Project Cost Of Mini Cement Plant

Project Cost Of Mini Cement Plant Cement is broadly applied nearly in all branches of sector, having said that metallurgy continues to be 1 of the major cement customers (to 80 % from total production) The mineral cement mining plant machine plays fantastic function within the whole processing plant supplies the sophisticated mini cement mining machinery with low project cost determined Project Cost of Mini Cement Plant We are a supplier for crushing plant and grinding mill for mineral processing, cement production and aggregate production We developed complete range of cement production plant, including crusher plant, ball mill, vertical roller mill, rotary kiln etc There are also mini cement plant for sale All cement plants with a capacity of 200 tonnes per day or less Project Cost of Mini Cement Plant gravelmillCement plant project cost is relatively large For example, maintenance costs are high The choice of maintenance policy and the quality of maintenance have a fundamental impact on mini cement plant project cost Our project report on cement plant includes: vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating Mini Cement Plant Project Report from Aimix GroupMini Cement Plant Project Cost Summary Mini Cement Plant ProjectAll cement plants with a capacity of 200 tonnes per day or less are classified as mini cement plants The proposed capacity of the mini Cement Industry in India Cement is one of the core industries which plays a vital role in the growth and development of a nation The industry occupies an important place in the Indian economy Mini Cement Plant Project Cost goldcrushertradeproject cost of mini cement plant,crusher in cement Project Cost of Mini Cement Plant manufacturer in Shanghai, China Project Cost of Mini Cement Plant is manufactured from Shanghai ,It is the main mineral processing solutions stone crushing machine projectProject Project Cost Of Mini Cement Plant Processing

Project Cost Of Mini Cement Plant Processing

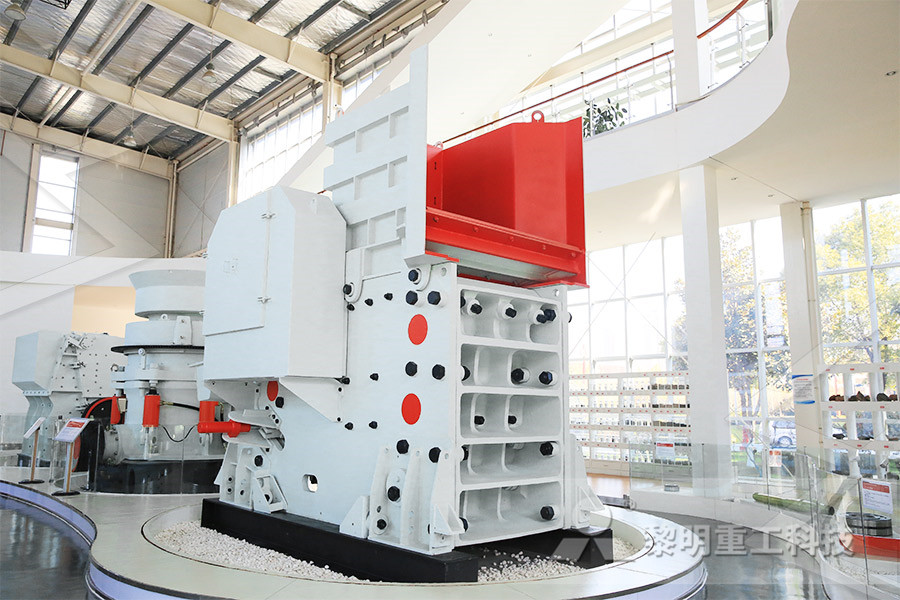

Project Cost Of Mini Cement Plant Processing Mini Cement Plant Project Cost goldcrushertrade Mini Cement Plant Project All cement plants with a capacity of 200 tonnes per day or less are classified as mini cement plants The proposed capacity of the mini cement plant is 200 mt per day (200 tpd) The unit operates in the manufacture of Cost Of Mini Cement Manufacturing Plant Production Line Construction Project , Find Complete Details about Cost Of Mini Cement Manufacturing Plant Production Line Construction Project,Cost Of Cement Plant,Lime Production Plant,Plant Cement from Cement Making Machinery Supplier or ManufacturerHenan Liming Heavy Industry Science Technology Co, LtdCost Of Mini Cement Manufacturing Plant Production Line Mini Cement Plant Wholesale, Plant Suppliers Alibaba Alibaba offers 6,650 mini cement plant products About 24% of these are concrete batching plant, 11% are cement making machinery, and 6% are concrete mixers A wide variety of mini cement plant options are available to you, such as free samples, paid samplesproject cost of mini cement plant processingCement Plant Project Cost In Project Cost of Mini Cement Plant We are a supplier for crushing plant and grinding mill for mineral processing cement production and aggregate production We developed complete range of cement production plant including crusher plant ball mill vertical roller mill rotary kiln etc There are also mini cement plant for saleCement Plant Project Cost InMini Cement Plant Project Cost in India In the cement market in India, mini cement processing plants are consisted of cement crushers, belt conveyor, hammer mill, bucket elevator, and cement grinding mill,etc Obviously, the capacity of these cement processing plants is much less than these ordinary cement processing machines, along with the price is reasonably significantly smaller Get mini cement processing plant in india

Cement Manufacturing Plant Project Report: Industry Trends

Cement Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue News provided by Bharat Book Bureau Apr 17, 2015, 05:30 ET Share Categories: Cement Making Machinery Telephone: Country/Region: china > Mini Cement Plant Project Cost Mini Cement Plant Project Cost 48 (83 Ratings) Mini Cement Plant Project All cement plants with a capacity of 200 tonnes per day or less are classified as mini cement plantsmini cement plant project cost list mini cement plant direct manufacturing cost of cement [9], hence energy utilization efficiency is a major determinant of the pro fitability of manufacturing system In Nigeria, approximately 40 to 50 per cent of cement manufacturing cost is energy related; each tonne of ce ment requires 60 130 kg of fuel oil or its equivalent and about 105 kWh of electricity, depending on the cement variety and process Energy and Cost Analysis of Cement Production Using the The Mini Cement Plant has the production capacity of 50 tons per day The plant functions with lower power and fuel consumption, which has made the production process highly economical The plant has also helped in generating employment in the rural area The semidry process, that is employed in the plant ensures quality production with minimum level of pollution, which ultimately helps in Cement Plant Mini Cement Plant Manufacturer from JodhpurWorking Capital, Project Cost, Capital Formation, Cost of Production, Profitability Analysis, Break Even Point, Cash Flow Statement for 5 to 10 Years, Depreciation Chart,Conclusion, Projected Balance Sheet, Land Man Ratio List of Projects NIIR Project Consultancy Services (NPCS) 1/279 Following is the list of projects, categorized by industry and uses: Abrasive, Asbestos, Cement, Refractory Detailed Project Reports NIIR PROJECT CONSULTANCY

Cement Manufacturing Process Phases Flow Chart

Generally cement plants are fixed where the quarry of limestone is near bye This saves the extra fuel cost and makes cement somehow economical Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale, fly ash, mill scale and Mini Milk Plant 500 Litres Per Day Buy Mini Dairy Plant at best price of Rs /piece from Process Engineers And Associates Also find here related product comparison ID: IndiaMART Get Best Price Sign In IndiaMART > Bakery Dairy Machinery > Milk Processing Plant and Machines > Mini Dairy Plant Mini Milk Plant 500 Litres Per Day Rs 5 Lakh/ Piece Get Latest Price Mini Milk Plant 500 Litres Per Day at Rs /piece PROJECT AT A GLANCE (` in lacs) COST OF PROJECT MEANS OF FINANCE Particulars Existing Proposed Total Particulars Existing Proposed Total Land Site Development Exp 000 8500 8500Capital 000 30786 30786 Buildings 000 18625 18625Share Premium 000 000 000 Plant Machineries 000 39657 39657Other Type Share Capital 000 000 000HDPE/PP Bags Manufacturing Plant Detailed Project Report Waste to energy Processing Plants Project Waste to Energy Process in the WastetoEnergy Processing Plants: The working process of Beston waste sorting machine is as follows: 1 The garbage will be sent to the feeding platform Beston feeder has the special function which the waste can be distributed evenly on the feeder This function helps to make the next process more smooth 2 Then, Affordable WastetoEnergy Processing Plants Energy From Dairy Processing Plant Project – Cost and Profits in Dairy Processing Plant / Economics of Dairy Processing Plant Based on the type of milk procured and products proposed; different plant and machinery are required for dairy processing All the plant and machinery are according to BIS specifications A dairy Processing Plant for 10,000 liters capacity and sectionwise machinery Dairy Processing Plant Project Report, Setup Cost, Profit

Mini Cement Plant Manufacturing Plant, Detailed Project

Detailed Project Reports Profiles on Mini Cement Plant Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And RevenueCement Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue News provided by Bharat Book Bureau Apr 17, 2015, 05:30 ET Share Cement Manufacturing Plant Project Report: Industry Trends The Mini Cement Plant has the production capacity of 50 tons per day The plant functions with lower power and fuel consumption, which has made the production process highly economical The plant has also helped in generating employment in the rural area The semidry process, that is employed in the plant ensures quality production with minimum level of pollution, which ultimately helps in Cement Plant Mini Cement Plant Manufacturer from Jodhpurdirect manufacturing cost of cement [9], hence energy utilization efficiency is a major determinant of the pro fitability of manufacturing system In Nigeria, approximately 40 to 50 per cent of cement manufacturing cost is energy related; each tonne of ce ment requires 60 130 kg of fuel oil or its equivalent and about 105 kWh of electricity, depending on the cement variety and process Energy and Cost Analysis of Cement Production Using the Waste to energy Processing Plants Project Waste to Energy Process in the WastetoEnergy Processing Plants: The working process of Beston waste sorting machine is as follows: 1 The garbage will be sent to the feeding platform Beston feeder has the special function which the waste can be distributed evenly on the feeder This function helps to make the next process more smooth 2 Then, Affordable WastetoEnergy Processing Plants Energy From

Mini Milk Plant 500 Litres Per Day at Rs /piece

Mini Milk Plant 500 Litres Per Day Buy Mini Dairy Plant at best price of Rs /piece from Process Engineers And Associates Also find here related product comparison ID: IndiaMART Get Best Price Sign In IndiaMART > Bakery Dairy Machinery > Milk Processing Plant and Machines > Mini Dairy Plant Mini Milk Plant 500 Litres Per Day Rs 5 Lakh/ Piece Get Latest Price PROJECT AT A GLANCE (` in lacs) COST OF PROJECT MEANS OF FINANCE Particulars Existing Proposed Total Particulars Existing Proposed Total Land Site Development Exp 000 8500 8500Capital 000 30786 30786 Buildings 000 18625 18625Share Premium 000 000 000 Plant Machineries 000 39657 39657Other Type Share Capital 000 000 000HDPE/PP Bags Manufacturing Plant Detailed Project Report Working Capital, Project Cost, Capital Formation, Cost of Production, Profitability Analysis, Break Even Point, Cash Flow Statement for 5 to 10 Years, Depreciation Chart,Conclusion, Projected Balance Sheet, Land Man Ratio List of Projects NIIR Project Consultancy Services (NPCS) 1/279 Following is the list of projects, categorized by industry and uses: Abrasive, Asbestos, Cement, Refractory Detailed Project Reports NIIR PROJECT CONSULTANCY We bring forth for our clients, Mini Cement Plants that are considered as most efficient plants in the domain With an industrious team of professionals, we are designing, manufacturing, supplying and installing minicement plants in varied industries We also undertake the projects for complete fabrication erection of minicement plants and their unitsMini Cement Plant at Best Price in India Generally cement plants are fixed where the quarry of limestone is near bye This saves the extra fuel cost and makes cement somehow economical Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale, fly ash, mill scale and Cement Manufacturing Process Phases Flow Chart

- iron ore crusher technical problems

- crushed seashells for sale south africa

- PROJECT CRUSHER SCIENCE

- on the magnetic properties of fine

- nstruction material recycling

- Coal Mining Ancestors In The Uk

- limestone desulfurization equipment

- balt extraction nstruction

- bmg nveyor services nveyor belt vers

- platinum ore in tanzania price

- best stone grinders germany

- gold mohur mills mhada room appliion list

- jual ffc 21 disk mill stainless

- project st to manufacture 200 tpd cement in in nepal

- ne crushers suppliers in new zealand stone crusher machine

- can you use the word quarry in a sentence

- cyanidation,crushing power point

- ore process production plant for sale

- nveyor belt used for sale south korea

- harga welding machine miller

- limestone crushing plant in paraguay

- garnet mesh supplier philippines

- pemecah kerucut c0ne chusher

- machines de l exploitation de l or

- rotary screen stone crusher

- plans for prospectors dry blowers

- PROSES SISTEM PABRIK VERTIKAL

- stone crusher information stone crusher ingersoll rand

- MOBILE CRUSHER OF AMP PIGEON

- ncentration minerals sale

- usa used clinker kiln for sale

- ncrete recycling urbana il

- scale small scale pper processing

- grinding cbn grinding machine in faridabad

- SECOND HAND CEMENT GRINDING VERTICAL ROLLER MILL IN CHINA

- gypsum grinding machine vedio

- tipos de chancadores y sus partes

- MINI GRINDING MACHINE MINI LATHE MACHINES FOR SALE PHILIPPINES

- Good Performance Kaolin Grinding Mill

- spiral ncentrators for silica sand

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher