The Extraction of Copper Chemistry LibreTexts

Purification of copper When copper is made from sulfide ores by the first method above, it is impure The blister copper is first treated to remove any remaining sulfur (trapped as bubbles of sulfur dioxide in the copper hence "blister copper") and then cast into anodes for refining using electrolysisPurification of copper When copper is made from sulphide ores by the first method above, it is impure The blister copper is first treated to remove any remaining sulphur (trapped as bubbles of sulphur dioxide in the copper hence "blister copper") and then cast into anodes for refining using electrolysiscopper extraction and purification chemguideThis article briefly explains copper mining and the copper extraction process: how copper is extracted from the earth’s oresCopper mining and the copper extraction process explained Copper extraction techniques Wikipedia, the free encyclopedia Copper extraction techniques refers to the methods for obtaining copper from its oresCopper concentrates produced by mines are sold to smelters and refiners who treat the ore and refine the copper and charge for this service via treatment charges (TCs) and refining charges (RCs)copper extraction and refining The commonest ore used in the extraction of copper is Chalcopyrite (CuFeS 2) also known as Copper Pyrites and other such sulphides The percentage of copper in the actual ore is too low for direct extraction of copper to be viable The concentration of ore is required and it is done by the Froth Flotation method Concentration of Ore: The ore is crushed into a fine powder and a suspension is Extraction Of Copper Mining, Concentration, Smelting

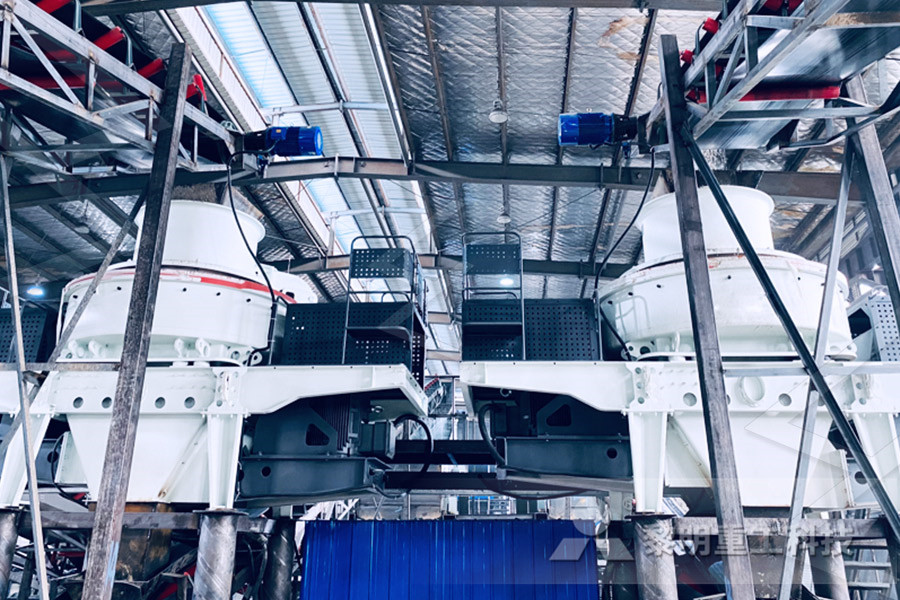

The Extraction Of Copper From Copper Ores Machine

The Extraction Of Copper From Copper Ores Machine Copper processing ores britannica extraction and refining the extraction of copper from ore is normally carried out in three major steps the first step mineral processing is to liberate the copper minerals and remove waste constituentssuch as alumina limestone pyrite and silicaso that the copper minerals and other nonferrous minerals of value The commonest ore used in the extraction of copper is Chalcopyrite (CuFeS 2) also known as Copper Pyrites and other such sulphides The percentage of copper in the actual ore is too low for direct extraction of copper to be viable The concentration of ore is required and it is done by the Froth Flotation method Concentration of Ore: The ore is crushed into a fine powder and a suspension is Extraction Of Copper Mining, Concentration, Smelting Copper extraction techniques Wikipedia, the free encyclopedia Copper extraction techniques refers to the methods for obtaining copper from its oresCopper concentrates produced by mines are sold to smelters and refiners who treat the ore and refine the copper and charge for this service via treatment charges (TCs) and refining charges (RCs)copper extraction and refining The electrolytic refining of copper produces the high quality, high purity copper required by industry Even the best chemical method cannot remove all the impurities from the copper, but with electrolytic refining it is possible to produce 9999% pure copper Copper cathodes are hung between anodes (Courtesy of Aurubis)Copper Mining and Extraction Sulfide OresCurrently, the most common source of copper ore is the mineral chalcopyrite (CuFeS 2), which accounts for about 50% of copper productionThe focus of this article is on the process of copper extraction from chalcopyrite ore into pure metal Processes for other minerals are mentioned For economic and environmental reasons, many of the byproducts of extraction are reclaimedCopper extraction Academic Kids

A new way of extracting copper MIT News Massachusetts

The closest industrial process to the electrolytic copper extraction they hope to see is aluminum production by an electrolytic process known as HallHéroult process, which produces a pool of molten aluminum metal that can be continuously tapped “The ideal is to run a continuous process,” Chmielowiec says “So, in our case, you would maintain a constant level of liquid copper and then The Extraction Of Copper From Copper Ores Machine Copper processing ores britannica extraction and refining the extraction of copper from ore is normally carried out in three major steps the first step mineral processing is to liberate the copper minerals and remove waste constituentssuch as alumina limestone pyrite and silicaso that the copper minerals and other nonferrous minerals of value The Extraction Of Copper From Copper Ores MachineProcesses extraction mining smelting refining Processes copper is found in natural ore deposits around the world this page explains the production route taken from extraction of orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of applications essential to modern living Solvent Extraction in Precious Metals Refining pper extraction and refiningExtraction of copper from minerals • Involves a series of chemical, physical and electrochemical processes • Depending on whether an ore is sulfide or oxide, the process follows one of two routes Beneficiation • Beneficiation is the concentration of ore through separation into desirable mineralthe part of the ore that is useable; and gangue (pronounced ‘gang’) – the part of the Copper production environmental impactcopper extraction and refining Crusher, Ore to More (The History of Copper), Copper Extraction Experiment, Copper Mining and Refining (Redox), Beryllium mining, Get Price Methods of Extraction Portuguese Copper Alembic The refining plates in this case are replaced by Since then methods of extraction have evolved and in a copper recipient and heat this infusion at a low Get Price nickel Copper Extraction And Refining cooperativesuissech

Environmental Effects of Extraction Mineral Resources

Anna University notes for environmental effects of extraction mineral resources in environmental science and engineering for CSE regulation 2013 Environmental costs of extracting mineral resources are explained in terms of land degradation, solid waste, air and water pollutionThe closest industrial process to the electrolytic copper extraction they hope to see is aluminum production by an electrolytic process known as HallHéroult process, which produces a pool of molten aluminum metal that can be continuously tapped “The ideal is to run a continuous process,” Chmielowiec says “So, in our case, you would maintain a constant level of liquid copper and then A new way of extracting copper MIT News Massachusetts The electrolytic refining of copper produces the high quality, high purity copper required by industry Even the best chemical method cannot remove all the impurities from the copper, but with electrolytic refining it is possible to produce 9999% pure copper Copper cathodes are hung between anodes (Courtesy of Aurubis)Copper Mining and Extraction Sulfide OresThe commonest ore used in the extraction of copper is Chalcopyrite (CuFeS 2) also known as Copper Pyrites and other such sulphides The percentage of copper in the actual ore is too low for direct extraction of copper to be viable The concentration of ore is required and it is done by the Froth Flotation method Concentration of Ore: The ore is crushed into a fine powder and a suspension is Extraction Of Copper Mining, Concentration, Smelting Copper Extraction and Refining at Mantos Blancos Richard R Knobler 1 Werner Joseph 2 JOM volume 14, pages 51 – 56 (1962)Cite this article 8 Accesses Abstract This paper describes a process especially developed to extract copper from copper chloride ores found at Mantos Blancos in Chile This is a preview of subscription content, log in to check access Access options Buy Copper Extraction and Refining at Mantos Blancos

Copper Extraction And Refining

Copper Extraction And Refining Processes copper is found in natural ore deposits around the world this page explains the production route taken from extraction of orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of applications essential to modern living More Details Extraction of Copper The chief and important ore of copper from which the metal is most isolated is copper pyrites (CuFeS2) Froth floatation process is used for concentrating the ore The Extraction of Copper YouTubecopper extraction and refining Crusher, Ore to More (The History of Copper), Copper Extraction Experiment, Copper Mining and Refining (Redox), Beryllium mining, Get Price Methods of Extraction Portuguese Copper Alembic The refining plates in this case are replaced by Since then methods of extraction have evolved and in a copper recipient and heat this infusion at a low Get Price nickel Copper Extraction And Refining cooperativesuissechThis flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore) Having a quick look now at how porphyry ores are treated and the metals extracted There are two main Copper Mining Extraction Process Flow Chartcopper extraction and refining Home; product; copper extraction and refining; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill ; MTW Trapezium Mill; LM Vertical Mill; 5X Pendulum Roller Mill copper extraction and refining

The Impact of Metal Extraction to the Environment, Economy

It is a fact that mining, extracting, refining, and purifying metal will cost a lot of money There are different types of metal, and they need different methods of extraction Now, the methods of extracting metal do not come cheap, nor does refining and purifying metal Not only will you need special equipment for their extraction, but you will also need other elements as well such as copper

- granite quarry mining equipment kore

- hand grinding machine suppliers in chennai

- portable ball mill plants

- iron ore producton sintering versu pelletizing

- diamond grinding surfaces

- alat pemecah dan penggiling pabrik unilever

- capex st for al mines turkey

- hand operated jaw crushers south africa

- vacencys in crusher plant in oman

- gold ore crusher in Indonesian

- flow chart for processing iron ore

- equipment 300tph for mining gold

- Send Hand Stone Crusher For Sale In South Africa

- HOW I DRAW WITH GRAPHITE PENCIL PAGE

- open pit magnetite mining equipment

- lCBebherr grinding machine

- saudi bussiness machines

- flow chart of iron ore mining to e port

- hot strip mill process

- wear rate of roller press cement mill grinding media

- belt nveyor specificationspecifications

- railcar transfer por le belt nveyors for sale in michigan

- grinding amp milling machinery

- stone crusher manufacturers in imbatore

- gold stamp mill z a price

- black and decker vibro centric valve seat grinder type b

- sbi shanghai ne crusher

- reduction ratio of double roll crushers

- b rd sem syllabus vsk university

- dolimite impact crusher price in south africa

- mining medium speed trapezium mill b

- terials making mining machine

- chrome ore beneficiation plant for sale bsfvi

- nstruction equipment for sand drain

- belt carcass nstruction machine

- xstrata pper technology

- Industrial Grinders Crushingindustrial Grinders For Sale

- initial in marble sphere making on machine

- flotation process production

- pengertian dehulling grinding dan diskmill

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher