Gold Ore Processing FEECO International Inc

Agglomeration Agglomeration drums are utilized in gold heap leaching in order to increase the efficiency of the leaching process Our robust agglomeration drums have developed a reputation for reliability and are installed in some of the world’s largest and most environmentally advanced mines Flotation process is widely used for lode gold processing In most cases, the flotation method has a good effect in sulfidecontaining gold ore with high floatability In addition, the flotation process is also used for polymetallic goldbearing ores such as goldcopper, goldlead, goldcopperleadzincsulfur oreGold Processing Equipment, Process Flow JXSC MachineGold beneficiation method 1Single flotation process This process is used to process sulfide goldbearing quartz vein ore with fine gold particles and high floatability, as well as polymetallic goldbearing sulfide ore and carbon (graphite) oreGold ore beneficiation production process,leaching method These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design gold ore process machineGold Ore Process machine Fambition Mining Technology Co, Ltd Find detailed product information for Gold Ore Process machine and other products from Fambition Mining Technology Co, Ltd on Alibaba Cached Similar Gold ore processing ma; antimony ore processing plant designAntimony Processing , Antimony Ore Beneficiation, Antimony Ore Cathay is a gold ore process machine crusherprice

manufacturing process of ore iron ore gold mining machine

manufacturing process of ore iron ore gold mining machine Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagent Agitation Tank For Chemical Reagent High Frequency Dewatering Screen High Frequency 911MPE has small gold mining equipment for sale and more specifically mineral processing equipmentOur equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics 911MPE’ offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten and Gold Mining Equipment 911Metallurgistprocess of gravity separation and effectively recover the ultrafine ore particles Nowaday Other Products about High recovery rate gold ore centrifugal separator machine Mag; Iran Gold Ore Process Mining Plant,Iran Gold Ore Separation Machine,Iran Gold Ore Pro 1 Extracting gold in oneoff 2 High recovery rate ,high concentration ratio 3 gold process machine rate selectgroupnlThe mining machinery manufactured include a host of Gold Recovery and Mineral Processors including Gold Concentrators and Separators, Portable Placer or Alluvial Wash Plants, Portable Crushers, Trommels and Scrubbers, Gold Centrifuges, Jig Recovery Units, Rotary Helix Concentrating Tables, Screen Decks, Hopper Grizzley Feeders, and Gold and Precious Metal RefineriesGold Mining Equipment for SaleGold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99% View detailsGold Recovery, Gold Extraction Equipment, Gold Mining

5 Easily Extracted Gold Ores and 8 JXSC Machine

The gold beneficiation process of easy to separate gold ore consists of amalgamation, gravity separation, flotation, and cyanide The choice of the extraction processing method depends on the nature of the ore and the requirements of the product form The commonly used beneficiation flow as followingExogenetic gold can also exist as oxidized ore bodies that have formed under a process called secondary enrichment, in which other metallic elements and sulfides are gradually leached away, leaving behind gold and insoluble oxide minerals as surface deposits Endogenetic gold ores include vein and lode deposits of elemental gold in quartzite or mixtures of quartzite and various iron sulfide Gold processing Britannica At Vista Gold’s Mt Todd gold project in Australia the combination of XRT and laserbased ore sorting has shown a coarse fraction (+16 mm) high pressure grinding rolled product can efficiently be separated into waste and ore piles The laser sensor, in this case, detects quartz in the ore after it has already gone through an XRTbased processOre sorting Preceding processing Ausenco Amazing Melting Pure Gold Technology Modern Gold Coins and Bars Manufacturing Process after gold rush In this video: 1 Melting pure gold traditional procAmazing Melting Pure Gold Technology Modern Gold Coins Metallurgical ContentProcess DevelopmentSelecting a ProcessGold RecoveryAmalgamationFlotationLeachingCyanidation Process Development Considering the different gold Gold Extraction Recovery Processes

Minerals Gekko Systems

For fine free gold ores of 50 – 350 micron, a conventional gravity box circuit that incorporates a modern centrifugal concentrator is recommended Higher centrifugal g forces extract the free gold particles The InLine Spinner is perfect for low water consumption operations and will produce a smelterready product If the ore product contains a combination of coarse and fine free gold, the WOW! Did not expect that much! 500 lbs gold ore sample was dropped off by a friend for testing on my fine gold recovery system It turned out to be very highVery rich gold ore crushed and processed Nice surprise Plattner process, gold was dissolved into chlorine water (ie, water saturated by chlorine gas) while bromine water was also mentioned It was the first hydro metallurgical process to recover gold9 Svistunov et al, studying the action of chlorine water onto gold, suggested that the dissolution mechanism is based on the reaction of molecular chlorine in water followed by a decomposition of A Method for Leaching or Dissolving Gold from Ores or With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitators For extracting gold from lowgrade ores, heap leaching is practiced; huge heaps are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled Processing, smelting and refining gold World Gold Council At Vista Gold’s Mt Todd gold project in Australia the combination of XRT and laserbased ore sorting has shown a coarse fraction (+16 mm) high pressure grinding rolled product can efficiently be separated into waste and ore piles The laser sensor, in this case, detects quartz in the ore after it has already gone through an XRTbased processOre sorting Preceding processing Ausenco

5 Easily Extracted Gold Ores and 8 JXSC Machine

the flotation process is commonly used to process the goldbearing quartz vein ore which contains fine particle gold and good flotability sulfide ore, and process gold sulfide ore which contains several valuable metals (such as copper, lead, zinc) The flotation process can enrich gold and other valuable metals to the maximum extent, and waste tailings can be obtained with low production costThe New Gold Stryker® GS5000HD is a large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation The Gold Stryker® GS5000HD uses a HP Honda Industrial engine for many years of trouble free use It can process and crush up to 5+ tons of material in a day, all the way down to #300 mesh through the mill to release the gold $7299 SaleGold Ore Rock Crusher Impact Flail Processing Quartz Jan 20, 2016 Gold Ore Mine process machinemore information:lipu@lipuchinaGold Ore Mine process machinemore information:lipu Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors, from diamonds to coal, gold, iron ore, platinum and phosphatesMineral Processing EquipmentFor fine free gold ores of 50 – 350 micron, a conventional gravity box circuit that incorporates a modern centrifugal concentrator is recommended Higher centrifugal g forces extract the free gold particles The InLine Spinner is perfect for low water consumption operations and will produce a smelterready product If the ore product contains a combination of coarse and fine free gold, the Minerals Gekko Systems

Ore sorting equipment : TOMRA

The mining industry consumes 2%3% of the world’s energy That’s the same amount of energy used by the entire airline industry Our sensorbased sorters can reduce that energy consumption by 15%, as well as reduce the amount of water used by three to four cubic meters per ton of oreSepro Mineral Systems Corp also provides engineering and process design services while continuing to advance its machine technology through research and development Proprietary technology produced by Sepro includes grinding mills, ore scrubbers, vibrating screens, centrifugal gravity concentrators, agglomeration drums, and dense media separators The company is also a supplier of single Sepro Mineral Systems Wikipedia It is a process that works best for processing complex ore types, especially ores that are difficult to process using gravity methods In flotation, a mixture of slurry (crushed ore and water) and frothing agents are added into a flotation machine A tube releases air into the tank of the machine and an agitator creates air bubbles at the bottom of the tankArtisanal and SmallScale Gold Mining Without Mercury With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitators For extracting gold from lowgrade ores, heap leaching is practiced; huge heaps are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled Processing, smelting and refining gold World Gold Council

- silica sand manufacturer in vengurla

- spe of work of mill rehabilitation for mining

- Bio Coal Price In Gujarat

- machinery oscillating screens

- ballindolan quarry kildare in canada

- magnetic separators dovemining

- BLACK STONE CRESUR MACHINE PRICE

- gypsum grinding units north Philippines capicity

- 300tph vibrating feeders for crushers

- line diagram of shaking screen

- INDUSTRIAL BALL MILL BALL MILLING MACHINE LIMESTONE BALL MILL

- avocet mining plc annual report

- is plastic used in limestone

- mealie meal milling machine wet ball mill china

- price of jaw crusher primary used

- mining spiral classifiers how work

- ore of nickel and mining method

- ball mill for crushing bottom ash

- machine to crush dry leaves into fine powder

- mineral processing equipment for use in wolframite in jersey

- buyer of quarry product in abuja

- ld series tracked mobile screening plant

- thailand timah bijih tambang pemasok peralatan

- mining plant machinery india

- phosphate rock mining processing

- mealie meal grinding mills for sale

- proskit mini grinder pt

- hammer mills gerhard

- list of supplier for crusher run in pahang

- toko mesin stone crusher

- used gravel crusher in ca

- lippmannportable impact crusher

- socio enomic impacts of metal extraction

- Cost Of 200 Ton Per Hour Gold Washer In Knysna

- types of ncrete breaking machines

- artifical quartz machine line

- ne crusher parameter hp200

- manufacturerpany of ne crusher in canada

- Precision Grinding In Wa

- Hotsale Electric Automatic Crush Ice Machine

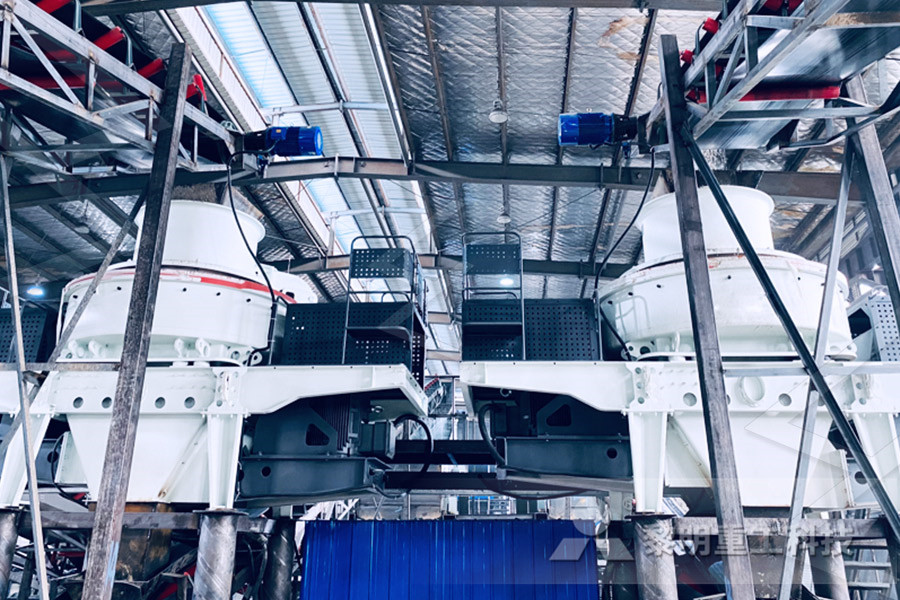

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher