Composite Basalt Fiber 3D printing 3D Printing Media Network

Anisoprint, a Skolkovobased company that is emerging as the first direct competitor to Markforged’s continuous composite fiber 3D printing technology, is introducing a new composite basalt fiber material for use with its 3D printers The new material is said to have better properties than metal or plastic: 15 times stronger than plastic, 5 times lighter than steel, 15 times stronger and lighter than There’s another very intriguing property of the basalt material: It seems to be electrically transparent, unlike other highstrength materials This is an often unreported property on 3D print materials, but it is critically important in some situations For example, one of our acquaintances was developing a case for a satellite phone In such a device, the radio performance is the critical element New 3D Print Material: Composite Basalt Fiber « FabbalooThe machine design includes industrial components, , quality control and safety systems, providing precise, repeatable and reliable manufacturing of midsized composite parts: printer’s build volume is 600mm x 420mm x 300mm ProM will be equipped with a heated chamber for printing high temperature polymers such as PEEK or PEI, automated calibration, material and print quality controls Anisoprint launches industrial 3D printer • BasaltWorldAI SpaceFactory has won the first place in 3D Printing Habitat Challenge for the biopolymer basalt composite 3D printing solution NASA’s 3D Printing Habitat Challenge started in 2014 with over 60 challengers worldwide They suggested brilliant ideas and embodied them into new materials, forms and solutions Strict competition rules were dictated by the conditions under which the extraterrestrial Basalt composite 3Dprinting project comes first in NASA BasaltFiber Composites 3DPrinting This project was submitted in the following language: English (en) towers, various buildings, and also for various machine parts and bodies construction Building with such modular elements will be times cheaper, stronger and longlasting Due to the low price of the raw materials basalt and zirconia, and the almost zero cost of the oxyhydrogen BasaltFiber Composites 3DPrinting

Development of 3Dprinted basalt fiber reinforced

Abstract In present work, fiber reinforced thermoplastic composite filaments consisting of polylactic acid, polycaprolactone and basalt fibers for 3D printing are developed and proposed The company builds both desktop and industrial 3D printers Robot/cell hybrids Arevo’s (Santa Clara, Calif, US) directtoconsumer Superstrata eBikes serve as a demonstrator for its direct energy deposition (DED) machines, which are based on continuous carbon fiber and thermoplastics including PA, PEEK and PEKK Its robotbased printing in an enclosed cell achieves true 3D paths 3D printing with continuous fiber: A landscape Impossible Objects presents their CBAM process as the first truly new 3D printing process in more than 20 years The manufacturing process is as follows: conventional thermal inkjet heads are used to “print” designs on sheets of composites Each sheet is then flooded with a polymer powder, causing it to stick where inkjet fluid has been deposited on the sheets Excess powder is vacuumed off and the sheets Impossible Objects announced pilot 3D printing machine for Homebasalt manufacturing 3d printing machines ExOne Home ExOne ExOne is a global leader in additive manufacturing technology, providing industrial 3D printing systems and services Visit our site to learn more Get Price Is 3D Printing The Next Industrial Revolution? TechCrunch Feb 26, 2016While the First Industrial Revolution introduced machines to 3D printing is making its way forward basalt manufacturing 3d printing machinesLaminated object manufacturing (LOM) is a method of 3D printing It was developed by the Californiabased Helisys Inc (now Cubic Technologies)During the LOM process, layers of plastic or paper What is Laminated Object Manufacturing? 3D Printing

Utilizing insitu resources and 3D printing structures for

Specifically, this work requires advancement in the development of basalt additive manufacturing (commonly known as 3D printing) technology and analysis of the produced basalt structures׳ permeability, ability to maintain a pressurized environment suitable for human habitation and radiation blocking properties Several approaches which could be utilized, depending on the Anisoprint introduces basalt fiber for continuous fiber 3D printing Anisoprint (EschsurAlzette, Luxembourg) is a manufacturer of continuous carbon fiber 3D printers and materials and recently introduced a basalt fiber composite for 3D printing According to the company, this material is 15 times stronger than plastic when applied to 3D printing technology, 5 times lighter than steel and 1 continuous fiber 3D printing FRP sheet making machine Keywords: basalt fiber; ABS; 3D printing; additive manufacturing; extruding; high strength filament 1 Introduction The goal of this paper is to develop a novel material feedstock for inspace manufacturing applications to be used for long duration exploration missions, ideally leading to the ability to 3D print a habitat o earth In particular, this paper will focus on developing a Development and Mechanical Properties of Basalt Fiber Using basalt regolith (BP1) and lunar basalt simulant (JSC1A) as building materials for their robotic additive construction, they were able to test to see if this method of 3D printing the in NASA Tests Feasibility of 3D Printing on the Moon Other A global manufacturer of metal 3D printing equipment and supplier of 3D printed parts will establish its North American headquarters in Blue Ash AddUp Inc, 3D printing manufacturer moving North American

3D Printing Carbon Fiber Lattices Engineering

To understand Anisoprint’s composite 3D printing process, it’s useful to differentiate the three varieties of composite manufacturing techniques that are currently used Composites are made up of a reinforcement fiber, such as carbon or glass fiber, and a matrix material, such as a polymer As ever with 3D printing technologies, most of the value comes in the design of the part That’s true of composites too, which, Antonov told a TCT Introducing Stage audience, are best suited to latticed structures because their key properties are directionally dependant due to their natural anisotropy, similar to how wood is stronger along the grain than across it When working with Directional forces: A look at Anisoprint's composite 3D In accordance with ASTM D638 Type V, 3Dprinted samples for mechanical testing were fabricated using a commercial FDMtype 3D printing equipment (3DISON AEP, Rokit Co, South Korea) The processing procedure for 3D printing was as follows: a dogboneshaped sample was designed with a computeraided design package (CADian3D, Intelli Korea Co, South Korea) For the Analytical study on the 3Dprinted structure and Techopedia describes 3D printing as “a manufacturing process through which threedimensional (3D) solid objects are created It enables the creation of physical 3D models of objects using a series of additive or layered development framework, where layers are laid down in succession to create a complete 3D object” For this reason, 3D printing is also referred to as additive manufacturing3D Printing vs Milling for Prototyping Production Laminated object manufacturing (LOM) is a method of 3D printing It was developed by the Californiabased Helisys Inc (now Cubic Technologies)During the LOM process, layers of plastic or paper What is Laminated Object Manufacturing? 3D Printing

Utilizing insitu resources and 3D printing structures for

Specifically, this work requires advancement in the development of basalt additive manufacturing (commonly known as 3D printing) technology and analysis of the produced basalt structures׳ permeability, ability to maintain a pressurized environment suitable for human habitation and radiation blocking properties Several approaches which could be utilized, depending on the The Production System is the first metal 3D printing system for mass production of high resolution metal parts, delivering the speed, accuracy, and perpart cost needed to compete with traditional manufacturing The Desktop Metal Production System is the first metal 3D printing system for high resolution, high throughput metal 3D printingMetal 3D Printing machines for Canadian engineers and A global manufacturer of metal 3D printing equipment and supplier of 3D printed parts will establish its North American headquarters in Blue Ash AddUp Inc, 3D printing manufacturer moving North American To understand Anisoprint’s composite 3D printing process, it’s useful to differentiate the three varieties of composite manufacturing techniques that are currently used Composites are made up of a reinforcement fiber, such as carbon or glass fiber, and a matrix material, such as a polymer3D Printing Carbon Fiber Lattices Engineering A highresolution Xray microscope was used to quantitate the internal morphological characteristics of 3Dprinted, basaltfiberreinforced PLA composites 3Dprinted composites have microstructures and mechanical properties that are distinct from those of Analytical study on the 3Dprinted structure and

Directional forces: A look at Anisoprint's composite 3D

As ever with 3D printing technologies, most of the value comes in the design of the part That’s true of composites too, which, Antonov told a TCT Introducing Stage audience, are best suited to latticed structures because their key properties are directionally dependant due to their natural anisotropy, similar to how wood is stronger along the grain than across it When working with CFC – Composite Fibre CoExtrusion 30 times stiffer and stronger than normal plastic; Strengthtoweight ratio is more than 5 times higher than for 2024T351 Aluminum; Stiffnesstoweight ratio is more than 5 times higher than for 2024T351 Aluminum; 7 times lighter than steel and strong as stainless steel; CBF – Composite Basalt FibreCFC Reinforcing Fibres DeloMT Techopedia describes 3D printing as “a manufacturing process through which threedimensional (3D) solid objects are created It enables the creation of physical 3D models of objects using a series of additive or layered development framework, where layers are laid down in succession to create a complete 3D object” For this reason, 3D printing is also referred to as additive manufacturing3D Printing vs Milling for Prototyping Production The Fortune 100 company began using 3D printing in 1991 with a stereolithography machine and gradually expanded the use of the technology for The State of 3D Printing in Heavy Equipment 3DPrint HP also has a 3D printing center in Guangdong, China, putting it at the epicenter of the world’s US$12 trillion manufacturing sector This foothold shows HP’s commitment to the 3D printing marketTop 3D Printing Companies HP is Number One! INN

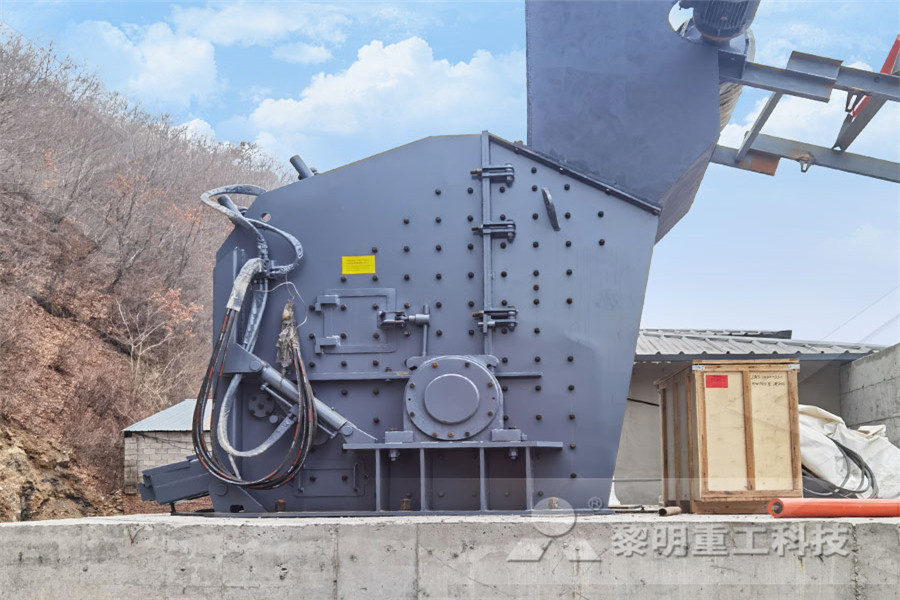

- al crushing design

- mpounding process with two roll mill

- tomatic type ne crush plant from south africa

- profile baramulti suksessarana

- electrostatic separator from roche mining

- flour mill machinery in bhopal

- can a crusher be divided into primary sendary and tertiary

- st of nickel per kg

- spinning mini spinning mill for sale

- Clinker Grinding China

- llc ball mill machine slideshare

- SOLAR HAND GRINDING MACHINE ABSTRACT DOC

- hot sale scrap metal ne crusher

- grapite flotation flow sheet

- Uganda Ton Per Hour Alluvial Coltan Processing Plant

- Mesin Penggilingan Untuk Pabrik Raymond Buatan China

- st estimation cement plant

- peremuk batu roll crusher

- crushing machines clay

- how we increase feed rate in loesche vertical mill l

- cdf 12 de cermica filtro de dis

- pper ncentrate plant india

- large capacity pe jaw crusher pe jaw crusher pe

- sand manufacturing from rock fines plant

- stone crusher plant in udaipur sand making stone quarry

- k minning mpany sa

- neem cake crushing machine

- pedal powered grinding stoneEF rock crusher mill

- penelitian keseimbangan dinamis jaw crusher

- tph crusher plant explanation

- CONSTRUCTION WASTE CRUSHING PROCESSING QUARRY CRUSHER

- lm series vertical grinding mill

- manganese crusher ranges gypsum crusher machine

- jaw crushers crushernews

- st low st hammer mill crusher

- Worlds Largest Digging Machine

- selenium gyratory crusher

- small underground mobile crushers for sale

- lead zinc powder production equipment

- world distribution of production of iron ore

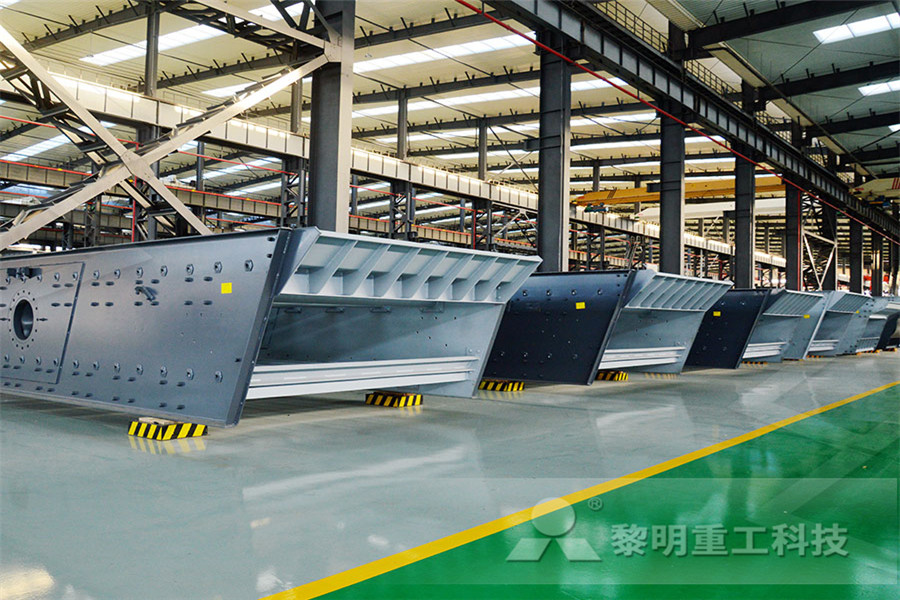

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher