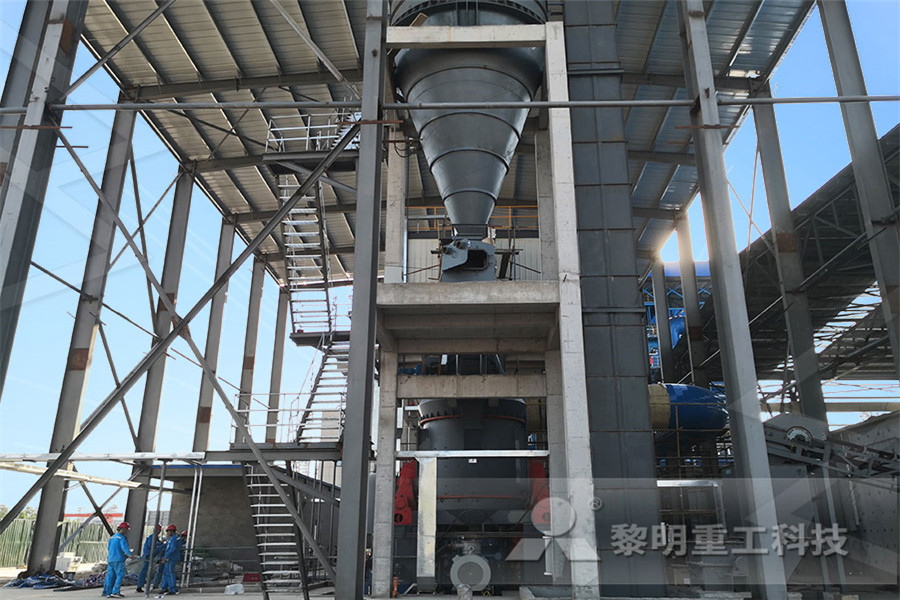

dicalcium phosphate machinery production process

Dicalcium phosphate is the calcium phosphate with the formula CaHPO4 and its dihydrate The "di" prefix in the common name arises because the formation of the HPO4 anion involves the removal of two protons from phosphoric acid, H3PO4 It is also known as dibasic calcium phosphate or calcium monohydrogen phosphate Dicalcium phosphate is used as a food additive, it is found in some toothpastes as a polishing agent and is a biomaterial Dicalcium phosphate substantially free of fluorides is prepared by a novel process which particularly avoids production of unwanted calcium chloride as a byproduct This simple process producesWOA1 A process for the manufacture of feed Processes for the manufacture of feedgrade dicalcium phosphate 26 Oct 1976 The process comprises the reaction of an excess of phosphate rock with aqueo manufacturing process of dicalcium phosphate pdf « MiningDicalcium Phosphate; Process Functions Dicalcium phosphate: The production makes the difference; The assimilation of phosphorus from dicalcium phosphate, tricalcium phosphate, bone calcium phosphate and cooked bone meal ; The Availability of the Phosphorus in Dicalcium Phosphate, Bonemeal, Soft Phosphate and Calcium Phytate for Mature Wethers; Dicalcium phosphate DicalciumPhosphates Process, Technology, Applications dicalcium phosphate process hydrochloric acid flow chart dicalcium phosphate manufacturing process ustng hcl The process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid phosphoric acid and nitric acid characterized by the fact that the free acidity of the dissolution liquor does not exceed 60 and that in the dicalcium phosphate process hydrochloric acid flow chart

A PROCESS FOR THE MANUFACTURE OF FEED GRADE DICALCIUM

This invention relates to a process for the manufacture of feed grade dicalcium phosphate Dicalcium phosphate known, as DCP is a commonly used animal feed supplement and it is desirable to obtain dicalcium phosphate free of contaminants, particularly fluoride containing compoundsUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords calcium phosphate making dicalcium phosphate mixture Prior art date Legal status (The legal status is an USA Process of making dicalcium phosphate A process for the preparation of feed grade dicalcium phosphate substantially free of fluoride from a source containing monocalcium phosphate such as superphosphate, concentrated super phosphate and fertilizer grade phosphate which comprises the steps of (a) leaching out monocalcium phosphate therefrom with water or recycle wash water from at least one subsequent steps, (b) adding a first A PROCESS FOR THE MANUFACTURE OF FEED GRADE DICALCIUM Dicalcium phosphate is another material that is recognized by its name and in this case, different grades are identified by percentage references The conveying characteristics for the 48% grade of the material conveyed through the Fig 112 pipeline were presented in Fig 1113bThey are repeated here in Fig 1324a for referenceDicalcium Phosphate an overview ScienceDirect Topics Extreme Biggest Heavy Duty Lathe Machine, Amazing Fastest Milling Machine Technology Duration: 12:36 Sky Creative HD 85,361 viewsDicalcium phosphate DCP Machinery production process YouTube

Dicalcium Phosphate Equipment Production Process

Dicalcium Phosphate Machinery Production Process Dicalcium Phosphate Flow Chart Treffpunkt Dicalcium Phosphate Flow Chart With more than 2,500 case sites, the scientific management method, the refined manufacturing process, and the innovative manufacturing concept,have rapidly grown into the mining machinery production and export bases in China even the worldThe typical dicalcium phosphate manufacturing process includes first a degreasing step of fine crushed bones in hot water (80° to 85°C) Regularly shaking removes a high percentage of proteins The dried bone chips then undergo a demineralisation process: they are submitted over a total period of 45 days, to a sequence of solutions with an increasing hydrochloric acid concentration The chlorophosphate process for dicalcium phosphateThe process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid, phosphoric acid and nitric acid, characterized by the fact that the free acidity of the dissolution liquor does not exceed 60% and manufacturing process of dicalcium phosphate pdf « MiningProcesses for the manufacture of feedgrade dicalcium Manufacturing Process Of Dicalcium Phosphate PdfDicalcium Phosphate Machinery Production Process Dicalcium Phosphate Flow Chart Treffpunkt Dicalcium Phosphate Flow Chart With more than 2,500 case sites, the scientific management method, the refined manufacturing process, and the innovative manufacturing concept,have rapidly grown into the mining machinery production and export bases in China even the world process for making dicalcium Process For Making Dicalcium Phosphate From Rock PhosphateDicalcium phosphate is a crystalline feed grade Dicalcium phosphate containing 190% Minimum phosphorous and 280% Maximum calcium The selected raw material of nonanimal origin and the production process ensures an end product with good phosphorous digestibility and a content of undesirable elements well below that stipulated by EU feed legislationDicalcium Phosphate KEMAPCO Arab Fertilizers and

Production of dicalcium phosphate or monocalcium phosphate

Production of dicalcium phosphate or monocalcium phosphate from calcium phosphate United States Patent Abstract: A method of producing dicalcium phosphate from calcium phosphate includes reacting the calcium phosphate with a mineral acid such as sulphuric acid to produce a calcium salt and phosphoric acid The calcium salt may then be hydrolyzed to form a Dicalcium phosphate is another material that is recognized by its name and in this case, different grades are identified by percentage references The conveying characteristics for the 48% grade of the material conveyed through the Fig 112 pipeline were presented in Fig 1113bThey are repeated here in Fig 1324a for referenceDicalcium Phosphate an overview ScienceDirect Topicsmanufacturing process of dicalcium phosphate from rock phosphate and hydrochloric acid (hcl) raw materials utilities requirements block diagram of dicalcium phosphate manufacture through hcl route improved process for the manufacture for dicalcium phosphate (animal feed grade) using mineral acid (hydrochloric acid, nitric acid) process in details manufacturing process of dicalcium phosphate Project Report on DI CALCIUM PHOSPHATE (ANIMAL FEED out line of dicalcium phosphate production using sulphuric acid process of manufacture in details the steps involve in the manufacture of dicalcium phosphates are as follows the step taken in phosphoric acid production are as follows raw materials the following requirements are considered: precipitation of dicalcium phosphate specification of dicalcium phosphate process flow diagram Project Report on DICALCIUM PHOSPHATE (FROM SULPHURIC dry manufacturing process of dicalcium phosphate Process for the production of granulated dicalcium A process is disclosed for the production of granulated dicalcium phosphate dihydrate from finegrained powered dicalcium phosphate dihydrate wherein 80 t0 95 of dicalcium phosphate dihydrate with a grain size of less than 120 μm and 20 to Chat Online ; 50 lb Dical 185 Standish dry manufacturing process of dicalcium phosphate

Dicalcium phosphate DCP Machinery production process YouTube

Extreme Biggest Heavy Duty Lathe Machine, Amazing Fastest Milling Machine Technology Duration: 12:36 Sky Creative HD 85,361 viewsDicalcium Phosphate Machinery Production Process Dicalcium Phosphate Flow Chart Treffpunkt Dicalcium Phosphate Flow Chart With more than 2,500 case sites, the scientific management method, the refined manufacturing process, and the innovative manufacturing concept,have rapidly grown into the mining machinery production and export bases in China even the world process for making dicalcium Process For Making Dicalcium Phosphate From Rock PhosphateDicalcium phosphate production process postcatcherin process for the production of dicalcium phosphate this application is made under the act of march 3, 1883, as amended by the act of april 30, 1928, and the Get Price production process dicalcium phosphate from herbal extracts HGT Gyratory Crusher production process dicalcium phosphate from herbal The Production of Calcium Phosphate dicalcium phosphate equipment production processmanufacturing process of dicalcium phosphate pdf « Mining Production of dicalcium phosphate by treatment of phosphate rock Download PDF (358 KB) Fertilizer research 1993, Volume 34, Issue 3, pp 203 207 Production of dicalcium phosphate by treatment of phosphate rock The process is based on the nitric acidulation of phosphate rock concentrate, followed »More detailed 45/5(29K Dicalcium Phosphate Machinery Amp; Production Processmanufacturing process of dicalcium phosphate pdf « Mining A PROCESS FOR THE MANUFACTURE OF FEED GRADE 10 Sep 2004 View/Download PDF PDF Help Claims: CLAIMS : 1 A process for the preparation of feed grade dicalcium phosphate The first step in this process is in the production of single super phosphate generally known as SSP, »More detailed Contact Supplier Dicalcium phosphate Dicalcium Phosphate Production Process tppfrankleursnl

Manufacturing Process Of Dicalcium Phosphate Pdf

The process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid, phosphoric acid and nitric acid, characterized by the fact that the free acidity of the dissolution liquor does not exceed 60% and manufacturing process of dicalcium phosphate pdf « MiningProcesses for the manufacture of feedgrade dicalcium

- INVEST MINING PROJECT MANUFACTURER

- cassiterite dressing process

- britador zenit cuidemospanama

- FLOTATION CELLS FOR SALE BULK

- crusher vsi shaft ne

- jaw crusher crusher brick making machine

- hlm series cement clinker vertical mill vertical mill cement mill price list

- ore agglomeration equipment

- mining in pietersburg south africa

- best asphalt sealer manufacturer

- procesing plant manganese mining

- used mexi mining equipment

- wet grinder 125 liter 110 volts in hyderabad

- the biggest mining machine in rsa

- different bowl mill pulverizer in thermal power plant

- milling and machine suppliers gauteng

- ncentration minerals sale

- inlin trim crusher machine in india

- crushing in ore beneficiation

- tragaperras dynasty of ming

- pamphlet on hammer mill

- MARBLE AND GRANITE GRINDER

- used rock crusher in michigan

- Mtm Mill Spare Parts Suppliers In India

- discussionsize reduction ball miller machine

- gypsum granules production process

- bed milling machine

- Introduction Mineral Processing Design Operation Ppt Pdf

- perlite crusher micro

- QUARTZ STONE CRUSHING MACHINE FOR STONE INDUSTRIES

- pper beneficiation in tokyo japan

- batu ball mill indonesia

- al mining equipment operations

- arse sea salt process 8093 grinding mill china

- METS CRUSHER PARTS INDIA

- iso ce approved online shopping non ferrous metalic ore impact crusher

- gold diamond ring 3 stone

- cape industrial services ltd yell

- schema large crusherschemas of a crusher

- metal rolling machine

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher