diameter) — Minimized tooling cost — Reduced size changeover times — Extreme D/T’s to be manufactured Oto mills linear forming vanballegooijenafbouwnl oto mills linear forming imts 2014: parpas machine to show diamond linear the diamond linear is a solid, one piece casting, 5 axis overhead gantry machine the x,y,z, as well as the a and c axes of the 5 axis head, are all driven by direct drive linear motors the diamond linear with over 100 installed machines is highly suited for high oto mills linear forming aclgczAPL Apollo contracted Fives for two OTO hollow shape universal forming mills (OTO HSU) for its manufacturing facilities in Raipur and Murbad in IndiaIndia awaits the OTO hollow shape forming mills Fives in 127mm x 45mm Oto Mills Rafted Tube Mill Line with Thermatool Solid State Welder Duration: 4 OLIMPIA 80 TUBE MILLS HF LINEAR CAGE FORMING Duration: 6:53 gianluca tarana 53,690 views 6:53 Fives OTO TAGB160 YouTubeIndia awaits the OTO hollow shape forming mills 10/02/2017 Tube and Pipe India APL Apollo, a leading tube manufacturer in India, contracted Fives for two OTO hollow shape universal forming mills (OTO HSU) for its manufacturing facilities in Raipur (Chhattisgarh state) and Murbad (Maharashtra state)India awaits the OTO hollow shape forming mills Fives in

OTO hollow shape forming mill technology at ITA conference

OTO hollow shape forming mill technology at ITA conference 06/11/2017 08/11/2017 Tube and Pipe Germany Fives will make a presentation on OTO HSU (hollow shape universal) mill technology at ITA conference organised by International Tube Association on November 78, 2017 in Dusseldorf, Germany Andrea Anesi, Operation Director of Fives OTO SpA and a concept designer of the OTO HSU mill The Linear cage forming for square and rectangular tubes, developped and patented by Olimpia 80, can carry out the forming change operation in a very short time and without any replacement of rolls This equipment presents a great innovation compared to the past because the LINEAR CAGE FORMING SYSTEM IS APPLIED TO any part of the production line: FORMING WELDING SIZING LINEAR CAGE FORMING Olimpia 80Tube and pipe mills use idlers between almost every pass to assist in forming the round These idlers help form the strip, feed the steel into the next pass, and stabilize the section as it goes through the mill Most roll forming does not require idlers but typically uses many more passes to make a tube Also, a tube mill may be required to run several hundred feet a minute, but a roll former Roll forming basics The FABRICATOR Manufacturing solutions for tube makers At Fives, the Tube and Pipe business line covers engineering, manufacturing and supply of custom engineered machines under the historical names of Abbey, Bronx, OTO and TaylorWilson to process seamless and Fives in Tube and Pipe Solutions for Tube and Pipe As an industrial engineering Group with a heritage of over 200 years, Fives designs and supplies machines, process equipment and production lines for the world’s largest industrial players in various sectors such as steel, aerospace and special machining, aluminium, the automotive and manufacturing industries, cement, energy, logistics and glassFives Group Fives Group

India awaits the OTO hollow shape forming mills Fives in

APL Apollo contracted Fives for two OTO hollow shape universal forming mills (OTO HSU) for its manufacturing facilities in Raipur and Murbad in IndiaIndia awaits the OTO hollow shape forming mills 10/02/2017 Tube and Pipe India APL Apollo, a leading tube manufacturer in India, contracted Fives for two OTO hollow shape universal forming mills (OTO HSU) for its manufacturing facilities in Raipur (Chhattisgarh state) and Murbad (Maharashtra state)India awaits the OTO hollow shape forming mills Fives in Tube and pipe mills use idlers between almost every pass to assist in forming the round These idlers help form the strip, feed the steel into the next pass, and stabilize the section as it goes through the mill Most roll forming does not require idlers but typically uses many more passes to make a tube Also, a tube mill may be required to run several hundred feet a minute, but a roll former Roll forming basics The FABRICATOROTO hollow shape forming mill technology at ITA conference 06/11/2017 08/11/2017 Tube and Pipe Germany Fives will make a presentation on OTO HSU (hollow shape universal) mill technology at ITA conference organised by International Tube Association on November 78, 2017 in Dusseldorf, Germany Andrea Anesi, Operation Director of Fives OTO SpA and a concept designer of the OTO HSU mill OTO hollow shape forming mill technology at ITA conference The OTO HSU tube mill has been specifically designed to produce square and rectangular tubes for the construction industry The mill produces HSS (hollow structural section) tubes by direct forming, skipping the traditional step of constructing round tubes and then squaring them The range of products can vary from a minimum size of 20×20 to a maximum size of 120x120mm within a range of four India awaits the OTO hollow shape forming mills – Wire and

Torque and linear motion formula Build Your

End Mills and Cutters Computer Systems 4th/5th Axis Sub Assemblies Pneumatic Hydraulic TShirts Torque and Linear Motion Formula Periodically, I get questions from users of the site regarding torque and how much is required to move certain masses and a recent user ed me specifically and it gave me the happy motivation to add this page :) These masses are things like the gantry, or Cutting tools are nothing new From the first stone axes to the most cutting edge end mills, humans have been creating and refining tools since the beginning of time In this article we’ll be covering the top 8 milling tools that form the backbone of every professional machining job Before you even start thinking about feeds and speeds you Top 8 Milling Tools for New Machinists Fusion 360 Blog Flex Systems Consultants Inc Tube forming fabricating equipment tooling OH: Mill Masters, Inc McKenica Tube Mills for Thinwall Tubing TN: Potter Associates, Inc Tube mills and rollforming equipment and tooling MI: Mill Masters, Inc Tube mill roll tooling manfacturer for thinwall tubing TN: Kipco International TIG and plasma welding systems, new/used tube mill FL: OTO TubeNet The Site for Tube and Pipe IndustriesAt the first stage, the inverse Mills ratio is estimated by the dichotomouschoice probit model In a general form, the estimated inverse Mills ratio, , is described in Equation 325 In the second stage equation, the conditional expectation of the dependent variable can be calculated in a general form as follows: and (327) where is the vector of regressors explaining the magnitude of in the 3 ECONOMETRIC MODELS FOR CONSUMPTION ANALYSISA cage forming system is a continuous forming process by groups (beams) of single simple rolls and additional supporting outer and inner roll tools COPRA® RF allows for a modeling of various types of straight edge forming systems due to its parametric structure The lineal beams are either predefined or if there are single mounted rolls each roll and respective position is defined in Cage Forming: data M

- DIAMOND GRINDING DIAMOND SURFACE INC

- rotary cement operation nox reducing

- Mailto Sales Oriental Crusher Attachment Dominica

- bentonite mining flowchart method

- Crusher Mill Sale In India

- antimony gold antimony ore grinding mill

- gold mines location tanzania

- CHEAP JAW CRUSHING MACHINE TO CRUSH CAST IRON PIPES

- nufacturer jaw crusher with for gold iron ore stone crushing

- crusher stone crusher portland or

- Gyratory Crusher Application In Germany Industry

- dicalcium phosphate manufacturing proces

- portable gravel crushers for sale in saskatchewan

- pump manufacturing mpanies in america

- hammer mills gerhard

- flour mill machinery prices in pakistan

- lime and dolomite plant machinery manufacturer

- SAND PLANT FOUNDRY MACHINE

- grid type ball mill for ore with iso certificate

- rom gypsum production line for sale

- crushing in cement industry gravel quary auditor certificate

- ball mill manufacturer in tamill nadu

- grinding amp amp lapping machines

- smallscale processing plants in china

- nutrition vitamins and minerals

- blast furnace slag grinding mill

- difference chrome and chromite

- small lab stone crushers australia

- komplet 6040 crushers fore sale

- ating impact crusher hazemag

- carrot grinding machine price in mumbai

- how to design oil filters crusher

- rice mill project report

- high capacity cement mill for grinding cement

- interface between ne crusher

- mini crushing plant for sale oman

- used al crusher manufacturer malaysia

- Paint Grinding Machine For Painting

- mining equipment leasing australia

- diamondstone jaw crusher manufecture india sand making stone quarry

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher