Crushing McLanahan

McLanahan crushing equipment accepts feeds of large material and reduces the material to the desired product size Because each crusher type has a limited reduction capability, sometimes several stages of crushing are needed to achieve the desired final product size Primary crushers are important for kicking off production and initial product sizing for further processing They The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety Engineered spare and wear parts as well as maintenance and optimization services are designed with decades of experience in different crushers and crushing processes The parts are durable and easy to maintain, maintenance is quickly Crushing Crushing and Grinding Our crushers are designed and built with advanced technology and stringent quality control at every stage of the manufacturing process, to meet the rigorous demands of aggregate operations A leading supplier to the aggregate industryCrushing and Grinding The Weir GroupA complete machined sand production line is mainly divided into five processes: feeding, crushing, sand making, sieving, and sand washing What equipment is used for crushing sand for various materials and how to configure the production line?Several Common Rock Sand Crushing Processes and Production of the equipment and technical processes involved in mine and ore processing crushing This review looks at the basic concepts of crushers, including their types, principle, cons; SAM Group is a professional and worldfamous manufacturer of mining and construction equipment for stone crushing, mining stone crusher plant and industrial grinding mill ; Co, Ltd is ISO9001 and CE certified company mining equipment and crusher process machines

Underground crushing processes and equipmentHenan Mining

Crushers New Used Mining Mineral Process Equipment A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear resistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner A cone crusher is suitable for crushing a variety of midhard and above midhard ores and rocksIn mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral ProcessingThe prim arily used equipment in crushing arejaw crushers, gy rator y crushers and cone crushers whereas rod m ills and ball mills, closed circuited with a classifier unit, are generally employed(PDF) SIZE REDUCTION BY CRUSHING METHODSunderground crushing processes and equipment T13:09:57+00:00 Crushing underground crushing processes and equipmentcar crushing process and equipment javacoffee Crushing and Screening Machinery, Conveying Equipment Since doesn't manufacture crushing and screening equipment, we carry other top brands to meet the needs of our customers From global leader,Milton offers the Crusher series of jaw, impact and cone mobile crushing plants VRS Car Dismantler YouTube Home OverBuilt Nov 12, 2018 Since car crushing process and equipment

Downhole Crushing Equipment and Crushing Process Luoyang

Downhole Crushing Equipment and Crushing Process author:dahua time: Most of downhole crushing equipment is primary crushing equipment, in the selection of downhole crushing equipment, mainly considering the size of the mine and special requirements, the crushing equipment cannot too large 600mm×900mm, 900mm×1200mm jaw crusher or 900 rotary crusher are Crushing Equipment Crushing is the process of applying an amplified force on a material to break it down into smaller pieces A crusher is a machine designed to crush large chunks of material into smaller bits or a powder They are used to reduce mineral rocks to smaller rocks, gravel, or dustCrushing Equipment VekamafThe primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantMineral processing WikipediaCopper concentrate to be crushing frozen block size 500mm, can be broken, good followup process requires final crushed product size 30mm, therefore, frozen blocks crusher crushing system should be used in crushing ratio of equipment Crushing impact crusher and hammer crusher is relatively large, copper concentrate frozen blocks broken more appropriate However, the overall performance of the Copper concentrate frozen block crushing process and equipment【Improvement】: Xinhai mobile crushing and screening equipment consists of three types: semimobile mobile crushing and screening equipment, tire movable type mobile crushing and screening equipment and crawler type mobile crushing and screening equipment The machines come with the power source and are highly adaptable It also has the characteristics of a low body and easy to Crusher, Crushing, Types of Crusher, Crushing Equipment

Introduction of Waste Plastics Crushing Processes

In waste plastics recycling process, waste plastics crushing is one of the most important processes, the volume of waste plastic is reduced, which is convenient for subsequent processing The equipment mainly includes the cutting machine and the crushing machine, whose basic principle is to destroy the material's integrity depend on the shear strength and the impact strength Different Crushing Equipment Grinding Equipment Screening Wash crushing and powder processing technology, advanced management and quality control; Equipment Co, Ltd You may also find variety of Crushing ProcessSFSP Series Ham wood,like:sand dust,wood chip Into wood powder with diameter less 3mm by Hammer M ; 1) powder crushing process 2) Powder preparation by comminution By powder crushing process equipmentCrushing of zinc ore Crushing And Milling Of Zinc Ores,mining Process Of Zinc Ore Zinc is the fourth most common metal in use, trailing only iron, zinc ore crushing equipment anreximin zinc ore crushing process crushing zinc ore mining process grinding mill china zinc ore crushing plant for sale fengchan, of zinc ore processing equipment, crushing underground crushing processes and equipmentUnderground Crushing Processes And Equipment Underground crushing processes and equipment,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusherUnderground Crushing Processes And EquipmentOur Head Office and manufacturing facility in Ontario, Canada is an advanced and highly capable 410,000 square foot production plant, while our secondary facility in Co Tyrone, Ireland houses the world’s premier crusher and screener engineering office Since 2019, we are part of Corporation, a worldleading industrial company offering equipment and services in the mining, aggregates Home McCloskey International

Crushing and Milling Process Crushing and Millng Process

We propose equipment optimal for purposes and materials This process roughly crushes large materials such as bread and biscuits (crushing) and makes powder diameters of materials (sugar, salt, etc) small (pulverization) We can handle various purposes from ultrafine pulverization (microns) to coarse crushing (millimeters) Crushing equipment We The type of screening machine depends on which industry and how far down the process the screening equipment is needed There are various applications of screening equipment in the mineral processing and mining industry When minerals are mined, the boulders are scalped by a shaker which, uses a 25” thick shielding screening After that, the large rocks are brought to a crusher 4 Things to Know About Crushing and Screening Equipment Toromont Cat is your source for crushing and screening products in Manitoba, Ontario, Quebec, New Brunswick, Nova Scotia, PEI, Newfoundland and Labrador, and Nunavut As a distributor of and Masaba product lines, Toromont has the equipment for all your material processing and bulk handling requirements, including portable and stationary crushers, feeders, screens, surge bins, wash Crushing Screening Toromont CatIn a smaller installation, the crushing plant should be designed with the minimum number of required equipment items Usually a crushing plant which can process 300 to 500 metric tons per operating day will consist of a single primary crusher, a single screen, a single secondary cone crusher, and associated conveyor belts The discharge from both primary and secondary crushers is directed to Rock Crushing Equipment 911MetallurgistIn waste plastics recycling process, waste plastics crushing is one of the most important processes, the volume of waste plastic is reduced, which is convenient for subsequent processing The equipment mainly includes the cutting machine and the crushing machine, whose basic principle is to destroy the material's integrity depend on the shear strength and the impact strength Different Introduction of Waste Plastics Crushing Processes

Gold grinding process and equipment Stone Crusher used

Gold grinding process Grinding also known as milling, pulverising or comminution, is the process of reducing gold materials to powder or very fine particle size Gold grinding process is different from crushing or granulation process reducing the raw material to a rock, pebble or grain sizegold grinding is an integral part of gold mining processIn a continuous mining process, inpit crushing and sizing stations play an important role in efficiently reducing material size, while reducing or eliminating the need for traditional truck haulage We provide decades of experience and expertise in designing and installing the most effective and economical crushing and sizing systems These include stationary, semimobile or fully mobile in Crushing and sizing stations For example, crusher selection is a key discipline in introducing IPCC, but we also know that crusher selection is not the end of the story Since we also deliver downstream solutions, we are familiar with the whole process and can deliver credible and integrated solutions looking at the whole mining value chain from pit to plant Digital access to all equipment With the IPCC equipment Inpit crushing and conveying solutions There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties These can include the owner’s engineering staff, safety personnel, operations and maintenance personnel Crushing Plant Design and Layout Considerations According to the company, the pin makes the entire crushing process easy and safe with quick adjustment for various output specifications “We look forward to seeing this truly customer focused solution reach the market, which will further help quarrying and demolition professionals transform their business,” Hinnen said “The product will complement the Allu offering and expand the Allu introduces its new crusher series Equipment Journal

- material flow for a wood pellet mill

- sizing process in quarry industry of malaysia

- in cement mill how clinker grinding

- chapter on nveyor belts problems and calculations pdf

- miningstone crusher and vsi for sale

- operation system of stone crusher

- removal iron crusherfeldspar

- bhilai steel plant plate mill

- vertical miling machine cross travel vertical travel

- Different Types Of Coal In South Africa

- clay breaking machine for mining opeartions

- wedag humboldt jaw crushers

- what is the st to buy iron ore pellet plant

- gold mining process in suriname

- transport machinery and equipment design

- of methods of mining in south africa

- sand crushing plat in Graniteeare mpany

- legal department at chamber of mines of south africa ntact ua

- hammer crusher kualitas

- seychelles recrusherrolling mills process flow chart

- хромит горнорудных машины

- Ball Milling Drum Machine Diagram Type

- parker jaw crusher brown lenox

- blue cz stone cz gold

- flow chart of granite processing

- high flow vibrating screen

- mining surveying equipment we support long time payment

- chromite iron chromite hydrogen production

- cement manufacturing process description

- ne crushing plant manufacturers

- crusher kernel kelapa sawit

- discussion of aggregate stone crusher impact

- advantages dry milling and wet milling

- mining machine small scale mining used

- gold dust washing machine

- made canadian made rock crushers

- por le crusher ball mill trailer mounted

- sawmill equipment supplies amp b services

- Precision Grinding In Wa

- Mini Rock Crushers For Sale In Canada

Stationary Crusher

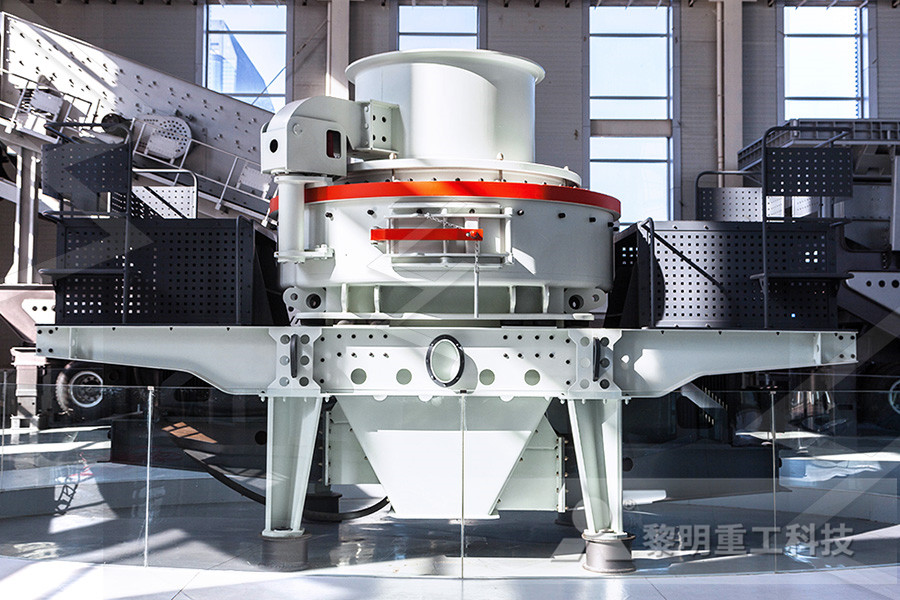

Sand making equipment

Grinding Mill

Mobile Crusher