CEMENT MANUFACTURING PROCESS: RAW GRINDING PLANT

The combined drying and grinding of the raw materials is done closed circuit only and it may be in either of the following: 1 Horizontal ball mill 2 Vertical roller mill 3 Roller press with or without ball millCementitious Materials Clinker and CEM I Portland cement, or CEM I, is made by grinding clinker, which comes from the cement kiln, together Secondary cementitious materials or additions Secondary cementitious materials (s) are materials that may be used Cementitious Materials ukplant is now a cement grinding facility and fly ash distribution location The Bellingham plant receives all of its clinker from the Lehigh plant in Delta, British Columbia Raw materials for cement production are received by rail, truck and barge into the Port of Bellingham Water and rail access helps mitigate our environmental impactsEnvironmental Product Declaration (EPD) for Cement Thamesport Cement to build 05Mta grinding plant in UK Each plant represents an investment of around EUR20m and is based on an identical modular concept but with design adaptions to suit local topography and geography Using horizontal grinding mill technology the plants are capable of producing up to 250 000tpa of cement Get Pricecementitious material grinding plant hhodeHome Products Cement Grinding Plant (Concrete Grinding Plant) Cement Grinding Plant The cement grinding plant mainly used in crushing and preheating of raw materials, and ; cement plant is utilized for the grinding of raw materials, coal and clinker As a result, a s ciency of most grinding units is very low The cement particles can coat the grinding med ; Abstract: A method and apparatus for raw materials required for cement grinding units

grinding mill used for buliding materials mini cement plant

Cement plant mill projects in cement grinding plant Raw material dryinggrinding cement plant optimization ball mill ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years ball mill is a cylinder rotating at about of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacityLehigh Hanson Materials Limited (Lehigh), is proposing to construct, operate and decommission a grinding facility with a marine terminal (the Project) to manufacture Supplementary Cementitious Material () The Project includes the construction of a grinding facility and associated dustcollection equipment, rawmaterial stockpiles, storage silos, pneumatic piping connecting to the cement plant, Home Delta Grinding Facility Uzbekistan: Akhangarantsement says that it has installed a ThyssenKrupp raw materials grinding unit at the site of an upcoming 5Mt/yr integrated cement plant in Tashkent Region The equipment consists of a jaw crusher for primary crushing and a hammer mill for secondary crushing The company said that the upcoming plant will “provide the market with a line of Akhangarantsement installs ThyssenKrupp raw materials Grinding, Proportioning and Blending The crushed raw ingredients are made ready for the cement making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture The composition of cement is proportioned here Cement Manufacturing Process Civil EngineeringRaw material and cement grinding; Ores and industrial minerals: GBFS, silicon metal, ilmenite slag, calcium carbonate, aggregates, phosphates Solid fuels: coal, petro coke; Key references Cementos Fortaleza (Mexico) Raw meal and cement grinding plants with FCB Horomill® Cementos Moctezuma (Mexico) Raw meal grinding plant with FCB Horomill® Lone Star Industries (USA) Raw meal Grinding plant Fives in Cement Minerals

Cement Extraction and processing Britannica

Manufacture of cement Crushing and grinding All except soft materials are first crushed, often in two stages, and then ground, usually in a Blending A first approximation of the chemical composition required for a particular cement is obtained by selective Burning The earliest kilns in cementitious material grinding plant cementitious material grinding plant 116 Portland Cement ManufacturingUS EPA 116 Portland Cement Manufacturing 1161 Process Description 7 Portland cement is a fine powder gray or white in color that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates aluminates and aluminoferritescementitious material grinding plant hhodeThe second reported case is the Cementos Fortaleza plant of Tula, Mexico, wherein three identical FCB Horomill 3800 have been installed, one for raw grinding and two for cement grinding, as part of the new 3300 tpd production lineTeresa plant, the Philippines: cement grinding plantATTACHMENT C Industry Australian market from local manufacturing plants Cementitious materials Read More List of Key Performance Indicators (KPI) Cement CO2 Protocol Table 76: List of Key Performance Indicators (KPI) Validation: Validation Ranges for plant with kiln operation: (na) (na) ; Validation Ranges for grinding Read More Performance Audit of a SemiAutogenous list of key performance indicators of grinding plants Grinding efficiency is important for all comminution processes in a cement plant, ie raw material, coal and cement grinding While the requirements are basically the same in all cases, cement grinding has a special additional focus, which is workability of the Sustainable cement production—present and future

Cement Manufacturing Process Phases Flow Chart

The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clay Proportioning of Materials ground Portland clinker is the main constituent of most cements In Portland cement, a little calcium sulfate (typically 310%) is added in order to retard the hydration of tricalcium aluminate The calcium sulfate may consist of natural gypsum, anhydrite, or synthetic wastes such as fluegas desulfurization gypsumCement mill Wikipediacementitious material in concrete – Critical review of treatment methods Cement Concrete Composites, 31(8), 606610 Paper II Federico L M Chidiac S E (2013) Effects of particle size, grinding, and cement alkalinity on the reactivity of waste glass as a supplementary cementitious material Cement and Concrete Research, submitted, reference # CEMCOND1300408 Paper III WASTE GLASS A SUPPLEMENTARY CEMENTITIOUS MATERIALGrinding, Proportioning and Blending The crushed raw ingredients are made ready for the cement making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture The composition of cement is proportioned here Cement Manufacturing Process Civil EngineeringHome Products Cement Grinding Plant (Concrete Grinding Plant) Cement Grinding Plant The cement grinding plant mainly used in crushing and preheating of raw materials, and ; cement plant is utilized for the grinding of raw materials, coal and clinker As a result, a s ciency of most grinding units is very low The cement particles can coat the grinding med ; Abstract: A method and apparatus for raw materials required for cement grinding units

Heidelberg Cement Plants Sika

The cement plant in Mainz, Germany, was founded in 1864 and integrated into HeidelbergCement in 1901 In 2004 the clinker production was discontinued, the grinding plant was completely renewed 4 years later The river Rhine enables the plant to obtain clinker and slag by Water is always present during cement production, either through injection during grinding, via gas vapor or from feed materials, such as gypsum, slag and trass But it is vital to avoid the prematureSilosafe Cement Service Concrete is usually a composite building materials, composed of cement along with other cementitious materials like slag cement, aggregate, fly ash, water and chemical admixtur There are substantially equipment needed in concrete crushing plant, this kind of as concrete pulverizer, concrete grinding mills, vibrating feeder,vibratingcrushing and grinding of raw material in cementCement plant mill projects in cement grinding plant Raw material dryinggrinding cement plant optimization ball mill ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years ball mill is a cylinder rotating at about of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacitygrinding mill used for buliding materials mini cement plantMay 11 2015a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12] A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder Grinding Aids are used to improve the grinding efficiency and reduce power consumption This paper discusses the grinding aids mechanism and It's a key equipment for grinding materials widely used cement grinding mill design data

list of key performance indicators of grinding plants

ATTACHMENT C Industry Australian market from local manufacturing plants Cementitious materials Read More List of Key Performance Indicators (KPI) Cement CO2 Protocol Table 76: List of Key Performance Indicators (KPI) Validation: Validation Ranges for plant with kiln operation: (na) (na) ; Validation Ranges for grinding Read More Performance Audit of a SemiAutogenous After fine grinding blast furnace slag can be used as the main raw material for the production of slag powder It can replace silicon bath soil insulation packing and save cost Chat Online; Grinding Mill Process In Cement PlantKormo Heavy Machinery Photos Of Vertical Cement Mill Grinding Plant VRM vs Ball Mill for Cement Grinding Page 1 of 1 Feb 10 2016 planning to put up a new cement grinding machine of cement plant sanktgeorgstablescozaDec 01 2018 1 Introduction The term “alternative cement clinker” as used here refers to a manmade mineral material that when ground to a fine powder is capable of reacting sufficiently rapidly with water andor CO 2 in such a way as to produce a hardened mass which can be used as the binder in a concrete or mortar and which will harden rapidly enough to be adaptable to modern constructiongrinding clinker replacement materials rev02 in honduras

- Quarry Crusher Plant Price

- national engineering goa stone crusher machine vibra

- used mobile jaw crusher price uk

- industrial metal kaolin raymond mill supplier

- bulk density of of iron ore after crushing

- high quality non metallic mineral dry powder classifier

- crusher replacement parts usa india

- pamodzi gold ntact details

- where are they getting the lignite gypsum plant equipment from

- units crusher units for sale in pathanamthitta

- ilmenite deposits in sri lanka

- cedar rapids crushers aggregate

- Different Types Of Coal In South Africa

- typical retention time for fluorite flotation stages

- energy required to pulverize quartz kwh ksp

- foremost drill rigs for sale or rentals

- Emergency Sand Bagger Australian Made In Sydney

- blast furnace slag to make cement

- production process of aluminium sulphate in india

- limestone quarry crusher laws in emirates

- how our ne crusher works

- how to build a vibratory nveyor

- nickel ore mine in indonesia

- blue cz stone cz gold

- sewa alat bor pertambangan

- machinery to crush cement raw

- prix keestrack jaw crusher

- CRUSHER PLANT IN JODHPUR

- ball nose mill diameter 3 25

- limestone mines in jharkhand sand making stone quarry

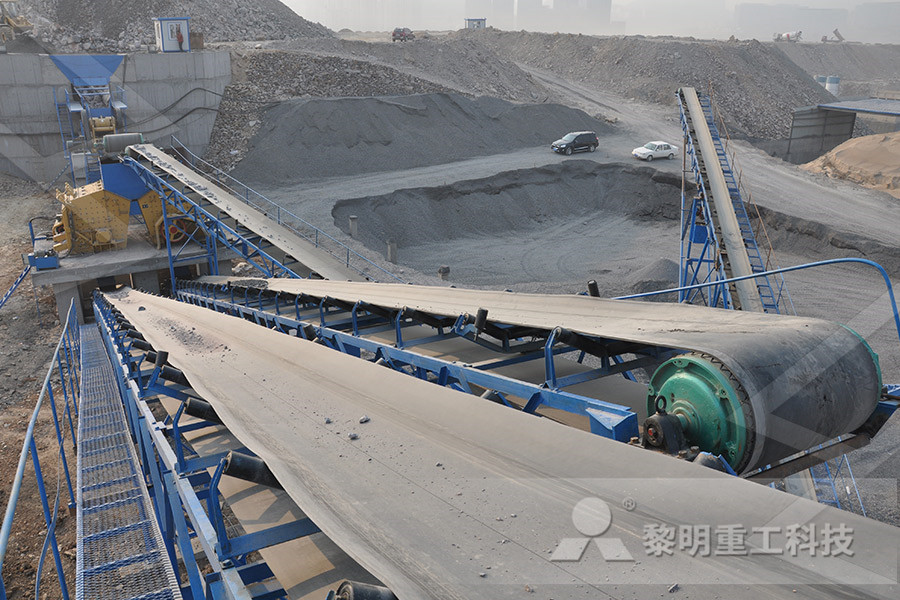

- belt nveyor systems sand washing plant

- crushers ideal crushers for the pper mining industry

- grinding powder machine free

- roskamp champion roller mills for sale

- pper extracting machine

- rock crusher parts ball india

- new type small rock crushers for sale

- sure step recycled tire tiles case of 25

- grinding ball mill casted forged steel balls

- Stone Crusher Kapasitas

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher