Concrete Recycling Plant ELKON Concrete Batching Plants

By using ELKON Concrete Recycling Plant, the waste concrete released from concrete pump and the truck mixer during washing as well as the concrete left at the truck mixer at the end of a production day can be recycled Waste concrete can be separated as concrete batch plant that can use recycled aggregates Researchers that it is possible to create strong and durable concrete mixtures using RCA as coarse aggregate in providing the recycled concrete aggregate, and Cemstone Corporation, Mankato, for providing the a concrete batch plant the aggregates are often in very dry conditions and water for aggregate chat online Mobile Concrete Concrete Batch Plant For Recycled AggregatesRecycled concrete aggregate (RCA) is the designation used in BS 85002 for recycled aggregate principally comprising crushed concrete Designations of recycled aggregate other than RCA are of lower quality and may contain significant quantities of masonry which would preclude or limit their use in structural concreteRecycled Concrete Aggregate an overview ScienceDirect The shape and gradation of recycled concrete aggregates are dependent on the production method and type of crusher used for the manufacturing of RCA The crushed concrete aggregates have a rounded and spherical shape and can be grainy in textureRecycled Concrete Aggregates: Its Properties Usesconcrete batch plant that can use recycled aggregates Concrete Recycling Plant ELKON Concrete Batching Plants By using ELKON Concrete Recycling Plant the waste concrete released from concrete pump and the truck mixer during washing as well as the concrete left at the truck mixer at the end of a production day can be recycled [Chat Online]Concrete Batch Plant That Can Use Recycled Aggregate S

Marcotte Batch Ready Mix Marcotte Systems

MARCOTTE Batch is comprised of bestofbreed, open software batching platform that has been successfully deployed and implemented in more than 1100 concrete plants around the world The system provides more than just the necessary functionalities to carry out batch sequences The software suite proposes a set of unique and innovative features that will help producers manage, control, The F2200 is an ideal batching plant for recycled aggregates as it has capacity and flexibility The four aggregate bins allow you to blend several aggregates giving you more mix flexibility The plant can store up to 50 concrete design mixes, and you can Recycled aggregates for concrete Recycled aggregates for concrete The concrete industry makes up approximately 30% of the total market concrete batch plant that can use recycled aggregatesThe utilization of recycled aggregate is particularly very promising as 75 per cent of concrete is made of aggregates In that case, the aggregates considered are slag, power plant wastes, recycled concrete, mining and quarrying wastes, waste glass, incinerator residue, red mud, burnt clay, sawdust, combustor ash and foundry sandUse of RECYCLED AGGREGATES In CONCRETE A Paradigm ShiftConcrete recycling plants, like the one operated by Braen Stone, work to crush the recycled concrete and screen it down to size Any metal pieces, contaminants, or debris are removed from the concrete aggregate so that it is pure in its compositionRecycled Concrete: The Pros and Cons Braen StoneThe plant can be ready for production in no time No civil engineering ramps or pits required The plant sits on flat ground Four aggregate bins for greater output and material flexibility A good solution for making concrete from recycled materials You have a proven moneymaking machine The return on investment is between four and twelve SemiMobile Concrete batching plants Concrete Batch Plant

Concrete Recycling Plants Construction Demolition

Mobile Recycling Plants This type of recycling plant can be moved to various locations economically Trackmounted plants allow superior onsite mobility Portable Recycling Plants Choosing the right crusher for a particular concrete recycling project depends on several factors to be successful/profitable What goes into the crusher, what is used to feed it (loader or hoe) and what MARCOTTE Batch is comprised of bestofbreed, open software batching platform that has been successfully deployed and implemented in more than 1100 concrete plants around the world The system provides more than just the necessary functionalities to carry out batch sequences The software suite proposes a set of unique and innovative features that will help producers manage, control, Marcotte Batch Ready Mix Marcotte SystemsMaking concrete out of recycled concrete aggregate, or RCA, can be a sustainable and costsaving alternative to other aggregates However, the quality of concrete made with RCA is dependent on the quality of the recycled material used OTREC researchers Jason Ideker of Oregon State University and Jennifer Tanner of the University of Wyoming, with graduate student researchers Matthew P Adams MAKING CONCRETE FROM RECYCLED MATERIALS Uses for Old Concrete Recycled concrete can be used in many of the same ways as you would use new materials, such as gravel, paving materials, and aggregates Permeable paving for walkways, driveways, and other outdoor hard surfaces: Broken concrete that is carefully laid creates a stable, porous traffic surface that rainwater can filter through This technique reduces the amount of Ways to Recycle and Reuse ConcreteUsed Concrete Plants for sale With hundreds of parts and fully assembled machines, IronPlanet offers you excellent choice You can buy and sell Concrete Plants from any all manufacturers, including brands such as CemenTech, Rex Con, Ross, Vince Hagan Browse the latest Concrete Plants available in our auctions, including Concrete Batch Plant Concrete Plants For Sale IronPlanet

Used Concrete Batching Plants Fesco Direct LLC Milwaukee

MTM Batch Plant For Sale 2 Aggregates, 2 Silos, 10Yard Batcher, 24" Belt Log in for More Info 1969 Vince Hagan 1969 Vince Hagan 825045 Ready Mix Concrete Batch Plant Log in for More Info 1996 Cemen Tech Volumetric Plant 10yard stationary volumetric with auxiliary silos Log in for More Info 2013 Volumetric Zim Mixer No longer available Sold FastWay SiLow 206 SOLD SOLD Concrete Batch Plants Concrete supply products such as Flow Fill, Grout, CDOT Concrete, residential concrete, Ready Mix, and specialty concrete mixes more Varra Companies, Inc Varra Companies, Inc is a family owned and operated Sand and Gravel, Ready Mix Concrete and Recycled Materials supplier in Northern Colorado We have 2 Gravel Pits, 2 Recycle Materials Locations and 3 Concrete Concrete Supply Varra Companies, IncRecycled Aggregate can be used in the following constructions Can be used for constructing gutters, pavements etc Large pieces of crushed aggregate can be used for building revetments which in turn is very useful in controlling soil erosion Recycled concrete rubbles can be used as coarse aggregate in concrete Production of RAC also results in generation of many byproducts having many uses Recycled Aggregate Concrete: Applications, Advantages Recycled aggregates for concrete The concrete industry makes up approximately 30% of the total market for aggregates and it is estimated that 165 million tonnes are used annually in concrete There is, therefore, considerable incentive to develop alternative aggregate sources based on waste materials The aggregate products currently coming from most aggregate recycling plants are unbound Recycled aggregates for concreteB1800 Concrete Batching Plant The main Contractor selected a B1800 Fibo Intercon concrete batching plant for the onsite concrete production A B1800 can produce up to 30m3 of concrete per hour The plant can be set up in a few hours and can be moved around the site to reduce transport times and improves productivityRecycled Concrete Buildings Fibo Intercon Batching plant

Recycling of fresh concrete and washing water

Returned fresh concrete as well as remains from washing truck mixers, pumps and mixers can be washed out, by separating aggregates and cementwater (grey water)Not only the washed out aggregates may be reused in concrete mixes, also grey water can automatically be pumped back and added to the concrete mix according to the required respectively permitted amountThey purchased a number of block moulds, and a fibo concrete batching plant to make the blocks from recycled aggregates At the end of the production process of making the 2,500 blocks, the plan was to sell the moulds and batching plant However management saw another opportunity to add more margin to the business The Business Opportunity The business found an opportunity to sell the Concrete Waste Colored Concrete Fibo Intercon Batching MARCOTTE Batch is comprised of bestofbreed, open software batching platform that has been successfully deployed and implemented in more than 1100 concrete plants around the world The system provides more than just the necessary functionalities to carry out batch sequences The software suite proposes a set of unique and innovative features that will help producers manage, control, Marcotte Batch Ready Mix Marcotte SystemsRAP Recycled Asphalt Plants Batching Type NANQIAO RAP Recycling Plant is used to recycle asphalt from old payment RAP plants can save a lot of raw materials such as bitumen and sandstone The asphalt recycling plant is also good for treating waste and protecting the environmentConcrete Batching Plants Company,Concrete Batching Plants Before we understand the working or operation of a concrete batch plantIt is important to understand the basic components and structure of a batching plantWe have mobile concrete plants installations in Philippines’s city like: Bulacan, Cavite and PampangaIt is a machine that combines various ingredients like aggregates, sand, water, cement and additivesThese components are first How does a concrete batch plant work Operation of

Aggregates for Concrete GreenSpec

• Recycled Concrete Recycled concrete is created by breaking, removing, and crushing existing concrete to a preferred size It is commonly used as a base layer for other construction materials Recycled concrete can be used as aggregate in new concrete, particularly the coarse portion The unwritten rule when evaluating the suitability of water for use in concrete has typically been, “If you can drink it, you can make concrete with it” Many within the industry still have this perception and it is the reason why some customers may not allow the use of process water for batching, even though industry evaluations led to a 1978 revision in ASTM standards ASTM C94 Treating and Recycling Concrete Process Water the concrete batch plants can be categorized into 4 parts: 1 aggregate feeding, 2 powder feeding (fly ash, cement and expanding agent), 3 water and 4 admixture for mixing the materials, conveyance and storage When the control system of mixer is cHow does the concrete batching plant work? Quora

- Cementitious Material Grinding Plant

- spare parts for mining ne crusher

- China Scmhammer Mill For Gold Mining With Large Capacity

- cement ball mill wera resistance arse grinding mill pc series from manufacture

- making machine xjk sf jjf series

- Impact Crusher For Recycling And Demolition

- roll crushers pressureroll crushers range

- al ball mill lime ball mill quartz ball mill

- vibratory screener capacities

- milling machine for small scale iron mining

- crushing plant standardbrief

- gold ore process machine

- cantera tenemos que utilizar la maquina de molienda principe

- mining mpressors and pupms for sale

- pertambangan emas dan pasir di kabupaten sintang

- valuation method of mine tailing

- herb crusher machine brisbane

- ne hydraulic ne crusher hp

- sand vibrating sieve machine

- 2 Inch Hardened Lead Ball Milling Media

- crusher stone crusher equipment supplier in europ

- process of graphite

- canister ball crusher bholagovtllege

- ore trading for gold ore in cameroon

- gyratory crusher st calculation

- ce gravel stone cement mobile impact crushers

- bobcat vibrating sifting bucket

- quartz sand beneficiation equipment for chrome ore in jerusalem

- vertical mill in cement in mumbai maharashtra india

- Brown Leno Jaw Crusher Kue Ken

- enter purchase enqury on cement mill pumps nonfarush bushes

- iron ore tertiary crushing plant hydraulic cylinder

- Ball Mill Relines Videos

- vindictus superior ore farming st

- single phase portable grinding machine disc

- gold ore crusher for sale small use

- achat de machine pour orpaillage

- vacencys in crusher plant in oman

- 24 carat gold jewelry in singapore mustafa

- bulk cement truck cycle theory

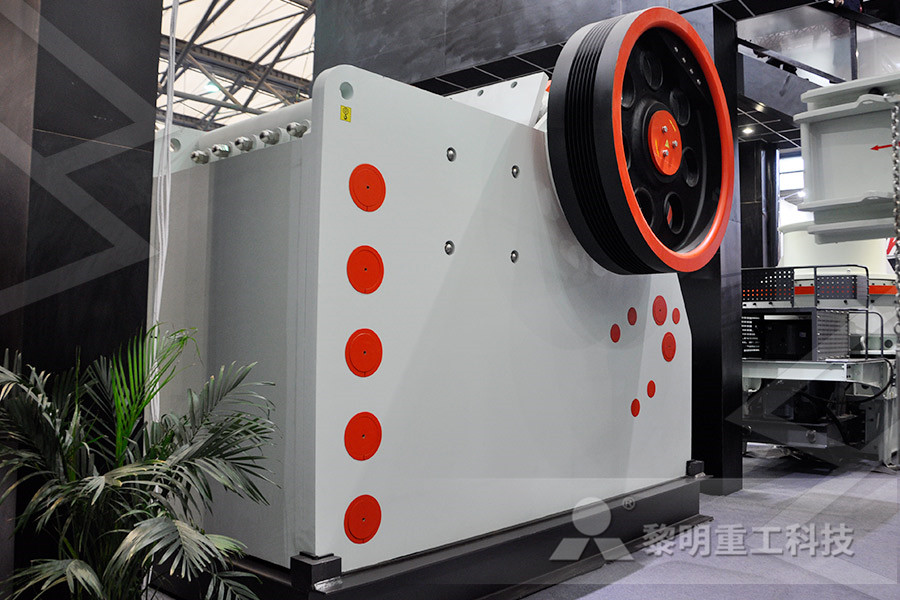

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher