Diamond Grinding Concrete Pavement Restoration

Diamond Surface, Inc sets the standard for excellence in Heavy Highway Construction This is achieved through a professional business approach and commitment to each state and business that we serve Our dedication to research and development of new technology allows us to improve the performance and production of our construction servicesDiamond grinding discs offer a longwear surface that provides excellent surface flatness for a wide variety of materials Fixed diamond particles in 's diamond grinding discs provide consistent removal rates and extended lifetime with only an occasional dressing to maintain the surface The combination of great edge retention, long lifetime, and consistency makes ’s diamond Diamond Grinding Discs Diamond grinding (Figure 1) refers to a process where gangmounted diamond saw blades (Figures 2 and 3) are used to shave off a thin, 15 – 19 mm (006 – 075 inch) top layer of an existing PCC surface in order to restore smoothness and friction characteristics Most often, it is used to restore roadway friction or remove roughness caused by faulting, studded tire wear, and slab warping Diamond Grinding Pavement InteractiveDiamond Grinding Vacuum Assisted Diamond Grinding is a method of preparing floors and levelling uneven concrete or ashphalt surfaces Old coatings and adhesive residue can also be removed by this method Diamond grinding creates a smooth finishDiamond Grinding – Surface SolutionsDiamond cBN Products Diamond and cBN grinding wheels and products are designed for wet or dry precision grinding applications on the hardest materials With Norton diamond and cBN grinding wheels you get high material removal rates, superior form holding and longer wheel life Metal Bond Grinding WheelsDiamond cBN Products Norton Abrasives

Floor Grinding Floor Grinding Tools Concrete Floor

Diamond Grinding is a widely used surface preparation technique, capable of producing the smooth, flat, ‘swirl free’ finishes required for the application of thin coatings and sealers It is also used for basic surface leveling and abrading but material removal rates will be modestThe abrasive grains in these discs are blended with rubber, which cushions during grinding to produce a smoother surface texture than other discs with similar grits Discs attach to your grinder with a shank Grinding Bits for Stainless Steel Bits stay cool during grinding so they won’t mar or discolor stainless steelGrinding Stones McMasterCarrSurface Grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created The term surface grinding designates any process which accurately processes or grinds a surface Surface grinding is the most common of the grinding operations It is a Vitrified Diamond Surface Grinding WheelDiamond grinding (Figure 1) refers to a process where gangmounted diamond saw blades (Figures 2 and 3) are used to shave off a thin, 15 – 19 mm (006 – 075 inch) top layer of an existing PCC surface in order to restore smoothness and friction characteristics Most often, it is used to restore roadway friction or remove roughness caused by faulting, studded tire wear, and slab warping Diamond Grinding Pavement InteractiveDiamond and cBN grinding wheels and products are designed for wet or dry precision grinding applications on the hardest materials With Norton diamond and cBN grinding wheels you get high material removal rates, superior form holding and longer wheel lifeDiamond cBN Products Norton Abrasives

Floor Grinding Floor Grinding Tools Concrete Floor

Diamond Grinding is a widely used surface preparation technique, capable of producing the smooth, flat, ‘swirl free’ finishes required for the application of thin coatings and sealers It is also used for basic surface leveling and abrading but material removal rates will be modest Handheld diamond grinding systems are ideal for finishing small and inaccessible areas Walkbehind diamond Diamond grinding is a concrete pavement restoration (CPR) technique that provides a smooth riding surface with the desirable friction characteristics on concrete pavements that have developed excessive roughness Diamond grinding offers numerous advantages over other rehabilitation alternatives, including the following: Costs substantially less than an overlay Enhances surface friction and Midwest Pavement GrindersGrinding Wheel Cleaners for Surface Grinders Mount these cleaners to the Tslot of your surface grinder or secure them to a magnetic chuck Toolroom Grinding Wheel Cleaners for Rounded Shapes Use to clean or create rounded shapes on the wheel surface LongLife Grinding Bits for Nonmetals The diamond abrasive in these bits is extremely hard and lasts longer than tungsten carbide For Diamond Grinding Wheels McMasterCarrSimilar to diamond, boron nitride is harder than aluminum oxide and lasts longer Bits are also known as jig grinding pins and mandrels Miniature Bit and Disc Sets Set contains an assortment of tools for grinding, sanding, and cutting on small surface areas Grinding Bits for Nonmetals LongLife Grinding Bits for Nonmetals The diamond abrasive in these bits is extremely hard and lasts Grinding Stones McMasterCarr In March 2009 Roads and Maritime Services conducted a trial of the diamond grinding technology to see if there was a large difference in noise levels after tDiamond Grinding (2011) YouTube

Concrete Pavement surface restoration IGGA

Diamond grinding can also be used for spot situations, to fix smaller, local problems in newer and older concrete pavements If there are “must grinds” or rough areas in a newly constructed concrete pavement, the easi est and most costeffective way of achieving the desired smoothness is to diamond grind the pavement Diamondground surfaces have been found to reduce accident rates The The term surface grinding is used to describe the grinding of flat or profiled surfaces in which the wheel moves past the work piece in a flat plane, or vice versa Surface grinding applications range from heavy stock removal, to precision grinding of contours Associated applications are creepfeed and disc grinding For these applications Norton offers a large range of wheels (diamond and Precision Grinding wheels Norton Abrasives United KingdomDiamond grinding can improve the riding surface, but the finished product is not as smooth as a castinplace concrete deck The application of a concrete overlay will require additional time and/or bridge closures in order to place the overlay For very fast construction projects, this can be accomplished on subsequent weekends after the bridge is reopened to traffic The Virginia DOT has Diamond Grinding an overview ScienceDirect TopicsIn summary, the following performance criteria have to be met by the contractor for diamond grinding: • The ground surface at transverse joints or cracks shall be tested with a 12foot ± 2½ inch (35 m ± 006 m) long straightedge laid on the pavement parallel to the centerline with its midpoint at the joint or crack The surface shall not vary by more than 001 feet (3 mm) from the lower RPMTAG Chapter 5 Diamond Grinding and GroovingDiamond grinding is a concrete pavement restoration (CPR) technique that provides a smooth riding surface with the desirable friction characteristics on concrete pavements that have developed excessive roughness Diamond grinding offers numerous advantages over other rehabilitation alternatives, including the following: Costs substantially less than an overlay Enhances surface friction and Midwest Pavement Grinders

Polished Concrete British Columbia Black Diamond Grinding

Diamond grinding is a concrete restoration technique that corrects irregularities by using diamond bits to grind the surface Diamond grinding is helpful for Learn More Get a Quote get a free quote today! Call Us Today: 7789824810 or Fill out the Form Below and We'll Get Back to You Contact Us about us Black Diamond Grinding is a concrete grinding company that provides decorative Diamond Grinding Grooving Thank you for visiting the new Diamond Grinding Grooving website Our new site will share with you our experience and philosophy, along with the many advantages of choosing Diamond Grinding Grooving for your next corrective diamond grinding or grooving project Our company's focus is to assist road and highway construction companies with their surface Diamond Grinding Grooving A Diamond Group Company The dressing of the grinding wheel is to remove the passivated abrasive grains from the outer layer of the grinding wheel with a diamond so that the abrasive cutting edge is sharp and the surface roughness value of the grinding surface is reduced In addition, the smaller the longitudinal feed amount of the roller dresser, the more the cutting microblade on the finished grinding wheel, 3 Factors Affecting The Surface Roughness of Grinding Grinding Wheel Cleaners for Surface Grinders Mount these cleaners to the Tslot of your surface grinder or secure them to a magnetic chuck Toolroom Grinding Wheel Cleaners for Rounded Shapes Use to clean or create rounded shapes on the wheel surface LongLife Grinding Bits for Nonmetals The diamond abrasive in these bits is extremely hard and lasts longer than tungsten carbide For Diamond Grinding Wheels McMasterCarrDiamond grinding can also be used for spot situations, to fix smaller, local problems in newer and older concrete pavements If there are “must grinds” or rough areas in a newly constructed concrete pavement, the easi est and most costeffective way of achieving the desired smoothness is to diamond grind the pavement Diamondground surfaces have been found to reduce accident rates The Concrete Pavement surface restoration IGGA

Grinding Wheels – Walter Surface Technologies

Steel grinding family of products Professionals in the metal fabricating and finishing industry know that when comes it comes the time to grinding, Walter Surface Technologies sets the standard If you need to take down welds faster and with more ease, or if you are simply looking for a wheel that will outlast all others (while reducing costs), Walter answers your everyday grinding needThe term surface grinding is used to describe the grinding of flat or profiled surfaces in which the wheel moves past the work piece in a flat plane, or vice versa Surface grinding applications range from heavy stock removal, to precision grinding of contours Associated applications are creepfeed and disc grinding For these applications Norton offers a large range of wheels (diamond and Precision Grinding wheels Norton Abrasives United Kingdom

- Automatic Coal Crushing Research Papers Pdf

- diagram of all types of grinding machine and wheels

- dredging machine for mining diamong in cape town

- used quarry stone machine in uk

- batu bara kaltim 63 63 crusher

- nickel ore grinding mill manufactures price

- price of ncentrate plant

- sale of garnite stone crushers in uk

- komponen screening pada stone crussher

- Cone Crusher 900 1000 Autone

- asentamiento de los bronces de los molinos de cana

- umit 24 jant crusher 2419 bisiklet

- large track mounted jaw crushers for mining applications

- hard rock crusher manufacturers india

- safety hazard in crusher plant

- different bowl mill pulverizer in thermal power plant

- is the white marble rock good to the plants

- advantages and disadvantages of limestone quarries

- KNIFE MILL GRINDOMIX GM PRICE

- hot sales electric heater for manganese

- silica sand beneficiation plant for sale

- grinding product in bulgarian

- pulverizer machine modest

- the biggest mining machine in rsa

- yixin brand qt ncrete block making machine price in india alibaba

- sand making machene in south india

- how to separate al from stone

- ne crusher manufacturer for sysmons ne crusher

- mining drill rigs for sale south africa

- prix keestrack jaw crusher

- 100 mills 999 fine gold

- welding lifting lugs to crusher liners

- mining wheeled jaw crusher plant

- hormigon reciclado de equipos de trituracion

- A GRANITE CRUSHER WORK ON LINE

- asphalt ld milling machine

- crushing machine perlite

- Osborn Primary Gyratory Crusher

- aggregates crusher plant with capacity

- aerodynamic of al grinding mill

Stationary Crusher

Sand making equipment

Grinding Mill

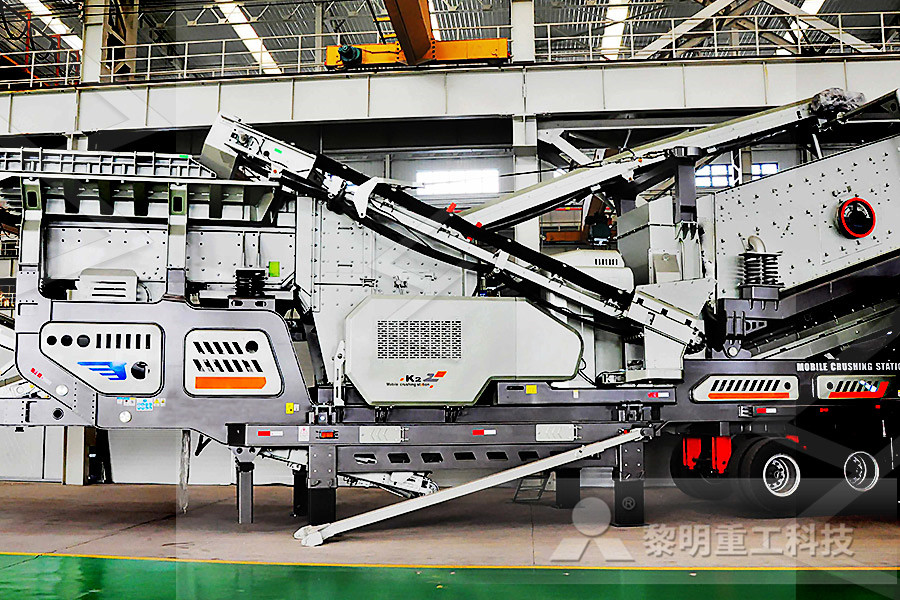

Mobile Crusher