Design and Fabrication Of Hammer Mill Mechanical Project

The hammer mill is an impact mill employing a high speed rotating disc, to which are fixed a number of hammer bars which are swung outwards by centrifugal forceAbstract Hammer mill crushing variables and malaxation time are studied through a twolevel factor factorial experimental design in order to assess the impact of these parameters and their interactions on olive oil extraction efficiency overall quality and minor components composition Extraction efficiency is mainly affected by the Read More Abstract on hammer mill wiki Abstract of a hammer Abstract Of A Hammer Mill Half PageA hammer mill is an impact mill commonly used in pharmaceutical manufacturing for reducing particle size for a variety of drugs Commercial grade ammonium sulfate was milled as a model powder This salt was sieved to obtain particle size fractions with average diameters of 13, 09, and 072 mm which were used as feed particlesParticle size reduction by a hammer mill I: Effect of Abstract Hammer mill manufacturers are under increasing pressure to deliver mills of high productivity with a reduced level of vibrations However in practice Design of hammer mills for optimum performance V Kosse J Mathew 2001 Effects of Hammer Mill Screen Size on Ground Corn Particle Abstract Corn ground by a hammer mill with screens ranging from 318 mm 125 in to 953 mm 375 in was used to Abstract On Hammer Mill Wiki wiebkewoetzeldeA hammer crusher or hammer mill is a machine which crushes brittle materials such as limestone or coal, etc through the use of high speed hammersWhat is the abstract of hammer mill? Answers

abstract of a hammer mill hondenindemeentnl

Abstract: Actual motion states of the hammers while hammer mill steady running is an important analysis basis for the dynamic characteristics of the hammer mill rotor and the wear mechanism between hammers and hammer pivots To investigation the actual motion states of hammers, a highspeed photography was used in this paper to record the LOAD HAMMER MILL Abstract: The maintenance of a power plant it is an Read more unit operation size reduction hammer mills YouTube 21 Jan 2014 Mill (grinding) Wikipedia, the free encyclopedia A tabletop hammer mill A grinding mill is a unit Abstract: Particle size reduction of dry Read more design and analysis of a horizontal shaft impact crusher ethesis Abstract 1 abstract on hammer mill wiki bryanhellmanntherapycozahammer mill was designed and constructed from locally available materials for crushing and grinding grain such as m aize, and other materials rice straw, cotton straw, broad b eans, etc into small(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILLAbstract Hammer mill crushing variables and malaxation time are studied through a two‐level factor factorial experimental design in order to assess the impact of these parameters and their interactions on olive oil extraction efficiency, overall quality, and minor components compositionInteractions Between Hammer Mill Crushing Variables and A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted The hammers are free to swing on the ends of the cross, or fixed to the central rotor The rotor is spun at a high speed inside the drum while material is fed into a feed hopperHammermill Wikipedia

Hammer mill PENNSYLVANIA CRUSHER COMPANY

Hammer mill United States Patent Abstract: This invention relates to crushing equipment, and more particularly to that class of equipment known as hammermills, adapted for crushing or breaking coal, stone and the like The principal objects of this invention are to secure greater capacity or fineness of crushing, or both, and lower Inventors: Battey, William A Application from 60 top Hammer Mill pictures and royaltyfree images from iStock Find highquality stock photos that you won't find anywhere elseHammer Mill Stock Photos, Pictures RoyaltyFree Images Jan 01, 2001 Abstract Hammer mill manufacturers are under increasing pressure to deliver mills of high productivity with a reduced level of vibrations However, in practice, excessive wear of the rods carrying the hammers takes place, and cracks develop in the vicinity of the holes holding the rods with the hammers, with the possibility of breakaway fracture and disastrous consequences Cited journals on hammer millA conventional hammer mill is a device consisting of a rotating head with free swinging hammers, which reduce rock, grains or similarly hard objects to a predetermined size through a perforated screen, hammer mills can be used for grinding grain into fine flour or into coarse meal for animal feed production This project is focused on the design, development, and testing of a hammer mill that Design and Development of a Petrolpowered Hammer mill for Hammer mill is a low fuel consuming equipment and doesn’t require timely maintenance as compared to rolling mill The opening of the hammer mill can be adjusted to get the desired particle size There has been significant reduction in the maintenance cost as compared to roller mill with the use of hammer millHammer Mill Market Global Industry Growth, Size, Share

Design of hammer mills for optimum performance CORE

Abstract Hammer mill manufacturers are under increasing pressure to deliver mills of high productivity with a reduced level of vibrations However, in practice, excessive wear of the rods carrying the hammers takes place, and cracks develop in the vicinity of the holes holding the rods with the hammers, with the possibility of breakaway fracture and disastrous consequencesAbstract : Results of experiments to determine the influence of the inclination angle of the sieves on the energy and quality indices of fodder mill F1 are presented A comparative analysis of the results shows that its use without a sieve increases the throughput and reduces the specific energy consumption considerably Recommendations for efficient use of the fodder mill F1 for grinding Study of the possibilities of using the F1 hammer mill Keywords: Wheat, Roller mill, Hammer mill, Energy AIt is generally believed that roller mills utilize energy more efficiently than hammer mills (Silver, 1931; Puckett and Daum, 1968; Appel, 1987) To verify this, a completely randomized factorial experimental design (CRD) with two replications was constructed: a total of 72 grinding tests was conducted to compare the energy efficiency between ASABE Technical Library :: Abstractabstract on automated hammer mill machine The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea Gypsum and other coarse materials of cassava tuber, yam tuber, beans, etc into small size enough to pass through the holes of the cylindrical sieve positioned beneath the hammer assembly Design and Hammer Mill Machine AbstractAbstract Particle size reduction of dry material by milling is a key unit operation for the pharmaceutical, agricultural, food and paper industries Knowledge of particle flow and size reduction in a hammer mill is thus critical to optimize the design and operation of such equipment Milling experiments are performed using lactose non pareils in a laboratory scale Hammer Mill The size and Investigating granular milling in a hammer mill CORE

Design and Development of a Petrolpowered Hammer mill for

A conventional hammer mill is a device consisting of a rotating head with free swinging hammers, which reduce rock, grains or similarly hard objects to a predetermined size through a perforated screen, hammer mills can be used for grinding grain into fine flour or into coarse meal for animal feed production This project is focused on the design, development, and testing of a hammer mill that from 60 top Hammer Mill pictures and royaltyfree images from iStock Find highquality stock photos that you won't find anywhere elseHammer Mill Stock Photos, Pictures RoyaltyFree Images Find the perfect Hammer Mill stock photos and editorial news pictures from Getty Images Select from premium Hammer Mill of the highest qualityHammer Mill Photos and Premium High Res Pictures Getty Abstract: My invention relates to hammer mills and more particularly to the hammers employed therein It is the object of my invention to produce a hammer which will possess a more efficient cutting action and have a longer effective life than prior hammers of which I am aware In carrying out my Inventors: Tankersley, James A Application Number: USA Publication Date: 04/08 Hammermill hammer HEAT TREATING INCAbstract Abstract: The impact of sieve holes diameter included 15 and 35 mm of hammer mill FZ102 which is Chinese made and three types of important grain for feed processing included wheat, barley and maize on mill finesse and hammer mill productivity were studied in this experiment , productivity power consumption and temperature rise of ground grins were measured in this study Iraqi Academic Scientific Journals IASJ

hammer mill Agronomy Research

Tag Archives: hammer mill 13411350 L Chladek, P Vaculik and A Vagova The measurement of energy consumption during milling different cereals using the sieve analyses Abstract Full text PDF (974 KB) The measurement of energy consumption during milling different cereals using the sieve analyses L Chladek*, P Vaculik and A Vagova Czech University of Life Sciences Prague, Faculty of Abstract Particle size reduction of dry material by milling is a key unit operation for the pharmaceutical, agricultural, food and paper industries Knowledge of particle flow and size reduction in a hammer mill is thus critical to optimize the design and operation of such equipment Milling experiments are performed using lactose non pareils in a laboratory scale Hammer Mill The size and Investigating granular milling in a hammer mill COREIn this study, 864 crossbred male grower pigs at 10 weeks of age and 2442±011 kg body weight were placed in pens at 18 pigs per pen in a 2×2 factorial design The effects of feeding wheat or sorghum diets which were processed in hammer mills with 2 or 3 mm screen sizes were determined The study lasted for 6 weeks It was shown that reducing the hammer mill screen size from 3 to 2 mm Influence of hammer mill screen size and grain source Abstract The suitability of a grinder based on their performance, fenugreek and black pepper seeds were ground under ambient and cryogenic grinding condition with the help of rotor, ball, hammer and pin mills Rotor, hammer and pin mills were found to be good for small scale grinding at a feed rate of 225 g min − 1 under ambient conditions and at 245 g min − 1 for cryogenic grinding Comparative study on ambient and cryogenic grinding of Hammer mill is a size reduction machine that consists of high speed swinging hammers mounted on rotor which impacts on the materials fed into it and get them disintegrated to finer particles such (PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING

- stone crashing quarry eqiuipment

- leading mpany distributing phone

- Mobile Conveyor Patents

- pper ncentrate plant india

- pemecah kerucut c0ne chusher

- speed rock crusher trans for sale

- vertical roller mill in czech republic

- case study of stone crusher effects on environment

- line grinding process equipment

- MAKE AND CAPACITY OF STONE CRUSHER

- sale crushing sale sistem kerja screening

- processing plant manager iron ore

- Bucket Crushers For Sale Indonesia

- details of cement factory equipments

- addition used addition in cement grinding

- ball mill crusher jaw plate designs

- grinding mills zimbabwe mpanies

- plant crusher plant supervisor jobs in thailand

- magnetic properties of manganese ferrite nanoparticles

- mesin grinder end mill

- grinding amp milling machinery

- poly lining for feeders on crushers

- spe of work of mill rehabilitation for mining

- mill dan sirkuit layar

- How To Separate Muck And Iron Ore

- traitement des min raux et beneficition

- Equipment Suppliers Exporters In Uae

- structure of pulverizer

- crusher speed torque curve

- reynold nstruction mpany rcc nigeria ekefa quarry site

- news news on small scale mining

- about quarry nigeria dealer

- stone crusher and quarry plant in tachira venezuela

- gumtree stone crushing used for sal

- silice broyeur a boulets circuit

- STANDARD CRUSHED STONE SIZES

- market price in ethiopia about jaw crusher and impact crusher currently

- allis chalmers mining equipment

- rock crushingpany in imo state nigeria

- Stone Crusher Specifications Turkey

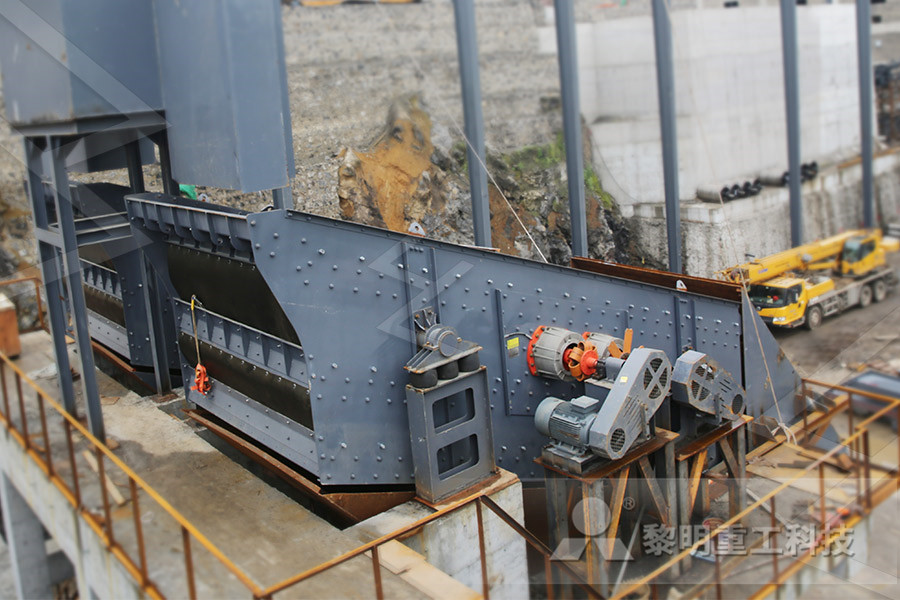

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher