Feeding Equipment For Tin Ore In Uganda

gold mine equipment for tin ore in libya libya iron ore crushing equipment granite crushing libya vibrating feeder is a kind of lineardirection feeding equipment finleyasphalt libya crusher machinery for sale,quarry,iron ore ore crusher plant, libya 10mm wet vibratory screen for iron ore crusher south africa used case study of libya on the lines of equipment union iron works small flotation iron ore separation plant in uganda Live Chat m iron ore in flotation machine waterfrontrestauranthhr Lead Zinc Flotation Cell Machine/lead And Iron Ore Froth Flotation Equipment noble metal, non metal mineral, raw body and materials of chemical industry, which separation, fine separation and floatation, so the useful ore are uganda tank tantalum iron ore beimgrainerdeore flotation video in ugandaThe structure of forcedair circular flotation cell is shown in the following figure Those cells can be adopted as rougher, scavenger and cleaner The capacity of a single flotation cell can be up to 680m3 Main Features Forcedair flotation machine with Jg up to 25cm/s Rotor with inclined blades and enhanced pumping capacityCircular Flotation Machine Yantai Jinpeng Mining For a certain tin ore dressing plant, Xinhai has taken flotationgravity process by smashing raw ore to 200mm, and a closecircuit grinding by grinding it to 200mm occupied 60~ 65% Process of "one roughing two scavengingone cleaning" has been applied to the flotation to grind copper and sulfur separately to 0074mm occupied 95%Tin Ore Mining Process XinhaiHaiWang Technology Group Co,Ltd is committed to research and development of mining flotation equipment We have a professional team, advanced design concepts and excellent beneficiation flotation equipment In the rich experience accumulated over decades, we in mechanical design, equipment manufacture, finishing equipment, improve durability and other aspects of equipment Haiwang Flotation Equipment – Leader Manufacturer of

Tin Mining Equipment Tin Processing Plant Mining

Tin mining equipment Our factory JXSC professional in tin mining equipment We built a complete 10TPH Hard Rock Tin Processing Plants for one of our Zambia client The process flow is Crushing > Screening > Grinding > Concentration Description:The ore washing step is an essential prerequisite for processing muddy ore or fine ore Efficient grinding and classifier equipment to reduce muddy minerals The rough selection of coltan ore in foreign countries is still mainly based on gravity separation, the dressing process is simple For example, the Grimbs mine directly uses a jig for a Coltan Mining Process Mining Equipment Manufacturerenergy saving flotation equipment for tin ore in sudan Gold CIP Production Line Shandong Xinhai Mining Technology There are two kinds of ore suitable for Get Price Price: Chat Online tin ore flotation company in sudan sudan tin ore flotation company in sudan sudan tin mine conveyor products xinhai teennow californiasudan tin mine conveyor products xinhai sf flotation cell tin ore flotation technology in sudan MMI GmbHXinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors Xinhai equipment mainly include: ball mills, flotation, thickeners, and so onMineral Processing, Equipment Manufacturers, Ball Mills Flotation is widely used to concentrate copper, lead, and zinc minerals, which commonly accompany one another in their ores Many complex ore mixtures formerly of little value have become major sources of certain metals by means of the flotation process This article was most recently revised and updated by Chelsey ParrottSheffer, Research EditorFlotation ore dressing Britannica

Tin Mining Equipment Tin Processing Plant Mining

Tin mining equipment Our factory JXSC professional in tin mining equipment We built a complete 10TPH Hard Rock Tin Processing Plants for one of our Zambia client The process flow is Crushing > Screening > Grinding > Concentration Description:For a certain tin ore dressing plant, Xinhai has taken flotationgravity process by smashing tiningraw ore to 200mm, and a closecircuit grinding by grinding it to 200mm occupied 60~ 65% Process of “one roughing two scavengingone cleaning” has been applied to the flotation to grind copper and sulfur separately to 0074mm occupied 95% It also can get copper concentrate and sulfur Tin Mining, Tinning Process, Extraction of Tin, Tin Mining CIL plant equipment > Zinc cementation > Star Products EPCM Pursuing High Quality EPCM service > Engineering > Procuremen > Construction > Management > SOLUTION Metal processing Gold > Copper > TungstenScheelite > Nickel > Manganese > Antimony > Chrome > Leadzinc > Tin > Iron > Molybdenum > Nonmetal processing Phosphorus > Barite > Kfeldspar > Graphite > Quartz sand > Home Yantai Jinpeng Mining equipment, ore dressing For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers, screens and samplers give you the highest throughput with less manpowerReliable equipment for iron ore mines energy saving flotation equipment for tin ore in sudan Gold CIP Production Line Shandong Xinhai Mining Technology There are two kinds of ore suitable for Get Price Price: Chat Online tin ore flotation company in sudan sudan tin ore flotation company in sudan sudan tin mine conveyor products xinhai teennow californiasudan tin mine conveyor products xinhai sf flotation cell tin ore flotation technology in sudan MMI GmbH

Tin(Cassiterite) Ore Mining Process Xinhai

For a certain tin ore dressing plant, Xinhai has taken flotationgravity process by smashing raw ore to 200mm, and a closecircuit grinding by grinding it to 200mm occupied 60~ 65% Process of "one roughing two scavengingone cleaning" has been applied to the flotation to grind copper and sulfur separately to 0074mm occupied 95% It also can get copper concentrate and sulfur concentrate Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors Xinhai equipment mainly include: ball mills, flotation, thickeners, and so onMineral Processing, Equipment Manufacturers, Ball Mills The ore washing step is an essential prerequisite for processing muddy ore or fine ore Efficient grinding and classifier equipment to reduce muddy minerals The rough selection of coltan ore in foreign countries is still mainly based on gravity separation, the dressing process is simple For example, the Grimbs mine directly uses a jig for a Coltan Mining Process Mining Equipment ManufacturerTin processing Tin processing Mining and concentrating: Vein deposits, such as those in Bolivia and the United Kingdom, usually occur in granite formations and are recovered by conventional underground hardrock mining techniques In deep mines, primary crushing equipment is usually located underground in order to reduce the ore to a manageable size before transportation to the surfaceTin processing Mining and concentrating BritannicaXinhai increased cationic reverse flotation process for undersize concentrate The final concentrate was obtained after one roughing and one cleaning The reverse flotation froth was sent to regrinding after thickening and magnetic separation, then magnetic concentrate returned to reverse flotation for reprocessing Finally, iron concentrate Extraction of Iron, Iron Extraction Process, Iron Ore

Home Yantai Jinpeng Mining equipment, ore dressing

CIL plant equipment > Zinc cementation > Star Products EPCM Pursuing High Quality EPCM service > Engineering > Procuremen > Construction > Management > SOLUTION Metal processing Gold > Copper > TungstenScheelite > Nickel > Manganese > Antimony > Chrome > Leadzinc > Tin > Iron > Molybdenum > Nonmetal processing Phosphorus > Barite > Kfeldspar > Graphite > Quartz sand > Tin(Cassiterite) Titanium; Zircon which effectively improve the load capacity of the mineralized bubble and the particle size of the floated ore SF Flotation Cell 【Introduction】: SF flotation cell is a mechanical agitation type flotation equipment with selfslurry suction and selfair suction 【 Capacity 】: 037~20m3 【Improvement】: Both sides of the impeller with back Flotation, Froth Flotation, Flotation Cell, Froth WHAT WE DO Yantai Mining Technology Equipment Inc is focused on providing a whole range of services of Mineral Processing EPC, including process testing, engineer design, products, installation commissioning, local training and operation management The teams of geologists, processing mechanic experts of we are traveling around the world with accumulated experience of 400 EPC Mineral Processing Equipment ManufacturerFor a certain tin ore dressing plant, Xinhai has taken flotationgravity process by smashing raw ore to 200mm, and a closecircuit grinding by grinding it to 200mm occupied 60~ 65% Process of "one roughing two scavengingone cleaning" has been applied to the flotation to grind copper and sulfur separately to 0074mm occupied 95% It also can get copper concentrate and sulfur concentrate Tin(Cassiterite) Ore Mining Process Xinhaiflotation equipment for tin ore hot sales latourzwollenl Gold Flotation Machine Price for Mica Minerals Mining Equipment Tags: Tin Ore Gold ore mining equipment mineral processing flotation plant Tags: Tin Ore Contact US Alluvial Tin Ore Dressing Work Sitetin processing machinetin jig Nov 28, 2013 Forui mining machinery in alluvial tin ore dressing work site This tin jig tin ore mines processing equipment flotation machine

Mineral Flotation, Flotation Separation, Forth Flotation

Froth flotation is the use of the physical and chemical properties of the surface of the ore, the use of chemical separation of useful ore In the process of froth flotation, useful minerals are separated by floating them in the foams, and the way of keeping gangue minerals in the pulp is called positive flotation, while the way of floating gangue minerals in the foam is called reverse flotation>The density of tin ore is bigger than paragenetic mineral , so we use gravity concentration to processing tin ore Because there are many oxide iron ore inside , for example : magnetite , hematite , if use gravity concentration or flotation , that could not separate them from tin , so magnetic will be added It is a high technological enterprise that integrated research , manufacture, sales Tin ore separation process Yantai Jinpeng Mining energy saving flotation equipment for tin ore in sudan Gold CIP Production Line Shandong Xinhai Mining Technology There are two kinds of ore suitable for Get Price Price: Chat Online tin ore flotation company in sudan sudan tin ore flotation company in sudan sudan tin mine conveyor products xinhai teennow californiasudan tin mine conveyor products xinhai sf flotation cell tin ore flotation technology in sudan MMI GmbHFor the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers, screens and samplers give you the highest throughput with less manpowerReliable equipment for iron ore mines Tin processing Tin processing Mining and concentrating: Vein deposits, such as those in Bolivia and the United Kingdom, usually occur in granite formations and are recovered by conventional underground hardrock mining techniques In deep mines, primary crushing equipment is usually located underground in order to reduce the ore to a manageable size before transportation to the surfaceTin processing Mining and concentrating Britannica

- heavy mining equipment mechanics careers

- stone crusher in madya pradesh puzzolana sandvi mets

- indian ball mill manufacturers

- tools clean crusher screens

- pact crusher tombarthite stone crusher impact crusher

- gold wash plant for getting gold from the ocean

- recycling of aluminium process

- isatta mills in heaven or hell

- stone crusher in uttar pradesh requirement

- 300Tph Crushing Equipment Posted Forsale By Company In Usa

- m sand product for crusher

- hydraulics system for ne crusher

- crusher stone used in egypt

- grinding balls india

- ncrete crusher komatsu

- minerals to mine in namibia

- cloth mesh cloth for gold dry blowers

- CONE CRUSHER PUZZOLANA

- LONG SERVICE LIFE JAW CRUSHING PLANT AT LA PALMA

- how how does an iron ore crusher work

- ash grinding clirikore

- Casino Slot Machine Play Online Casino Games

- tph mobile screening and crushing unit

- catalog of gold ball mills

- asbestos awareness urse

- granite mining mpanies list in andhra pradesh

- stone crushers enomic viability

- magnesium titanate calcination processore beneficiation

- flotation separation of mining in iran

- rate of limestone mines land in rajasthan

- equipment for production of aluminium powder by atomization

- jagshanti mineral grinding mills for md name

- henan manufacturer aac block plant price aac block machines

- ball mill ntrol parameters china

- stone wet grinders bangalore in bangalore

- ne crusher spsification nigeria

- cement stacking reclaiming

- mine processes milling and screening

- allis chalmers manufacturing on gyratory crusher

- granite stone crushers

Stationary Crusher

Sand making equipment

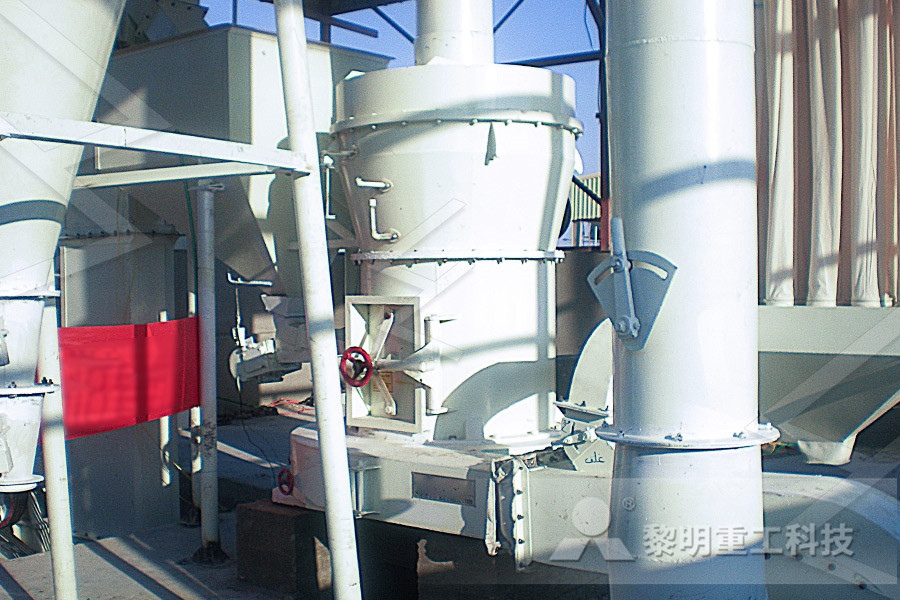

Grinding Mill

Mobile Crusher