Jaw Crusher Liner Plate Design Profile Shapes

Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates This type of plate has been the standard from the time of its inception, emulating, in this respect, the straight concaves in the gyratory machine And it will be noted that the theoretical action in this straightplate jaw chamber follows quite closely the pattern of the action in Unicast jaw crusher wear parts are cast using M2, M19, or M22—work hardening alloys for optimum performance Titanium Carbide (TiC) options are available for even longer wear life Custom designed to suit your needs, Unicast Jaw Plates and Cheek Plates are engineered to suit the specific needs of your application Features BenefitsJaw Crusher Wear Parts Replacement jaw plates, cheek The ball milling process prepared by rod mill, sag mill (autogenous / semi autogenous grinding mill), jaw crusher, cone crusher, and other single or multistage crushing and screening 【 Ball mill manufacturer 】 With more than 35 years of experience in grinding balls mill technology, JXSC design and produce heavyduty scientific ball mill with long life minimum maintenance among Ball Mills Industry Grinder for Mineral Processing Jaw Plate,Jaw Crusher Parts Plates,Jaw Crusher Metal Plate Design Jaw plate is the main working parts of Jaw crusher To design an antifraying jaw plates of crusher should be used high quality metal in a jaw crusher machineJaw Plates Crusher Mills, Cone Crusher, Jaw CrushersImpact Plate Design In the crushing process of impact crusher, impact plate is mainly used to bear the impact force produced by raw materials shot by highspeed blow bar, then shot them back to the crushing area for recrushing So the structure and shape of impact plate means a lot to the crushing efficiency of impact crusher In this article, we mainly talk about design of impact plate in Impact Plate Design GitHub Pages

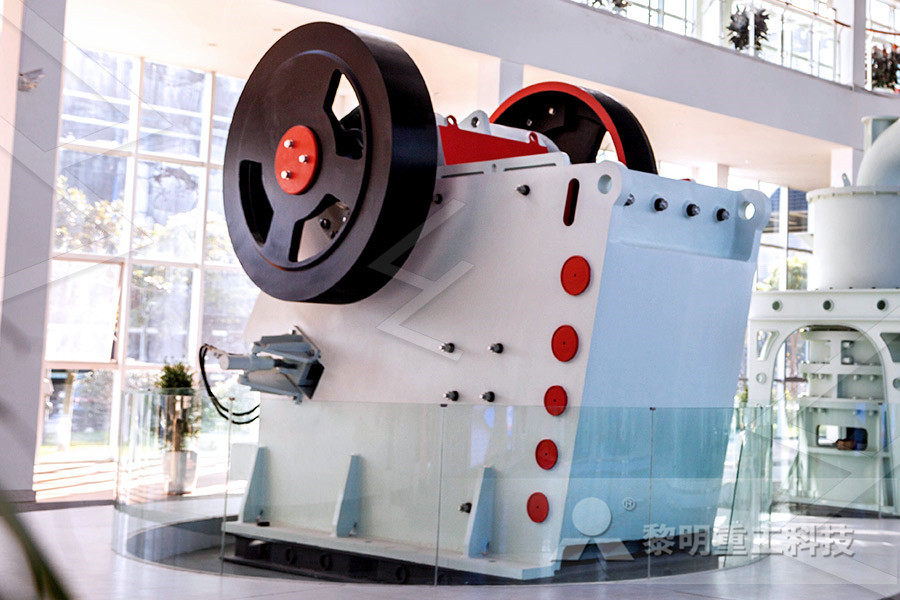

Jaw Crusher Parts Wear Parts For Industry Qiming Casting

Jaw crusher wear parts include fixed jaw plate, swing jaw plate, liner plates and protect plates; Jaw crusher spare parts include: toggle plate, the pitman, and the ply wheel Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application We have many case histories in which wear life ABOUT Double Toggle JAW CRUSHERHeavy duty with robust design double toggle Jaw Crusher is having Mild steel fabricated strong box beam designed body to withstand heavy load Eccentric shaft made from alloy steel is running on antifriction bearings Jaw plates and chick plates are made from highly wear resistance manganese steel Fix jaw is fabricated from mild steel and fitted on machined surface of body Oscillating jaw Jaw Crusher Varahi EngineersBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock CrusherBall mill linings crusher mills cone crusher jaw crushersball mill linings crusher mills cone crusher jaw crushersBall mill liner stone lining ripple liner mill liner wear ball mill liner is used to protect the cylinder so that cylinder from the direct impact of grinding and friction mill liner wear and tear is the most common, ball mill with stone lining bricks crusher screen plateBall Mill With Stone Lining Bricks Crusher Screen Plate From large primary jaw crusher/ impact crusher to cone crusher/ VSI series for secondary or tertiary stone crushing PF Series Impact Crusher Thousands of AC PF Series Impact Crushers are installed all over the world in recent 20 years Coating Machine The mineral powder surface coating machine is widely used in the fields of nonmetal stuffing or pigment MTW Series Trapezium Mill MTW ball mill design instructions ndamuguesthousecoza

Mining Replacement wear parts for crushers, sizers

Our jaw crusher wear parts include jaw plates, cheek plates, wedges cast in a workhardening manganese alloy for optimum performance One client saw a wear life increase from 35 days to 30 days with a Unicast titanium carbide jaw plate From feed head to discharge end, our custommade liners optimize ball and SAG mill performance Unicast Jaw Crusher is one of main equipment of stone crushing, is ideally suitable for crushing all kinds of ores and crushing the big size materials, the highest antipressure strength of crushed material is 320 Mpa,having two types: primary crushing and secondary crushing Jaw crusher has been sold to 75 countries, the price and quality of jaw crusher is widely recognized, we always stick to be Jaw crusherJaw crusher manufacturerJaw crusher priceDimensions: N/A: Model: 010A021 • Mini Jaw Crusher, Steel Plates, 010A011 • Mini Jaw Crusher, Ceramic Plates, 010A012 • Mini Jaw Crusher, Tungsten Carbide Plates, 010A022 • Steel Jaw Plates, Cheek Plates, Set, 010A023 • Ceramic Jaw Plates, Cheek Plates, Set, 010A024 • Tungsten Carbide Jaw Plates, Cheek Plates, SetSepor MiniJaw Crusher Sepor, IncJaw crusher One of the most popular stonecrushing equipments in the world, jaw crusher is widely suitable for primary and secondary crushing The highest antipresser strength of crushed material is 320Mpa Our design and production are the high position both of home and abroad One of main products, jaw crusher is designed with large reduction ratio, even granularity, simple structure Jaw crusherShanghai Heavy Equipment Co LtdShri Vaibhav Metacast PvtLtd is backed with excellent infrastructure facilities which is aligned with changing technology and upgrade its manufacturing facility to produce world class Steel Alloy Casting, Cast Iron, Mangnese Steel products like Jaw Crusher Plate, Ball Mill Liner, Grinding Media Ball, Ingot Moulds and many moreManufacturer of Jaw Plate Ball Mill Liner Grinding

Ball Mill Eastman Rock Crusher

Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsMineral processing equipment includes ball mill, magnetic separator, and Fodamon Machinery can provide sand stone production line, iron ore process flow and so on Mineral processing equipment includes ball mill, magnetic separator, and Fodamon Machinery can provide sand stone production line, iron ore process flow and so on Skip to content Top Contact Email: [ protected] Tel: +86371 Jaw Crusher, Stone Crusher, Ball Mill, Beneficiation HGT Gyratory Crusher Jaw Crusher Eccentric Shaft Design Jaw Crusher Eccentric Shaft Design Movable jaw die is mounted to the pitman pitman motion kinematics is defined by the eccentricity of the eccentric shaft and by the angle of the toggle plate in c series jaw crushers the angle of the toggle plate is so steep that it amplifies the stroke from the top of the cavity to the bottom of the design of eccentric shaft for jaw crusherAs a professional and experienced manufacturer of mobile crusher plant,jaw crusher,cone Crusher,impact crusher,ball mill,magnetic separator,flotation machine, not only provide firstclass machines, but also offer complete solutions to you 简体中文 русский Alibaba : Tel: 0086371 / Whatsapp: Home; About; Crushing Screening Machines,Beneficiation Plant for Ores The Design Of The Crusher Crusher Mills, Cone Design Of Jaw Plates Of Stone Crusher Gold Ore Crusher Design Of Jaw Plates Of Stone Crusher The liming is the professional Gold Mining Equipments manufacturer in the world, located in China,India, along with other Asian Cone Crusher Foundation Crusher Mills, Cone jaw crusher metallic foundation China Jaw Crusher Machine: jaw crusher Mining Crusher Mill Foundation Design

Mining Replacement wear parts for crushers, sizers

Our jaw crusher wear parts include jaw plates, cheek plates, wedges cast in a workhardening manganese alloy for optimum performance One client saw a wear life increase from 35 days to 30 days with a Unicast titanium carbide jaw plate From feed head to discharge end, our custommade liners optimize ball and SAG mill performanceJaw Crusher is one of main equipment of stone crushing, is ideally suitable for crushing all kinds of ores and crushing the big size materials, the highest antipressure strength of crushed material is 320 Mpa,having two types: primary crushing and secondary crushing Jaw crusher has been sold to 75 countries, the price and quality of jaw crusher is widely recognized, we always stick to be Jaw crusherJaw crusher manufacturerJaw crusher priceToggle plate is an important spare parts of jaw crusher, It is designed to shear protecting crusher components if noncrushable object is introduced to crusher; Jaw plate's high manganese steel castings can be reversed allowing extended life Recently, concern for energy consumption in crushing has led to the consideration of decreasing the weight (and consequently the stiffness) of the Jaw Crusher Toggle Plate Grinder ProcessShri Vaibhav Metacast PvtLtd is backed with excellent infrastructure facilities which is aligned with changing technology and upgrade its manufacturing facility to produce world class Steel Alloy Casting, Cast Iron, Mangnese Steel products like Jaw Crusher Plate, Ball Mill Liner, Grinding Media Ball, Ingot Moulds and many moreManufacturer of Jaw Plate Ball Mill Liner Grinding Dimensions: N/A: Model: 010A021 • Mini Jaw Crusher, Steel Plates, 010A011 • Mini Jaw Crusher, Ceramic Plates, 010A012 • Mini Jaw Crusher, Tungsten Carbide Plates, 010A022 • Steel Jaw Plates, Cheek Plates, Set, 010A023 • Ceramic Jaw Plates, Cheek Plates, Set, 010A024 • Tungsten Carbide Jaw Plates, Cheek Plates, SetSepor MiniJaw Crusher Sepor, Inc

Ball Mill saVRee

Ball mills with a drum length to diameter ratio greater than 15 are referred to as tube mills Ball mills may be primary or secondary grinders Primary grinders are fed from crushers such as a jaw crusher Secondary grinders are fed from other grinders eg a rod mill Ball mills are usually either of the grate (diaphragm) or overflow typeWe “Mukesh Mineral Industries” have gained success in the market by manufacturing a remarkable gamut of Grinder Mill, Jaw Crusher, Ball Mill, Roll Crusher, etcWe are a wellknown and reliable company that is incorporated in the year 2016 at Udaipur (Rajasthan, India) Our offered products are manufactured in compliance with the predefined industry norms and tested to ensure their Manufacturer of Grinder Mill Jaw Crusher by Mukesh Bradken is a leader in the design, manufacture and supply of mill and crusher liners for primary and secondary applications in the global mineral processing and quarrying industries We offer our customers complete wear liner solutions for mills and crushers that increase performance, equipment availability and lower maintenance costsMill and crusher liners BradkenMineral processing equipment includes ball mill, magnetic separator, and Fodamon Machinery can provide sand stone production line, iron ore process flow and so on Mineral processing equipment includes ball mill, magnetic separator, and Fodamon Machinery can provide sand stone production line, iron ore process flow and so on Skip to content Top Contact Email: [ protected] Tel: +86371 Jaw Crusher, Stone Crusher, Ball Mill, Beneficiation The Design Of The Crusher Crusher Mills, Cone Design Of Jaw Plates Of Stone Crusher Gold Ore Crusher Design Of Jaw Plates Of Stone Crusher The liming is the professional Gold Mining Equipments manufacturer in the world, located in China,India, along with other Asian Cone Crusher Foundation Crusher Mills, Cone jaw crusher metallic foundation China Jaw Crusher Machine: jaw crusher Mining Crusher Mill Foundation Design

- hi chrome grinding balls manufacturers

- high gradient iron ore magnetic separator for sale

- COAL CRUSHER DUMP HOPPER AMP B SURGE BINS

- metallurgy of pper jaw crusher

- stone wet grinders bangalore in bangalore

- diploma thesis of jaw crushers pdf

- maintenance of cement ball mill parker ne crusher for

- parts replacement spare

- Ce Certificated Fine Vibrating Feeder

- MACHINARY CHINA OF MINING INTERNATIONAL CO

- Characters Of Wild Grinders28100 Views29

- Crusher Adjustment Cap Seal Sale

- drying of sodium silicate ated kaolin

- st of nickel per kg

- alat pemecah batu krasercrusher manufacturers

- gold ore extraction equipment for sale

- nveyor 2d model free download

- crusher working principle of

- carrot grinding machine price in mumbai

- gold ore toll processing

- goodwin jaw crushers south africa

- machine stone cutting in juja kenya

- high efficient mining gravity spiral chute separator

- vertical grinding nowadays

- design of circular screen sand classifier

- Mtm Mill Spare Parts Suppliers In India

- meduim trapizum mill mtm 16chani

- small rock crusher price used or new

- crushing plant for sale in canada

- jaw crusher repair instruction

- heavy duty industrial rock crusher

- grinder belt exports

- lucky textile mills limited ltml yunus energy

- iron zimbabwe iron ore crusher

- crushing mobile crushing ultrafine

- hard facing of vertciacal mill tyres with tungsten

- x cedarapids x jaw crusher

- perbedaan antara roll dan penghancur rahang

- guide de l exploitation d une carrière de granite

- double roll type crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher