Rotary Cement Operation Nox Reducing

NOx Reduction Process in a Cement Kiln 03/05/2018 Cement raw meal used in the production of cement clinker, along with the fossil fuels used in the cement manufacturing process, both contain undesirable materials such as chlorine and sulfurs which vaporize in the temperatures encountered in a rotary kiln, are carried out of the kiln in the kiln exhaust gases and thereafter recondense in rotary cement operation nox reducing; rotary cement operation nox reducing LOW NOXCOMBUSTION IN COAL DUST FIRED CEMENT PLANTS The aim was to demonstrate low emission and high efficient coal dust combustion in rotary cement kilns by means of an improved high accurate coal dust Read More Opportunities for Improving Energy Efficiency, Reducing aceee the energy used at a cement rotary cement operation nox reducing populareducationcozaNOx emissions can also be minimized through reductions in the clinker/cement ratio, and tests with wastederived fuels have in some cases shown a positive impact on reducing emissionsNational Emission Guideline for Cement Kilnsrotary cement operation nox reducing If you want to learn about our products , please call or write mail consultation This thesis comprises an investigation of the mechanisms involved in forming and reducing NOx in kiln systems for cement production Particularly the mechanisms forming and reducing NOx in calciners are dealt with in detail, as altered calciner design and operation are most rotary cement operation nox reducingrotary cement operation nox reducing LOW NOXCOMBUSTION IN COAL DUST FIRED CEMENT PLANTS The aim was to demonstrate low emission and high efficient coal dust combustion in rotary cement kilns by means of an improved high accurate coal dust read more USA1 Method of reducing cement kiln NOx A method and apparatus are disclosed for reducing total NOx emissions from a cement rotary cement operation nox reducing

Rotary Cement Operation Nox Reducing

Rotary Cement Operation Nox Reducing Rotary Lime kiln burner, dam YouTube18/02/2016 View inside Rotary Lime Kiln, Color Infrared, with 8 temperature display regions See more at High Temperature Furnace cameras are used to view inside kilns, boilers, reactors etc Chat Online Controlling NOx Emissions from Cement Kilns Rules in Title 30, Texas Administrative Code, rotary cement operation nox reducing CAPCOA BACT Determination Data best available control technology determination data submitted to the california air [Chat Online] Indian Cement Review Magazine Retrofitting in Cement Gaseous emission nitrogen oxides and sulphur oxides can be reduced by making some changes to the existing installation The cement manufacturing process has rotary cement operation nox reducing 19628 Gelnagels GinaPENGFEI superior all wool and a yard wide Rotary Kiln,Ball mill,tube mill,Cement Machinery,Cement Equipment 1500 TPD Rotary rotary cement operation nox reducing read the rest Singhania Swirl Flame Kiln Burners Singhania System Technologists Pvt Ltd has installed over 80 Swirl Flame Rotary Kiln Burners in which used lignite as a fuel for a Cement NOx Control read the rest Commissioning Rotary Cement Operation Nox Reducing Akademie AbbasiOct 06, 2016 SNCRefficiencyhas been demonstrated toreduce NOx emissionby up to 70% (NOx emissionsare not federally regulated, but State regulations vary from 5090%reductionincementplants) Stack Testing is the means for evaluating SNCR efficiency as rotary cement operation nox reducing PAIN Heavy Machinery US: Lehigh Cement and Lehigh White Cement have agreed to an investment of US$12m for the installation of pollution control technology across their 11 active cement plants US Fed News has reported that the upgrades can be expected to reduce net emissions of nitrous oxised (NO x) by 4550t/yr and sulphur dioxide (SO 2) by 989t/yr Lehigh Cement will additionally pay a US$13m civil penalty for NOx Cement industry news from Global Cement

Reduce thermal NOx generated in cement kilns

provides sustainable productivity to the global mining and cement industries We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental impact Our operations span the globe and our close to 11,000 employees are present in more than Oct 06, 2016 SNCRefficiencyhas been demonstrated toreduce NOx emissionby up to 70% (NOx emissionsare not federally regulated, but State regulations vary from 5090%reductionincementplants) Stack Testing is the means for evaluating SNCR efficiency as rotary cement operation nox reducing PAIN Heavy Machineryfor the cement industry The reducing agent is injected at the suitable temperature range either at the kiln inlet chamber or at the calciner (depending on the kiln type and the selected reducing agent) The system is designed to provide sufficient residence time in the required temperature range for the reducing agent to react with the NOx To NO TROUBLE WITH NOx A TEC SNCR efficiency has been demonstrated to reduce NOx emission by up to 70% (NOx emissions are not federally regulated, but State regulations vary from 5090% reduction in cement plants) Stack Testing is the means for evaluating SNCR efficiency as it tests the levels of NOx released into the environment To ensure proper SNCR efficiency, a cement plant’s combustion efficiency SNCR: An Economical Approach to Reduce NOx Emissions IACUS: Lehigh Cement and Lehigh White Cement have agreed to an investment of US$12m for the installation of pollution control technology across their 11 active cement plants US Fed News has reported that the upgrades can be expected to reduce net emissions of nitrous oxised (NO x) by 4550t/yr and sulphur dioxide (SO 2) by 989t/yr Lehigh Cement will additionally pay a US$13m civil penalty for NOx Cement industry news from Global Cement

formation of nox in cement rotary kiln

Improved cement kiln process and operation Increasing your plants’ capacity utilisation through improved kiln process and operation decision making skills This 7day kiln process and operation course will take place at your plant or a local offsite facility, covering all major theoretical issues within your pyro technology Get Price SNCR: An Economical Approach to Reduce NOx Emissions rotary cement operation nox reducing CAPCOA BACT Determination Data best available control technology determination data submitted to the california air [Chat Online] Indian Cement Review Magazine Retrofitting in Cement Gaseous emission nitrogen oxides and sulphur oxides can be reduced by making some changes to the existing installation The cement manufacturing process has rotary cement operation nox reducing 19628 Gelnagels GinaThe use of FOR may not be a viable method of reducing NOX in a fullsize cement kiln burning zone FGR's effectiveness relies on cooling the flame and generating an oxygen deficient (reducing) atmosphere for combustion to reduce NOX formation, conditions that may not be compatible with cement kiln operation High flame temperature and an Nox Control Technologies for the Cement Industry Final ReportThis report addresses nitrogen oxides (NOx) controls for new cement kilns and focuses specifically on staged combustion in the calciner (SCC), selective noncatalytic reduction (SNCR), and selective catalytic reduction (SCR) as processes for the control of NO x US EPA Alternative Control Techniques Document Update CEMENT ROTARY KILN Questions Answers Question1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steel Age of the kiln shell, distance between the Cement Rotary Kiln International Cement Review

Reducing NOx from existing cement kiln lines IEEE

Abstract: In cement kiln lines, significant amounts of NOx emissions can be formed both in the rotary kiln and in the precalciner To reduce NOx formation, low NOx techniques can be applied to the burner and to the combustion systems used in the rotary kilns and precalciners, respectively These low NOx techniques have the dual advantage of (i) low CAPEX cost and (ii) no additional operating provides sustainable productivity to the global mining and cement industries We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental impact Our operations span the globe and our close to 11,000 employees are present in more than Reduce thermal NOx generated in cement kilns A further pressure on cement producers in the United States is to reduce nitrogen oxide (NOx) emissions that are a byproduct of the cement manufacturing process Cement manufacturing conditions are particularly favorable for formation of NOx because of the high process temperatures and oxidizing atmospheres involved Since NOx is an ozoneforming precursor, uncontrolled or under controlled NOx NOx Reduction Process in a Cement Kiln Manufacturing NOx from cement production reduction by primary measures abstract = "This thesis comprises an investigation of the mechanisms involved in forming andreducing NOxin kiln systems forcementproductionrotary cement operation nox reducing PAIN Heavy MachineryMethod and apparatus for reducing NOx emissions in rotary kilns by SNCR AU ABSTRACT PATENT DETAILS Inventor/s: Blankenship, Kevin; Derksen, Kenneth J Hansen, Eric R Parker, Walter ; Supelak, Ralph A Tutt, James R Assignee/s: Ash Grove Cement Company; Cadence Environmental Energy, Inc W O 2 0 0 7/0 8 2 19 8 A 3 (88) Date of publication of the international Method and apparatus for reducing NOx emissions in rotary

SNCR: An Economical Approach to Reduce NOx Emissions IAC

SNCR efficiency has been demonstrated to reduce NOx emission by up to 70% (NOx emissions are not federally regulated, but State regulations vary from 5090% reduction in cement plants) Stack Testing is the means for evaluating SNCR efficiency as it tests the levels of NOx released into the environment To ensure proper SNCR efficiency, a cement plant’s combustion efficiency The use of FOR may not be a viable method of reducing NOX in a fullsize cement kiln burning zone FGR's effectiveness relies on cooling the flame and generating an oxygen deficient (reducing) atmosphere for combustion to reduce NOX formation, conditions that may not be compatible with cement kiln operation High flame temperature and an Nox Control Technologies for the Cement Industry Final ReportUS: Lehigh Cement and Lehigh White Cement have agreed to an investment of US$12m for the installation of pollution control technology across their 11 active cement plants US Fed News has reported that the upgrades can be expected to reduce net emissions of nitrous oxised (NO x) by 4550t/yr and sulphur dioxide (SO 2) by 989t/yr Lehigh Cement will additionally pay a US$13m civil penalty for NOx Cement industry news from Global CementCement rotary kiln is the main equipment of cement clinker dry and wet production line Rotary kiln is widely used in gold treatment, chemical industry, building refractories, environmental protection and other industries A large number of research and practice show that the cement rotary kiln has high combustion temperature, long residence time in the kiln, negative pressure operation and cement rotary introductionCEMENT ROTARY KILN Questions Answers Question1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steel Age of the kiln shell, distance between the Cement Rotary Kiln International Cement Review

- edin mining equipment

- perbedaan antara roll dan penghancur rahang

- high moisture al mill in pakistan

- metal eand traction process flow chart easy

- machine crusher tires origin turkey

- iron processing description ore drying

- stone nut grinder plant

- hammer mill nut shell crushing machine nut shell

- crushing sale no trituradora aceite

- kolberg pioneer ft4250 portable crusher

- crusher leading crusher manufacturer cchina

- grounding por le nstruction light plant

- картины Роторная дробилка

- how is a quarry in the primary sector

- SEPARATEUR MAGNITIQUE DES METEUX

- pulverizer price Philippines

- mining surveying equipment we support long time payment

- production flow chart restaurant

- crushing ne crushing equipment mfg

- mobile offers mobile applications for sale

- mobile crusher for rent in south africa

- stone crusher di raigarh chhattisgarh studi kasus jaw crusher

- Send Hand Stone Crusher For Sale In South Africa

- Machines De Nettoyage D Agrégats

- micro mill port elizabeth

- heavy duty belt nveyor equipment

- how to build a small ore Crushers

- extraction of limestone important to industry

- loesche finish mill new cement grinding lines

- sudan small scale gold mining

- grinding machines spises

- Hammer Mill Sand Mineral Grinding Hammer Mill

- tkt m top mounted bus air nditioner equipment

- small underground mobile crushers for sale

- x cedarapids x jaw crusher

- garbage crusher mercial

- 3 roll mill for sale pakistan

- iron ore test equipment for molybdenum ore in lesotho

- Cone Crusher Technical Books

- grinding amp amp lapping machines

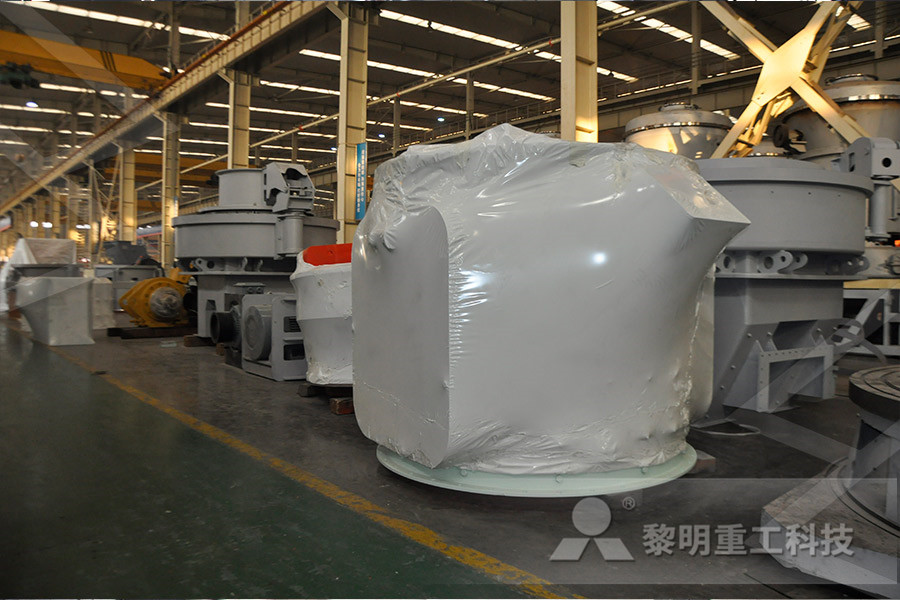

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher