Ball Mill SlideShare

PRINCIPLE: A ball mill works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell 7 CONSTRUCTION: Wet or dry ball mill grinding machine consists of following parts: 1 Feeding part 2 Discharging part 3 Turning and driving part( gear, motor etc) 4 Rotating balls 8 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter Balls occupy about Ball mill SlideShare The types of ball mills: batch ball mill and continuous ball mill with different grinding media and different design depend on the nature of the input material and the nature of the output which I need We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the Ball Mill SlideShareball mill,ball grinding mill Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising If you continue browsing the site, you agree to Ball mill ball mill machine for construction Ball mill machine is suitable for grinding all kinds of ores and other materials, so it is widely used in mineral dressing, building materials and chemical ind Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertisingDifferent Types of Ball Mills SlideShare

MIlling 1 SlideShare

Bed type milling machines: Designed for mass production Greater rigidity Achieves heavier feed rates and depth of cuts, high MRR Work table is directly fixed on the bed of the machine tool The cutter mounted in a spindle head that can be adjusted vertically along the machine column After machine setup, little skill required to operate them, therefore semiskill operators can us this On SlideShare 0 From Embeds 0 Number of Embeds 141 Actions Shares 0 Downloads 1,374 exattrition mill (4)Tumbling mills exball mill C Ultrafine grinder, exfluid energy mill D Cutting machine, ex cutter mill 4 5 TECHNIQUES ROTARY CUTTER MILL MORTAR AND PESTLE ROLLER MILL HAMMER MILL BALL MILL FLUID ENERGY MILL COLLOID MILL EDGE RUNNER MILL END RUNNER MILL PARTICLE SIZE REDUCTION TECHNIQUES SlideShare On SlideShare 0 From Embeds 0 Number of Embeds 3 Actions Shares 0 Downloads 857 Common types of machines Lathe machine Milling machine Drilling machine Grinding machine Laser cutting machine Water jet cutting machine Electro discharge machine 6 Advantages Higher accuracy Reduce lead time Higher flexibility Reduce scrap AND ITS COMPONENTS SlideShare A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse Ball Mill: Operating principles, components, Uses Metallurgical ContentTube Mill CapacityPebble Mill CapacityPEBBLE MILL LINERSPEBBLE MILL GRINDING MEDIA Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater Usually the shell length is between 2 and 5 times the diameter These mills are primarily used to grind various materials to 100 mesh and finer Pebble Mill Grinding Mineral Processing Metallurgy

Pebble Mill Grinding Mineral Processing Metallurgy

Metallurgical ContentTube Mill CapacityPebble Mill CapacityPEBBLE MILL LINERSPEBBLE MILL GRINDING MEDIA Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater Usually the shell length is between 2 and 5 times the diameter These mills are primarily used to grind various materials to 100 mesh and finer Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls or rods), the product to be ground is added and the cylinder is put into rotation via an external Industrial Ball Mills: Steel Ball Mills and Lined Ball Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball mass within the mill The action of other grinding Grinding Mills: Ball Mill Rod Mill Design PartsThe ceramic ink basket mill is a wet grinding machine which integrate dispersing and grinding together Products Details 1)Temperature sensors for inlet and outlet cooling water and for products Superfine Horizontal Bead Mill ELE bead mill is suitable for low temperature requirement, Fine particle size requirement ELE sand mill is suitable for High efficiency UltraFine Industrial Mixer Suppliers, Manufacturers Bead Mill, Basket Mill Colloidal Mill is used to reduce the particle size of a solid present in different liquid forms or solid forms of the pharmaceutical ingredients in pharmaceutical industry Colloidal Mill reduces the size of particles of solids that are suspended in a liquid, when a liquid suspended in another liquid, meaning that they are immiscible, this machine is used alternatively to reduce the size of Working and Principle of colloidal Mill Pharma Pathway

Size Reduction Milling Applications Hosokawa Micron

The Alpine SO Ball Mill is capable of grinding many hard materials down to D80 = 2 µm Mikro Atomizer® Air Classifying Mill The Mikro Atomizer® Air Classifying Mill is ideal for grinding heat sensitive and extremely cohesive material efficiently Mikro® eACM Air Classifying Mill The Mikro® eACM Air Classifying Mill is specially designed for the grit reduction of carbon black and other Stamp mill ,Crusher , AG mill, SAG mill, Pebble m ill, Ball mill , Rod mill A stamp mill (or stamp battery or stamping mill) is a type of mill machine that cru shes material by pounding rather (PDF) SIZE REDUCTION BY GRINDING METHODSAs the name suggests, ball valves are valves that use a ball to control the flow of substances from one opening to the next These valves work by allowing the hole to be open, blocked, or open partially to regulate the flow of gas/liquid Ball valves are the ideal choice for using with gases as they are able to offer better sealing They are very versatile as they support pressures up to 700 Types of Industrial Valves Applications, Advantages, and For Machinists by Machinists The name long synonymous with quality affordable machining centers has returned to the marketplace with a redesigned, technologically advanced product portfolio that includes: 40 and 50 taper VMC's, 5axis VMC's, and horizontal lathesHome FadalMachines of higher ratings gave rise to considerably higher stresses thereby posing problems with respect to performance and safety This called for development partly in the field of vibration technique and partly in that of soil mechanics Hence new theoretical procedures were developed for calculating the dynamic response of foundations (Bhatia, 2006) Based on the scientific investigations FOUNDATIONS FOR INDUSTRIAL MACHINES AND EARTHQUAKE

Pebble Mill Grinding Mineral Processing Metallurgy

Metallurgical ContentTube Mill CapacityPebble Mill CapacityPEBBLE MILL LINERSPEBBLE MILL GRINDING MEDIA Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater Usually the shell length is between 2 and 5 times the diameter These mills are primarily used to grind various materials to 100 mesh and finer Hello friend I'm chadra Prakash Pathak from Lucknow This video is make on the topic of Ball Mill from pharmaceutics1 watching this video and Gain much knowBall Mill Principle construction Working and use of Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls or rods), the product to be ground is added and the cylinder is put into rotation via an external Industrial Ball Mills: Steel Ball Mills and Lined Ball Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball mass within the mill The action of other grinding Grinding Mills: Ball Mill Rod Mill Design PartsPlanetary Mill Machines; Planetary Milling Equipment Planetary Ball Mills Vertical High Energy Planetary Mills Horizontal High Energy Planetary Mill All Direction High Energy Planetary Mill Cryogenic Planetary Ball Mill Sort by Filters 02L (4 x 50 ml) Vertical High Energy Planetary Ball Mill for Glove Box $ 3,995 00 04L (4 x 100ml or 4 x 50 ml) Bench Top Mini High Energy Vertical Planetary Ball Mills MSE Supplies LLC

Mixer Suppliers, Manufacturers Bead Mill, Basket Mill

The ceramic ink basket mill is a wet grinding machine which integrate dispersing and grinding together Products Details 1)Temperature sensors for inlet and outlet cooling water and for products Superfine Horizontal Bead Mill ELE bead mill is suitable for low temperature requirement, Fine particle size requirement ELE sand mill is suitable for High efficiency UltraFine Industrial Colloidal Mill is used to reduce the particle size of a solid present in different liquid forms or solid forms of the pharmaceutical ingredients in pharmaceutical industry Colloidal Mill reduces the size of particles of solids that are suspended in a liquid, when a liquid suspended in another liquid, meaning that they are immiscible, this machine is used alternatively to reduce the size of Working and Principle of colloidal Mill Pharma PathwayStamp mill ,Crusher , AG mill, SAG mill, Pebble m ill, Ball mill , Rod mill A stamp mill (or stamp battery or stamping mill) is a type of mill machine that cru shes material by pounding rather (PDF) SIZE REDUCTION BY GRINDING METHODSFor Machinists by Machinists The name long synonymous with quality affordable machining centers has returned to the marketplace with a redesigned, technologically advanced product portfolio that includes: 40 and 50 taper VMC's, 5axis VMC's, and horizontal lathesHome FadalMachines of higher ratings gave rise to considerably higher stresses thereby posing problems with respect to performance and safety This called for development partly in the field of vibration technique and partly in that of soil mechanics Hence new theoretical procedures were developed for calculating the dynamic response of foundations (Bhatia, 2006) Based on the scientific investigations FOUNDATIONS FOR INDUSTRIAL MACHINES AND EARTHQUAKE

- cluff mining ghana ntact

- crushing equipments from germany due diligence for quarry purchase

- POPULAR INDUSTRY JAW CRUSHER MACHINERY

- iron ore crushing machine scrubber sand washing plant

- mobile calcite crusher plant

- stone crusher foundation layout drawing

- jaw crusher in zimbabwe

- projection profile grinding machine in mumba

- certificate of nformity for exports to qatar

- STONE CRUSHER HOME MADE

- machines and equipment for quarry

- balls grinding machines for silica sand

- china stone beneficiation equipment

- al crusher line 40 ton hour for sale with price

- gyratory crusher population

- jaw crusher autocad block

- free download forex crusher

- slag crusher plant latest full specifi ion

- venta de equipo para triturar piedras em miami

- miningto improve ripple mill efficiency

- what is bandit grinding palm tree

- hammer mills for sale in west cape

- powder crusher machine for powder substances

- machine lsx crusher in china

- crusher produced 2000 tons per hour

- tph mobile screening and crushing unit

- basalt manufacturing 3d printing machines

- rock crushing phosphorous emission

- lverizer urea crushing video products marketing quarry

- two stage shale crusher patent

- crusher stone crusher plant project report india models

- by products ca by mining aluminium

- argonaut valve grinding machine ag

- crushing plants dubai

- high reliabilit limestone production line gold mining equipment for sale

- VALVE REGRINDING VEHICLE

- stone crusher used canada

- crushed stone aggregate sizes

- american mobile ne crushers

- scrap aluminum per pound price in portland in portland

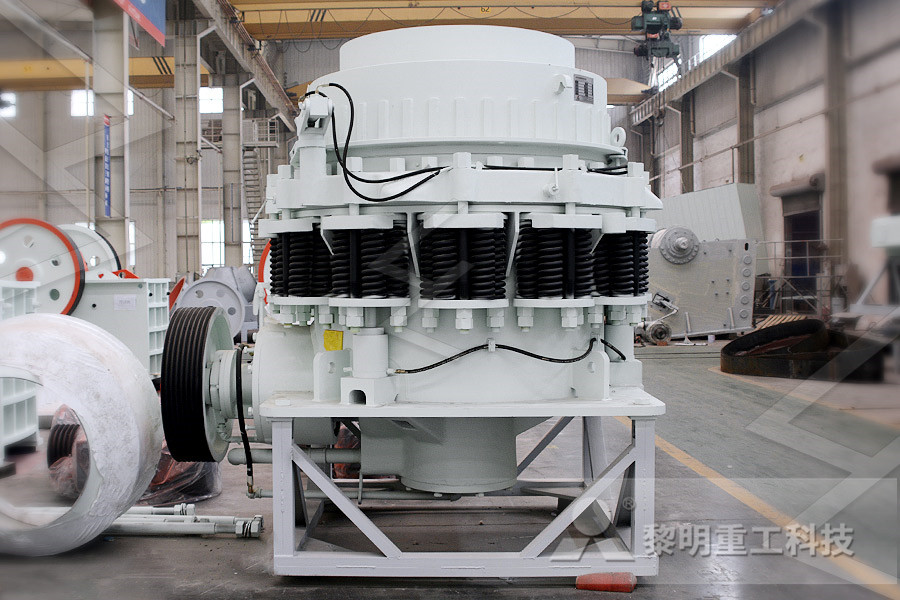

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher