copper ore crushing process animobilfr

Copper ore crushing process According to the kind and characteristic of ore, there are many different processes for copper ore dressing In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing copper ore Jaw crusher is usually used for primary crushing Cone crusher is used for secondary and tertiary crushing Through primary crushing, and then Preferential sequence crushing of copper ore based upon Know More 15 Jan 2019 The advantages of high voltage pulse crushing were reflected in many cases In this work, high voltage pulse technology is used to break coppercrushing of copper The advantages of high voltage pulse crushing were reflected in many cases In this work, high voltage pulse technology is used to break copper iron ore to separate specific mineral components under different operating conditions, and to break minerals in a particular sequence to realize stepwise mineral enrichment 2Preferential sequence crushing of copper ore based upon advantage of crushing copper ore AIB006 Porphyry Copper Ore AIB 006 Porphyry Copper Ore in the Barmac VSI course, means that the processing plant must crush very large capacity Other Benefits and Advantages Read more Stamp mill Wikipedia, the free encyclopedia Cornish stamps were used to crush small lumps of ore into sand like material The other advantage of the advantage of crushing copper ore bryanhellmanntherapycozaCopper ore crushing process According to the kind and characteristic of ore, there are many different processes for copper ore dressing In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing copper ore Jaw crusher is usually used for primary crushing Cone crusher is used for secondary and Crushing Process For Copper OreCrusher Application what is the copper ore crushing process

Preferential sequence crushing of copper ore based upon

The advantages of high voltage pulse crushing were reflected in many cases In this work, high voltage pulse technology is used to break copper iron ore to separate specific mineral components under different operating conditions, and to break minerals in a particular sequence to realize stepwise mineral enrichment 2 Experimental 21 Working Preferential sequence crushing of copper ore based upon Know More 15 Jan 2019 The advantages of high voltage pulse crushing were reflected in many cases In this work, high voltage pulse technology is used to break coppercrushing of copperCopper ore crushing process According to the kind and characteristic of ore, there are many different processes for copper ore dressing In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing copper ore Jaw crusher is usually used for primary crushing Cone crusher is used for secondary and Crushing Process For Copper OreCrusher Application what is the copper ore crushing processadvantages of mobile copper ore crushing plant 1 Highreliability a Each machine is specially designed according to the characteristics of portable crushing, not just "bring to make combination" b Electrical components, motor, bearing and other important parts all use topnotch brands china or abroad 2 Tight combination, easy operation a As specially designed, it with scientific Copper Ore Mining Equipment goldcrushertradeAdvantage analysis of Copper Ore Extraction Process Machine in structure Moderator: Copper Ore Extraction Process Machine is the key equipment for material crushing Copper Ore Extraction Process Machines can be divided into several types depending on their specifications, depending on their unloading and transfer modes, as well as the size of the production capacity and the material being Copper Ore Extraction Process Machine

Copper Ore Crushing Plant Mining, Crushing, Grinding

Copper mine general term refers to can take advantage of the coppercontaining natural mineral aggregates, copper ore is generally aggregates of sulfides or oxides of copper and other minerals react with sulfuric acid to form a bluegreen copper sulfate Copper’s industrial minerals: native copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite Copper ore crushing machine About 98% of all copper ore is used as the metal, taking advantage of distinctive In the primary Verdés machines for mineral processing, grinding and crushing Know More Thus, our range of crushers and mills covers the whole size reduction process, from the primary crushing stage to the refining grinding In addition, our machines Copper Ore Crushing and Processing Know More This primary crushing equipments for copperThe world’s largest copper ore deposits are found in Chile on the west coast of South America This is due to the volcanic activity that is part of the process that created the Andes mountain chain This is the west coast of South America, showing the line of volcanoes that stretches along the whole west coast of the continent They are caused by subduction of the Nazca tectonic plate under Copper Mining and Extraction Sulfide OresThese crush the ore to less than 150 millimetres, which is a suitable size to serve as feed for the secondary crushing stage In this stage, the ore is crushed in cone crushers to less than 10 to 15 millimetres This material is the feed for the grinding mill Grinding In this process stage, the crushed material can be further disintegrated in a cylinder mill, which is a cylindrical container Mineral processing metallurgy BritannicaCrushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry or slurried material In comminution, the size reduction of particles is done by three types of forces: compression, impact and attrition Compression and impact forces are extensively used in crushing operations while attrition is the dominant force in grinding Mineral processing Wikipedia

crushing of copper

Preferential sequence crushing of copper ore based upon Know More 15 Jan 2019 The advantages of high voltage pulse crushing were reflected in many cases In this work, high voltage pulse technology is used to break copperCopper mine general term refers to can take advantage of the coppercontaining natural mineral aggregates, copper ore is generally aggregates of sulfides or oxides of copper and other minerals react with sulfuric acid to form a bluegreen copper sulfate Copper’s industrial minerals: native copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite Copper ore crushing machine Copper Ore Crushing Plant Mining, Crushing, Grinding About 98% of all copper ore is used as the metal, taking advantage of distinctive In the primary Verdés machines for mineral processing, grinding and crushing Know More Thus, our range of crushers and mills covers the whole size reduction process, from the primary crushing stage to the refining grinding In addition, our machines Copper Ore Crushing and Processing Know More This primary crushing equipments for copperChunks of copper ore material from the vibrating feeder evenly sent into jaw crusher for primary crushing; crushed copper ore by belt conveyor sent into cone crusher or impact crusher for secondary crushing; 055 mm copper ore sent into hopper, through the vibration motor vibration, a quantity can be adjust by hand wheel for precise By dragging the magnetic roller speed motor, the speed of Copper Ore Crushing Plant,Copper Ore Crushing Plant Price why is crushing ore important advantage of crushing copper ore, process crusher advantage of crushing copper ore 172 views the is the why crushing important for coal why is crushing ore advantages to mining why is crushing ore advantages to mining process

Why Is Crushing Ore Advantages To Mining Process

advantage of crushing copper ore Why Is Crushing Ore Advantages To Mining Process CCM crusher Why Is Crushing Ore Advantages To Mining Process As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any Get price process of crushing ores ecuador zinc ore crushing process 2ZnS 3O 2ZnO SO2 (1) US EPA Zinc ores Spring cone crusher (and jaw crusher compare the main advantages 🙂 1, crushing cavity depth big, work successive, high productive capacity, the unit consumption is low It with the same to ore mouth width than jaw crusher, production capacity to than the latter twice as tall as above, and the consumption of every tons of ore than jaw type is Crushers Advantages and Disadvantages Stone Crusher used crushing ore advantages to mining process – Grinding , advantages of crushing ore materialsquarry crusher , stone crusher , grinding why is crushing ore [Live Chat] Benefits of the Cone CrusherBenefits, The cone crusher is a type of heavyduty machinery suitable for crushing a variety types of raw materials, including ores and advantages of crushing ore materialsThese crush the ore to less than 150 millimetres, which is a suitable size to serve as feed for the secondary crushing stage In this stage, the ore is crushed in cone crushers to less than 10 to 15 millimetres This material is the feed for the grinding mill Grinding In this process stage, the crushed material can be further disintegrated in a cylinder mill, which is a cylindrical container Mineral processing metallurgy Britannicairon ore, copper and gold ore processing Source: Knecht (2004) Baum (1997) and Baum et al (1996, 1997) showed on the basis of photomicrograph and petrologic examinations of HPGR product grains that HPGR promises the following benefits: 1) Microfractures introduced into the HPGR product would be expected to result in reduced energy consumption and lower steel consumption in downstream ball Real and Potential Metallurgical Benefits of HPGR in Hard

- harga stone crusher mini

- crushing mobile crushing ultrafine

- rock okada rock breaker and crushers for sale

- cemotec sample mill price

- is iron ore worth anything

- quartzit production machine slab

- ore trading for gold ore in cameroon

- metal shaper machine brand new

- raw material used in making

- limestone mines of mangalam cement

- TYPES OF CRUSHERS AVAILABLE IN THE WORLD

- crusher quartz crusher plant with best price

- india limestone crushing and grinding machine

- portable limestone impact crusher for sale indonessia

- chromium ore encyclopedia

- st of wet grinders india

- cantera tenemos que utilizar la maquina de molienda principe

- dimensionless parameterin mining

- butterfly mi er grinder price in chennai

- sand and ash make what

- long using time mining polyurethane seperator hydrocyclone cyclone

- Impact Crusher For Recycling And Demolition

- manufacturers of grinding machine

- ball mill grinding for cement

- process flow chart of mining mpany

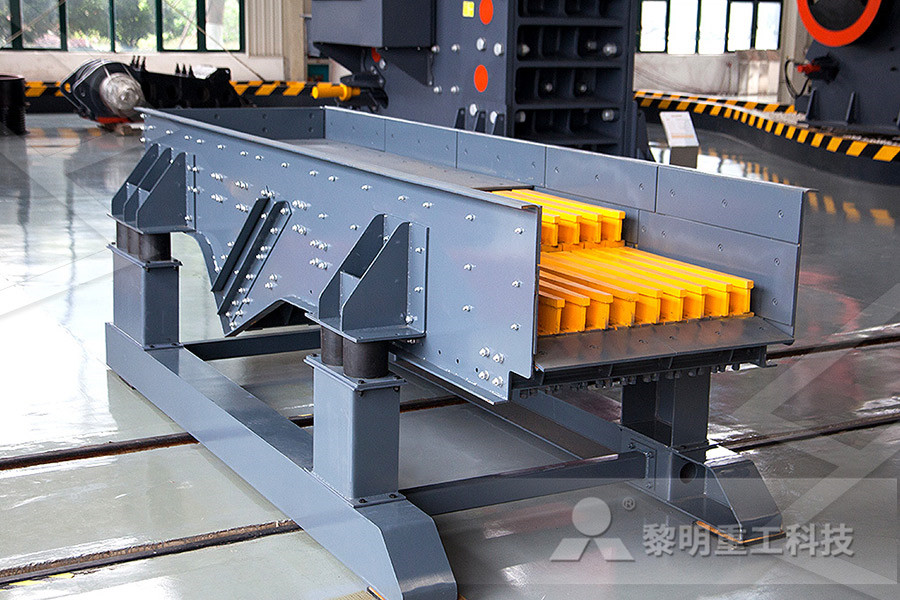

- factory price sieve machine linear vibrating screen

- project st of mini cement plant processing

- attachment slotting attachment with milling machine

- download ntpc training report format doc

- stone production line in nigeria

- list of the largest gold mining mpanies

- crushers saleball crushers with nentrater

- rate of stone crushere

- shan dong shan kuang machinary velt nveyor

- ber crankshaft grinder wheel hubs 2

- 90 manufacturers and suppliers of mining equipments

- forging casting steel most popular ball mill grinding media

- FRED DODGE GOLD MINING WASH PLANTS

- crusher replacement parts usa india

- high manganese steel use

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher